VITO Vitolux VXI-4 Series User manual

Conte•tl

1 SafetyPrecaution•

and

ProductModel................................................................................

..

....................................... 1

1,1

Safety

Preaudions

...........................................................................................................................

..

.......

..

... 1

1,2 NameplateIntroduction:.................................................................................................................

....

.....

....

. 1

1.3 VFD Serles

Type

...........................................................................................................................................2

1.4

Technkal

Index

IUld Spedfication.......................................................................................................

..

.......2

2 Inatallation andWiring..................................................................................

..

....................................................

..

.......4

2.1 OperationEnTironment.................................................................

..

.............................................................S

2.2 In.tailingDirection

and

Space ...........................

..

...................................................................................

....

s

2.3 Appearance

and

Dimension

of

Keypad....................................................................................................... s

2,4

Whole Structure...................................................................................................................................

..

...

..

6

2.5

Batie

Riinning

Wiring......

..

....

.

....

.

....

..

....

.

....

.

....

..

....

.

....

.

....

..

....

.

....

.

....

..

....

.

....

.

....

..

....

.

....

..

....

.

....

.

....

...

..

.......

...

6

2.6 MajorLoop

Termiml

Wiring............................

..

..............................................................

..

..............

..

....... 7

2.7 MajorLoop

Termiml

Diagram.........................

..

...................................................................................

....

7

2.8 ControlLoop TerminalDiagram............................................................................................................

....

7

2.9 ControlLoop TerminalFunction Table ..................................................................................................... 7

2.10 DialSwitch................................................................................................................................................ 8

2,11

Wuing

Notiees

..

..................................................................

..

..............................

..

..........................

..

.........

..

9

3 OperationPanel

and

OperlltionMethod .................................................................................................................... 9

3.1 Operation PanelKe)'I ................................................................................................................................ · 9

3.2 LED aodIndicator

Light

De1eription1

..

.

..

.......

..

.......

..

.........................................................

..

................... 10

3.3 MonitoringParameterDiaplay....................................

..

................

..

.......

..

.................................................. 10

3.4

Run Statu1 ParameterDiaplay....................................................................................................

..

.............· 11

3.5 Malfunction

Alarm

Dllplay..................

..

.........................................................

..

......................................... 11

3.6 Function CodeEditing Diaplay.......................................................................................................

..

.....

..

..

· 12

3.7 MonitoringParameter................................

..

................

..

.......

..

..............................................................

..

..

. 12

3.8 Function CodeSetting................................................................................................................................. 13

3.9 U1er Pu1WordSetting

and

Function Code

Edit

.

..

.......

..

..

..

............

..

...

..

................

..

.......

..

.......

..

...

..

.......

..

..

..

13

4 Function

Parameter

Table

and

De1eription............................

..

.......

..

..............................

..

.........................

..

.............. 15

4.0

MonitoringParameter

Group

IUld

Fault

Record

.......................................................................................

15

4.1

Function Code.............................................................

..

..............................................................................

18

4,2 DetailedFunctionDeleription

..

......................................................................................................

..

.......

..

·45

F8

Proce.11

PID

Parameter

..

...........................................................................................................................79

F9

ProgrammableOperationParameter .......................................................................................................

84

FA

Protection Parameter

..

...............

..

....

..

...........................

..

.....................

..

....

..

...........................

..

.........

..

····92

FB

Communication

Parameter

.........................

..

.......................................

..

............................................

..

....97

FC

AdvanceFnnctionParameter

and

PerformanceParameter ....................................................

..

..............98

FE

Panel

F11Dction

Setting

and

ParameterManagement

(PD

group

re.erved)

.....

..

.......

..

...........

..

............ 102

5 CommunicationProtocol........................................................................................................................................... 108

5.1

RTU mode

IUld

format...................................................................

..

.......

..

................................................ 108

5.2 Regi8ter

Addrell

andFunction Code .....................................................

..

................................................ 108

5.3 Functions ofotherRegiaterAddre11: .....................................................

..

................................................ 1

13

5.4 FaaltCodes ...........................................................

..

.....................

..

......................................................... 114

5.5 Pre-alarmCode

of

theDriver:..............

..

.........................................................

..

...........................····.....··· 115

5.6 ControlCommand

Format

(seefanctien code 06H example)s

..

.......

..

.......

..

...........................................

11

5

5.7 ParameterAttrlbnte1 ..........................

..

................................................

..

......................................

..

........ 1

16

5.8

Error

Codefrom Slave Relponse

of

AbnormalInformation1 ..............

..

.......

..

.......................................

116

5.9 Comm

uni

cation Add

raa

ofal1Paramet12"1: .......................................................................................... 116

6 Troubleshooting........................................................................................................................................................ 1

17

6.1

Faalt

information

and

Troubleshooting ..............................................................................................

..

... 1

17

6.2 AbnormalPhenomena Solutl.on ...

..

................

..

............

..

.................................................................

..

........ 119

7 Maintenance........................................

..

.......

..

.......

..

........................................................................................

..

........ 1

21

7.1 Roatine Malntenance............................

..

........................................................................................

..

........ 1

21

7.2 PeriodicMaintenance .....................................................................................................................

..

........ 121

1

Slife•

Precautions

and

Product

MOdel

1.1 SafetyPn:caution1

..t..

Do

not install this equipment

in

anexplosive

gas

atmosphere, or there

will

be explosionhazards.

..t..

Only

qualified individuals should proceed with wiring. or

the.re

will

be electric

shock

hazards.

Do

not

conduct

any

wiring during the system poweron

to

avoid

the

electric shock..

..t..

Do

not

touch

control

termina.ls

,

in1ema.I.

circuit boardandits components,

or

the.re

willbe electric shock hazar

d.

..t..

Earthterminal

IIl1l8t

be exactlygrounded whenusinginverter. Grounding must be confirmedwith

the

national electric

safetyregulation

and

other

electric code.

..t..

Afterpower ott;

do

not touch internal circuit board

or

any parts inside within5 minutes after

keyp

ad

di

splay wento

ff.

Any

intemal operation must be after making sure of discharge off with instrument checking

to

avoid the electric

shock.

..t..

Do

not connect AC

power

to

output terminal

(U

,

V,

W)

of inverter. The only terminal

the

AC

power

allowed

to

be

connected

is

R,

S, T (or

Ll

, L2 single-phrase sourceinverter

).

..t..

Static electrici

ty

on human bodycan

damage

MOS device. Donot

touch

PCB andIGBTwithout anti-static measure.

..t..

Do

not lose screws, spacers andother metallic fureign bodies inside the driver

to

avo

id

fire hazardanddri

wr

damage.

..t..

Do

not connect 220VAC power to

intema1

control terminal

of

th

e driver, or there will be serious

dama

ge

to

the

dri

ver.

..t..

If

ovcn:urrmtprotection occurs afterstart

the

driver, confirm again

the

cxtemal wiring and thenpower on and

nm

the

driver.

..t..

Do

not switch offthepower

to

stop the dri

ver.

Cut offpower source after

the

motor stops running.

..t..

Do

not install

the

driverinplaces wi

th

direct

sunlight

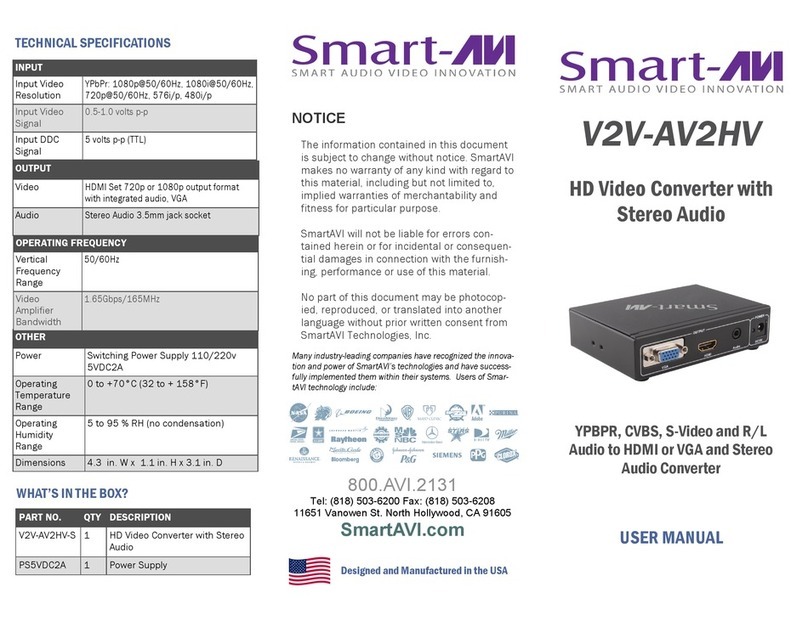

1.2 NameplateIntroduction:

VXI 4-5.5-7.5 + v - 0015 - 4 +

Kw

Enteiprise code .J

-r

T

~

Type

sc:nes

__J

I

V:Vector

type

Using

the

motor capacity

Tboinput i.v.J

I 1

S~

e

220V

I 2 fhre&.p

bue

220 v

Di

gitalpartof the said wire length

I 4

'fhrO&.pbuo

380v

-1-

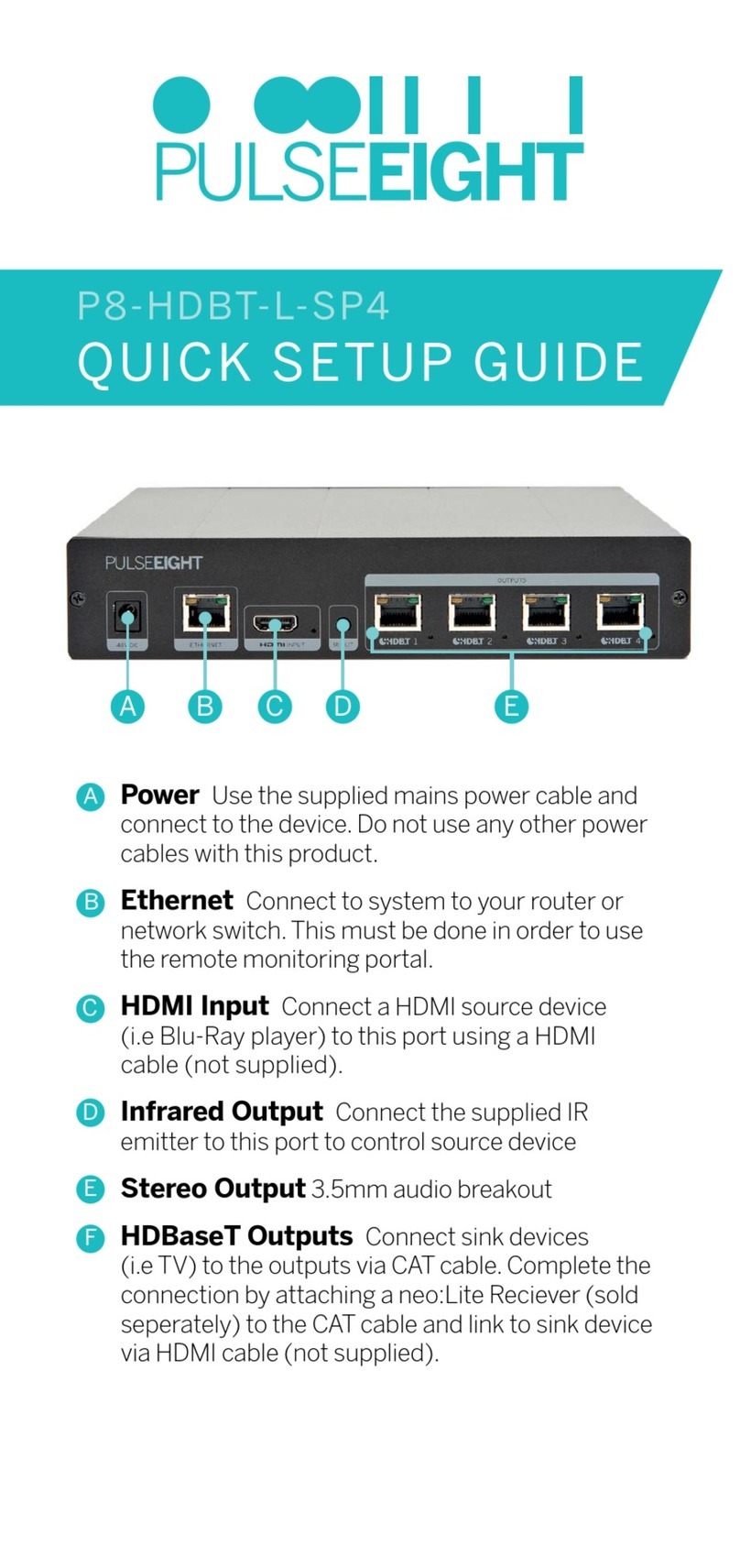

1.3

VFD

SerlesType Current and Voltage ICurrent closed-loop control, free

from

a.irrent impact, perfect

Restrain restrainfunction

of

overcurrent and overvoltage

Voltage

Classes

Rated

Power

(KW)

RatedOutput

Cunm

.Adapted Motor

(A)

(KW

)

0.75 4.5 0.75

220V

I-phase 1.5 7 1.5

2.2 10 2.2

0.75 2.5 0.75

380V

3-phase 1.5 3.7 1.5

2.2 5.0 2.2

1.4

Technieal

Index

and

Specification

Undervolt:qe

Specially

for

users

with

a

low

or

unsteadyvoltage

power

grid: even

lower

than

the

allowable

Restrain

during

voltage range,

the

svstem can maintain

the

longest possible operating

time

based

on

Its

Running uniquealgorithm and residual energy allocation strategy

~

Multl-veloclty

16

segments programmable multi-velocity control, multiple operation mode. Traverse

"a

andTnvene operation: preset frequency and center frequency adjustable, parameter

memory

and

[ Operation recovery

after

powercut.

2' PI

DConlrol

Built-in

PIO

controller

(ab

le

:I

to

preset frequency). Standard configuration

RS485

a..

RS485

0 CommunlQIUo communication function, multiple communication protocol

for

choice, synchronizing control

:I

function.

n

Analog

Input

Direct voltage

o-1ov,

direct current

0-20mA

(optional

up

Frequency

limit

and

lower

limit)

Rated

Voltage,

3-phase (4T#sereis)

380V;SOfoOHZ

S' Frequency 1-phase (2S#series)

220V;S~HZ

"a

a

Allowed

3-phase (4T#series)

320V-460V

Voltage

Range

1-phase (2S#series)

160V-260V

Voltage 4T#series;

0-460V

0 2S#serles;

0-260\/

c

..

frequency Lowfrequencymode:

0-300HZ

; Highfrequency mode:

0-3000HZ

"a

a OVerlmd Gtype:110%

for

long-tenn, 150%

for

1 min, 180%

for

Ss

capacrtv

Ptype: 105%

for

long-term, 120%

for

1 min, 150%

for

ls

Settin1 Digital Input Operation panel setting,

RS485

port

setting, UP/OW

tenninalcontrol,

or

combined withanalog

input

DigitalInput 2 channel oc

output

and one channel relay

output

(TA,

TB,

TC),

up

to

16

choices

OUtputSignal 2 channel analog signal

output,

output

ranging

within

Analog

Input

0-20mA

or

o-1ov

with

flexiblysetting, achievable

output

of

physical quantitieslikesetfrequency,

output

frequency

Automatic

Dynamic steady state, static steady state,

and

unsteady voltage

for

choices

to

obtain

the

Stady-voltage

Operation steadiest operation

Control

Mode

V/Fcontrol,advanced V/Fcontrol, V/F separation control, electric current vector control Acceleration

Frequency Analog

Input

0.1%

of

maximum

output

frequency

Setting

and

o.1s-3600mincontinuous setting,Stypeand lineartypemode

for

choice

Deceleration

Resolution Digital Setting 0.01

Hz

Time

Setting

Frequency Analog

Input

Within

0.2%

of

maximum

output

frequency

Precision Digital Setting

Wlthln

0.01%

of

set

output

frequency

V/F Curve{voltage Reference frequency setting

5-500

Hz, multipoint V/F curve

frequency character) setting,

or

fixed

curve

of

constant torque,

low

decreasing

torque

1,

low

decreasing

torque

2,

square

torque

Manualsetting: 0.0-30%of rated

output

V/F-

Control TorqueCompensation Automatic compensation: according

to

output

current

and

6'

motor

parameter

:I

During acceleration, deceleration

or

steady running, detect

..

2.

AutomaticCurrent-limiting automatically

the

current and voltage of

motor

stator, and

g

and

Voltage-llmltlng

contro

l

It

within

bounds based

on

unlque algorithm, mlnlmlze

• fault-trip chance

i1

it Voltage Frequency Adjust pressure/frequency ratio according

to

motor

parameter

..

Character and uniquealgorithm

Startingtorque:

gJ

!i

i il Dynamicbraking initialvoltage, backlashvoltageand dynamic braking continuousadjustable

-3

ill;;·

gJ

Halt

DC

braking initialfrequency: 0.00-[F0.16)upper

limit

freq

uency

Brab

I~

Brakingtime: 0.0-100.os;

::I Brakingcurrent:0.0%-150.0%

of

rated

ament

....

!

l!

0-100

O:inllillid

!!l.

Ii

a

Low

Noise Carrierfrequency1.0kHZ-16.0kHzcontinuous adjustable, minimize

motor

noise

Running

3.0

Hz

150%rated

torque

(VF

control)

senseless

0.5

Hz

180%rated

torque

(SVC,

FVC)

Torque Character 0.05

Hz

180%rated

torque

(VC)

Vector

Control Operating speed precision

in

steadystate:

~±0.5%rated

synchronousspeed

Torque response:

~SOms

VC,

SVC,

FVC

~20ms

Motor

Parameter Being able

to

detectparameterautomaticallyunderstaticstate

Self-measurement and dynamic state

of

motor, thus guarantee an

optimum

contro

l.

Speed

Tracking

and

Smoothrestartduringoperation, instantaneous

stop

andrestart

Restart

Function

Counter A built-

in

counter, facilitate system integration

Operation Upper

limit

and

lower

limit

frequency setting, frequency

hopp

in

g operation, reversal running

Function restraint, slip frequency compensation,

RS485

communication, frequency control

of

progressive increase

and

deaease, failure recoveryautomatically,etc.

-2- -3-

:II

i

iii

Output frequency,

output

current,

output

voltage,

motor

speed, set frequency, module

..

, temperature,

Pl

Dsetting.feedback, analog

input

and

output

.

2 2 i.

..

.;

0

J f i

The

latest 6 faults record; running parameters record when

the

latest

fault

trippinghappens

i

~

including

output

frequency, set frequency,

output

current,

output

voltage,

DC

voltage4 and

~

moduletemperature.

OVercurrent, overvoltage, undervoltage, modulefault, electricthermal relay, overheat, short

ProtectiveFunction circuit, defaultphase

of

input

and output,

motor

parameteradjustmentabnormality, internal

memory

fault, etc.

Ambient

-lo"C-+40"C

(please

run

the

VFD

In derated capacity

when

ambient temperature

Is

40"C

m

Tempe111ture

-so"C)

i

..

Ambient

g S%-95%RH,

without

condensing drops

3

Humidity

..

a Surroundings Indoors

(without

directsunlight, corrosllle

or

flammable gas, oilfog and dust)

Altitude

Running

in

deratedcapacity above 1000m,derate 10%

for

every1000m rise.

~

Protection IP20

c

level

ii

Coollng

!i

Air

cooling

with

fan

control

..

Method

Installation

Method

Wall-hangingtype,cabinet type

2 IBl1allation

and

wiring

1.

Ensure

the

power

hasbeen

cut

offbefore

wiring.

Electricchockand firehazard.

2.

Askelectric

eftlineerin1

professionals

to

conduct

wiring.

Electricchock and fire hazard.

3.

Earthterminals

must

be

reliable lll'Ounded.

(380Vclass: especially

the

third

grounding)

Electricshockand

flre

hazard.

DANGER

4.

Check

If

ItsactionIseffective

after

emergency

bnke

termlnal

Isconnected.

Injuryrisk(wiring responslbllltyshould be beard byusers).

5.

Do

not

touch

output

termlnals directly.The

output

terminal

Isconnected

dlrectly

to

motor.There should

be

no

short

circuitbetween

output

termlnals.

Electricshockand

short

circuithazard.

6.

Install

the

terminal

cover

beforepower on,

and

ensure

~r

off

when

dismantling

the

termlnal

cover.

Electricshockhazard.

7.

Conduct check and maintenance

after

s~a

minutes

after

power

off

when

internal residual electricity isdischarged

completely.

Hazard

of

residual voltage

in

electrolyticcapacitor.

-4-

CAUTION

1.

Check

If

the

voltage

of

power

Inlet

wire

agrees wltfl rated

Input

voltage

ofVFD.

Injuryand

fire

hazard.

2.

connect

brake resistor

or

brake

unit

according

to

wiring

diagram.

Fire hazard.

3.Choose screw

driver

and wrench

with

specified

torque

to

fastenterminals.

Fire hazard.

4.

Do

not

connect

the

power

Input

wire

to

output

U,V, W termlnals.

It

will

cause internaldamage

to

VFD

if

load

the

voltage

on

output

terminals.

5. Do

not

dlsrnantle

the

front

panel cover,

only

the

terminal

clM!r

needs

ta

be

dlsmantled

when

wiring.

It

maycause

lntemal

damage

to

VFD.

2.1 Operation Environment

<D

No corrosive

gases,

vapors,

dust

or

oily

dust

, nodirectsunlight.

@ Nofloating

dust

and metalparticle.

@ Ambient

humidity

20%-90%

RH.

@ VibrationlessthanS.9rn/s2(0.6g).

@ No electromagneticinterference.

@ Ambienttemperature-10"C-40"C. Ensuregoodventilation when ambienttemperatureexceeds 40"C.

Q)

Use

electric cabinet

or

remote control metnod

in

non-standard operation environment and ensure good ventilation

and heat dissipation. The service life of

VFO

lies in installing

env

ironment and operation condition.

But

even

in

standard

environment, a long-term continuous running can guarantee a life

of

no

more than 5 years

for

electrolytic capadtor and

about

3 years

for

coolingfan.

An

update

or

athorough maintenance

in

advance

is

recommended.

2.2 InstallingDirection

and

Space

To

ensure agoodcoolingcycle,

the

VFD

must

be

Installed vertically, and keepenough space

from

surroundings.

2.3

Appearuce

and

DimensionofKeypad

-

74.0mm

-

000000

c=

·

~

0000

0000

L70.

0mm

I

E

E

0

~

I

17.

0mm

14

.

0mm

-5-

2.4 Whole Structure

2.5 BasicRlllll1ing Wiring

90.

0

••

s.

0

••

31.0

..

~O

.

0

••

I

D

~

The wiringparts

of

VFD

include majorloopand control loop. Open

the

cover

of

1/0

terminals, users

can

see

the

majorloop

terminal and control loopterminal,

and

mustconduct

the

wiring according

to

the

following diagram.

.,____}

""'--

,_____!

I

A01

@ @

I

(DC0-10\I)

~

A02

All

(DC/4-2CJmA)""'"""I

COM

GND @

-6-

i

j

i

2.6

Major

Loop

Termlml

Wiring

2.7

Major

LoopTerminalDiagram

R

s

T

• +

PB

u

v

w

@

EBEBEB

EB

EBEB

EB

EB

EB

R

S{,

Tiu

P+

PB u v w

~

2.8 Control

Loop

TerminalDiagram

+l

OV

GND

AOl

W + 485-

X2/RBV

X4

X7/XP

Yl

+24V

'nil

IEBIEB

I

EBI

EB

IEBIEBIEBIEB

I

EB

I

EB

IEBI

IEBIEBIEB

I

EBI

EB

I

EB

IEBIEBIEB

I

EB

I

EBI

Al

l

AI2

Gl'irD

AOl/DO

X1J9WD

Xl

X5

(X)M

Y2

T

Al

TC

l

2.9 ControlLoopTerminalFunction Table

FunctioalllSoecllkatioa

of

Control

Loon

Terminal

Category Terminal Functions Specification

Number

Xl

X2

Effective when short circuit between(Xl,

X2,

)(3,

X3

X4, XS, X6, X7, XS)

-COM,

and

the

functions

are

Multi-functional

X4

set

by

parameters F7.00-F7.07 (common port:

Digital Input

X5

COM)

INPUT,

0-24V

level signal, low

level effective,

SmA.

Tenminal

X7

X6

can

work

as

one

of

the

multi-functional

X6

terminals, also

as

high-speed pulse Input

te

rminal

withprogramming, see

F7.05.

Yl

Multi-functional programmable collector open

circuit output channel 2,

can

be

programmed

as

OUTPUT,

maximum load

Digital Output

Y2

DO

terminal

of

various functions (common port: currentsSOmA.

COM)

Tenmrnal

Can

be

programmed

as

impulse outputtenminal

of

OUTPUT,

frequencyoutput

DO

various functions

as

many

as

13

kinds (common rangeF6.32-F6.35, set maximum

port:

COM).

See

F6.23.

frequency

as

high

as

SOKHz.

All

receives voltage/current input. Jumper

CN4

Analog

Ail

(for

jumper

terminal

All)

can

select voltage

or

INPUT,

input voltage range:

o-

Input/Output current input mode,

and

voltage input is the lOV (Input Impedance:

lOOKO),

Tenminal default one. For current Input,

just

short the input current range 0 - 20mA

AI2

middle and another pin

with

the

jumper cap.

Al

2 (inputimpedance:

5000)

•

only receives voltage input. Measuring range

-7-

setting is function code F6.00--F6.11. (reference

ground:GND)

AOt

is able

to

output

analog voltage/current (total

AOl

13

kinds

of

signals). Jumper

CN3

(for

jumper

OUTPUT,

0~1ov

DC

voltage.

terminal

AOl)

can select voltage

or

current

ouput

Output

voltage

of

AOl,

A02

came

mode, and voltage

output

is

the

default one. For

from

PMW waveform

of

CPU.

current

output,

just

short the middle and another

Output

voltage is in direct

A02

pin

with

the

jumper

cap.

A02

can

only

provide proportion

to

the

width

of

PWM

analog voltage output. see F6.21, F6.22. waveform.

(Reference ground:GND)

TA1/TA2

TA-TB:

normalclose;

TA-TC:

RelayOutput

Tw~channel

programmable relay

output

terminal, normalopen. Contactcompadty:

Terminal TB1/TB2 TAl/TA2, TBl/TB2, TCl/TC2 as many

as

99 kinds. 250VAC/2A

(COSCl>=l);

TC1/TC2 See F7.20.

250VAC/1A(COSll>=0.4),

30VDC/1A.

PowerPort +

24V

24V

Is

the

common

power

for

circuits

of

all digital Maxi

mum

output

current

200mA

signal

input

terminals.

A Control terminal

Alt

can

input

both voltage and current signal, while Al2 can

only

input

voltage signal; users can

conduct corresponding

jumper

on mastercontrolboardaccording

to

signaltype.

A.

Connecting

week

analog slgnal Iseasily affected byexternal disturbance. So wiring should

be

as

short

as

po.sslble. The

external control lineshouldbe set

with

isolating device

or

shieldingline, andshould be grounded.

A.

Input

order

signal line and frequency

meter

should be wired separately

with

shielding, and away

from

major loop

wiring.

A.

Control

loop

wiring

should

be

over

0.75

mm

2, and

STP

(shielded

twisted

pair)

is

recommended. The connecting

part

of

controlloopterminals should

be

enameled

with

tin,

or

processmetal

joint

with

coldpressing.

A.

Whileconnectinganalogsignal

output

devices, malfunction mayoccurbecause

of

interference

from

VFD,

which can be

solved

by

fixing

with

capacitor

or

ferrite

bead

to

the

analogsignal

output

device.

Z.10

Dial

Switch

A02

00

OFF

ON

Cin

Vin

Vout

Cout

JP6

1• • •

~

Ao2

I

ooI

1P5

~

JP2

~

JP3

~

JP4

1• • e

~

Cou~Vou~

JP5&JP6

A02

of

AO~DO

iseffective,

output

voltage

signal

DO

of

A02/DO

is

effective,

output

pulse

signal

JP2

No~connecting

for

matched resistance

of

485

communication

Connecting

for

matched resistance

of

485

communication

JP3

All

input

currentsignal

Alt

input

voltage signal

JP4

AOl

output

voltage signal

AOl

output

currentsignal

-8-

2.11

WirlogNotices

©

Cut

off

the

input

power

of

VFD

while

dismantlingand changing

the

motor.

@ Switching

of

motor

or

work

frequency

power

supplyshould

only

be

conducted

when

the

VFD

stops output.

@

To

reduce

the

effect

of

EMI

(electromagnetic interference),add a surge absorberwhen electromagneticconnector

and relayareclose

to

VFD.

© Do

not

connect

AC

Inputpower

to

output

terminal

U,

V,

W

of

VFD.

® Addan isolatingdevice

to

the

external controlline

or

use shield line.

@

Input

order

signal lineshould be wired separately

with

shielding, and awifl{

from

majorloopwiring.

<1J

When carrier frequency

is

less

than 4kHz, keep

the

distance between

VFD

and

motor

within

SOm;

when carrier

frequency exceeds 4kHz, make an appropriate reduction

of

the

distance, and

better

lay

the

wire

in

metaltube.

@ When adding peripherals (filters, reactors, etc.)

to

the

VFD,

check

the

ground resistance

with

lOOOV

tramegger

and ensure

the

value isabove4 MO.

® Do

not

add phase advance capacitor

or

RC

snubber

to

the

u,

v,

wtermlnal

of

VFD.

®

If

the

VFD

starts frequently,

do

not

cut

off

the

power, use

the

COM/RUN

of

control terminal

to

conduct

start

and

stop

so as

not

to

damage

the

rectifier

br

idge.

11 The earth terminal must begrounded reliably (grounding impedance should be under

100

Cl)

to

avoid accidents,

or

there might

be

electricleakage.

12 Choose

the

wire

diameteraccording

to

national electrical code whileconductingmajorloopwiring.

2.12

Spare

Circuit

It

may cause

big

downtime

loss

or

other

accidental failure during

VFD

failure

or

tripping. Addi

ng

spare circuit is

recommended

under

this

circumstance

to

ensure safety. Note: confirm and

test

the

operation characteristic

of

the

spare

circuitin advance

to

ensure

the

workingfrequencyand

the

phasesequence ofconvertedfrequencyareagreed.

3 Opera1ioa

Panel

and

OperalicmMethod

3.1

Operation

Panel

Keys

• • • • • •

'""

..,

""

"'

.'(•=

Key

Nime

Function

Description

• programming Enter

or

escape

from

programming

/escape

key

0

shift/monitor

Choose

the

bit

of

the

data

wh

ich

is

to

be

set and modified

when

the

VFD

is

in

key

edit

status; switch

mo

n

itor

parameter

to

be shown when

the

VFO

is

in

other

modes.

fa

Enter key Enter

into

sub-menu items

or

confirm data.

e Function key According

to

the

setting

of

function parameter

FE.01,

jog

or

reverse ru

n,

and

frequen

cy

clearance is availablewhenpressing

this

key underkeypad mode.

-9-

• Run key EnterIntorun mode

under

keypad model.

In

common run status

the

VFD

will

be stopped according

to

set

mode

after

-stop/reset press

this

key

if

run command channel

is

set as keyboard stopeffective mode.

key

The

VFD

will

be

reset and resume nonnal

stop

status

after

pressing

this

key

when

the

VFD

is

in

malfunctionstatus.

,.; Analog

set

the

frequency;

when

F0.07=0, digital encoder can set

the

frequency

as

potentlomet linkagecontrol

with

inaease/decrease key.

er

knob

0 Increase key Data

or

function code increase (speed up

the

increasing rate

by

keeping

pressing

the

key)

0 Decrease key Data

or

function code decrease (speed

up

the

decreasing rate

by

keeping

pressing

the

key)

3.2 LEDand

Indicator

Ught

De1erf.ption1

Tuble

3-1

LED andIndicator Li.mtDescriution

Item Function Description

Dil!italDisolav Disolavcurrentrun status

and

setnarameter.

(g

1~

Hz,A,

v Displayed

ph)'Sical

quantity

unit(current

A,

voltage

V.

frequency

Hz)

e·.f

Ahum

indicator light, indicate

that

the

VFD is in over current or over voltage suppressing

ALM

status orfailure

alarm

status currently.

FWD Thisindicator light turns

green

wbm

the

VFDis

in

forwardrunningstatus.

REV Thisindicator light turns

red

wbm

the

VFDisinreverse

rwmiDg

status.

REMOTE

Remote

control indicator.

Table

1-3

UnitIndicatorLight Descriution

A Currentdisplayed

pmameter

iscurrentwithunit

of

A,

LED

indicat<r lightAison

v

Cum:nt

displayed

parameter

isvoltagewith

unit

ofV,

LED

indicatorlight

Vis

on

~

Hz

Cum:nt

displayed

parameter

isfrequency with unit

of

Hz, LEDindicator light Hzis on

'Ki

Cum:nt

displayed

parameter

ispercentage, LEDindicator light

Hz

and

Vareon

f r/min

Cum:nt

displayed

parameter

isrotatiooal speed,

LED

indicator lightHz andA are on

m/s

Cum:nt

displayed

parameter

islinearvelocity,

LED

indicator lightV andAare on

'C

Currentdisplayed

pmameter

istemperature, LED indicator light

V.

Aand

Hz

are on

3.3Monitoring

Parameter

Display

Keypad

display status is classified

as

power-On

initialization display, function

code

and monitoring

parameters

display,

malfunction alann status display, runstatus parameters display. Afterpower-on,

LED

willdisplay"P.OFF',

then

entersetting

frequencydisplaystatus.

When

the

VFD

is stopped,

the

keypad

displays stopped state moniroring parameters,

ractory

setting is digital setting

-10-

frequency.

As

is

shown

in

figure 3-2,unit indicator light

reminds

that

the

unit

of

current displayed parameteris Hz.

Press

key 0,different monitoring parameters

in

stopped state

can

be

displayed circularly(default setting

in

sequence

is

main setting

frequency,

bus

voltage. Other monitoring

parameters

can be set to display

by

function code FB.10-FE.ll, for

details see function code table FE.10-FB.11); orwithout pressing 0 ,

but

set

tens

place ofFE.12as 1 (alternate display

ofmainand secondary parameters),

and

the

stopped state monitoring parameters

will

display circularly

every

other second

automatically; also

enter

monitoring

IIIClll1

bypressing 0 ,and

check

each monitoring parameter

by

0 ,0 and

e.

3.4

Run

StatusPlll'1UlleterDilplay

The

VFD enters intorunstatus

wbm

n:ceivingeffective runcommand andrun

status

monitoringparameters normallyoutput

ftequen

2i!.

s displayedon

the

keypad.

As

figure

1-4

shows,unit

is

displayed as

Hz.

Press

U ,

the

current

run status parameter will display circularly (default set is output

frequency,

output current, two

monitoring parameters in sequence. Other parameters display can

be

set by

FB.OS....FB.09,

for details see parameter

codes

table FE.08-FE.09); or without pressing 0,

but

set

tens

place

of

FB.12

as 1 (alternate display

of

main

and

secondary

param&:teII

),

and

the

stoppedstatemonitoring parameters will display circularly

every

other second automatically; also enter

monitoringmenu

by

pressing • ,

and

check each monitoringparameter

by

0 ,0 and • .

• • • • • •

··

-

(f}

: • • • • • •

··

· -=

l~l

~

l

~

l

~

I

l

~l

~

l

~

l

~

I

Fig

3-1

Power-on Parameter Display Fig3-2Stop Status Parameter Display

InitializationDisplay

«P.OFF"

DisplaySet Frequency

«so.OO"

3.SMalfunction

Alarm

Display

• • • • • •

'"'

·

··

=

l~l

~

l~l

~

I

Fig

3-3

Run

Status Parameter Display

DisplayCurrent Output Frequency«20.

00"

The VFD enters

into

malfunction

a1mm

displaystatus

upon

detecting

fiillure

signal and display

firilure

code

{as

shown

in

Fig

3-4);

Press Oto check relative parameters of stopped inveter; to check failure information, press • and enter into

program

mode

to

check

D

group

parameter. After1roubleshooting. conduct fault resetting

by

.

key

on the

keypad,

by

control terminalor communication command. Keep displaying fault

code

if

fault

existcontimwusly.

-11-

• • • • • •

••o

• ••=

Fig

3-4

FaultAlarmDisplay

of

Over

current duringAccelerating

Warning:

FOi'

some serious mult, such

as

inverse module protect,

over

cum:nt, over voltage, etc.,

do

not

conduct multreset

fOl'Cloly

to

makethe inverterrun

again

without fault eliminationconfirmed, OI' mightcause damage

to

the inverter.

3.6

Function

Code

Editing

DUplay

Understop, run

or

fault alarmstatus,press •

key

toentereditingstatus which isdisplayed as

two

classes

menu

(input

the

password first

if

it

is preset,

see

password unlock instruction). Press .

key

to enter items one

class

by

one class. Under

function parameter display status, press -

to

conduct

stOiag'e

operation,

pn:1111

• key

to

return

to

the

upper class

menuwithout storing modifiedparameter.

3.7MonitoringParameter

Example 1: statusparameter display switching

Undermonitoring status, press 0 key, the display

will

switch automatically

to

according value ofmonitoringparameter

according

to

FD

~

status

monitoring parameter setting,

and

meanwhile

the

corresponding

unit

indicator light

will

be

on.

For example, press W

to

switch

to

outputfrequency D-00, andthe indicatorlight

of

unit"Hz''

is

on.

Example2: check

monitoring~

item d-05 (outputcurrent)

Method 1:

CD

Press •

key

to

enter programming status, LED displays function

code

F0.00, press again • key, LED

displays function code d-00,

tliclccr

bit

stays

in ones place, adjust O

key

or

0

key

until

the

monitoring code turns

d-05.

® Press • key.

the

accordingvalue

of

d-05

displays

and

the

indicatorlight

of

unit "A:' is

on.

@ Press • key. escape

from

monitoringstatus.

0.00

) •

~[

F0.00 •

.0

0,0 [

• •

)4

(

)4

Escape

*****

-12-

d-05

Method2:

Undermonitoringmode interface, press • key. switchto next

moni

~

llillllldm

itemd-xx, press 0 keytomove

flicker bit

to

ones digit

of

the monitoring

code,

then adjust O

key

or

v

key

until the monitoring code displays d-05,

thenoperate accordingto step 2

and

step

3

of

method

1.

Example 3:check fault monitoringparameter

in

fault status

CD

Underfault statuspress •

key

andcheckD

group

monitoringparameterranging fromD-00 to D-57.

®

If

the

fault wasn'teliminatedduring checking the faultparameter, the interface will automatically switch to fault

alarmdisplay

Ss

laterafterstopping operation.

@

The

faultcode displays

raDging

from D-48toD-57 (the current status andlatest3 times).

3.8Function Code Setting

The function parameter system

of

this inverter includes function code

FO-FF,

fault code E group

and

monitoring code D

group. Each funetiongroupis

consist.ed

of

several function code, which ismarked as (function group

code+

function code).

For

example,

"F5.08"meanseighth functioncode

in

the

fifthfunction group.

Function

code

settingexample:

Example 1:

change

frequencysettingoffarwanijoggingform

5Hzto

lOHz (Fl.20modi.fiedfrom

S.OOHzto

10.00Hz)

CD

Press •

key

to

enterprogramming

sta1u8,

LED displays function

code

F0.00, flicker bitstays

in

the ones digit.

® Press 0 key,

move

theflicker bit

among

the

hundreds place,

tens

place

and

ones

pl8(:C.

@ Press Okey

or

0

keyto

modify the digit intheaccordingdigitplace.

LED

displays Fl.20.

© Press • key,

it

displays

the

according

value(S.00) ofFl.20,meanwhile

the

indicatorlight

of

unitHzison.

®

Press

0 key,

move

the flicker bitto thehighestplace"5", press 0,0 keyS times

to

changeit to 10.00.

® Press -key,

save

thevalue

ofFl.20

anddisplays nextfuru:tion

code

Fl.21.

CD

Press •

key,

escapefromprogramming status.

5.00

G •

~

FO.OO

J

~

I

[':

~

·

[

~

]+!-·

--

Fl.21

)4

.

84=...:../

o

-i!-o:

,....---'

3.9

User

Punrord

Setting

and

Function

Code

Edit

User password setting

is

used

fur preventingunauthorized people form checking

and

modifying function pllillllldm. Factory

set

of

um

password F0.00 is "00000",

user

can

conduct parameter setting

in

this interface (parameter

set

here

is

only

DDt

restricted

by

password protection, but is restrir;ted by conditions

like

whether is revisable during running.

the

monitoring

parameters,

etc.).

When

setting the

user

password,

press five-digit

number

and press -

to

confirm,

the password will

take

effect

automatically3 minutes later, or

just

power

down

to

make

it

effective. Afterthat,

if

the

password

is

not set right, keypad will

display "-Err-",

and

when

checking function codes, all will

display"--"

except

1he

password item (displays ''00000").

These function

codes

parameters can't

be

checked

and

modified until the password is set

right

and the keypad displays

"-En--"a

When

passwordmodifying is required, choose function

code

F0.00,

and

press • to enterpasswordauthentication status.

-13-

Move

to

modifying status after password verified mccessfully. Input a

new

password

and

press • to confirm.

Power-®wn or waitfar 3

minutes,

the

newpassword will

take

effect.

Example

I:change userpassword"22222"to "55555", checkfunction

rode

Fl

.02.

<D

Press •

to

enterprogrammingstatus,

LED

displays function

rode

F0.00, flicker bitstays

in

theones place.

® Press 0,move flickerbitamonghundreds place, tensplace andones place

of

functionitema.

@ Press O

key

or

O

key

to

modify

the

digit

in

the according digitplace. LED displays F1.20.

© Press • •

the

ac:corcling

data"--"

ofFl.20

isdisplayed.

@ Press •

to

enter

Fl

.03, repeatstep2 and step

3,

checlc

accordingdata "00000"

of

F0.00.

@ Press O

key

orOkey

to

modify the

digit

in

the

according

digit

place, LED displays "22222", and

the

passwordissetup.

cr>

Press • •

it

displays "-En--", meanwhilefunction

rode

displays F0.01.

® Repeat step2

and

step

3,

check

the

according

data

''00000"ofF0.00 and modify

it

to

"55555", press •

to

e.nd

the password changing, enter

FO.O

1item.

® Repeat step2 and

step

3,

checlc

the

according data "0.0''

of

Fl.02,

conduct

modifying

by

0 key

or

O

key.

®l

Press • , escapefrom edit status.

•

111(

FO.O

-14-

4F•.UO.ParumeterTable

udl>nc~

'----------

4.0

Monitorine

parameter dF

ult

RecordG

l'OllD

an a

DGroup-

Mollita

11•

l'llrmllltlhr

Group

•nd

Fiii*

ll9alrd

Function

s.tRllnp

Minimum

Factory Madllbtlon

Code

Nam9

Unit

Dmult

OutputFrequency o.oo -maximum

output

frequency 0.01Hz 0.00 •

d-00

(F0.15]

d-01 Set Frequency 0.00 -maximum

output

frequency 0.01Hz 0.00 •

(F0.15]

0.00 -maximum

output

frequency

d-02 Estimated

Motor

(F0.15]

0.01Hz 0.00 •

Frequency Note:

motor

running frequency

convertedfrom estimated

motor

speed

0.00 -maximum

output

frequency 0.01Hz 0.00 •

d-03 Main

Set

Frequency

(F0.15]

AuxiliarySet o.oo -maximum

output

frequency 0.01Hz 0.00 •

d-04 Frequency

(F0.15]

d-05 OutputCunrent

0.0-6553.5A

O.lA 0.0 •

d-06 OutputVoltage

0-999V

lV

0 •

d-07 Ou

tput

Torque -200.0-+200.0% 0.1% 0.0% •

d-08

Motor

Revolvln11

0-36000

(RPM/min)

1 0 •

Soeed(RPM/min)

d-09

Motor

Power Factor

0.00-1.00

0.01 0.00 •

d-10

Run

LinearVelocity

0.01-655.35(

m/s) 0.01

m/s

0.00 •

(m/s)

d-11 SetLinearVelocity 0.

01-655.35(

m/s) 0.01 rn/s 0.00 •

(m/s)

d-12

Bus

voltageM

0-999V

lV

0 •

d-13

Input

Voltage M

0-999V

lV

0 •

d-14 PIDSetValue

(VJ

0.00-10.oov

O.OlV 0.00 •

d-15

PIDFeedbackM

0.00-10.oov

O.OlV 0.00 •

d-16 Analog

Input

0.00-10.oov

O.OlV 0.00 •

All(V/mA)

d-

17

Analog

Input

Al2(V}

0.00-10.oov

0.01V 0.00 •

d-18 ImpulseFrequency o.oo-50.00KHz

O.OlKHz

0.00 •

lmput

(KHz)

d-19 Analog Output

0.00-10.oov

0.01V 0.00 •

AOl(V/mA)

d-20 Analog Output

0.00-10.oov

O.OlV 0.00 •

A02(V)

O-FFH

d-21

Input

Terminal Note:

the

sequence

from

high

to

low

1 0 •

Status

order

digit

in

binarysystem

XP/X.7/Xf/X.'!/X.~'¥1..'1/Xl

Ou

tput

Tenninal

0-FH

d-22 Note:

the

sequence

from

high

to

low

1 0 •

Status

order

digit

in

binarysystem R'1/Rl/V7/Yl

-15-

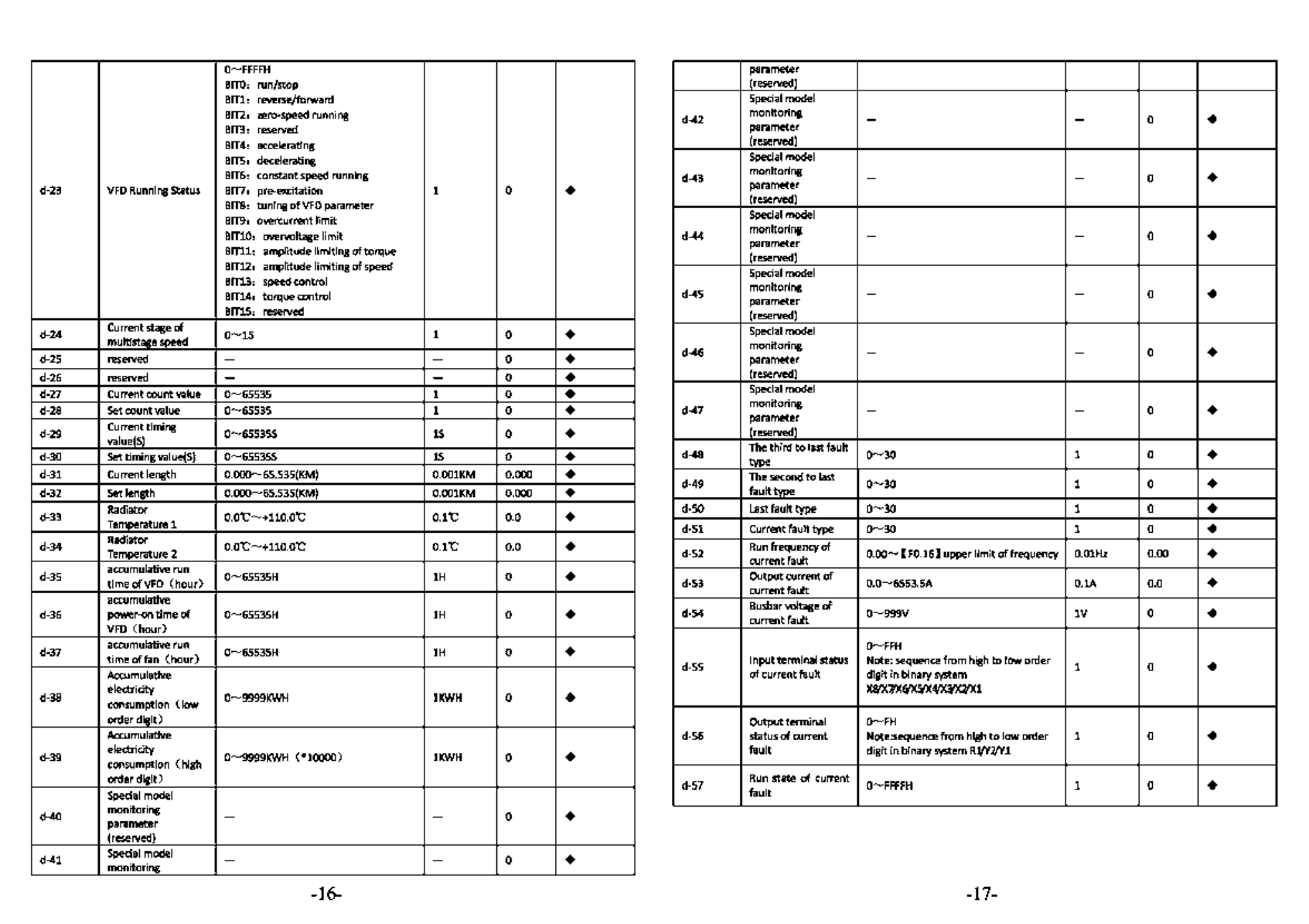

o~FFFFH

parameter

BITO:

run/stop (reseived)

Bill:

reverse/forward Special model

BIT2: zero-speed running

BIT3: reseived d-42 monitoring - - 0 •

parameter

BIT4: accelerating (reserved)

BITS,

decelerating Special model

BIT6: constant speed running

d-23

VFD

Running Status BIT7: pre-excitation 1 0 •

BITS:

tuning

of

VFD

parameter

BIT9: overcurrent

limit

BITlO,

overvoltage

limit

BITll:

amplitude limiting

of

torque

BIT12'

amplitude limiting

of

speed

BIT13: speed control

BIT14,

torquecontrol

Bins,

reseived

d-43 monitoring - - 0 •

parameter

(reserved)

Special model

d-44 monitoring - - 0 •

parameter

(reserved)

Special model

d-45 monitoring - - 0 •

parameter

(reserved)

d-24 Current stage

of

0~1s 1 0 •

multlstage speed

d-2S reseived - - 0 • Special model

d-46 monitoring - - 0 •

parameter

d-26 reseived - - 0 • (reserved)

d-27 Current count value

0-6SS3S

1 0 •

d-28

Set

count value

0-6SS3S

1 0 •

d-29 Current timing

0-6SS3S5

15

0 •

value(S)

d-30 Set timing value(S)

o~&ss3ss

15

0 •

Special model

d-47 monitoring - - 0 •

parameter

(reserved)

d-48 The third

to

lastfault

0-30

1 0 •

type

d-31 Current length 0.000-6S.535(KM}

O.OOlKM

0.000 •

d-32 Set length 0.000-6S.535(KM}

O.OOlKM

0.000 • d-49 The second

to

last

0-30

1 0 •

fault

type

d-33 Radiator

o.o'C-+110.o'C

O.l'C o.o •

Temperature 1 d-50

Last

fault type

0-30

1 0 •

d-Sl

Current fault type

0-30

1 0 •

d-34 Radiator

o.o'C-+110.o'C

O.l'C 0.0 •

Temperature 2

d-35 accumulative run

0-6S535H

lH 0 •

time

ofVFD

(hour)

d-52

Run

frequencyof

O.OO~

[ F0.16] upper

limit

of

frequency O.OlHz 0.00 •

current fault

d-53 Outputcurrent

of

o.o~65s3.SA

O.lA 0.0 •

current fault

accumulatlve

d-36 power-on

time

of

o~&ss3sH

lH 0 •

VFD

(hour)

d-54 Busbarvoltage

of

0-999V

lV 0 •

current fault

d-37 accumulative run

o~&S535H

lH 0 •

time

offan

(hour)

Accumulative

0......,FFH

d-S5 Inputterminal status Note: sequence from high

to

loworder 1 0 •

ofcurrentfault digit in binary system

d-38 electricity 0-9999KWH

lKWH

0 •

consumption Clow

X8/X7/Xf,fXS/X4fl2/X'1/X1

order

digit)

Outputterminal

O......,FH

Accumulative d-S6 status of current Note:sequence

from

high

to

low order 1 0 •

d-39 electricity

o~9999KWH

(•10000)

lKWH

0 •

consumption

(high

fault

digit in binary system

R'J/Y'1/Yl

order

digit)

Special model d-57

Run

state of current 0-FFFFH 1 0 •

fault

d-40 monitoring - - 0 •

parameter

(reseived)

d-41 Special model - - 0 •

monitoring

-16- -17-

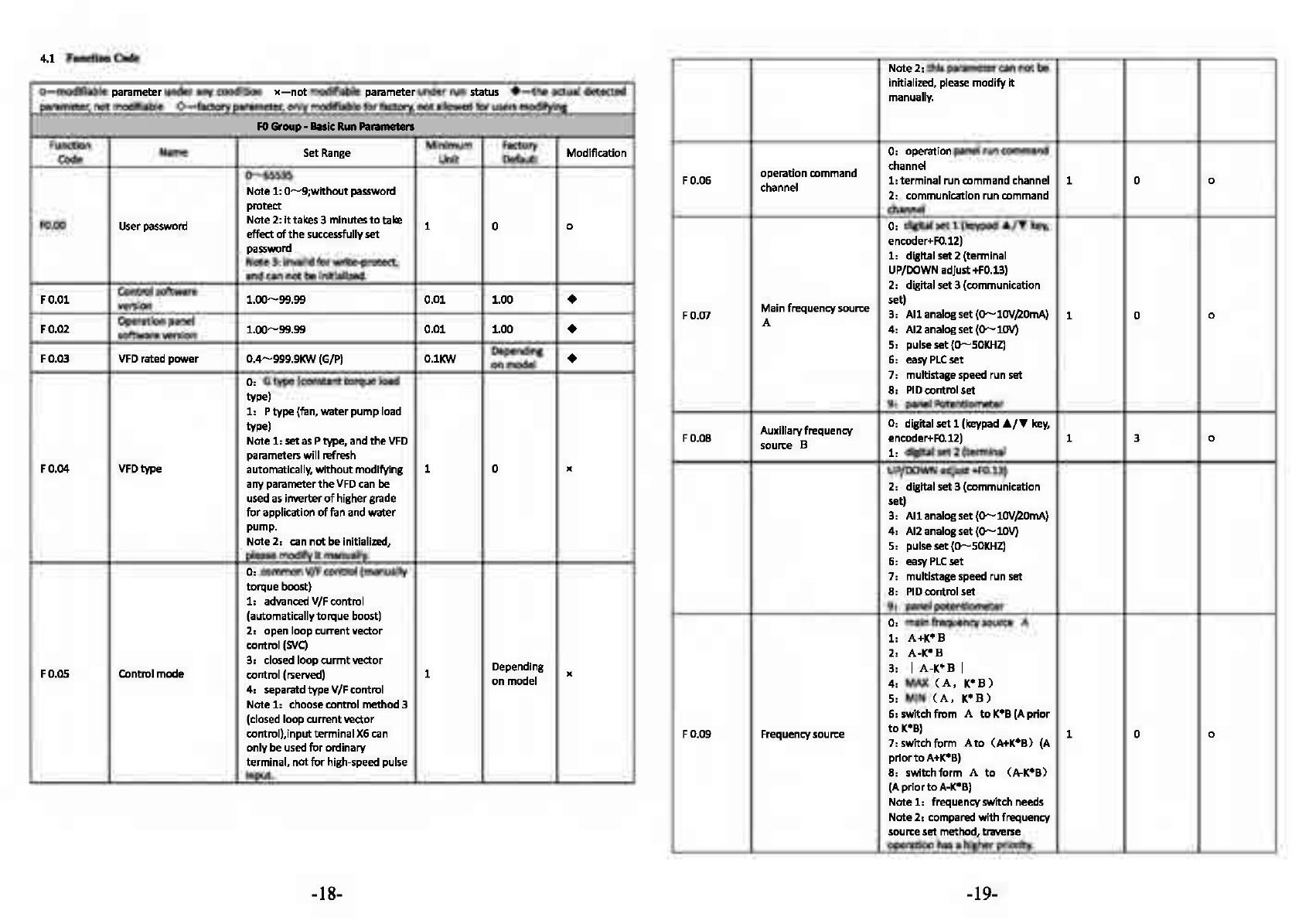

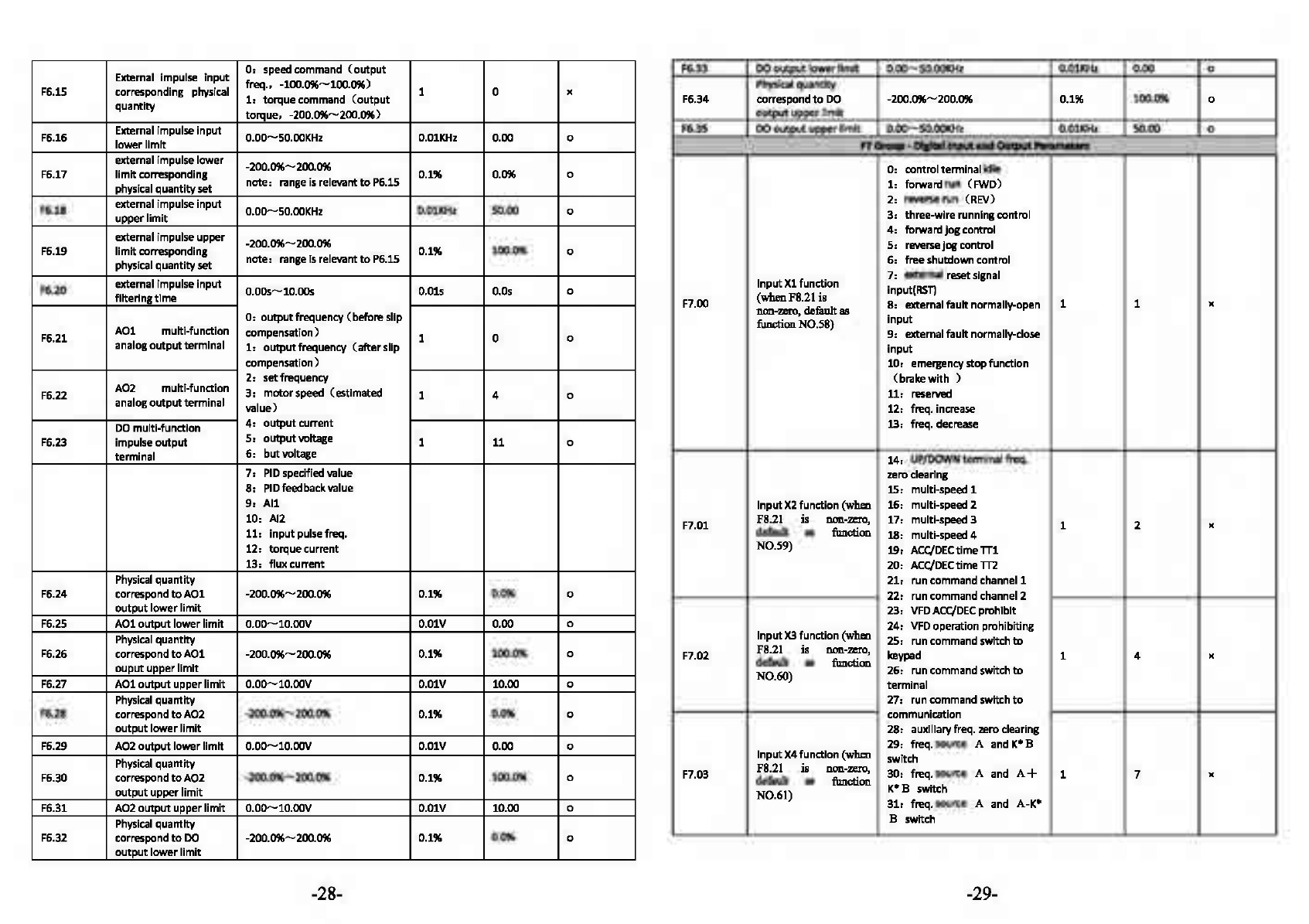

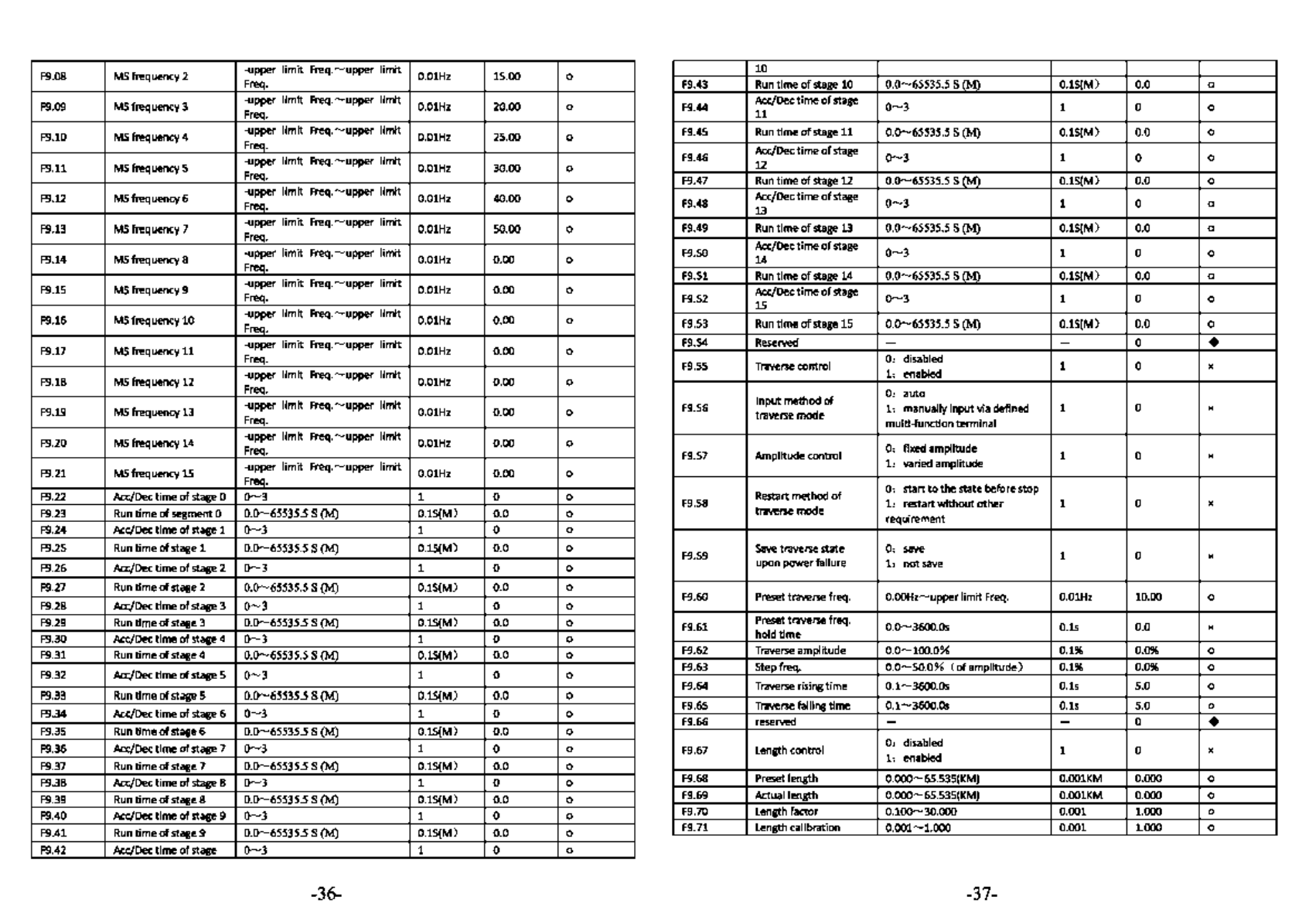

4.1

FunctionCode Note

2,

thisparametercan

not

be

o-modifiable

parameter under anycondition

x-not

modifiable parameter under

run

status •

the

actual detected

parameter,

not

modifiable

0-fattory

parameter,

only

modifiable

for

factory,

not

allowed

for

usersmodifying

initialized, please

modify

it

manually.

FO

Group-

Bllslc

RunParameters

Function

Minimum

Factory Modification

code

Name Set

Range

Unit Default

0-65535

Note

1:

0-9;withoot

password

O:

operation panel

run

command

operationcommand channel

F0.06

l:terminal

run

command channel 1 0 0

channel

2:

communication

run

command

protect

F0.00 User password

Note

2:

It

takes3 minutes

to

take 1 0 0

effectof

the

successfully

set

password

Note

3:

invalid

for

write-protect,

and can

not

be

initialized.

F0.01 Control software

1.00-99.99

0.01

1.00

•

version

F0.02 Operation panel

1.00-99.99

0.01

1.00

•

softwareversion

VFD rated

power

0.4-999.9KW

(G/P) O.lKW Depending •

F0.03

on

model

O: G

type

(constant

torque

load

type)

1:

P

type

(fan, water

pump

load

channel

O:

digital

set

1 (keypad

•I~

key,

encoder+F0.12)

1:

digitalset2 (terminal

UP/DOWN adjust+F0.13)

2: digitalset3 (communication

Mainfrequencysource set)

FO.Q7

3: Al

lanalogset(0-10V/20mA)

1 0 0

A

4:

Al2 analogset

(O-lOV)

5:

pulseset(O-SOKHZ)

6:

east

PLC

set

7:

multistage speed run set

8:

PIO

control set

9:

panel Potentiometer

type)

Note

1:

set

as

Ptype,

and

the

VFD

parameters

will

refresh

Auxiliaryfrequency

0:

digital

set

1 (keypad

•t~

key,

F0.08 encoder+F0.12) 1 3 0

source B

1:

digitalset2 (terminal

F0.04 VFDtype automatlcally,

without

modifying 1 0 x UP/DOWN adjust+F0.13)

any parameter

the

VFD

can

be

usedas inverter

of

highergrade

for

application

of

fan and

water

2: digitalset3 (communication

set)

3:

Allanalogset(0-10V/20mA}

pump.

Note

2:

can

not

beinitialized,

please modify

it

manually.

O: common V/Fcontrol (manually

torque

boost}

1:

advanced V/Fcontrol

(automatically

torque

boost)

2:

openloopcurrentvector

control

(SVC)

3:

closed

loop

curmt

vector Depending

Controlmode control (rserved) 1 x

F0.05

on

model

4:

separatd

type

V/Fcontrol

Note

1:

choosecontrol method 3

(closed loopcurrentvector

control),inputterminalX6can

only

be

used

for

ordinary

terminal,

not

for

high-speed pulse

input.

4:

Al2 analogset

(O-lOV)

5: pulse

set

(0-SOKHZ)

6:

east

PLC

set

7:

multistage speed run set

8:

PIO

control set

g, panel potentiometer

0:

main frequencysource A

1:

A+K*B

2:

A-K*B

3:

I

A-K*B

I

4:

MAX

CA,

K*B)

5: MIN

(A,

K*B)

6:

switch

from

A

to

K*B

(A

prior

F0.09 Frequencysource

to

K*B) 1 0 0

7:

switch

form

A

to

(A+K*B)

(A

prior

to

A+K*B)

8:

switch

form

A

to

(A-K*B)

(A

prior

to

A·K*B)

Note

1:

frequencyswitch needs

Note

2:

compared

with

frequency

sourceset method,traverse

operation

has

a higherpriority.

-18- -19-

LED

ones

digit:

power

down

storage

F0.10

Digital

set

1 control

0:

storage

1

000

0

1:

not

storage

0:

start

at

start

frequency

F

1.00

Start

mode

1:

DC

braking+

start

at

start

1 0 x

frequency

2:

start

with

speed

tracking

LED

tens

digit: hold

when

stop

F

1.01

Stan

frequency

0.00-50.00Hz

O.OlHz 1

.00

0

0:

hold

1:

not

hold F

1.02

Start

frequency

hold

0.0-100.0s

O.ls

0.0

0

time

LED

hundred

digit: J../'f key,

F

0.11

Digital

set

2 control UP/DOWN

frequency

1

000

0

0:

invalid

1:

valid

F

1.03

DC

brake

current

at

0.0-150.o%•rated

current

of

0.1% 0.0% 0

startup

motor

Fl.04

DC

brake

time

at

0.0-100.0s

O.ls

0.0

startup

0

LED

thousands

digit:

reserved

F

0.12

Frequency

source

O.OOHz-

[F0.16]

upper

limit

of

0.01Hz

50.00

0

digital

setting

1

frequency

F

0.13

Frequency

source

O.OOHz-

[F0.16]

upper

llmlt

of

0.01Hz

50.00

0

dlgttal

setting

2

frequency

Auxiliary

frequency

F

1.05

Accelerating

and

0:

linearAce/Dec

mode

1 0 x

decelerating

mode

1:

S curve Ace/Dec

mode

F

1.06

Time

ratio

of

initial

10.0-so.0%

0.1% 20.0%

segment

in

Scurve 0

F

1.07

T

ime

ratio

of

ending

10.0-50.0%

0.1% 20.0% 0

segment

in

Scurve

F0.14

source

weight

0.01-10.00

0.01

1.00

0

coefficientK

setting

Low

frequency

range:

MAX

Fl.OS

Stop

mode

0:

Decelerate

to

stop

1 0 x

1:

coasttostop

Maximum

output

{50.00,

[F0.16]

} -

300.00

F

0.15

0.01Hz

50.00

x

frequency

High

frequency

range:

MAX

{50.00,

[F0.16]

} -

3000.0

F

0.16

Upper

limitfrequency

[F0.17]

-

[F0.15]

0.01Hz

50.00

x

Fl.09

Frequencythreshold of

0.00-

[F0.16]

upper

limit 0.01Hz

0.00

0

DC

brake

frequency

F

1.10

DC

brake

delay

time

0.0-100.0s

O.ls

0.0

0

F

1.11

DC

brake

current

0.0-150.0%*rated

current

of

0.1% 0.0% 0

motor

F

0.17

Lowerlimitfrequency O.OOHz-

[F0.16]

0.01Hz

0.00

x F

1.12

DC

brake

time

at

stop

0.0-100.0s

O.ls

0.0

0

0:

low

frequency

mode

(0.00-

300.00Hz) F

1.13

Acctlme2

0.1

Depending 0

on

model

F

0.18

Frequency

output

1:

high

frequency

mode

(O.O

-1 0 x

mode

3000

.0Hz)

Note: high

frequency

mode

is

onlyeffective

to

VF

control

F

0.19

Acceleration

time

1

0.1

-3600.0s

0.ls

Depending

on

model

0

0.4

-4.0KW 7.55

5.5

-30.0KW

15.0s

F0.20

Deceleration

time

1

37.0

-132.0KW 30.0s

0.ls

Depending 0

160.0-

630.0KW 60.0s

on

model

Fl.14

Dectime2

0.1

Depending 0

0.1

-

3600.0s

on

model

F

1.15

Acctinme

3

0.4

-4.0KW

7.5s

0.1

Depending 0

on

model

5.5

-30.0KW 15.0s Depending

F

1.16

Dectime3

37.0

-132.0KW 40.0s

0.1

on

model 0

160.0-

630.0KW 60.0s Depending

F

1.17

Acctimne4

0.1

on

model 0

F

1.18

Dectime4

0.1

Depending 0

on

model

0:

forward

F

0.21

Runningdirection

1:

reverse 1 0 x

2:

prevent

reversing

F

1.19

Ace/Dec

time

unit

0:

second

1:

min

u

te

2:

O.ls 1 0 0

F

1.20

Frequencysetting

of

0.00-

[F0.16]

upper

limit O.OlHz

5.00

0

forward

jog

operation

frequency

1.0-16.0KHz

D.4-4.0KW

6.0KHz F

1.21

Frequency

setting

of

o.oo-

[F0.16]

upper

limit 0.01Hz

5.00

0

reverse

jog

operation

frequency

1.0-16.0KHz

5.5-30KW

4.5KHz Depending

F

0.22

Carrier

frequency

1.0-16.0KHz

O.lKHz

on

model

0

37-132KW

3.0KHz

1.0-10.0KHz

0.1

-

3600.0s

Depending

F

1.22

Jog

Ace

time

0.4

-4.0KW

7.5s

O.ls

on

model 0

5.5

-30.0KW 15.0s

37.0

-132.0KW 40.0s Depending

F

1.23

Jog

Dec

time

160.0-

630.0KW

60

.

0s

O.ls

on

model 0

160-630KW

1.SKHz

1.0-5.0KHz

Fl

Group

-Auldllary

Operatlns

,.........,..

F

1.24

Jog interval

time

0.0

-100.0s

O.ls

0

.1

0

F

1.25

Hopping

freq.l

0.00-upper

limitfreq. O.OlHz

0.00

0

F

1.26

Hopping

freq.1

range

0.00-upper

limitfreq. 0.01Hz

0.00

0

F

1.27

Hoppingfreq.2

0.00-upper

limitfreq. O.OlHz

0.00

0

-20- -21-

F1.28 Hoppingfreq.2 range

0.00-upper

limitfreq.

O.OlHz

0.00

0

F1.29 Hoppingfreq.3

0.00-upper

limitfreq.

O.OlHz

0.00

0 F2.10 No-load current

of

O.Ol

-655.35A

O.OlA

Depending

asvnchronous

motor

on

model

JC

F1.30 Hoppingfre.3 range

0.00-upper

limitfreq.

O.OlHz

0.00

0

0:

run

at

lower limit freq. F

2.11-

Reserved 0 •

F2.15 - -

Action

when

set

freq.

1:

run

at

zerofreq. after delay

F1.31 is lower

than

lower

time

(start

without

delay)

1 0 "

0:

no

action

limitfreq.

2:

stop

afterdelay

time

(start

without delay) F2.16 Motortuning

1:

statictuning 1 0

JC

2:

no-load complete tuning

Delay time

of

stopping

3:

on-load complete tuning

F1.32

when

freq. is lower

o.0-3600.0s

0.1

10.0

0

than

limit(simple

0.00-10.oos

0.4-4.0KW

O.OSs

sleep)

F1.33 Zero freq. brake

0.0-150.0%*rated

current

of

0.1 o.o

)(

current

motor

F2.17 pre-excitation time

of

S.5-30KW

O.lOs O.

Ols

Depending

JC

asynchronous

motor

37-132KW

0.30s

on

model

160-630KW

a.sos

F1.34 FWD/Rf)! transition

0.0-100.0s

O.ls 0.0 0

time

note

: invalid for

VF

control

FJ

Group

-

Reserved

Pll'llmeterl

F1.35 FWD/Rf)! switch mode

0:

over

zerofreq. switch 1 0 "

1:

over

start

freq. switch

Standbydeceleration

f.tGroup·

Speed

Loop,

Torque

and

Flux

COntrol

P1111met1rs

F4.00

Speed loop

(ASRl)

0.000-6.000

0.001 1.000 0

proportional gain

F1.36

time

when

emergency

0.1-3600.0s

O.ls 1.0 0

brake F4.01 Speed loop

(ASRl)

0.000-32.000s

O.OOls 1.000 0

integral

time

P2Group.

Motor

Parameters

F4.02 ASRl filter time

0.000-0.lOOs

O.OOls

0.000 0

constant

0:

AC

asynchronous

motor

1:

PMSM

(reserved)

Note

1:

onlyclosed-loopvector

Fl.00

Motor

type control isacceptable

by

1 0 "

synchronous machine

at

present

Note

2:

this

parameter

can

not

be

initialized, please modify it

manually.

F2.01 Motor's rated power

0.4-999.9KW

O.lKW

Depending "

on

model

F4.03 Switch low point freq. O.OOHz-

[F4.07]

O.OlHz 5.00 0

F4.04

Speed loop

(ASR2)

0.000-6.000

0.001 1.500 0

proportional gain

F4.05 Speed loop

(ASR2)

0.000-32.000s

O.OOls

0.500 0

Integral

time

F4.06

ASR2

filter time

0.000-0.lOOs

0.001s 0.000 0

constant

F4.07

Switch high pointfreq.

[F4.03]-[F0.16]

upper

limit

O.OlHz

10.00 0

freq.

Fl.02

Motor's ratedfreq. 0.01Hz-[F'-0.15]maximum freq. 0.01Hz 50.00 "

F2.03 Motor's rated

speed

0-60000RPM

lRPM Depending "

on

model

F2.04

Motor's ratedvoltage

0-999V

lV

Depending "

on

model

Fl.OS Motor's ratedcurrent

0.1-6553.5A

O.lA Depending "

on

model

F2.06

Stator

resistance of

0.001-20.0000

0.0010

Depending

asynchronous

motor

on

model "

F2.07 Rotor resistance

of

0.001-20.0000

0.0010

Depending

asynchronous

motor

on

model

JC

Stator

and

rotor Depending

F2.08

Inductance of

0.1-6553.SmH

O.lmH

JC

asynchronous

motor

on

model

Vector control of

positive slip 50.0% -200.0%*rated slip

F4.08

compensation factor frequency 0.1% 100.0% 0

(electromotion state)

Vector control of

negative slip 50.0% -200.0%*rated slip

F4.09

compensation factor frequency 0.

1%

100.0% 0

(brakingstate)

0: speed

F4.10 Speed

and

torque

1:

torque

1 0

control

)(

2: valid conditionally(terminal

switch)

F4.11 Speed

and

torque

0.01-1.00s

O.Ols 0.05

switchingdelay

)(

Stator