Vitrek Xitron 2000 Series User manual

USER GUIDE

2000 Family

DC / Temperature Source

Instruments

Warranty 3

Warranty

This Vitrek instrument is warranted against defects in material and workmanship for

a period of two years after the date of purchase. Vitrek agrees to repair or replace any

assembly or component (except batteries) found to be defective, under normal use,

during the warranty period. Vitrek's obligation under this warranty is limited solely

torepairing any suchinstrument, which in Vitrek's sole opinion proves to be

defective within the scope of the warranty, when returned to the factory or to an

authorized service center. Transportation to the factory or service center is to be

prepaid by the purchaser. Shipment should not be made without prior authorization

by Vitrek.

This warranty does not apply to any products repaired or altered by persons not au-

thorized by Vitrek or not inaccordance with instructions provided by Vitrek. If the

instrument is defective as a result of misuse, improper repair, or abnormal conditions

or operations, repairs will be billed at cost.

Vitrek assumes no responsibility for its product being used in a ha-zardous or

dangerous manner, either alone or in conjunction with other equipment. Special

disclaimers apply tothis instrument. Vitrek assumes no liabili-ty for secondary

charges or consequential damages, and, in any event, Vitrek's liabilityfor breach of

warranty under any contract or otherwise, shall not exceed the original purchase

price of the specific instrument shipped and against which a claim ismade.

Any recommendations made by Vitrek or its representatives, for use of its products

are based upon tests believed to be reliable, but Vitrek makes no warranties of the

results to be obtained. This warranty is in lieu of all other warranties, expressed or

implied and no representative or person is authorized to represent or assume for

Vitrek any liability in connection with the sale of our products other than set forth

herein.

Instrument Serial Number:______________________________________________

2000I & 2000M Instrument’s User Guide, Revision B

4

Document Part Number MO-2000-M Revision C

Copyright

Copyright© 2019 Vitrek. All rights reserved.

All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any

form with prior written consent from Vitrek. This product’s user guide is

copyrighted and contains proprietary information, which is subject to change

without notice. The product displays and instructional text may be used or copied

only in accordance with the terms of the license agreement.

is a trademark of Vitrek. All other trademarks or

registered trademarks are acknowledged as the exclusive property of their

respective owners.

In the interest of continued product development, Vitrek reserves the right to

make changes in this guide and the product it describes at any time, without

notice or obligation.

Vitrek

12169 Kirkham Road

Poway, CA 92064

Telephone: 858–689-2755

Email: [email protected]

Contents 5

Contents

Warranty _______________________________________________ 3

Introduction_____________________________________________ 9

Product Description _________________________________________ 9

Features _________________________________________________ 10

Front Panel Controls and Connections _______________________ 11

Display __________________________________________________ 11

“POWER” Switch _________________________________________ 11

Battery Indicators__________________________________________ 12

Red “BATT CHG” Light _________________________________ 12

Green “OK” Light _______________________________________ 12

“OUTPUT” Terminals ______________________________________ 12

Keypad __________________________________________________ 13

Numeric Keys __________________________________________ 13

+/– Key _______________________________________________ 13

Arrow Keys ____________________________________________ 13

Multiplier Keys _________________________________________ 13

Units/Enter Keys ________________________________________ 14

“CLR” Key ____________________________________________ 14

“MNU” Key ___________________________________________ 14

Rear Panel Connections and Controls________________________ 15

Charging Connector ________________________________________ 15

Compensated Thermocouple Connection _______________________ 15

Interface Connectors _______________________________________ 16

2000-IE-BAT Connector__________________________________ 16

2000-RS-BAT Connector _________________________________ 16

Rear Panel Switch _________________________________________ 16

Charging the Battery _____________________________________ 19

The Internal Battery ________________________________________ 19

2000I & 2000M Instrument’s User Guide, Revision B

6

To Charge the Battery ____________________________________ 19

Charging Status _________________________________________ 20

Charging from the Charging Module___________________________ 20

Charging Modules _______________________________________ 21

Charging from an External DC Voltage Supply __________________ 22

Continuous Power from External Supply _______________________ 22

Operating the 2000 Instrument _____________________________ 23

Front Panel Operation ______________________________________ 23

Initial Power Application _________________________________ 23

Connecting to the OUTPUT Terminals ______________________ 24

Displaying Instrument Status ______________________________ 24

Numeric Data Entry _____________________________________ 26

Direct Entry of Required Output Level_______________________ 27

Changing Displayed Multiplier_____________________________ 28

Direct Entry of Temperature Data___________________________ 29

Reversing Polarity of the Present Output Level ________________ 29

Adjusting Output Level or Simulated Temperature _____________ 30

Increasing or Decreasing Output Level_______________________ 31

Changing Adjustment Value _______________________________ 32

Terminating Adjust mode _________________________________ 32

Selecting Default Power on Condition _______________________ 32

Range Locking _________________________________________ 33

Calculating Output Mode of Operation_______________________ 34

Selecting Measurement Mode______________________________ 37

Deselecting Measurement Mode____________________________ 37

Rear Panel Operation _______________________________________ 38

Using Thermocouple Simulation ___________________________ 38

Deselecting Thermocouple Simulation Mode__________________ 41

Using the Memory Options________________________________ 43

Memory Organization ______________________________________ 43

Front Panel Memory _____________________________________ 43

Rear Panel Memory______________________________________ 45

General Memory Considerations ___________________________ 46

Applications ___________________________________________ 48

Low-level DC Power _______________________________________ 48

Ensuring Stable Voltage Connections________________________ 49

Contents

7

Ensuring Stable Current Connections ________________________ 50

Process Control Industry Applications__________________________ 52

Calibrating in Process Control Environments__________________ 52

Simulating Thermocouple Systems__________________________ 55

Measuring Thermocouple Outputs __________________________ 56

Engineering Laboratory Environment Applications _____________ 57

Calibration and Maintenance ______________________________ 61

Internal Calibration ________________________________________ 61

External Calibration ________________________________________ 62

Equipment Required to Recalibrate _________________________ 62

Initiating External Calibration______________________________ 64

Performing External Calibration ____________________________ 65

Periodic Maintenance_______________________________________ 71

Internal Maintenance _______________________________________ 72

Replacing the Internal Battery ________________________________ 73

Interface Operation ______________________________________ 75

RS232 Interface Option _____________________________________ 75

Selecting RS232 ________________________________________ 76

RS232 Handshake Lines __________________________________ 76

IEEE488 Interface Option ___________________________________ 76

Remote/Local Operation __________________________________ 77

Address Selection _______________________________________ 77

IEEE488 Handshake Lines ________________________________ 77

Bus Commands _________________________________________ 78

Other IEEE488 Specific Items _____________________________ 78

Reading Data Via an Interface ________________________________ 79

Sending Data Via an Interface ________________________________ 79

Command Set for the 2000 Instrument _________________________ 79

Keypress, Simulation Command Characters___________________ 79

Firmware Version F.02 ___________________________________ 81

Extended Command Set __________________________________ 81

Command String Usage _____________________________________ 82

Setting an Output Voltage or Current ________________________ 82

Adjusting Output Level___________________________________ 83

Reading Present Output Level______________________________ 83

Internal Calibration ________________________________________ 83

External Calibration ________________________________________ 84

2000I & 2000M Instrument’s User Guide, Revision B

8

Appendix A– Output Specifications _________________________ 85

DC Voltage Output Specifications_____________________________ 85

DC Current Output Specifications _____________________________ 86

Voltage Measurement Specifications___________________________ 87

Thermocouple Specifications_________________________________ 87

Appendix B– General Specifications ________________________ 93

Warm-Up Time _________________________________________ 94

Environmental __________________________________________ 94

Isolation_______________________________________________ 94

Computation ___________________________________________ 94

Tables

Table 1: Resistance Values for Transfer 58

Table 2: Voltage Accuracy Margins 62

Table 3: Current Accuracy Margins 63

Table 4: Command Characters 80

Table 5: Shortcut Command Character Sequences 80

Table 6: Extended Command Set 81

Table 7: DC Voltage Output 85

Table 8: DC Current Output 86

Table 9: Thermocouple Simulation and Measurement Specifications 88

Table 10: CJC Stability-Simulation and Measurement 89 & 90

Introduction 9

Introduction

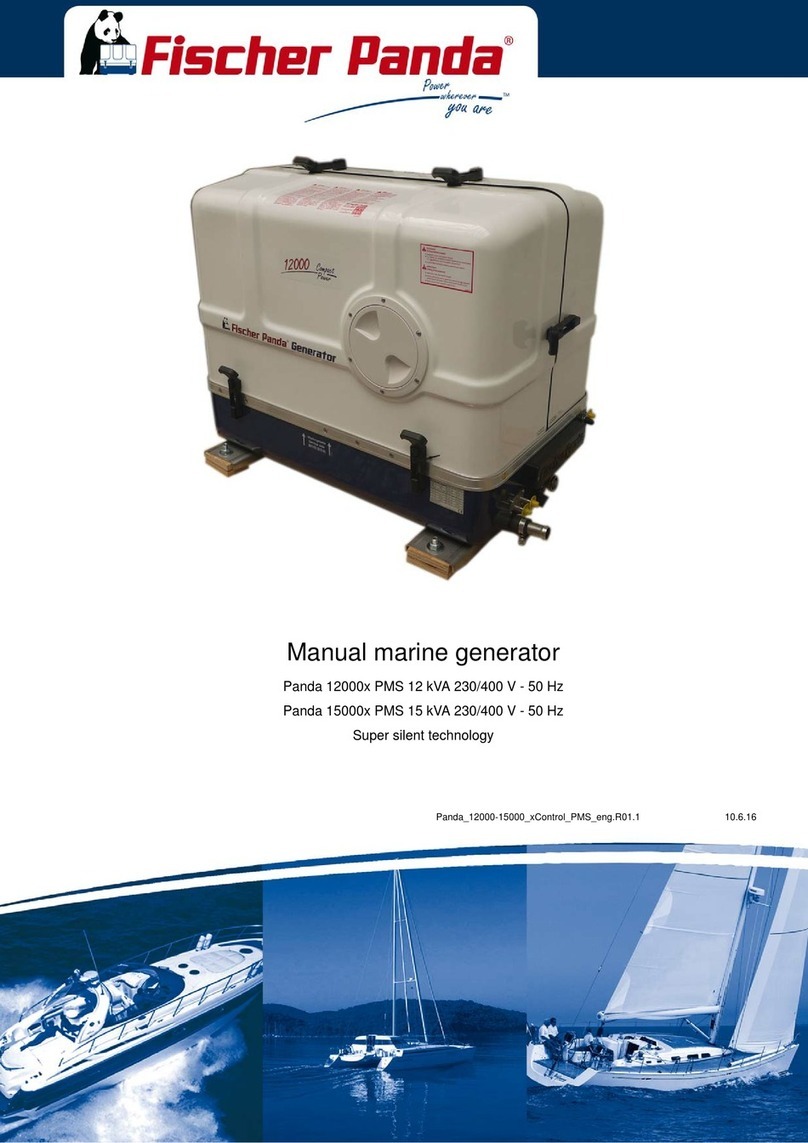

This chapter describes the 2000I, 2000M, 2000IN and 2000MN DC power source

instruments and highlights their features and functionalities. The 2000 instru-

ments were introduced in 1989 to support the fields of Process Control, Calibra-

tion, and General Equipment Testing.

Product Description

The 2000I, 2000M, 2000IN and 2000MN products are portable, lightweight DC

power source instruments. Their capabilities include the generation of precision

bipolar DC voltages1; precision bipolar DC currents2; the high accuracy simula-

tion of a variety of thermocouple types with optional active cold junction com-

pensation; and measurement of voltage and thermocouple outputs. On a 2000

instrument, you may enter a scaling factor, an offset factor and a “units” text

string, which enables the calibration of four 20mA loops in the “actual” units and

scaling of the transducer. Optional IEEE488 or RS232 isolated interfaces further

enhance the 2000 instruments, allowing them to be used in varying applications.

The 2000I, 2000M, 2000IN and 2000MN 2000MN instruments use microproces-

sor and digital-analog conversion technologies to produce highly flexible, accu-

rate instruments with high reliability. The combination of HCMOS

microprocessor technologies with low-power precision analog circuitry yields a

long battery life while maintaining a lightweight rugged package and a 0.5ppm

analog output resolution.

Automatic internal calibration and simple front panel (covers on) external calibra-

tion maintain high accuracy. A comprehensive range of computational abilities

enable a variety of applications.

1DC voltage expands up to 22V and down to 10nV resolution

2DC current expands up to 22mA and down to 10pA resolution

2000I & 2000M Instrument’s User Guide, Revision B

10

Note: To ensure full use of this instrument, review this complete user guide at

setup.

Features

Fully bi-polar DC voltage and current output capability.

DC output of 22 volts at 10ppm accuracy and 22mA at 40ppm accuracy.

Temperature simulation with 0.01 degree resolution, 0.03 – 0.06 degree

accuracy.

Temperature measurement with 0.1 – 0.2 degree accuracy.

Auto cold-junction compensation.

Battery or line operation.

Suited for “in field” calibration requirements of the process control indus-

try.

Portable for use in remote sites.

Functions as a “transducer replacement” with computed output levels and

enabled data entry in: psi, KPa, mmHg, and g/sec units.

Able to calibrate at the “sending” unit.

2000M and 2000MN instruments perform thermocouple simulations.

Connects in parallel with a transducer 4 -20mA output enabling to modify

its output interfaces.

Small size and weight

Low noise performance

IEEE488: Full Talk/Listen capabilities. Isolated from output circuitry up to

500V peak

RS232: Full Talk/Listen capabilities. Selectable baud of 1200 or 19,200

baud. Isolated from output circuitry up to 500V peak.

Front Panel Controls and Connections 11

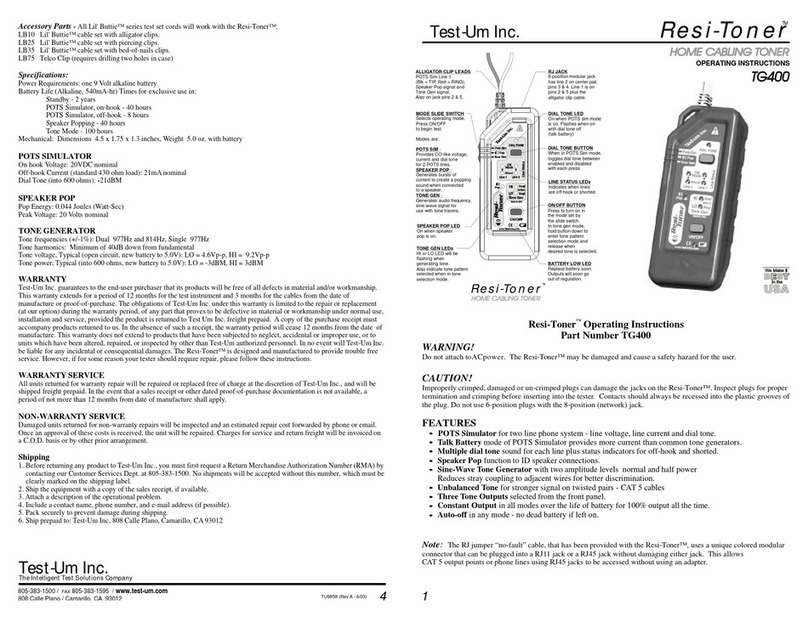

Front Panel Controls and Connections

This chapter discusses the basic use of the various controls, connectors and indi-

cators on the front panel of the 2000I, 2000M, 2000IN and 2000MN DC power

source instruments.

Before using your instrument refer to the text on Charging

the Battery.

For a

complete discussion on the methods used to perform specif-

ic tasks refer to Front Panel Operation.

Display

The 2000 Families DC power source

instrument display is a 16 character,

single line reflective liquid crystal

(LCD). This display shows selectable

status or the present output of the

instrument.

During interactive sequences the dis-

play enables you to select a mode and

enter a value for your desired output,

calculation or measurement

.

The 2000 Instrument

“POWER” Switch

This toggle switch controls the power applied to the circuitry in the instrument.

Note that the charging module is always connected to the charging control circui-

try in the instrument, thus the POWER switch does not control the charging of the

battery.

2000I & 2000M Instrument’s User Guide, Revision B

12

When the POWER switch is toggled up, in the ON position, the microprocessor

and analog circuitry is powered and the instrument may be operated normally.

The power source may be either from the battery or the charging module, as ap-

plicable. When the power switch is toggled down, in the OFF position, the only

operation enabled is charging the internal battery.

Battery Indicators

These indicators reflect the status of the lead-acid battery (2000I, 2000M) and the

Nickel Metal Hydride batteries used (2000IN and 2000MN).

Red “BATT CHG” Light

This red light (LED) illuminates when the internal battery is being charged. Upon

full charge this light extinguishes.

Green “OK” Light

This green light (LED) illuminates when the power switch is turned on for 2000I

and 2000M. For the 2000IN and 2000MN products, the Green LED is used as a

Fuel Status indicator as well as showing that the unit is powered on. It is recom-

mended that the unit is plugged in to the supplied power supply when the Green

LED begins to flash

Note: To continue using if the light extinguishes, connect the instrument to a

charging module or an external DC supply, turn the unit off and then back on to

reset the internal cutoff circuitry.

“OUTPUT” Terminals

All output voltages, currents and temperatures are available from this pair of

binding posts mounted on the instrument’s front panel. These terminals, one red,

one black, accept banana plugs, spade leads or wires, as required.

Front Panel Controls and Connections 13

Keypad

These 20 keys are used for all manual entries into the instrument and to initiate

any required actions. These keys are in the following groups:

Numeric Keys

These keys: “0, 1, 2, 3, 4, 5, 6, 7, 8, 9,” and “.”are used to enter numeric data

into the instrument. While the display is showing the actual output level, these

keys initiate a numeric entry of a new output level; this entry will be completed

by pressing the required unit’s key.

+/– Key

The change sign (+/–) key may be used during a numeric entry to change the

polarity of the entered data. If this key is pressed while the actual output level is

being displayed (i.e., when not in a numeric entry) then the output level is re-

versed (i.e., the output polarity is changed).

Arrow Keys

During a menu selection, and during the “Adjust” mode, the “2, 4, 6 and 8” keys

are arrow keys, which scroll through various actions that show in the display.

These keys are used to select the

previous displayed action.

4 key has a (left arrow)

2 key has a (down arrow)

These keys are used to select the

next action.

6 key has a(right arrow)

8 key has an (up arrow)

To abort the selection of an activity and return the instrument to its previous con-

dition, press the MNU key.

Multiplier Keys

The “m” (milli) key and µ (micro) key are used during a numeric entry to select

the required multiplier for the entered data. If the m key is pressed then the en-

tered numeric is divided by one thousand. If the µ key is pressed then the entered

data is divided by one million.

2000I & 2000M Instrument’s User Guide, Revision B

14

Note that prior to selecting the required units key, an entered multiplier may be

changed by pressing the other multiplier or cleared by pressing the multiplier key

a second time. Pressing a multiplier key while an actual output level or measured

input level is being displayed (i.e., not during numeric entry) changes the display.

If the multiplier key is different from the display, then the display format

changes to use the selected multiplier.

If the multiplier key is the same as the display, it toggles the usage of the

selected multiplier in the display format.

Units/Enter Keys

The V, A, ºC and ºF keys are encircled within a white line on the keypad. These

keys are used to output in the selected units, which terminates a numeric entry.

They can also select the displayed action. For example in “Measure” mode

(2000M only) the V, A, ºC and ºF keys are used to change the displayed units of

the measured data.

“CLR” Key

This key is used to reinitiate a numeric entry (i.e., clear the display ready for res-

tarting the entry), or during a choice selection, this key aborts the action in

progress. During the “Adjust” mode of operation, this key deselects that mode

with the output remaining at the present level.

“MNU” Key

This key is used to select one of the “special” activities of the instrument. When

initially pressed, you are prompted to select the desired action. Press any of the

keys that have an arrow (2, 4, 6 or 8) to scroll through the textual options to dis-

play the required selection and then press a unit’s key to execute it.

Rear Panel Connections and Controls 15

Rear Panel Connections and Controls

This chapter discusses the basic use of the various controls and connectors lo-

cated on the rear panel of the 2000I, 2000M, 2000IN and 2000MN power source

instruments. For a complete discussion of the methods used to perform specific

tasks refer to Front Panel Operation.

Charging Connector

This connector, located on the rear panel in the lower right-hand corner, is the

receptacle for the connector of the charging module. See Charging the Battery

for further details regarding the usage of this connector.

Important Note: When connecting a charger other than that provided by

Vitrek, ensure the selected charger’s output voltage is: 12V at 1.5A and the

center conductor is positive polarity and uses 2.5mm DC plug.

Compensated Thermocouple Connection

This thermocouple output and measurement connections are only present on the

2000M and 2000MN instruments. Use this connection whenever the active cold

junction compensation (CJC) mode of thermocouple simulation or measurement

is being used.

This thermocouple connection, located in the lower center back of the instrument,

is wired in parallel with the output terminals on the front panel. Thus normal out-

put voltages or currents can be obtained using an uncompensated connection.

During calibration of thermocouple measuring instruments, be sure to use ther-

mocouple wire between the 2000M or 2000MN instrument and the unit being

calibrated.

2000I & 2000M Instrument’s User Guide, Revision B

16

Interface Connectors

A connector slot is available at the top center in the back panel. A connector in

this location is only present when either of the interface options IE-BAT or RS-

BAT is fitted in the instrument.

IE-BAT Connector

This is a standard IEEE488 connector, and is fitted if option IE-BAT is fitted in

the instrument. The usage of this connector and the method of using the IEEE488

interface are fully described in the Interface Operations chapter.

RS-BAT Connector

This is a female 9-pin sub-miniature D type connector, and contains the RS232

connections for the RS-BAT option of the instrument. The connections are as

follows:

1. Data Carrier Detect (Output from instrument)

2. Transmit Data (Output from instrument)

3. Receive Data (Input to instrument)

4. Data Terminal Ready (Input to instrument)

5. Ground (Common return for these signals)

6. Data Set Ready (Output from instrument)

7. Request To Send (Input to instrument)

8. Clear To Send (Output from instrument)

9. Ring Indicate (Output from instrument)

Note: These connections enable using a straight through connected cable to an

IBM AT® compatible RS232 connector. Use of this connector and the RS232

interface is fully described in the Interface Operations chapter.

Rear Panel Switch

The rear-panel mounted toggle switch is only present when the IE-BAT option is

fitted in the instrument. When ON (up position), the internal interface is enabled

for operation and is disabled when OFF (down position).

Rear Panel Connections and Controls 17

Note that the battery life is considerably shortened when the IE-BAT Interface is

enabled, thus it is highly recommended that this switch be maintained in the OFF

(down) position whenever this interface is not being used. The IE-BAT Interface

is only usable when this switch is in the ON position.

2000I & 2000M Instrument’s User Guide, Revision B

18

Charging the Battery 19

Charging the Battery

This chapter discusses the methods available for charging the internal battery and

for continuously powering the 2000 instruments from an AC power supply.

Note: Charge the battery with the IE-BAT interface option enabled, although the

time taken to recharge will be extended when the instrument is in this condition.

The Internal Battery

The 2000 instruments are powered from an internal sealed lead-acid battery

(2000I and 2000M) or a Nickel Metal Hydride battery for the 2000IN and

2000MN product builds. The battery isfullycharged when shipped from Vitrek.

During shipping or storage the battery may discharge. We recom-mend the

battery be recharged for at least 12 hours prior to its initial use. Use the charging

unit provided Vitrek to charge the internal battery and to operate this instrument.

Ensure that the included charging unit is compatible with your local power

ratings and socket connection.

Caution: If using an external DC supply other than the provided charger ensure

the selected charger’s output voltage is: 12V at 1.5A and the center conductor is

positive polarity, the DC connector is a 2.5mm Power Jack.

To Charge the Battery

A full charge to the internal battery is achieved by inserting the small plug of the

charging unit into the socket in a recess of the rear panel and then plugging the

charging unit into a suitable AC power outlet.

2000I & 2000M Instrument’s User Guide, Revision B

20

Charging Status

For battery charge status, refer to the front panel’s red BATT CHG light.

If the BATT CHG light extinguishes then the battery is fully charged.

If the BATT CHG light does not extinguish after several hours of charg-

ing, turn the unit OFF and back ON (2000I and 2000M Only).

If the light remains illuminated then continue to charge the unit for a few

more hours and retry turning the unit OFF and back ON.

And if the light still does not extinguish then replace the unit’s battery.

Charging from the Charging Module

If the internal battery has become discharged, recharge it by plugging the DC

output plug on the Charging Module’s cable end into the recessed receptacle on

the instrument’s rear panel and plugging the Charging Module into the local AC

supply. Ensure that the voltage rating of the Charging Module is in accordance

with the local AC supply voltage.

Note: For the fastest possible recharging time, place the front panel POWER

switch in the OFF position.

While charging the internal battery, the BATT CHG light will be illuminated.

When this LED becomes extinguished, the internal battery is fully charged.

The instrument can be operated while it’s charging. Note that when doing so, to

fully charge the internal battery may take up to 15 hours. If the instrument is not

operated during charging then a full charge will take up to 12 hours.

Caution: If the instrument is connected to other circuitry or instrumentation

when the Charging Module is connected, ensure that less than 500V of common

mode potential to ground is present; SEVERE DAMAGE could result if exces-

sive common mode voltages are present.

This manual suits for next models

4

Table of contents

Popular Portable Generator manuals by other brands

Agilent Technologies

Agilent Technologies ESG series Installation note

Et system

Et system EAC-4Q-KS Series manual

WURM

WURM CAN-Bridge quick start guide

Tektronix

Tektronix AFG3000 Series Quick start user manual

Parker

Parker Oildyne 108 Series instruction manual

New Holland

New Holland MN3100PR Operation manual