Vitris Portavant 80 automatic User manual

Manual (EN)

Gebr. Willach GmbH

Stein 2

53809 Ruppichteroth

Germany

Contents 1

Revision 12/2017

Contents

1Introduction.................................................................................................................2

2Safety notices..............................................................................................................3

2.1 Intended purpose ......................................................................................................3

2.2 Legal conditions ........................................................................................................3

2.3 Residual risks............................................................................................................4

2.4 Safety analysis by installer ........................................................................................5

2.5 Limitation of liability / Exclusion of liability for the USA and Canada..........................5

2.6 General safety notices...............................................................................................6

General safety precautions for installation, maintenance and cleaning...............................6

3Function description...................................................................................................8

3.1 General information...................................................................................................8

3.2 Teach-in cycle / power failure....................................................................................8

3.3 Operating modes and safety levels ...........................................................................8

3.4 Collision with obstacles..............................................................................................9

4Technical data...........................................................................................................10

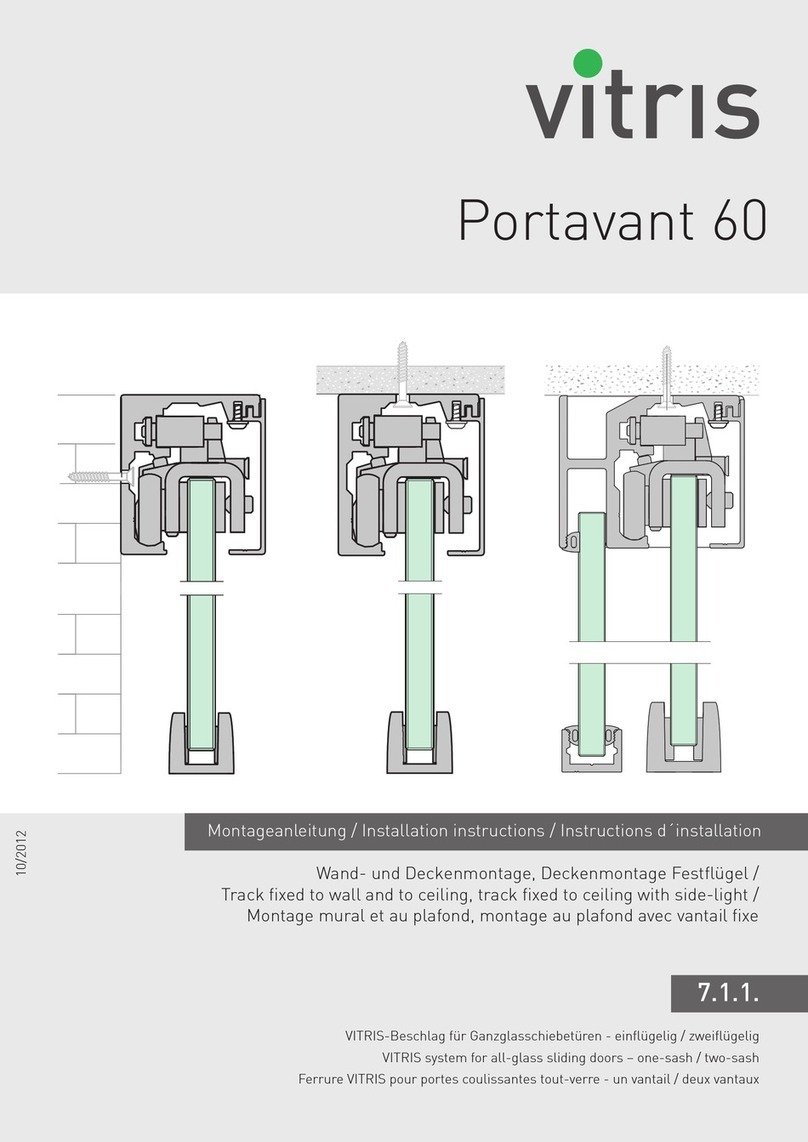

5System overview.......................................................................................................11

6Installation and commissioning by the installer.....................................................12

7Safety analysis by the installer according to DIN 18650 / EN 16005......................13

7.1 Performing the safety analysis.................................................................................13

7.2 Declaration of conformity by installer.......................................................................19

8Operating instructions..............................................................................................21

8.1 Settings via the user menu......................................................................................21

8.2 Operating the door ..................................................................................................22

9Approval, inspection and maintenance according to DIN 18650 / EN 16005 ........25

10 Troubleshooting........................................................................................................28

11 Contacting the manufacturer ...................................................................................30

12 Declaration of Incorporation / Conformity and type examination by TÜV ............31

12.1 EC Declaration of Incorporation ...........................................................................31

12.2 EC Declaration of Conformity...............................................................................32

12.3 Type examination by TÜV....................................................................................33

13 Appendix....................................................................................................................35

13.1 Parts overview and designations..........................................................................35

Portavant 80 automatic 2

Revision 12/2017

1 Introduction

Please observe the separate installation manual to ensure the safe installation and

commissioning of the Portavant 80 automatic drive system. Be sure to perform all steps

required for installation and commissioning and observe all information, instructions and

precautions provided before operating the drive system. Observe the operating instructions

and all safety information and safety instructions provided in this document to ensure safe

operation. Keep this manual in a safe place for future reference and ensure that it is

available to all users.

Portavant 80 automatic 3

Revision 12/2017

2 Safety notices

This operating manual contains safety notes pointing out the unavoidable residual risks

associated with the operation of the Portavant 80 automatic system. The following warnings

are used:

DANGER!

(Type and source of the danger)

Ignoring warnings indicated by the signal word "Danger" may lead to death or

most severe injury.

Caution!

(Type and source of the risk)

The signal word "Caution" indicates potential material damage. Ignoring

warnings indicated by the signal word "Caution" may lead to damage to the

product, other objects in its proximity or to the environment.

2.1 Intended purpose

The Portavant 80 automatic fitting system may only be used for the power-assisted and

manual opening and closing of sliding doors in protected building interiors and under normal

ambient conditions (see section 4 "Specifications"). Special influences like direct splash

water, an atmosphere containing chlorine or elevated temperatures are not allowed. This

excludes, in particular, the use of Portavant 80 automatic for shower doors or doors in

saunas, steam baths or swimming pools.

The system may only be used with single-sash doors weighing between 20 and max. 80 kg

(incl. handle, etc.) and with double-sash doors weighing between 20 and max. 60 kg each

(incl. handle, etc.). Only tempered safety glass or laminated safety glass made of may be

used. The assembly instructions contain further information and must be observed.

DANGER!

The Portavant 80 automatic system must not be installed in escape or

emergency routes. It must not be used in smoke-control and fire doors.

Caution!

Outdoor use, or indoor use for shower doors or doors in saunas, steam baths

or swimming pools, is expressly excluded.

2.2 Legal conditions

The motion area of an automatic door must always be secured by safety sensors (in

compliance with DIN 18650 / EN 16005 and other standards).

Safety sensors may be omitted in many situations in case of automated doors operating at a

low level of kinetic energy where door mass and speed are kept sufficiently low so that the

collision between a person and the door edge and the subsequent reversing motion of the

Portavant 80 automatic 4

Revision 12/2017

door can be seen as uncritical (see DIN 18650 / EN 16005). The situation must be analysed

by the installer in each individual case if doors are to be used by particularly vulnerable

persons such as children or persons with disabilities. The conditions on site must be

considered in the analysis (see section 2.4 "Safety analysis by the installer" and section 7

"Safety analysis by the installer according to DIN 18650 / EN 16005").

Related to EN 16005 an operation at a low level of kinetic energy means that the kinetic

energy of the door is below 1.69 Joule.

Evaluation:

E = m*v²/2 (E = kinetic Energy [J]; m = mass of the door [kg], v = velocity of the door [m/s])

DANGER!

(Risk of crushing/shearing/impact)

To avoid potential danger, the installer must perform a safety analysis

according to DIN 18650 / EN 16005 (see section 7).

2.3 Residual risks

Automatic doors may imply the risk of crushing, shearing, impact and drawing-in at the

closing edges (primary and secondary closing edges).

Depending on the installation conditions in the building and on the installation variant

(installation method), residual risks cannot be fully excluded.

DANGER!

(Risk of crushing/shearing/impact)

Never rush through a closing door, but start the opening motion and

wait until the door has opened sufficiently wide.

Never let children play with the Portavant 80 automatic system and

always keep the remote control out of the reach of children.

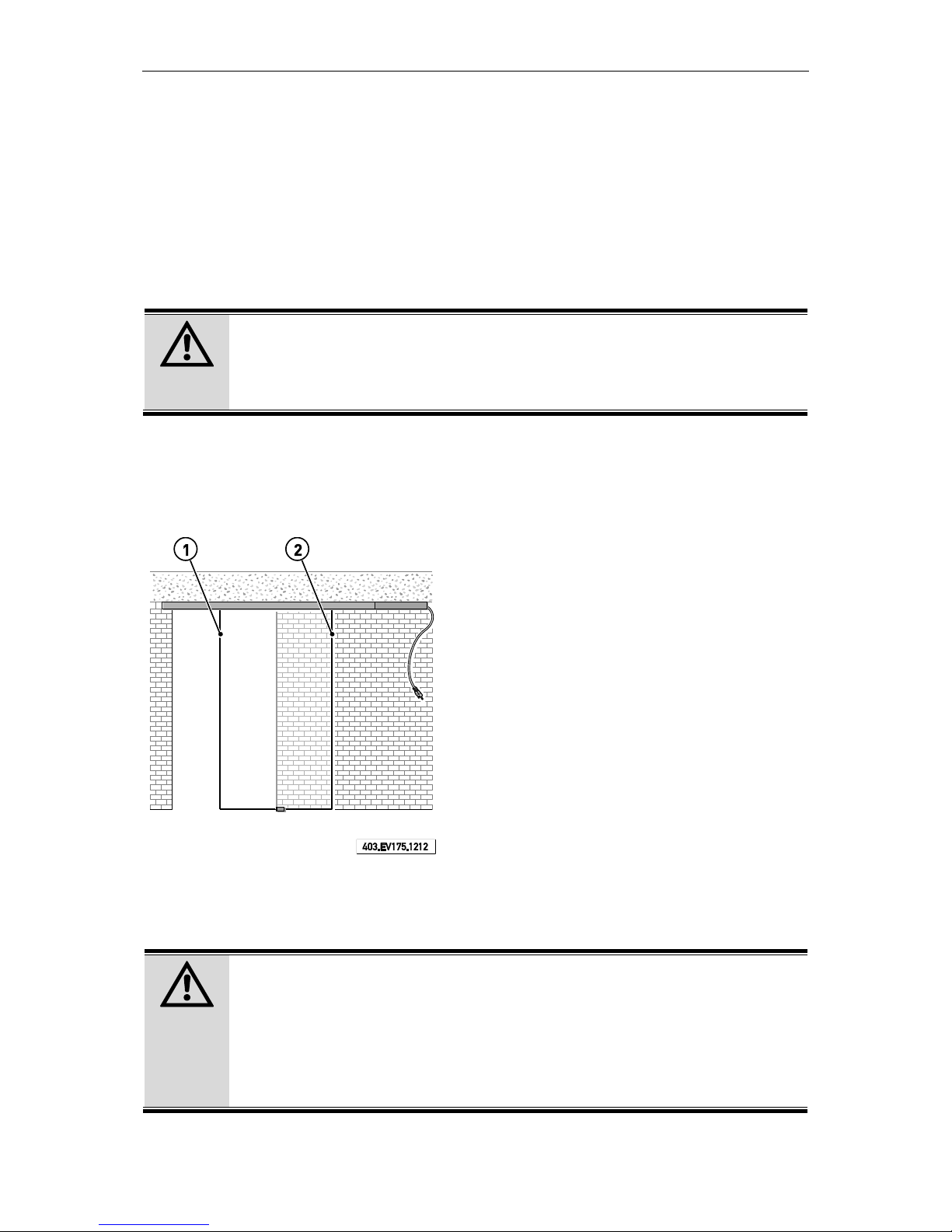

(1) Primary closing edge

(2) Secondary closing edge

Portavant 80 automatic 5

Revision 12/2017

The Portavant 80 automatic system can be operated as a manual sliding door temporarily or

permanently if so required to ensure the safety of particularly vulnerable persons (see

section 8 "Operating instructions"). The operating instructions also explain how to reduce the

immanent residual risks by using the semi-automatic mode and or by reducing the door's

motion speed (primarily the closing speed). See also section 3.3 "Operating modes and

safety levels".

In general, the Portavant 80 automatic system features a very high safety level.

2.4 Safety analysis by installer

Before installing the Portavant 80 automatic system, the installer must perform a safety

analysis of the entire doorset with due consideration of the conditions of the installation site

and the anticipated user groups of the door. If it is assumed that the doorset may represent

an unreasonable hazard to particularly vulnerable persons, then the operating mode of the

door can be changed and set in such a way that the mode (e.g. semi-automatic or manual)

cannot be manipulated without major intervention. See section 7 "Safety analysis by the

installer according to DIN 18650 / EN 16005".

DANGER!

(Risk of crushing/shearing/impact)

To avoid potential danger, the installer must perform a safety analysis

according to DIN 18650 / EN 16005 (see section 7).

It is not possible to fit the Portavant 80 automatic system with safety

sensors as an option. If the result of the safety analysis shows that

safety sensors are required, then the Portavant 80 automatic system

may not be installed.

2.5 Limitation of liability / Exclusion of liability for the USA and Canada

The Portavant 80 automatic system may only be used for its intended purpose (see section

2.1 "Intended purpose"). The manufacturer excludes any liability for damage resulting from

unauthorised changes to the Portavant 80 automatic system.

Operation of the Portavant 80 automatic system in the United States of

America (USA) or Canada is not permissible.

Portavant 80 automatic 6

Revision 12/2017

2.6 General safety notices

DANGER!

(Risk of electric shock and of crushing/shearing/impact)

The use of control elements, settings or methods not described in this

documentation may result in electric shock or other risks caused by electric

voltage or current and/or damage by mechanical procedures. Danger of life

by electric shock!

It is mandatory to observe all instructions in this manual to ensure your

safety. Incorrect installation and/or incorrect commissioning may lead to

severe injury.

The master menu (installer's menu) accessible after removing the cover

secured by fastener may only be used by specialist technicians trained

by the manufacturer.

General safety precautions for installation, maintenance and cleaning

DANGER!

(Risk of electric shock and of crushing/shearing/impact)

Installation, maintenance and cleaning work may only be performed by

specialist technicians trained by the manufacturer.

Ensure that the Portavant 80 automatic system is completely isolated from

mains power before commencing any installation, maintenance or cleaning

work. Pull the mains connector from the power socket or, in case of a

hard-wired system, disconnect the fuse switch or circuit breaker. After

removing the aluminium cover profile, pull the mains connector at the

housing of the drive unit to prevent unintended reconnection to mains

power by third parties (danger to life by electric shock).

Take measures to prevent unauthorised persons from accessing the work

area to avoid injury by falling tools or components.

Fastening material such as bolts, screws and plugs must be selected by

the installer according to the building structure material and the load. The

installer is responsible for the secure and permanent attachment of the

components of the Portavant 80 automatic system to the building

structure.

Do not expose the Portavant 80 automatic system to water or any other

liquid (danger to life by electric shock).

Never introduce any objects into the openings of the drive unit's housing

(danger to life by electric shock).

The mains connection housing may be opened by specialist technicians

(qualified electricians) only (danger to life by electric shock).

Work on parts carrying live voltage may be performed by qualified

electricians only (danger to life by electric shock).

Route the mains power cable in such a way that no one can trip over it and

tear it off (danger to life by electric shock).

Never use the Portavant 80 automatic system if the mains power cable is

damaged. Replace the cable immediately if damaged (danger to life by

electric shock).

Portavant 80 automatic 7

Revision 12/2017

Always pull on the connector housing when pulling the mains power cable

from its socket, never on the cable itself (danger to life by electric shock).

Do not attach any pictures, power sockets, switches or other objects to the

wall within the travel path of the door. Keep the travel path clear of objects

such as vases or umbrella stands. Remove skirting or door frame, if

required. Observe the regulations concerning safety clearances (see

installation instructions and section 7 "Safety analysis by the installer

according to DIN 18650 / EN 16005").

Never place ladders or other objects within the travel path if motorised

motion is imminent.

Check the settings and functionality of the Portavant 80 automatic system

after installation.

The installation described in this manual is an example. The situation on

site, the building structure or available aids or other conditions may require

alternative suitable procedures.

Caution!

The drive and control unit must not be disposed of as household refuse.

Developed in accordance with the latest safety standards:

Low kinetic energy operation in accordance with DIN 18650 / EN 16005

- Initial inspection by TÜV

- CE marking of drive unit by manufacturer

- Designation of classification in accordance with DIN 18650 by manufacturer

TÜV certificate and CE declaration are included in this manual (see section 12 "Declaration

of incorporation, Declaration of conformity and Initial inspection by TÜV").

This manual must be kept for future reference.

Portavant 80 automatic 8

Revision 12/2017

3 Function description

3.1 General information

The Portavant 80 automatic system is an electro-mechanical drive system for single-sash or

double-sash interior doors. In single-sash operation, the permissible door weight including

add-on parts such as handles ranges from 20 to max. 80 kg. In double-sash operation, the

permissible door weight including add-on parts such as handles ranges from 20 to max.

60 kg per sash. The door sash is connected by roller assemblies.

The maximum permissible opening and closing speed is different for single-sash and

double-sash variants and depends on the door weight set by the installer via the control

panel. The only adjustment that can be made by the user is to reduce the actual motion

speeds. The user-adjustable speeds comply with the requirements for low kinetic energy

operation according to DIN 18650 / EN 16005.

3.2 Teach-in cycle / power failure

When commissioning the device, the installer must make the system perform a teach-in

cycle in order to calibrate the end positions of the door.

If a power failure occurs after commissioning, the door must be push-started manually into

either direction. The user must ensure that the travel path of the doors is free of

obstructions. Push-starting the door will start the automatic teach-in cycle during which the

door slowly moves into its end positions. Settings made via the control unit are not lost in

case of power failure.

3.3 Operating modes and safety levels

Manual mode:

This mode allows the door to be moved manually like a sliding door without power-

assistance. In this mode the motor drive is disabled. All signal senders (push buttons, motion

detectors, etc.) are disabled. The belt drive remains connected to the door, causing it to be

moved when the door is operated manually. This has no adverse effects on the drive unit or

the control system. Manual mode may be used over extended periods.

It represents the highest safety level as the motorised drive is disabled.

Semi-automatic mode:

In semi-automatic mode the door opens and closes automatically when being triggered by a

signal. However, any motion detectors connected are disabled. Door motion must be actively

triggered by push-starting the door at the door handle [Push&Go] or by using the push

button or remote control. The door only moves if willingly commanded to do so by the user.

Accordingly, the user then always has the opportunity to check whether the travel path of the

door is free, and can observe the door as it moves.

This mode represents the second-highest safety level as all door motions are deliberately

triggered and can be observed.

Automatic mode:

In automatic mode, the installed motion detectors can be enabled or disabled by the user

e.g. to temporarily prevent pets from entering or leaving rooms. The door opens when

receiving an impulse from the motion detector or by someone pushing the door handle

[Push&Go] or pressing the push button or remote control. It then closes after an adjustable

open period without any further impulse from the user. This mode represents the third-

highest safety level as door motion is triggered by motion detectors or a timer without a

deliberate decision by the user.

Portavant 80 automatic 9

Revision 12/2017

All motor-assisted operating modes comply with the definition of low kinetic energy

according to DIN 18650 / EN 16005.

DANGER!

(Risk of crushing/shearing/impact)

The use of radio motion detectors that could theoretically be connected to

the radio receiver (intended for radio push button and remote control) is not

permissible. The use of radio motion detectors has been deliberately omitted

by the manufacturer in order to prevent any adverse effects on the safety

concept described above. Any mention of motion detectors in this document

always refers to the hard-wired connection of one or more motion detectors to

the dedicated terminals provided at the drive unit.

3.4 Collision with obstacles

If a door collides with an obstacle in its travel path, it stops immediately to return to its

opposite end position. Depending on the operating mode, it remains in this end position until

the next impulse is received or it commences another closing motion once the open period

has elapsed. If another collision occurs at the same position, then the door is disabled

(possibly only when it has arrived at its end position). It must then be push-started manually.

This disabling feature prevents the door from repeatedly colliding with the same obstacle.

Should the reversing door, after the initial collision, run into a second obstacle, then the door

will stop and be disabled immediately at this position.

The low kinetic energy mode of the door ensures that static forces do not exceed 67 N.

Portavant 80 automatic 10

Revision 12/2017

4 Technical data

Mains connection

Voltage supply: 100-240 V AC; 50 –60 Hz

Mains supply stability: +/- 10%

Circuit protection on site: 16 A

Cable type: min. 2 x 0.75 mm², protection class 2

Power consumption without external consumers

In stand-by mode: max. 1 W

In drive mode: max. 60 W

Ambient conditions

Permissible ambient temperature: 0 –40 °C

Permissible relative humidity: < 70 %

Use in dry interior locations only. No splash water. Protection class IP 20.

Permissible door dimensions

Door weights for single-sash operation: 20 to 80 kg (200 –800 N)

Door weights for double-sash operation: 20 to 60 kg (200 –600 N) per sash

Caution! Consider add-on parts such as door handles when determining door weight.

Maximum height-to-width ratio: 2.5 : 1

Intended pass-through rate

Average motion cycles per day: approx. 150 –200 (planning basis for several

years of operation)

Max. motion cycles per hour: approx. 200 (extend open period, if required)

Operating sound

Operating sound of drive: max. 55 dB (A)

(Resonances within the building structure must be checked on site and be eliminated)

Portavant 80 automatic 11

Revision 12/2017

5 System overview

(6) Control panel

(10) Cover for Master Menu button

(11) Master Menu button

(12) Menu button (user menu)

(13) "+" button

(14) Two-line display

(15) "-" button

(16) Reset button

(17) LED of radio receiver, if applicable

(18) Position of optional radio receiver

(1) Track profile and cover profile

(2) Drive and control unit

(3) Supply cable

(4) Door sash

(5) Floor guide

(2) Drive and control unit

(6) Control panel

(7) Control panel connecting cable

(8) Drive belt

(9) Terminals for external signal senders

Portavant 80 automatic 12

Revision 12/2017

6 Installation and commissioning by the installer

In accordance with DIN 18650 / EN 16005, the Portavant 80 automatic system may only be

installed and commissioned by technicians (installer) trained by the drive unit manufacturer.

A separate installation and commissioning manual is included in the product packaging. The

installation and commissioning manual is available from the drive unit manufacturer, if

required (see imprint). Please specify the production date of the drive unit (see CE sticker on

drive unit).

The installer must perform a safety analysis in accordance with section 7 before installing

the Portavant 80 automatic system.

The installer is considered the manufacturer of the complete doorset and is obliged to

provide a declaration of conformity in accordance with section 7 and to attach a CE mark to

the doorset in accordance with section 8.

After installation, the installer must commission the system, including a function test, in

accordance with the installation manual and must also approve the system in accordance

with section 9. The approval must be documented in the inspection record in section 9.

Portavant 80 automatic 13

Revision 12/2017

7 Safety analysis by the installer according to DIN 18650 / EN 16005

7.1 Performing the safety analysis

The safety analysis

must consider the necessary security measures during the planning phase;

must be performed prior to commissioning at the latest;

states how potential dangers can be eliminated or reduced at the doorset in view of

the actual installation conditions and the user groups;

indicates potential residual risks.

The installer of the doorset

is obliged to perform and document a safety analysis (danger analysis / risk analysis)

in accordance with DIN 18650 / EN 16005 or Directive on Machinery 2006/42/EC;

must create a EC declaration of conformity and attach a CE mark at the doorset.

In general, avoiding points of danger always takes priority.

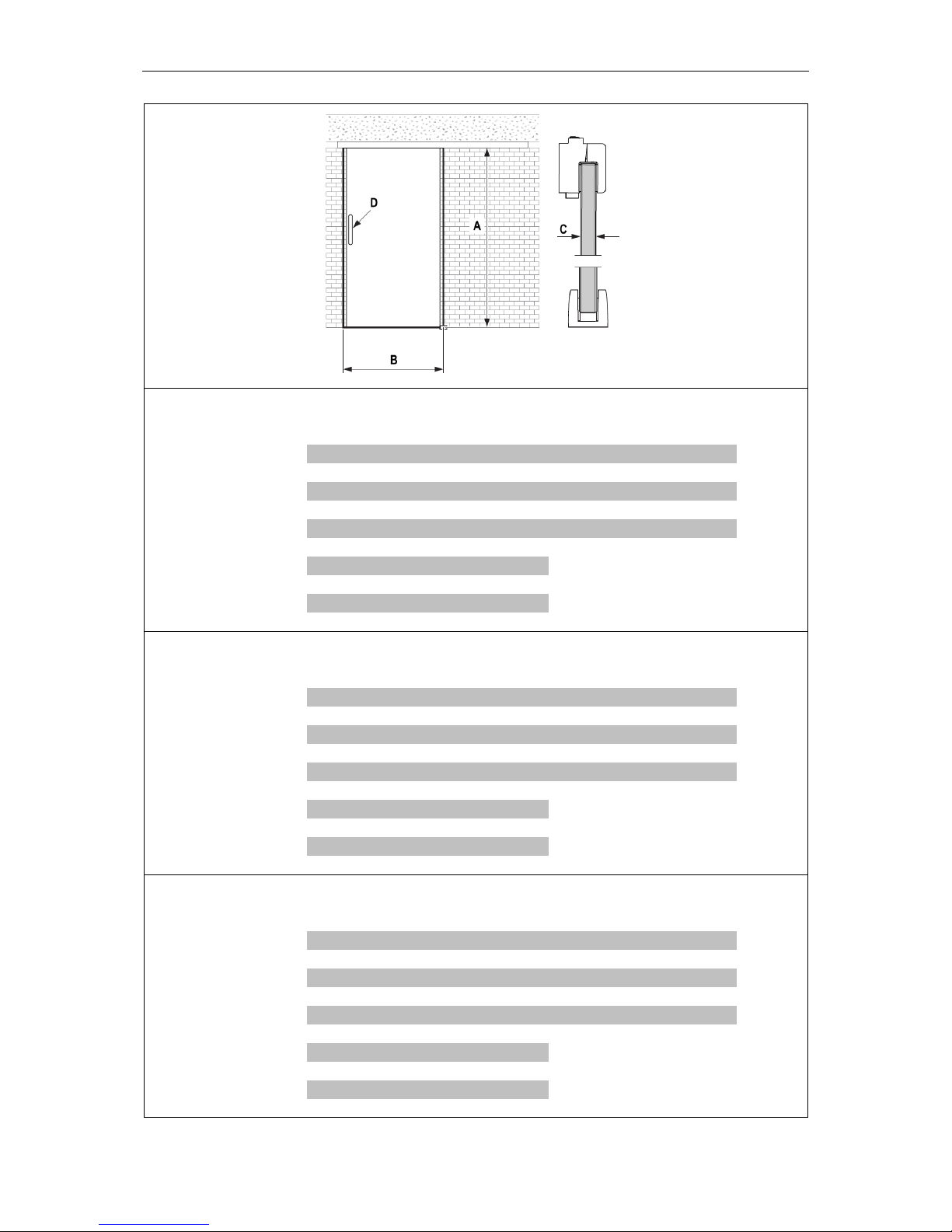

Door data:

Building: ___________________________________________________

Street: ___________________________________________________

Post code / City: ___________________________________________________

Location inside building, door number, designation:

___________________________________________________

Sash width: ______________ mm

Sash height: ______________ mm

No. of sashes: ________

Calculation of door weight:

Door weight = sash height A [dm] x sash width B [dm] x glass thickness C [dm] x 2.5

kg/dm³ + weight of add-on parts D [kg]

Round the result to the next 5 kg and adopt this value in the control system.

Door weight: __________ kg

Portavant 80 automatic 14

Revision 12/2017

Safety analysis author:

Name: ________________________________________________

Street: ________________________________________________

Post code/City: ________________________________________________

Date: ___________________________

Signature: ___________________________

Doorset operator:

Name: ________________________________________________

Street: ________________________________________________

Post code/City: ________________________________________________

Date: ___________________________

Signature: ___________________________

Manufacturer of (complete) doorset (installation contractor):

Name: ________________________________________________

Street: ________________________________________________

Post code/City: ________________________________________________

Date: ___________________________

Signature: ___________________________

Portavant 80 automatic 15

Revision 12/2017

DANGER!

(Risk of crushing/shearing/impact)

Please check each of the following items, ticking the applicable square

brackets [ ] in cases of compliance. Round brackets ( ) are provided

where an alternative selection is possible. If compliance is not given,

please take measures to establish compliance, otherwise do not

commission the Portavant 80 automatic system.

[ ] General check of system periphery

Door sashes may not open into areas that are used for other passing traffic.

[ ] Check of safety clearances

Automatic doorsets must be realised in such a way that any risk of crushing, shearing,

impact and drawing-in by the opening or closing sash is avoided, else suitable safety

measures must be in place, e.g. by maintaining safety clearances or by providing

protection wings (and by limiting door operating forces by low kinetic energy mode).

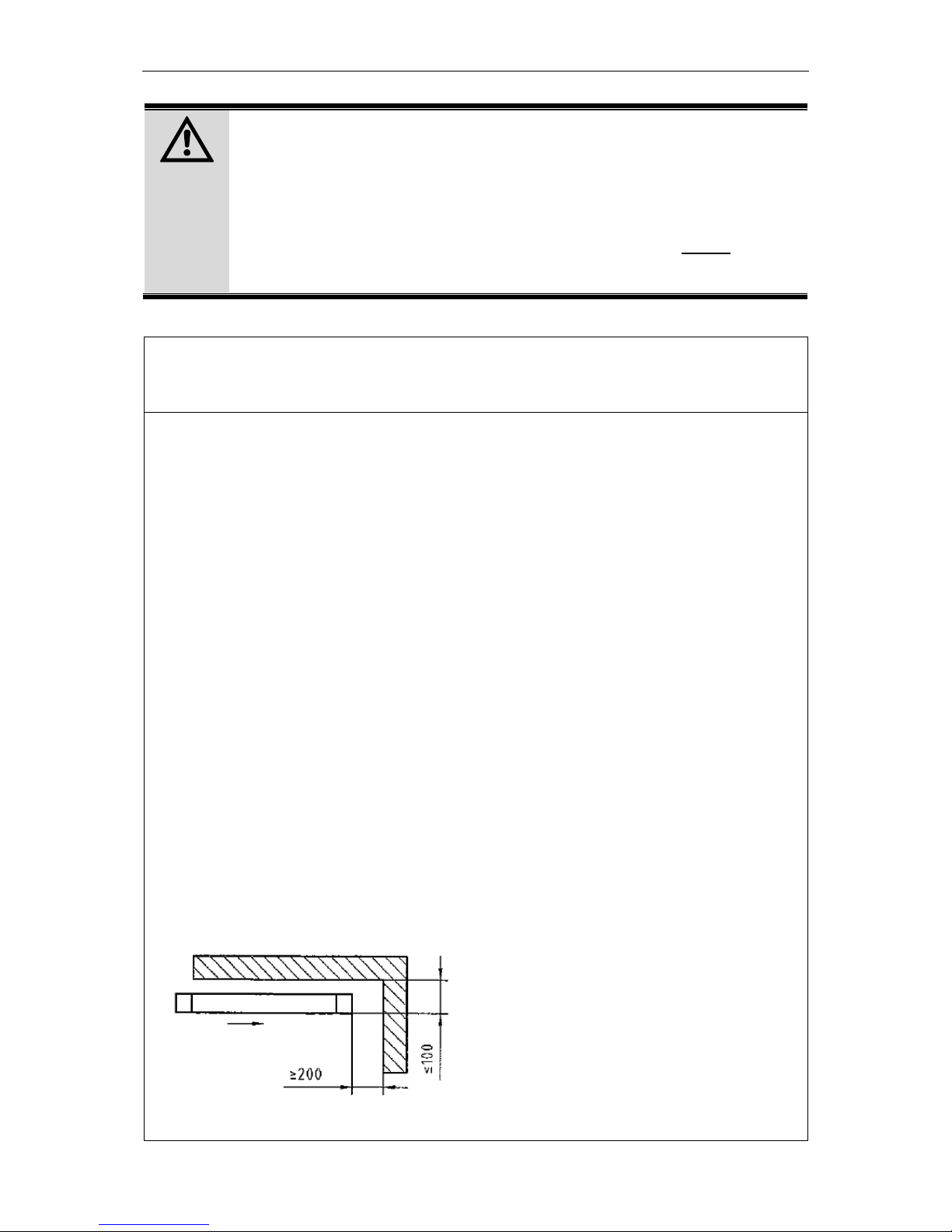

Safety clearances must be dimensioned as follows to provide a sufficient level of

protection against crushing:

- for fingers or hands >= 25 mm

- for the head >= 200 mm

- for the body >= 500 mm

Safety clearances must be dimensioned as follows to provide a sufficient level of

protection against drawing-in:

- for fingers or hands <= 8 mm

- for fingers or hands <= 30 mm

Always consider any add-on parts such as (finger-pull) handles!

Compare the conditions on site with the specifications shown in the following illustrations

(all dimensions in mm). Not all illustrations necessarily comply with the actual conditions

on site.

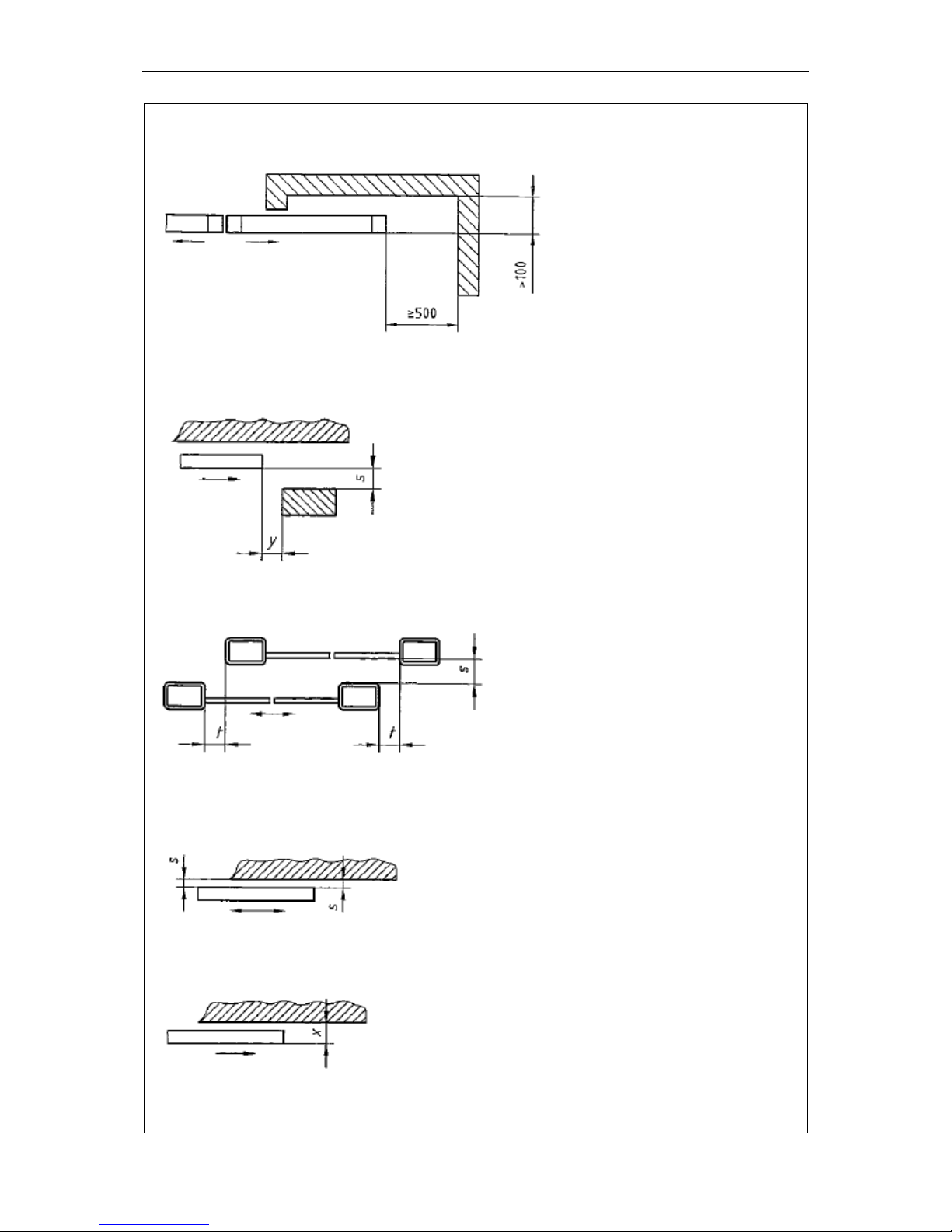

(a) Danger for the head (crushing)

s ≤ 100, then y ≥ 200

Portavant 80 automatic 16

Revision 12/2017

(b) Danger for the body (crushing)

s > 100, then y ≥ 500

(c) Danger for the body (crushing)

s ≥ 500, then y ≤ 0

(d) Finger protection (shearing)

s ≤ 8, then t ≤ 0

s > 8, then t ≥ 25

(e) Finger protection (drawing-in)

Fingers: s ≤ 8 or 25 < s ≤ 30

(f) Clearance between sash front edge to fixed sidelight

x ≤ 100

Portavant 80 automatic 17

Revision 12/2017

Check of (finger-pull) handles or other add-on parts

[ ] no sharp edges AND

[ ] not shearing points/sufficient safety clearances

Check of glass panel

[ ] no sharp edges/no edge pitting AND

[ ] safety glass AND

[ ] transparent sashes are marked (stickers/frosted strips) at eye level in such a

way that the closed door is recognised by the user, AND

[ ] a label stating "Automatic" mode is attached

[ ] Check of door weight entered in menu

Verify that the correct door weight including add-on parts such as handles has

been entered in the master menu.

Safety is ensured by low kinetic energy operation

Note: The display of "2x60kg" indicates that a double-sash doorset with a door weight of

60 kg each is in operation. Accordingly, "1x60kg" indicates a single-sash doorset with a

weight of 60 kg.

DANGER!

(Risk of crushing/shearing/impact)

Never enter a door weight that is too low, and make sure that in case of a

double-sash door "2x" precedes the door weight. This is a prerequisite to

ensure that the maximum door speeds calculated from the door weight comply

with the low kinetic energy mode according to DIN 18650 / EN 16005.

Incorrect entries may cause severe injury.

[ ] Check of push buttons (only if applicable)

Wall-mounted push buttons and their location must comply with user requirements.

They must be located in such a way that the user is not impeded by the opening

door and cannot collide with it. Also, the location of the button must ensure that the

user has a clear view of the door, enabling the user to check before opening the

door that the moving door does not represent a hazard to other persons. Wall-

mounted push buttons must be designed and located in such a way that the risk of

accidental actuation is as small as possible. They must be located within the reach

of the users and must be clearly identifiable.

[ ] Check of motion detectors (only if applicable)

The activation threshold of any motion detector triggering the door should extend

approx. 1,000 mm to 1,500 mm forward of the door face. The detection range must

at least cover the door's overall opening width.

Portavant 80 automatic 18

Revision 12/2017

[ ] Particularly vulnerable persons (e.g. infants, physically challenged persons,

etc.)

( ) It is not assumed that particularly vulnerable persons will be using the door OR

( ) the operator of the doorset ensures that the user groups of the doorset do not

include particularly vulnerable persons.

OR

If it must be assumed that the door will be used by particularly vulnerable persons,

then the safety level of the doorset must be increased by:

( ) reducing the opening speed (as long as the opening speed still allows

comfortable passage of the door) AND/OR

( ) reducing the closing speed AND/OR

( ) selecting semi-automatic mode AND/OR

( ) disabling the user menu (to prevent users from tampering the safety

concept) OR

( ) by the doorset operator ensuring that the doorset is operated in semi-

automatic mode or manually if particularly vulnerable persons are present.

DANGER!

(Risk of crushing/shearing/impact)

If the suggested measures for the protection of particularly vulnerable

persons are considered as insufficient, then the Portavant 80 automatic

system must not be commissioned.

Portavant 80 automatic 19

Revision 12/2017

7.2 Declaration of conformity by installer

The manufacturer of the door drive (Willach) has attached a CE mark at the drive system

(incomplete machine) and has provided proof of type-approval and classification according

to DIN 18650 to the greatest possible extent.

Declaration of conformity by the installer (manufacturer/installation contractor):

The installer incorporates the door drive with the fittings, the sash (not included in scope of

supply of door drive manufacturer) and the peripheral building structure. According to the

Directive on Machinery 2006/42/EC, only this procedure turns the incomplete machine into a

complete machine. The installer or the contractor performing the installation thereby

becomes manufacturer or assembler of the complete machine, i.e. the complete doorset.

The doorset must be tested for its conformity with the Directive on Machinery (Safety

analysis, see section 7.1 as well as Directive on Machinery 2006/42/EC and DIN 18650/EN

16005). Proof of conformity must be documented by providing a CE declaration. To this end,

the drive system manufacturer (Willach) requests the doorset installer to utilise the CE mark

provided on the drive and to complete the classification in accordance with DIN 18650 so

that it applies to the complete doorset.

The first six digits and the eighth digit of the classification have already been printed onto the

label on the drive unit by the manufacturer (Willach).

Classification DIN 18650 I 2I 1 I 2I 0I 1 3 I 0I __ __ __ I 4I

1st digit: Drive type 2Sliding door drive

2nd digit: Durability of the drive 1200,000 testing cycles

3rd digit: Door type 2Sliding door

4th digit: Fire-protection door suitability 0Not suitable as fire-protection door

5th digit: Safety devices at drive 1Force limitation

3Low (kinetic) energy

6th digit: Special requirements for drive 0No special requirements

7th digit: Safety measures at automatic doorset ?To be determined by installer

8th digit: Ambient temperature 4Temperature range according to

drive manufacturer's specifications

The 7th digit must be entered by the installer as follows:

0 –No additional safety devices

1 –With sufficiently dimensioned safety clearances

2 –With protection against crushing, shearing and drawing-in of fingers

A "0" indicates that no safety devices are installed. Such safety devices may be permanently

installed protective wings for instance. (Note: It is not possible to fit the Portavant 80

automatic system with sensor edges.)

Digit "1" indicates that all safety clearances are sufficiently dimensioned. See fig. a) to f) in

section 7.1 (in general, the ">" symbol).

Digit "2" indicates that measures have been implemented against crushing, shearing and

drawing-in of fingers. These measures may be implemented e.g. by observing the

clearances according to fig. a) to f) in section 7.1. Suitable covers of excessively large gaps

(e.g. for in-wall systems) may also be suitable measures.

Table of contents

Other Vitris Door Opening System manuals

Popular Door Opening System manuals by other brands

QUAD

QUAD EZ-4000 Owners and installation manual

Tucker Auto-Mation

Tucker Auto-Mation SW10 installation guide

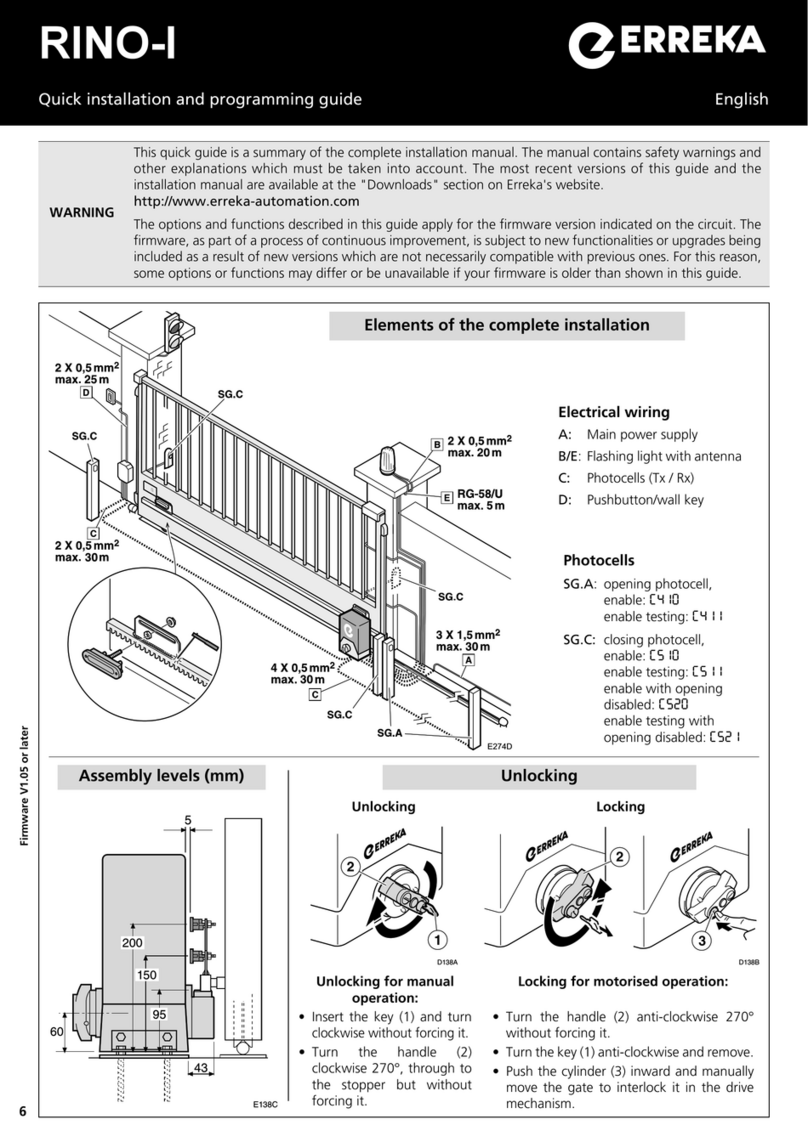

Erreka

Erreka RINO-I Quick installation and programming guide

SECO-LARM

SECO-LARM ENFORCER SD-962AR-36M installation manual

Dorma

Dorma ES 200 Mounting instructions and Instruction manual

4Ddoors

4Ddoors 4DR2 Installation instructions and user guide