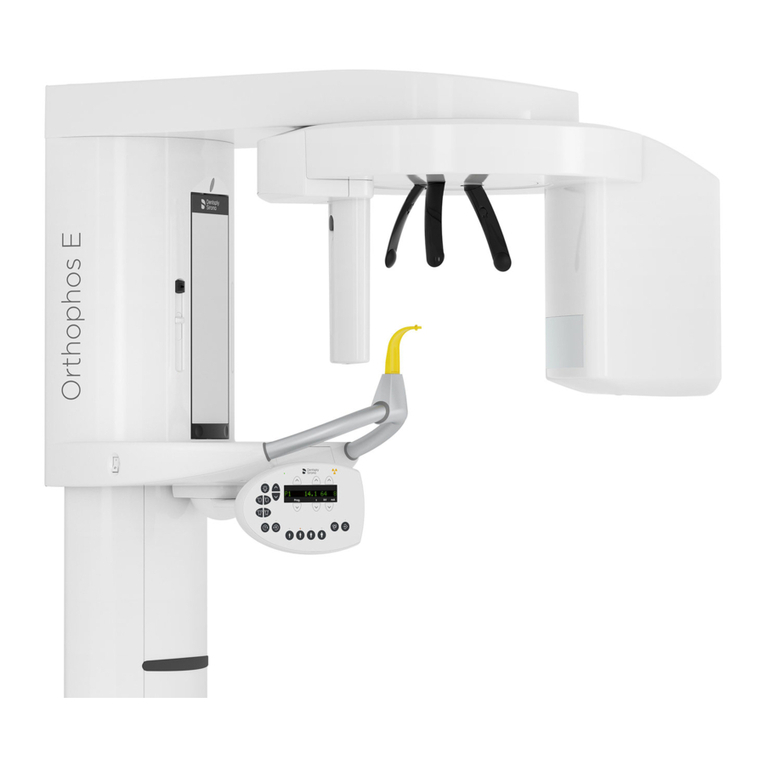

VITALI T5 Evo User manual

DENTAL UNITS & CHAIRS

Technical

Manual

EN

T5 Evo Dental Units T5 Evo / V8e

1

2

3

4

5

6

7

8

9

10

Foreword

This technical manual, which is provided to VITALI distributors, in-

cludes the information necessary for the execution of operations

which can be carried out by appropriately trained and authorized

technical staff.

The document is divided into sections identified by a number and

by a colour. Each section contains several explanatory chapters of

the issue being discussed.

The manual is structured in such a way as to allow for the inclusion

of additional sections/chapters.

The first letter used in the identification code of connectors, fuses

and LEDs present on the electronic cards indicates their position:

P = chair power card and motherboard, R = cuspidor card, S =

instrument preselection card (e.g., SC1 connector, SF2 fuse, etc.).

Operator’s manuals

• WARRANTY

• SYMBOLS USED

• TECHNICAL DATA

• INSTALLATION NOTES

• SERIAL NUMBER AND LABELS LOCATION

• ROUTINE MAINTENANCE

Installation manuals

• INSTALLATION MANUAL

• 1:1 TEMPLATE INSTALLATION

Hydro-pneumatic circuit

Chair’s electric unit

• LOCATION

• ELECTRONICS CARDS

• ELECTRIC DIAGRAM

Water unit

• LOCATION

• ELECTRONICS CARDS

• ELECTRIC DIAGRAM

Operator’s table

• LOCATION

• ELECTRONICS CARDS

• ELECTRIC DIAGRAM

• SETTINGS

• DIAGNOSTICS AND ALARMS

Assistant’s console

• LOCATION

• ELECTRONICS CARDS

• ELECTRIC DIAGRAM

Foot controls

• LOCATION

• ELECTRONICS CARDS

• ELECTRIC DIAGRAM

Maintenance:

• ROUTINE MAINTENANCE

• SPECIAL MAINTENANCE

• REPAIRING AND/OR REPLACEMENT

FORM

Assembly diagrams for accessories

TECHNICAL MANUAL

DENTAL UNIT Mod. T5 Evo / V8e

(COD. 66000024-EN - UPG. 27/05/2013)

Whenever assistance/maintenance work involves the

equipment, the MAINTENANCE CARD contained in

the Operator’s Manual relating to the maintained device

must be filled out.

WARNING: DO NOT FILL OUT THE MAINTENANCE

CARD CONTAINED IN THE ATTACHED OPERATOR’S

MANUAL.

WARNING: after switching off the equipment by pressing

the main switch, ,power may still be supplied to some

parts of the equipment. Therefore, in case of access to

parts under tension, it is always necessary to disconnect

the supply plug or to act on the general disconnecting

switch of the electric plant.

3.0 1/2

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 12/03/2012

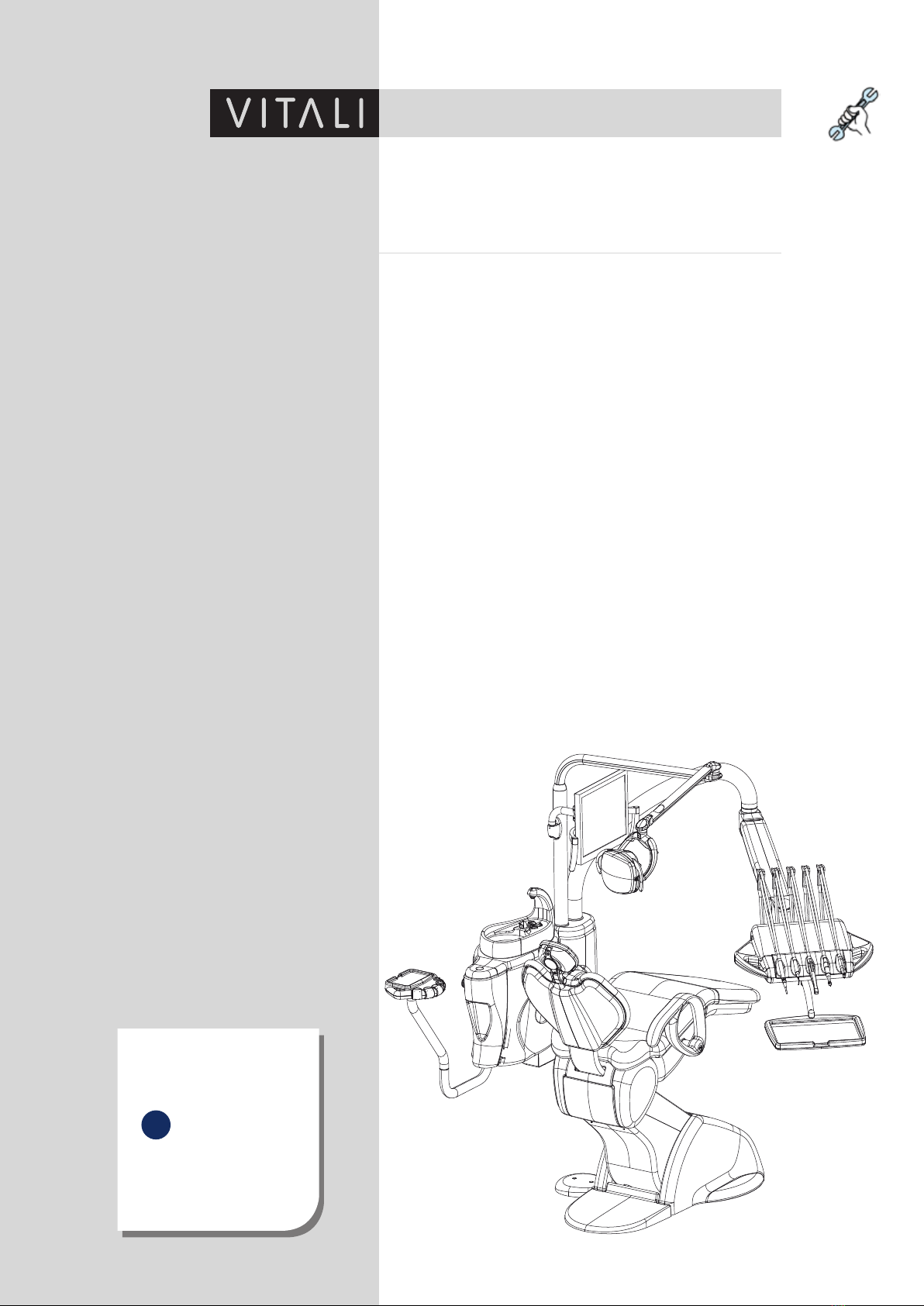

Hydro-pneumatic diagram

WARNING:

(*) the pressure adjuster must be calibrated according to the instrument that needs The highest pressure.the flow adjusters must be calibrated to

ensure the proper working pressure to instruments with a lower pressure/consumption of air.

(**) if there is the water boiler, the flow of water to the tumbler cannot be changed

TUMBLER WATER

SOLENOID VALVE

NOT

CONNECTED

AIR

INTAKE

DRAINAGE

SURGICAL SUCTION (WET SYSTEM)

Ø4mm YELLOW

Ø4mm YELLOW

Ø4mm RED

“T” QUICK JOINT

TUMBLER

WATER BOILER

(OPTIONAL)

FLOW REGULATOR

ADJUSTED FOR THE AIR

DRIVING OF THE TURBINE

OR THE AIR COOLINGFOR

THE MICROMOTOR (*)

Ø4mm WHITE

Ø3mm TRASPARENT

Ø6mm BLUE

Ø6mm BLUE

Ø6mm WHITE

Ø6mm WHITE

Ø8mm GREEN

Ø6mm GREEN

Ø6mm GREEN

Ø6mm GREEN

Ø4mm GREEN

Ø6mm WHITE

TUMBLER WATER

SOLENOID VALVE

(OPTIONAL) (**)

SPITOON WATER

SOLENOID VALVE

SPITOON WATER

FLOW ADJUSTER

TUMBLER WATER

FLOW ADJUSTER

MAIN WATER INLET

(Ø 8 mm HOSE)

MAIN AIR INLET

(Ø 8 mm HOSE)

TURBINE or

MICROMOTOR

SYRINGE SCALER

QUICK JOINT

HEADRESTAIR (INLET PRESSURE)

INSTRUMENTS WATER (2.2±0.2 bar)

CHIP-BLOWER AIR, INSTRUMENT SPRAY AIR,

SYRINGE AIR (3.6±0.2 bar)

DRIVING AIR FOR TURBINE, COOLING AIR

FOR MICROMOTOR (ACCORDING TO THE TYPE OF

INSTRUMENT DEFAULT 2.2±0.2 bar – EXHAUST <0.4 bar) (*)

PRESSURE ADJUSTER

MAIN WATER PRE-FILTER

COLLECTOR

PRESSURE SAFETY VALVE (10 bar)

MAIN AIR FILTER

ONE-WAY VALVE

SURGICAL

SUCTION

TERMINAL Ø17

ELECTROPNEUMATIC

VALVE (OPTIONAL)

WATER VESSEL

EMPTYING VALVE

MAIN WATER FILTER

T5 EVO CHAIR

T5 EVO WATER UNIT

T5 EVO INSTRUMENT TABLE

SURGICAL

SUCTION

TERMINAL Ø11

GREEN

GREEN

TRASPARENT

TRASPARENT

BLUE

BLUE

HEADREST BRAKE

PUSHBUTTON

2/23.0

Technical manual ›

T5 EVO/V8e

COD. 66000024-EN - 12/03/2012

WARNING:

(*) the pressure adjuster must be calibrated according to the instrument that needs The highest pressure.the flow adjusters must be calibrated to

ensure the proper working pressure to instruments with a lower pressure/consumption of air.

(**) if there is the water boiler, the flow of water to the tumbler cannot be changed

TUMBLER WATER

SOLENOID VALVE

NOT

CONNECTED

AIR

INTAKE

DRAINAGE

SURGICAL SUCTION (WET SYSTEM)

Ø4mm YELLOW

Ø4mm YELLOW

Ø4mm RED

“T” QUICK JOINT

TUMBLER

WATER BOILER

(OPTIONAL)

FLOW REGULATOR

ADJUSTED FOR THE AIR

DRIVING OF THE TURBINE

OR THE AIR COOLINGFOR

THE MICROMOTOR (*)

Ø4mm WHITE

Ø3mm TRASPARENT

Ø6mm BLUE

Ø6mm BLUE

TUMBLER WATER

SOLENOID VALVE

(OPTIONAL) (**)

SPITOON WATER

SOLENOID VALVE

SPITOON WATER

FLOW ADJUSTER

TUMBLER WATER

FLOW ADJUSTER

MAIN WATER INLET

(Ø 8 mm HOSE)

MAIN AIR INLET

(Ø 8 mm HOSE)

TURBINE or

MICROMOTOR

SYRINGE SCALER

QUICK JOINT

TO THE ARM BRAKE

RELEASE AIR

HEADRESTAIR (INLET PRESSURE)

ARM BRAKE (INLET PRESSURE)

INSTRUMENTS WATER (2.2±0.2 bar)

CHIP-BLOWER AIR, INSTRUMENT SPRAYAIR,

SYRINGE AIR (3.6±0.2 bar)

DRIVING AIR FOR TURBINE, COOLING AIR

FOR MICROMOTOR (ACCORDING TO THE TYPE OF

INSTRUMENT DEFAULT 2.2±0.2 bar – EXHAUST <0.4 bar) (*)

PRESSURE ADJUSTER

MAIN WATER PRE-FILTER

COLLECTOR

PRESSURE SAFETY VALVE (10 bar)

MAIN AIR FILTER

ONE-WAY VALVE

SURGICAL

SUCTION

TERMINAL Ø17

ELECTROPNEUMATIC

VALVE (OPTIONAL)

WATER VESSEL

EMPTYING VALVE

MAIN WATER FILTER

V8e CHAIR

V8e WATER

UNIT

V8e INSTRUMENT TABLE

HEADREST BRAKE

PUSHBUTTON

SURGICAL

SUCTION

TERMINAL Ø11

GREEN

GREEN

TRASPARENT

TRASPARENT

BLUE

BLUE

Ø4mm GREEN

Ø6mm GREEN

Ø6mm GREEN

Ø6mm WHITE

Ø6mm WHITE

Ø6mm GREEN

Ø8mm GREEN

4.0 1/1

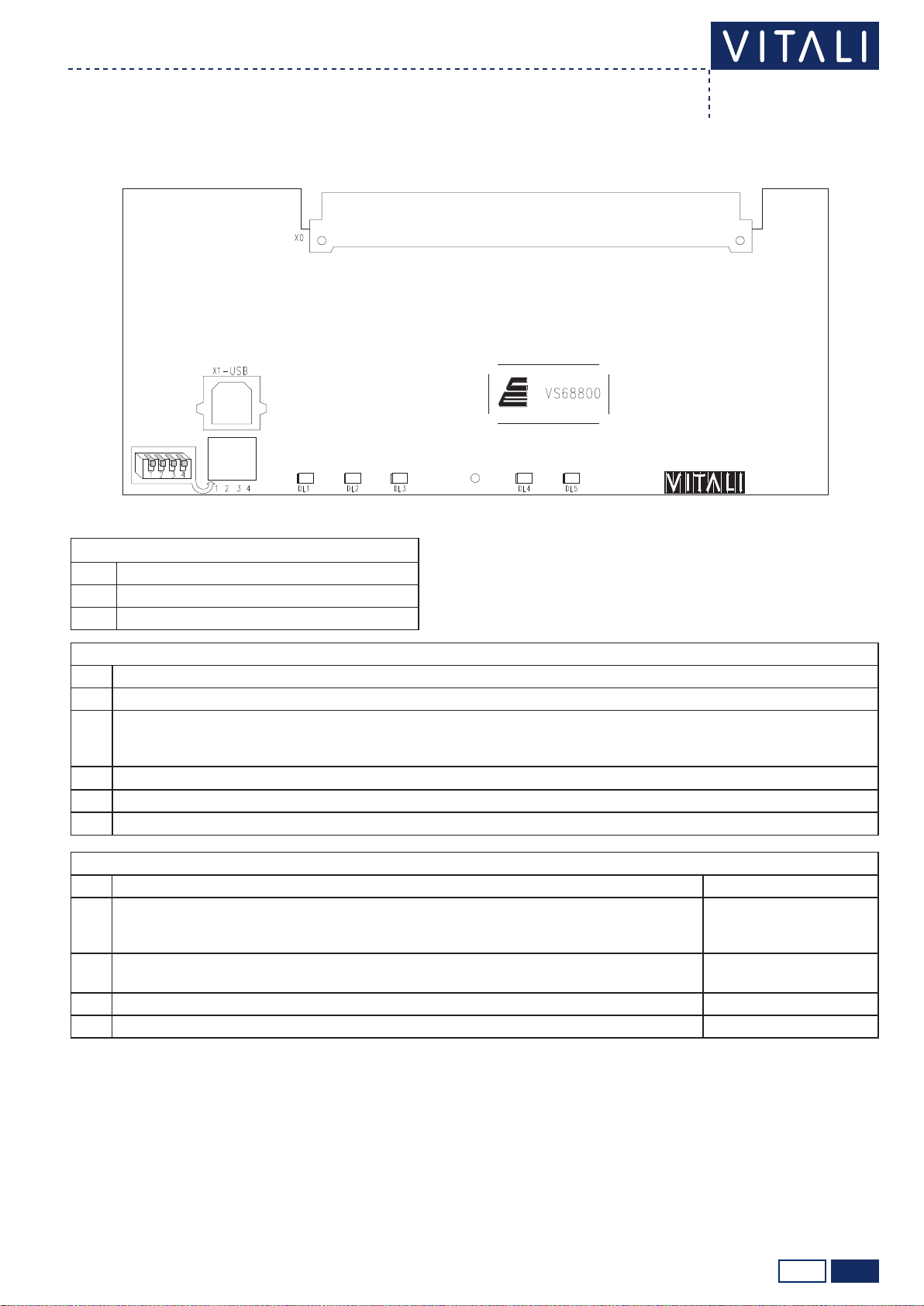

PC1

PC2

PC4

i

i

PF1 PF2

59400048

59400049

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 01/01/2012

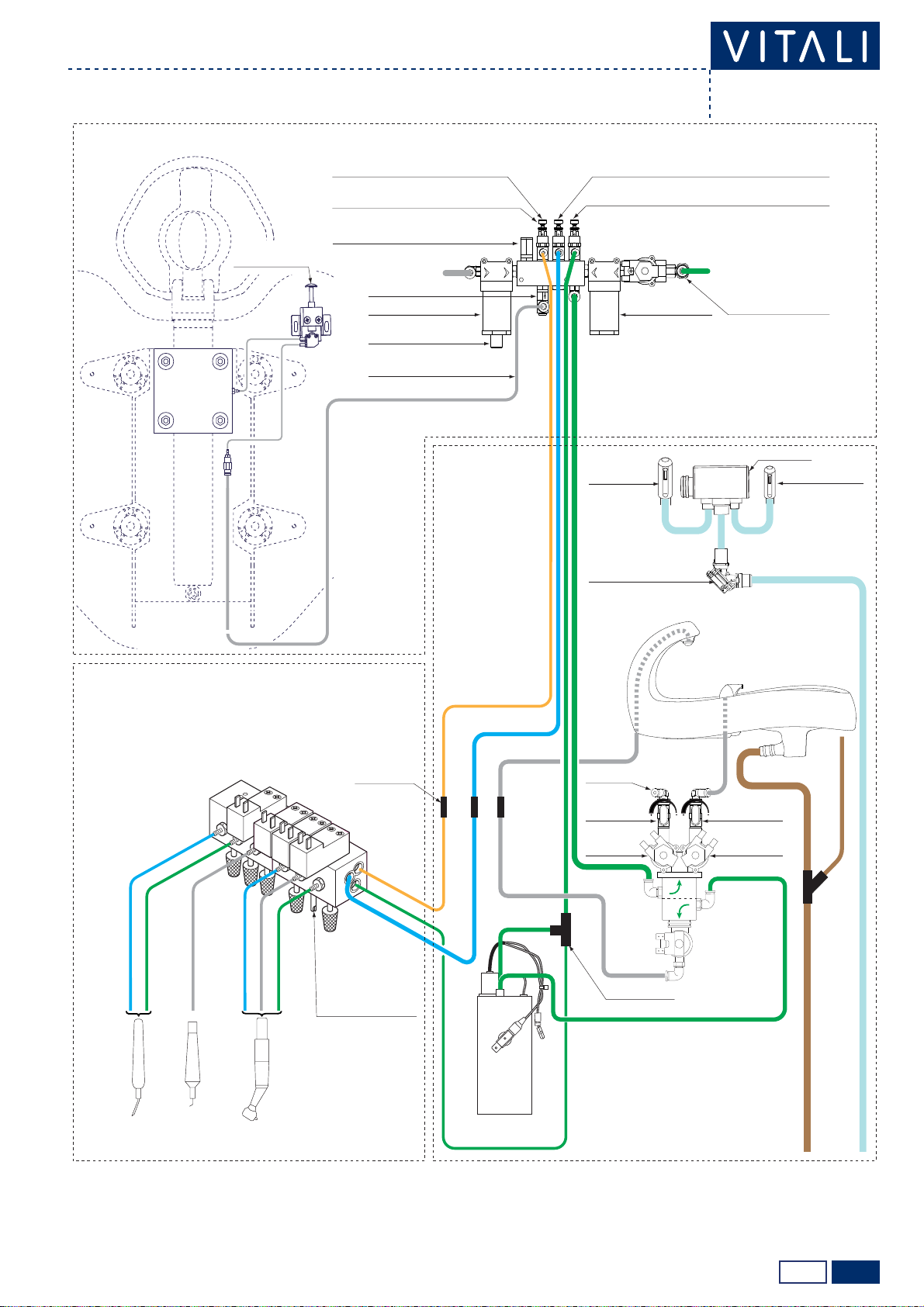

Location

Chair’s electrict unit

To replace fuses PF1 and PF2, draw out

the fuse-holder tray by using a athead

screwdriver in the points shown with the

arrows (see image on the side).

PC2, PC3: auxiliary connections whose use is meant only for

the connection of additional devices approved by VITALI.

230VAC 50-60 Hz outlet present also

with disconnected network switch.

230VAC 50-60 Hz outlet not present

also with disconnected network

switch.

To have access to the electric unit, take away the transparent guard as indicated in the T5 EVO Installation

Manual (cap. ELECTRIC, WATER AND PNEUMATIC CONNECTIONS).

4.1 1/2

PCB COD. 59400048

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 01/05/2011

Chair card ref. 59400048

Chair electric unit

CONNECTORS

N° DESCRIPTION

PC0 Connection for logic unit cod.59400049

PC1 1 - IN 230 Vac

2 - IN 230 Vac

3 - Earth

PC2 1 - 230 Vac (AUX - no interrupted by main switch)

2 - 230 Vac (AUX - no interrupted by main switch)

3 - Earth

PC3

1 - IN 230 Vac (main switch)

2 - IN 230 Vac (main switch)

3 - OUT 230 Vac (main switch)

4 - OUT 230 Vac (main switch)

PC4 1 - 230 Vac (AUX)

2 - 230 Vac (AUX)

3 - Earth

PC5 1 - 230 Vac (AUX)

2 - 230 Vac (AUX)

PC6 1 - 230 Vac (1st TRS)

2 - 230 Vac (1st TRS)

PC7 1 - 230 Vac (UV-Osmo)

2 - 230 Vac (UV-Osmo)

PC8

1 - +25 Vdc (AUX)

2 - CAN H (serial communication)

3 - CANL (serial communication)

4 - Ground

5 - 24Vac (AUX)

6 - 24Vac (AUX)

PC9

1 - Normal Open contact assistant call

2 - N.O. contact a.c. (24Vac/dc, 3A, resistive load)

3 - Normal Open contact suction motor

4 - N.O. contact s.m. (24Vac/dc, 3A, resistive load)

PC10

1 - 24 Vac (instrument selection card)

2 - 21 Vac (instrument selection card)

3 - 21 Vac (instrument selection card)

4 - 24 Vac (instrument selection card)

5 - CAN H (serial comunication instr. selec. card)

6 - CAN L (serial comunication instr. selec. card)

7 - +34 Vdc (instrument selection card)

8 - +25 Vdc (instrument selection card)

9 - Ground

CONNECTORS

N° DESCRIPTION

PC11

1 - 24 Vac (instrument selection card Clip6)

2 - 21 Vac (instrument selection card Clip6)

3 - 21 Vac (instrument selection card Clip6)

4 - 24 Vac (instrument selection card Clip6)

5 - CAN H (serial comm. for instr. sel. card Clip6)

6 - CAN L (serial comm. for instr. sel. card Clip6)

7 - +34 Vdc (instrument selection card Clip6)

8 - +25 Vdc (instrument selection card Clip6)

9 - Ground

PC12

1 - 25 Vac (2nd TRS)

2 - 21 Vac (2nd TRS)

3 - 24 Vac (2nd TRS)

4 - 25 Vac (2nd TRS)

5 - 21 Vac (2nd TRS)

6 - 24 Vac (2nd TRS)

PC13

1 - +25 Vdc

2 - CAN H (serial communication VDS keyboard)

3 - CAN L (serial communication VDS keyboard)

4 - Ground

PC14

1 - +25 Vdc

2 - CAN H (serial communication foot control)

3 - CAN L (serial communication foot control)

4 - Ground

PC15

1 - 34 Vdc (chair motor power supply) (+/-)

2 - 34 Vdc (chair motor power supply) (-/+)

3 - 34 Vdc (backrest motor power supply) (+/-)

4 - 34 Vdc (backrest motor power supply) (-/+)

PC16

1 - + (10 kΩ chair potentiometer) (*)

2 - Cursor (10 kΩ chair potentiometer)

3 - - (10 kΩ chair potentiometer)

4 - Chair descent limit microswitch

5 - Common micro. descent and chair safety

6 - Chair safety microswitch

7 - Chair rise limit microswitch

8 - Chair rise limit microswitch

CONNECTORS

N° DESCRIPTION

PC17

1 - + (backrest potentiometer 10 KΩ) (**)

2 - Cursor (backrest potentiometer 10 KΩ)

3 - - (backrest potentiometer 10 KΩ)

4 - Backrest descent limit microswitch

5 - Common micro. descent and backrest safety

6 - Backrest rise limit microswitch

7 - Common micro. rise and backrest safety

8 - N.C.

PC18

1 - Emergency stop button (N.O.)

2 - Emergency stop button (N.O.)

3 - Red LED (maintenance or emergency)

4 - Green LED (ordinary operation)

5 - Common LED

6 - N.C.

PC19

1 - + Solenoid valve N.A. 1 (instruments water)

(VDS)

2 - - Solenoid valve N.C. 1 (VDS)

3 - + Sol. valve N.C. 2 (Multiclean drawing) (VDS)

4 - - Solenoid valve N.C. 2 (VDS)

5 - + Sol. v. N.C. 3 (air for Multiclean pressurized

bottle) (VDS)

6 - - Solenoid valve N.C. 3 (VDS)

7 - + Sol. v. N.C. 4 (sterile liquid) (VDS)

8 - - Solenoid valve N.C. 4 (VDS)

9 - + Sol. v. N.C. 5 (sterile liquid air) (VDS)

10 - - Solenoid valve N.C. 5 (VDS)

PC20 1 - + Main water inlet solenoid valve

2 - - Main water inlet solenoid valve

PC21

1 - Common pressure switch (+25Vdc)

2 - Water pressure switch (for VDS only)

3 - Air pressure switch (for VDS only)

4 - Ground (not used)

PC22 1 - UV lamp alarm (for UV-Osmo or VDS only)

2 - UV lamp alarm (for UV-Osmo or VDS only)

PC23 1 - Earth

(*) chair rise = 10 KΩ between 2 and 3, chair descent = 10 KΩ between 1 and 2.

(**) backrest rise = 10 KΩ between 2 and 3, backrest descent= 10 KΩ between 1 and 2.

2/24.1

Technical manual ›

T5 EVO/V8e

COD. 66000024-EN - 01/05/2011

LED

N° INDICATION

DL1 Presence of 12 Vcc voltage

DL2 Presence of 25 Vcc voltage

DL3 Integrity fuse PF3

DL4 Integrity fuse PF4

DL5 Integrity fuse PF5

DL6 Integrity fuse PF6

DL7 Integrity fuse PF7

DL8 Nurse call activation

DL9 Surgical aspirator activation

FUSES

N° PROTECTED PARTS VALUE AND

TYPE

ANOMALIES THAT CAN BE DETECTED AFTER INTERRUPTION

FUNCTIONS LIGHTS

PF1 230Vac line T. 4AL (5x20)

DELAYED

Nothing works. Main switch off.

PF2 230Vac line T. 4AL (5x20)

DELAYED

Nothing works. Main switch off.

PF3 Auxiliary 24 Vac line (PC8) T. 6.3AL (5x20)

DELAYED

The relay for suction motor con-

trol (optional) and any users con-

nected to PC8 are not working.

DL3 off.

PF4 24 Vac line T. 8AL (5x20)

DELAYED

The users fed in alternating

mode are not working (amalgam

separators, 6F syringe, polyme-

riser, etc.).

DL4 off.

PF5 21 Vac line T. 6.3A (5x20)

DELAYED

The operating light is not wor-

king. DL5 off.

PF6 Feeder power supply 34 Vcc T. 8A (5x20)

DELAYED Nothing works. DL6, DL7, emergency button ring

off.

PF7 34 Vac line T. 6.3A (5x20)

DELAYED

The driving air and instrument

cooling solenoid valves are not

working.

The micromotor and the turbine

are not running.

DL6, DL7, emergency button ring

off.

4.2 1/3

O

N

PCB COD. 59400049

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 01/05/2011

Chair card ref. 59400049

Chair’s electric unit

CONNECTORS

N° DESCRIPTION

X0 BUS FOR CONNECTION TO THE CHAIR CARD CODE 59400048

X1-USB USB SWITCH FOR CONNECTION TO PC

LED

N° INDICATION

DL1 Active USB connection.

DL2

If all the dip-switches of SW1 are turned off (OFF), it indicates the proper functioning of the serial connection. With the dip-

switch 1 of SW1 on (ON), the LED is dedicated to the calibration of potentiometers (see below, description of Dip-Switch

SW1).

DL3 Reserved.

DL4 Chair movement in progress.

DL5 Presence of card power supply.

DIP-SWITCH SW1

N° ON OFF

1 Adjustment of limit switch and potentiometers (see procedures “Adjusting limit switch and

potentiometer for T5 Evo chair rise” and “Adjusting limit switch and potentiometer for T5 Evo

backrest”).

Standard operation.

2 Transfer of rmware to peripheral devices (see under “Software update”) and visualization/

reset of maintenance timer (see under “Adjusting the maintenance timer”).

Standard operation.

3 Not used. Not used.

4 USB connection (see under procedure “Software update” ). Standard operation.

2/34.2

Technical manual ›

T5 EVO/V8e

COD. 66000024-EN - 01/05/2011

FIRMWARE UPDATE

You can update the rmwares of the cards of the chair (code 59400049), cuspidor (code 59400056)

or instrument preselection (code 59400052), by following the procedure described below.

Required components: personal computer with Microsoft Windows XP® (or latest) operating sys-

tem, A/B-type USB cable (male/male).

Procedure:

1. turn on the PC that contains the les of updated rmwares;

2. turn off the main switch of the equipment;

3. if you wish (this is not essential), you can remove the chair card from its housing (N.B: do not

remove other cards);

4. put the switch 4 of SW1 of the chair card on ON;

5. connect the type-B USB plug to the X1-USB connector;

6. if the chair card is in its housing, turn on the main switch of the equipment;

7. connect the type-A USB cable to the PC;

8. in “My Computer”, go to “VITALI_Disk” to display the les on the chair card:

DESCRIPTION FILE NAME

(FIRMWARE)

DATE OF LAST

CHANGE (REVISION) (*)

Firmware for chair card cod. 59400049 SP33001000V0 Chair 1.cry 08/09/2011 14.00

Firmware for cuspidor card cod. 59400056 SP33006000v0 Riuni 1.cry 08/06/2011 14.00

Firmware for 1st instrument preselection card

cod. 59400052 present in instrument table

SP33009000v0 Selec 1.cry 05/05/2011 12.00

Firmware for 2nd instrument preselection

card cod. 59400052 if present in water unit.

SP33009000v0 Selec 2.cry 05/05/2011 12.00

(*) non-real data, example of date/hour format.

9. drag&drop or cut&paste the new rmware into the “VITALI_Disk” (the le of the new rmware

may have different names, this is irrelevant for updating purposes);

10. carry out the “Safe Hardware Removal” and disconnect the USB cable from the PC when the

system so allows;

11. if necessary, update the other cards, repeat steps 7 to 10 for each new rmware you want to

load.

12. if the chair card is in its housing, turn off the main switch of the equipment;

13. place the switch 4 of SW1 on OFF;

14. put the chair card back into its housing (if necessary);

15. wait for about 10 seconds and turn on the main switch of the equipment;

16. the chair card has been updated;

17. if the rmwares of other cards have been loaded on the chair card, you need to follow the proce-

dure “Uploading rmwares to peripheral devices” to complete the update process.

N.B: the data on the settings of the equipment is in the chair motherboard; however, the updating of

the rmware of this card does not alter stored data.

3/34.2

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 01/05/2011

UPLOADING FIRMWARES TO PERIPHERAL DEVICES

This procedure is required to transfer updated rmwares from the chair card to cuspidor/instrument

preselection cards.

Procedure:

1. put the dip-switch 2 of SW1 on ON;

2. the ignition of the LEDs of storable positions identify which peripheral devices are connected;

more specically:

= card cod. 59400056 (water unit)

= card cod. 59400052 (1° instrument selection card present in the instrument table)

= card cod. 59400052 (2° instrument selection card, if present in the water unit)

3. keep the key pressed and, without releasing it, press the key that identies the peripheral

device that you want to update for 5 uninterrupted seconds (e.g. + to update the instru-

ment table selection card);

4. the corresponding LED (1, 2 or 3) starts to ash, indicating that the rmware transfer is under-

way;

5. 5. release both keys, wait for the LED to light up and stop ashing, and for a long conrmation

beep;

6. 6. if required, repeat steps 3 to 5 for the other cards that require updating;

7. 7. put the dip-switch 2 of SW1 on OFF;

8. 8. turn the equipment off and then on again;

9. 9. wait for about 10 seconds for the system to overwrite the old rmware.

N.B. if you upload the rmware of the card code 59400056, the restarting of the equipment will be

accompanied by an intermittent sound. The tonality of the last sound of the series indicates whether

or not overwriting has been effective (low/deep sound = failure).

ADJUSTING THE MAINTENANCE TIMER

After about 1,000 hours of operation, the functioningindicator starts ashing for about 1 minute

when the equipment is started (see chapter 9.0).

To change the number of hours counted:

10. Put the dip-switch 2 of SW1 on ON .

11. The LEDs from 1 to 10 of the unit’s keyboard display the remaining time.

(all the LEDs ≈ 1,000 hours, e.g. 1 2 3 4 5 6 7 8 9 10 ≈ 300 hours).

The gure is viewable even in diagnostic mode (see chapter 6.6: Group 0.9).

12. Press and, without releasing it, to set the timer at 1,000 hours or press and, without

releasing it, to set the timer at 0 hours. Wait for the acoustic signal and release both keys.

13. Put the dip-switch 2 of SW1 on OFF.

WARNING: the dip-switch 2 of SW1 can also be used to update the rmwares of peripheral devices

(see chapter UPLOADING FIRMWARES TO PERIPHERAL DEVICES).

N.B: if the chair motherboard is replaced, it is necessary to repeat every customization previ-

ously made to the equipment (see chapter 6.7).

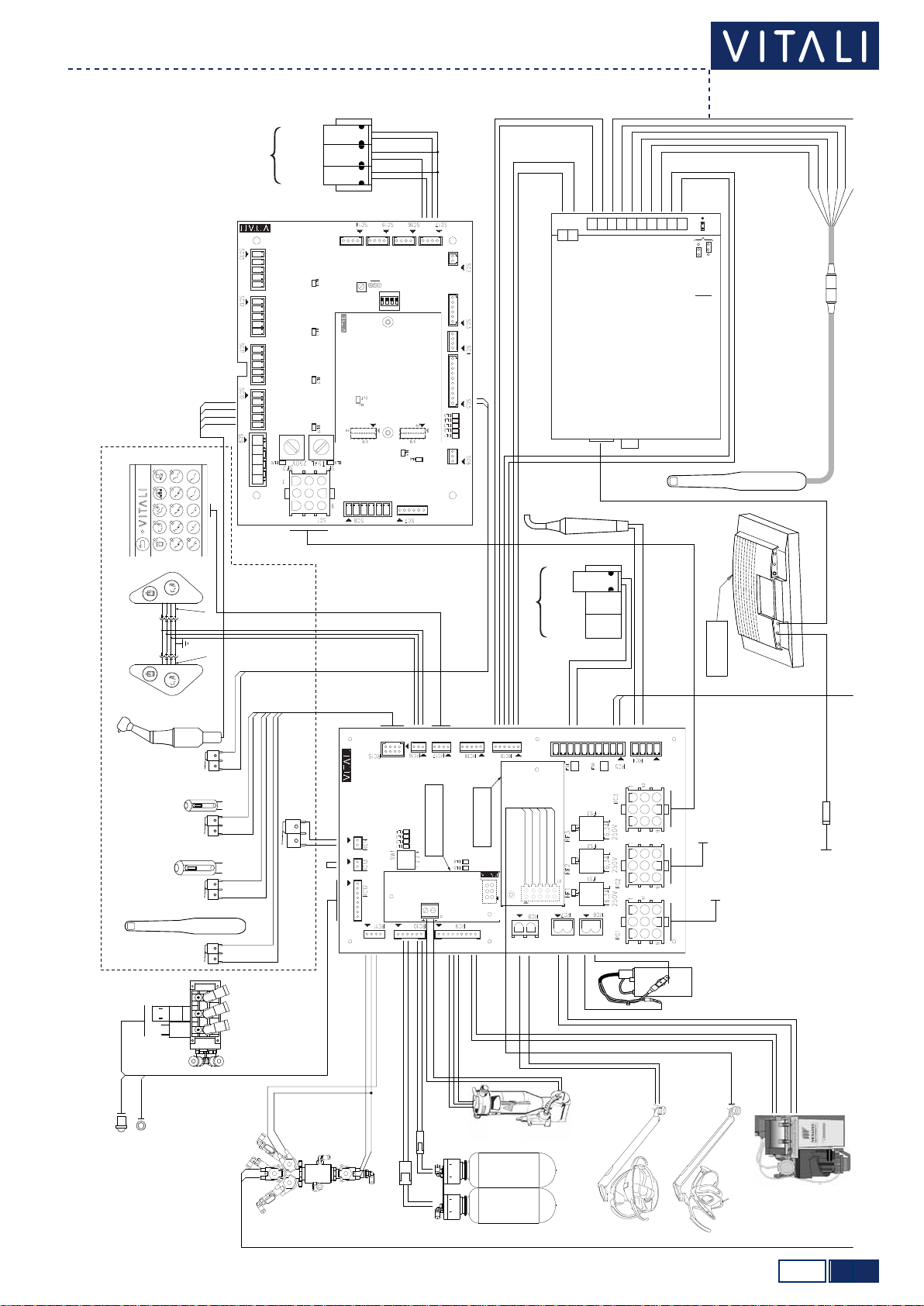

4.3 1/1

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 12/03/2012

Electric diagram

Chair electric unit

PCB COD. 59400048

PCB

COD. 59400050

PCB COD. 59400051

MOTOR 24VCC LA31

BACKREST MOVEMENTS

MOTOR 24VCC LA34

CHAIR MOVEMENTS

LINE

230 VAC 50/60 HZ

PANTOGRAPH COVER SAFETYCHAIR COVER SAFETY

CHAIR

POSITION

TRANSDUCER

CHAIR

DESCENT

LIMIT SWITCH

CHAIR RISE

LIMIT SWITCH

BACKREST

POSTION

TRANSDUCER

EMERGENCY

STOP BUTTON

FUNCTIONING

INDICATOR

WATER GENERAL

SOLENOID VALVE

BIPOLAR

LUMINOUS

MAIN SWITCH

230VAC

50/60Hz

24VAC

50/60Hz

24VAC

50/60Hz

SUCTION

CONTROL

RELAY

UV-OSMO LAMP

VITALI DISINFECTION SYSTEM (OPTIONAL)

TO LINE 230 VAC

50/60 HZ

FOOT CONTROL

PUSH BUTTON

FOOT CONTROL

BACKREST

COVER SAFETY

CHAIR DESCENT

LIMIT SWITCH

BACKREST RISE

LIMIT SWITCH

TO RC1 PCB COD. 59400056

VDS KEYBOARD

VDS SOLENOID VALVES GROUP

TO THE MONITOR

MONITOR

FEEDER

UV-OSMO POWER

FEEDER

TRANSFORMER

V

V I T L I

V

D

S

PCB COD. 59400055

PCB OD 5940 055

PRESSURE SWITCHES

5.0 1/1

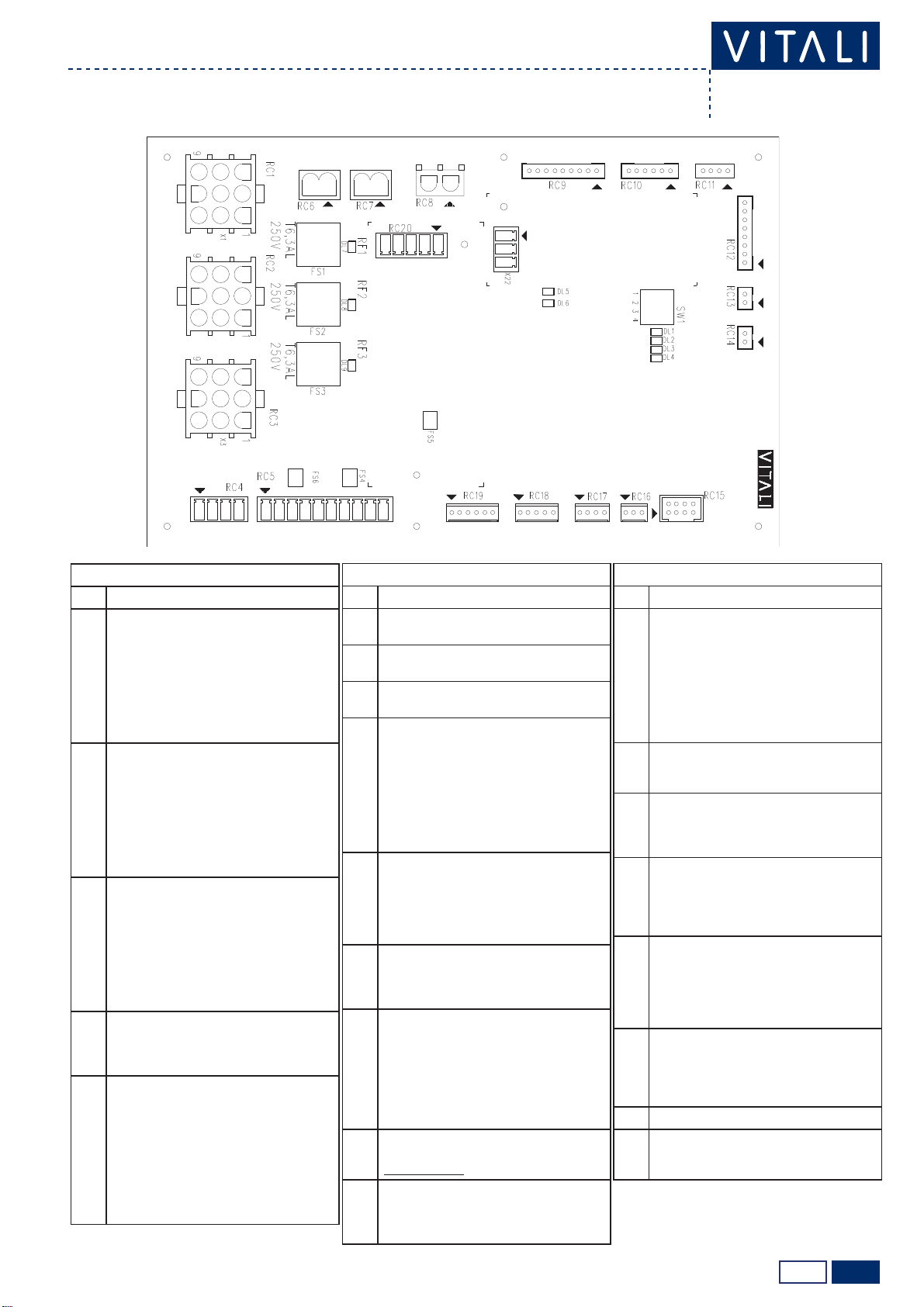

59400056

T5 EVO V8e

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 01/01/2012

Location

Water unit

To have access to the cuspidor column, remove the covers as indicated in the T5 Evo or V8e Installation Manual.

5.1 1/2

PCB COD. 59400056

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 12/03/2012

Water unit card ref. 59400048

Water unit

CONNECTORS

N° DESCRIPTION

RC1

1 - IN 24 Vac

2 - IN 21 Vac (phase)

3 - IN 21 Vac

4 - IN 24 Vac (phase)

5 - CAN H (SERIAL COMMUNICATION)

6 - CAN L (SERIAL COMMUNICATION)

7 - IN + 34 Vdc

8 - IN +25 Vdc

9 - Ground

RC2

1 - 24 Vac

2 - 21 Vac (phase)

3 - 21 Vac

4 - 24 Vac (phase)

5 - CAN H (SERIAL COMMUNICATION)

6 - CAN L (SERIAL COMMUNICATION)

7 - + 34 Vdc

8 - +25 Vdc

9 - Ground

RC3

1 - 24 Vac

2 - 21 Vac (phase)

3 - 21 Vac

4 - 24 Vac (phase)

5 - CAN H (SERIAL COMMUNICATION)

6 - CAN L (SERIAL COMMUNICATION)

7 - + 34 Vdc

8 - +25 Vdc

9 - Ground

RC4

1 - AUX 24 Vac

2 - AUX 24 Vac (phase)

3 - 24 Vac phase

4 - 24 Vac (phase) Curing light

RC5

1 - Ground

2 - +25 Vdc

3 - + 34 Vdc

4 - Reserved

5 - Reserved

6 - Reserved

7 - + 24Vcc instrument spray water sol. valve

8- Ground instrument spray water sol. valve

9 - +24 Vcc instrument spray air sol. valve

10 - Ground instrument spray air sol. valve

CONNECTORS

N° DESCRIPTION

RC6 1 - 24 Vac Glass water heater

2 - 24 Vac (phase) Glass water heater

RC7 1 - 24 Vac Amalgam separator

2 - 24 Vac (phase) Amalgam separator

RC8 1 - 24 Vac Halogen lamp

2 - 24 Vac (phase) Halogen lamp

RC9

1 - +25Vdc Spittoon drainage contact

2 - IN Spittoon drainage contact

3 - Probe A for miniseparator max level

4 - Probe B for miniseparator min level

5 - Probe C for miniseparator common levels

6 - Minicaster rinsing solenoid valve

7 - Minicaster rinsing solenoid valve

8 - Electropneumatic valve

9 - Electropneumatic valve

RC10

1 - Reserved

2 - Clean water system level control

3 - Ground clean water system level control

4 - Reserved

5 - Clean water syst. lev. contr. (Multiclean)

6 - Ground clean water syst. lev. contr. (Multiclean)

RC11

1 - Glass solenoid valve

2 - Ground glass solenoid valve

3 - Spittoon solenoid valve

4 - Ground spittoon solenoid valve

RC12

1 - Clean water syst. start button (+25Vdc)

2 - Clean water syst. start button

3 - Common LED

4 - Red LED clean water system level

5 - Green LED clean water system level

6 - Clean water syst. start solenoid valve

7 - Ground Solenoid valve

8 - Disconnected

RC13 1 - Microswitch for spittoon security (+25Vdc)

2 - Microswitch for spittoon security

Short it if unused

RC14

1 - Security microswitch for instrument arm on

assistant’s console (+25Vdc)

2 - Security microswitch for instrument arm on

assistant’s console

CONNECTORS

N° DESCRIPTION

RC15

1 - Common micro. instr. arm on nurse’s side

(+25Vdc)

2 - Microswitch instrument 1

3 - Microswitch instrument 2

4 - Microswitch instrument 3

5 - Microswitch instrument 4

6 - Microswitch for suction terminals supports

7 - Microswitch for saliva ejector

8 - Ground

RC16 1 - Common cuspidor control keyboard (+25Vdc)

2 - Glass fill-up button

3 – Spittoon rinsing button

RC17

1 - +25 Vdc

2 - CAN H (serial comm. keyboard on assistant’s console)

3 - CAN L (serial comm. keyboard on assistant’s console)

4 - Ground

RC18

1 - Start auxiliary instrument (+25Vdc)

2 - Start auxiliary instrument (Ground)

3 - Disconnected

4 - Auxiliary instrument power adj. (0÷5 Vdc)

5 - Auxiliary instrument power adj. (Ground)

RC19

1 - 24 Vac (Videocamera module supply)

2 - 24 Vac (phase) Videocam. module supply

3 - Videocam. freeze control (open norm. contact)

4 - Videocam. freeze control (open norm. contact)

5 - Videocam. start control (open norm. contact)

6 - Videocam. start control (open norm. contact)

RC20

1 - 21 Vac (Halogen lamp supply Code 59400061)

2 - 21 Vac (phase) Halogen lamp supply Code 59400061

3 - Common remote controls for LED lamp (brown)

4 - Common UP remote controls for LED lamp (white)

5 - Common DOWN remote controls for LED lamp (green)

RC21 Reserved

RC22 1 - +34Vdc(DrainagepumpcardsupplyCode59400062)

2 - Pump start

3 – Ground

2/25.1

Technical manual ›

T5 EVO/V8e

COD. 66000024-EN - 12/03/2012

LED

N° INDICATION

DL1 It indicates the proper operation of the serial connection.

DL2 It indicates when a direct (non-serial) input changes status.

DL3 It indicates when a direct (non-serial) output changes status.

DL4 Reserved.

DL5 Presence of 25 Vcc voltage

DL6 Presence of 5 Vcc voltage

DL7 Integrity of fuse RF1

DL8 Integrity of fuse RF2

DL9 Integrity of fuse RF3

FUSES

N° PROTECTED PARTS VALUE AND

TYPE ANOMALIES THAT CAN BE DETECTED AFTER INTERRUPTION

FUNCTIONS LED

RF1 Glass water heater. T. 6.3AL (5x20)

DELAYED The hot water glass function is

not working (optional). DL7 switched off.

RF2 Amalgam separator. T. 6.3AL (5x20)

DELAYED The amalgam separator is not

working (optional). DL8 switched off.

RF3 Curing light.

Intraoral camera.

AUX output on RC4.

T. 6.3AL (5x20)

DELAYED

The curing light is not working.

The intraoral camera is not

working.

An eventual user connected to

the AUX output of RC4 is not

working (pin 1 and 2 RC4).

DL9 switched off.

5.2 1/1

PCB COD. 59400061

PCB COD. 59400062

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 01/05/2011

Water unit

Drainage pump card Code 59400061

Halogen lamp card Code 59400062

CONNECTORS

N° DESCRIPTION

X1 Unit card connection cod. 59400056 (RC22)

X2 1 - +12 Vdc (Drainage pump supply)

2 - Ground

CONNECTORS

N° DESCRIPTION

X1 Unit card connection cod. 59400056 (RC20)

5.3 1/1

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 01/05/2011

Electric diagram

Water unit

4

PCB COD 59400056

1 2 3 4

ON

SW1

RV1

AB

PCB COD. 59400052

Camera ON/OFF switch

Camera ON/OFF switch

Camera power supply

Ground

Luminance (Y)

Chroma (C)

Handpiece freeze button

Pedal (freeze)

Pedal (freeze)

COMPOSITE OUT

S-VIDEO OUT

SOPRO’

DOCK595MU

Power supply (24Vac)

Power supply (24Vac)

1

2

Handpiece

Pedal

Selection for

freeze source

1

2

3

4

5

6

7

8

9

10

PCB COD. 59400060

PCB COD 59400062

4

321

PCB COD. 59400061

11

22

33

44

11

22

33

44

8

7

ASSISTENT’S CONSOLE

INSTRUMENT SOLENOID

VALVES GROUP

WATER

START

CHIP BLOWER

KEYBOARD

COD. 57000020

KEYBOARD (OPTIONAL)

COD. 57000023

KEYBOARD

COD. 57000019

SHIELDING

MICROMOTOR(OPTIONAL)

INTRAORAL CAMERA

(OPTIONAL)

SUCTION TERMINAL D.11

SUCTION TERMINAL D.17

SCALER/SYRINGE

SOLENOID VALVES GROUP

SCALER

WATER

SYRINGE

WATER

SYRINGE

AIR

TO THE FEEDER (CHAIR BASE)

TO PC1 OF CARD COD. 59400048

TO SC1 OF CARD COD. 59400052

SOLENOID VALVES GROUP OF

PRESSURIZED BOTTLE KIT

(ONLY IN THE ABSENCE OF VDS)

PRESSURIZED BOTTLE KIT

START BUTTON

YELLOW WARNING LIGHT FOR

PRESSURIZED BOTTLE KIT

LCD MONITOR

(BACK SIDE)

POWER (12Vcc) S-VIDEO

ALYA OPERATING LIGHT

EDI OPERATING LIGHT

YELLOW 3

GREEN 4

ORANGE 5

YELLOW 3

BLACK 2

ORANGE 1

PINK 2

PINK 3

BLACK 5

BLACK 6

INIHIBITION SECURITY MICROSWITCH

FOR ASSISTENT’S CONSOLE

JUMPER

BLUE

BROWN

BROWN

WHITE

GREEN

0.75mm2

0.75mm2

0.35mm2

0.35mm2

0.35mm2

PRESENT ONLY

WITH EDI LAMP

PRESENT ONLY WITH

DRAINAGE PUMP

ABC

CP1

CP5 GLASS

+25Vcc

SPITTOON

SOPRO 595 o 617

BROWN

BROWN

RED

RED

BLACK

BLACK

GREEN

YELLOW

RED

SH ELDING (WHITE+BLACK+GREY)

BLACK

WHITE

START

WATER

CHIP BLOWER

COMMON

SH ELDING

- MM

+ MM

- FO

+ FO

TUMBLER WATER BOILER

(OPTIONAL)

TUMBLER WATER

SOLENOID VALVE

CATTANI SEPARATOR

WITH DRAINAGE PUMP

AMALGAM

SEPARATOR

METASYS MTS1

NOT USED

SALIVA EJECTOR

SPITTOON RINSING

SOLENOID VALVE

CURING LIGHT

(OPTIONAL)

CN87

CLEAN WATER

BOTTLE

MULTICLEAN

BOTTLE

6.0 1/1

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 01/01/2012

Location

Operator’s table

To have access to the Operator’s Table remove the upper cover as shown in the T5 Evo or V8 Installation Manual.

OIL COLLECTOR

SOLENOID VALVES

59400052

59400060

59400055

59400054

59400053

(only for V8e model)

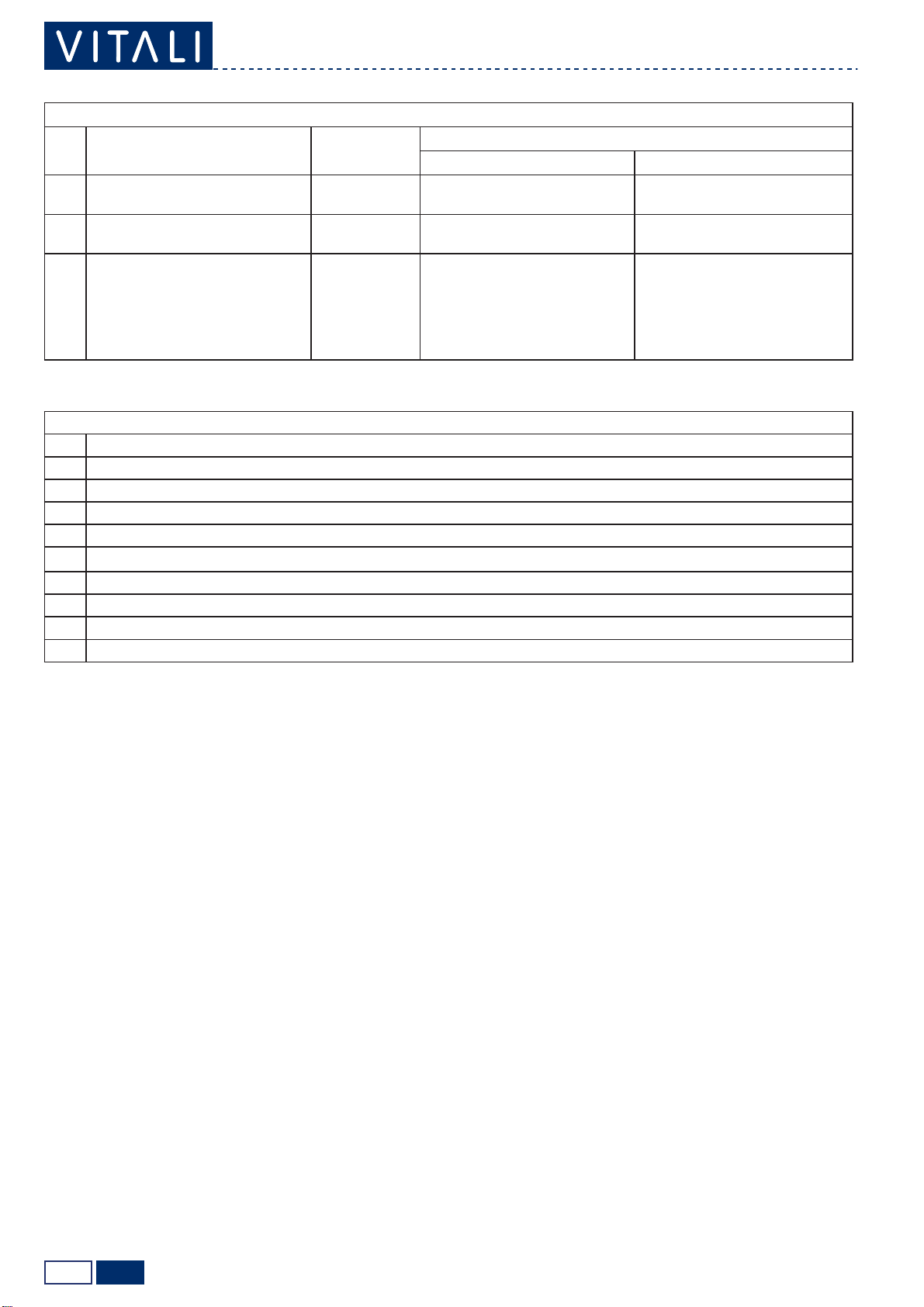

6.1 1/2

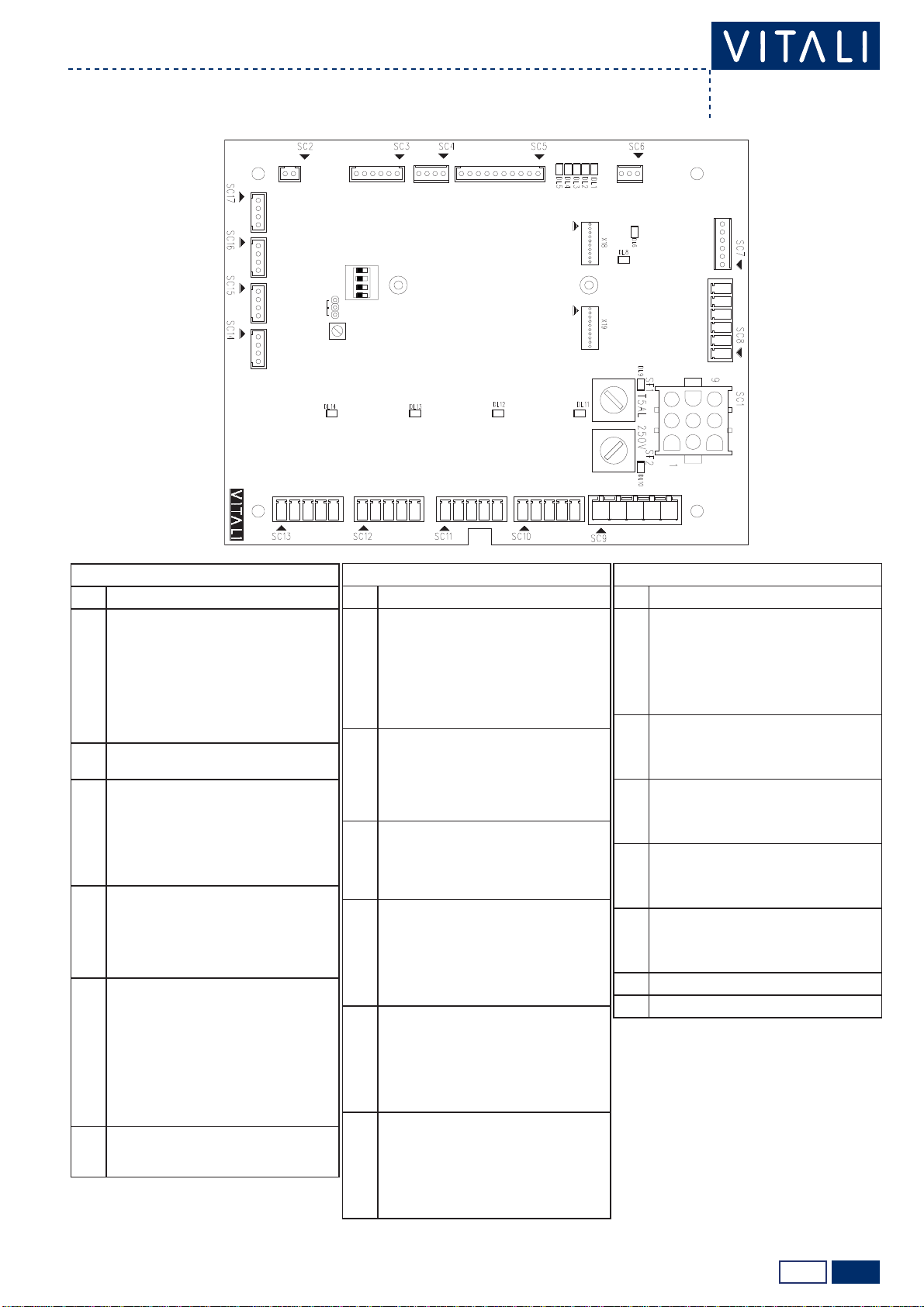

1 2 3 4

ON

SW1

RV1

AB

PCB COD. 59400052

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 01/01/2012

Instrument selection card Ref. 59400052

Operator table

CONNECTORS

N° DESCRIPTION

SC1

1 - IN 24 Vac

2 - Not connected

3 - Not connected

4 - IN 24 Vac (phase)

5 - CAN H (SERIAL COMMUNICATION)

6 - CAN L (SERIAL COMMUNICATION)

7 - IN + 34 Vdc

8 - IN +25 Vdc

9 - Ground

SC2 1 - Reserved

2 - Reserved

SC3

1 - +25 Vdc (Arm brake module supply cod. 59400053)

2 - Enable signal for arm brake (Connection to

arm brake module cod. 59400053)

3 - Ground (Arm brake module supply cod. 59400053)

4 - Not connected

5 - +24 Vdc arm brake solenoid valve

6 - Ground arm brake solenoid valve

SC4

1 - +25 Vdc

2 - CAN H (serial communication operator’s table

keyboard)

3 - CAN L (serial communication operator’s table

keyboard)

4 - Ground

SC5

1 - IN microswitch of instrument arm 1

2 - IN microswitch of instrument arm 1

3 - IN microswitch of instrument arm 2

4 - IN microswitch of instrument arm 2

5 - IN microswitch of instrument arm 3

6 - IN microswitch of instrument arm 3

7 - IN microswitch of instrument arm 4

8 - IN microswitch of instrument arm 4

9 - IN microswitch of instrument arm 5

10 - IN microswitch of instrument arm 5

SC6 1 - +25 Vdc

2 - 0÷5 Vdc (scaler power adjustment)

3 - Ground

CONNECTORS

N° DESCRIPTION

SC7

1 - Cont. normally open activation of brushless

micromotor

2 - Cont. normally open activation of brushless

micromotor

3 - 0÷5 Vdc (micromotor speed adjustment)

4 - Ground

5 - Serial communication brushless module (RX)

6 - Serial communication brushless module (TX)

SC8

1 - +34 Vdc (Brushless module supply)

2 - Ground

3 - Disconnected

4 - IN phase W brushless micromotor

5 - IN phase V brushless micromotor

6 - IN phase U brushless micromotor

SC9

1 - +34 Vdc AUX

2 - +25 Vdc AUX

3 - Ground

4 - 24 Vac (phase) AUX (e.g. syringe 6F)

5 - 24 Vac - AUX (e.g. syringe 6F)

SC10

1 - phase W brushless micromotor 1

2 - -electric micromotor 1 (phase V brushless

micromotor)

3 - + electric micromotor 1 (phase U brushless

micromotor)

4 - + illumination of instrument 1 (FO)

5 - - illumination of instrument 1 (FO)

SC11

1 - phase W brushless micromotor 2

2 - -electric micromotor 2 (phase V brushless

micromotor)

3 - + electric micromotor 2 (phase U brushless

micromotor)

4 - + illumination of instrument 2 (FO)

5 - - illumination of instrument 2 (FO)

SC12

1 - phase W brushless micromotor 3

2 - -electric micromotor 3 (phase V brushless

micromotor)

3 - + electric micromotor 3 (phase U brushless

micromotor)

4 - + illumination of instrument 3 (FO)

5 - - illumination of instrument 3 (FO)

CONNECTORS

N° DESCRIPTION

SC13

1 - phase W brushless micromotor 4

2 - -electric micromotor 4 (phase V brushless

micromotor)

3 - + electric micromotor 4 (phase U brushless

micromotor)

4 - + illumination of instrument 4 (FO)

5 - - illumination of instrument 4 (FO)

SC14

1 - Ground solenoid valves instrument 1

2 - Solenoid valve of chip blower instrument 1

3 - Solenoid valve of instrument spray 1

4 - Driving air/cooling solenoid valve instrument 1

SC15

1 - Ground solenoid valves instrument 2

2 - Solenoid valve of chip blower instrument 2

3 - Solenoid valve of instrument spray 2

4 - Driving air/cooling solenoid valve instrument 2

SC16

1 - Ground solenoid valves instrument 3

2 - Solenoid valve of chip blower instrument 3

3 - Solenoid valve of instrument spray 3

4 - Driving air/cooling solenoid valve instrument 3

SC17

1 - Ground solenoid valves instrument 4

2 - Solenoid valve of chip blower instrument 4

3 - Solenoid valve of instrument spray 4

4 - Driving air/cooling solenoid valve instrument 4

X18 Connection micromotor module cod.59400060

X19 Connection micromotor module cod.59400060

2/26.1

Technical manual ›

T5 EVO/V8e

COD. 66000024-EN - 01/01/2012

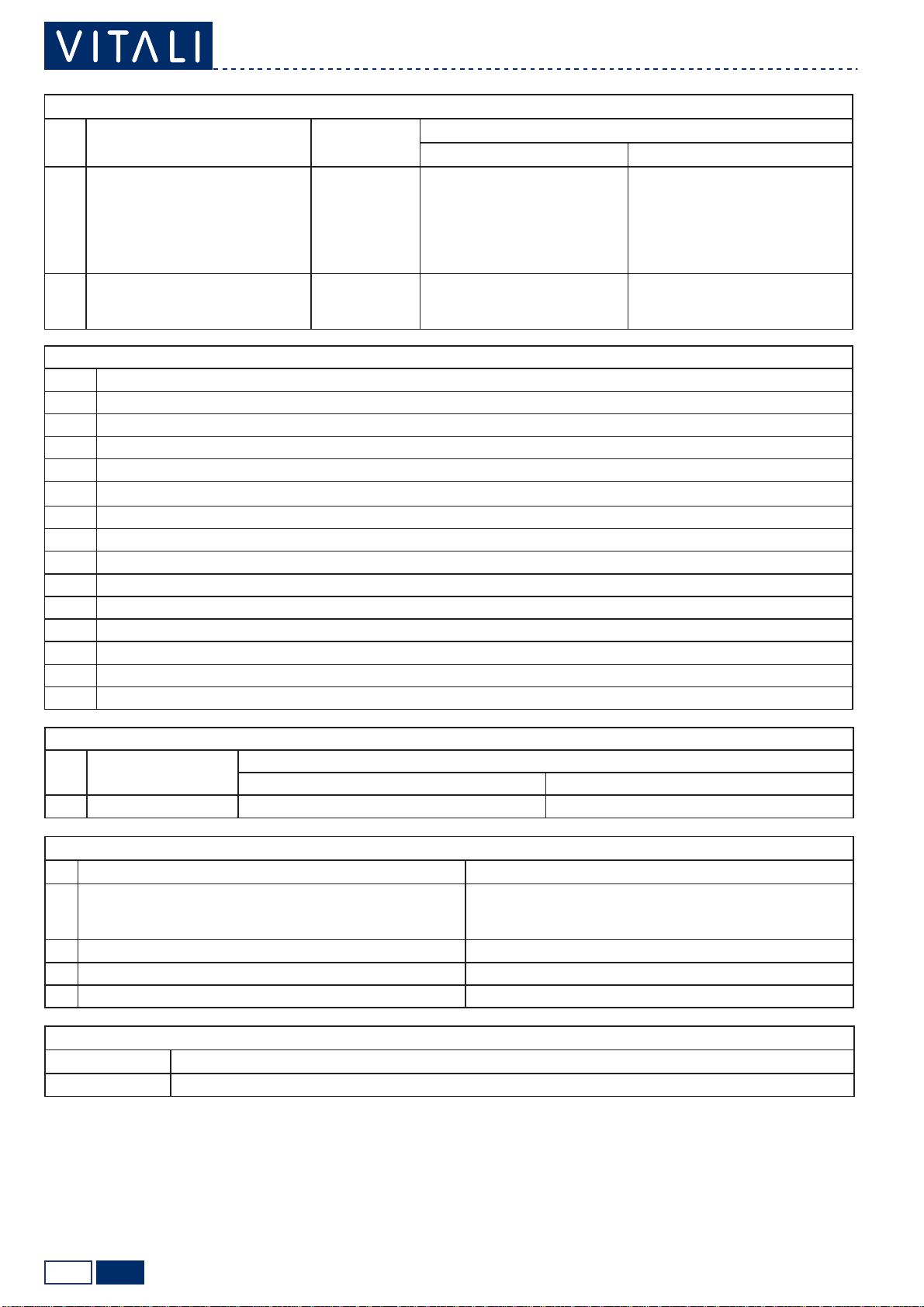

LED

N° INDICATION

DL1 It indicates the proper operation of the serial connection

DL2 It indicates when a direct (non-serial) input changes status

DL3 It indicates when a direct (non-serial) output changes status

DL4 It indicates the updating of the flash memory, flashing when the equipment is restarted after a new firmware is uploaded

DL5 Presence of 5 Vcc voltage

DL6 Activation of brushless micromotor

DL7 Activation of external circuit management of brushless micromotor (micromotor module Code 59400060 off)

DL8 Activated reverse rotation of micromotor

DL9 Integrity of fuse SF1

DL10 Integrity of fuse SF2

DL11 Activation of instrument 1

DL12 Activation of instrument 2

DL13 Activation of instrument 3

DL14 Activation of instrument 4

FUSES

N° PROTECTED PARTS VALUE AND

TYPE ANOMALIES THAT CAN BE DETECTED AFTER INTERRUPTION

FUNCTIONS LED

SF1 Parts 34 Vdc powered

T. 5AL (5x20)

DELAYED

Any eventual parts connected

to pins 1 and 3 of SC9 are not

working.

The micromotor or turbine that

can be modulated is not work-

ing.

DL9 switched off.

SF2 Parts 24 Vac powered

T. 5AL (5x20)

DELAYED

Any eventual users connected

to pins 4 and 5 of SC9 are not

working.

DL10 switched off.

JUMPER

N° FUNCTION STATUS

AB

J1 Reserved Reserved Normal operation (standard position)

N.B: for the proper operation of the card, each instrument must be properly configured (see chapter 6.7).

DIP-SWITCH PSW1

N° ON OFF

1 It identifies the card as secondary to the one that is present

in the operator’s table (e.g. an additional card for additional

instruments in the nurse’s console).

Standard position (card in the operator's table).

2 Reserved Reserved (standard position)

3 Reserved Reserved (standard position)

4Reserved Reserved (standard position)

TRIMMER

N° FUNCTION

RV1 Maximum voltage adjustment for handpieces illumination (FO) (standard ≈3.2 ± 0.1 Vcc, 0.700 mA)

6.2 1/1

PCB COD. 59400060

Technical manual ›

T5 EVO/V8e COD. 66000024-EN - 01/05/2011

Micromotor card Ref. 59400060

Operator table

CONNECTORS

N° DESCRIPTION

X18 X18 Selection card connection Code 59400052

(X18)

X19 X19 Selection card connection Code 59400052

(X19)

LED

N° INDICATION

DL1 It indicates the activation of the micromotor, its brightness is directly proportional to the speed of rotation.

This manual suits for next models

1

Table of contents

Other VITALI Medical Equipment manuals