vitro Vitrolux H V2 User manual

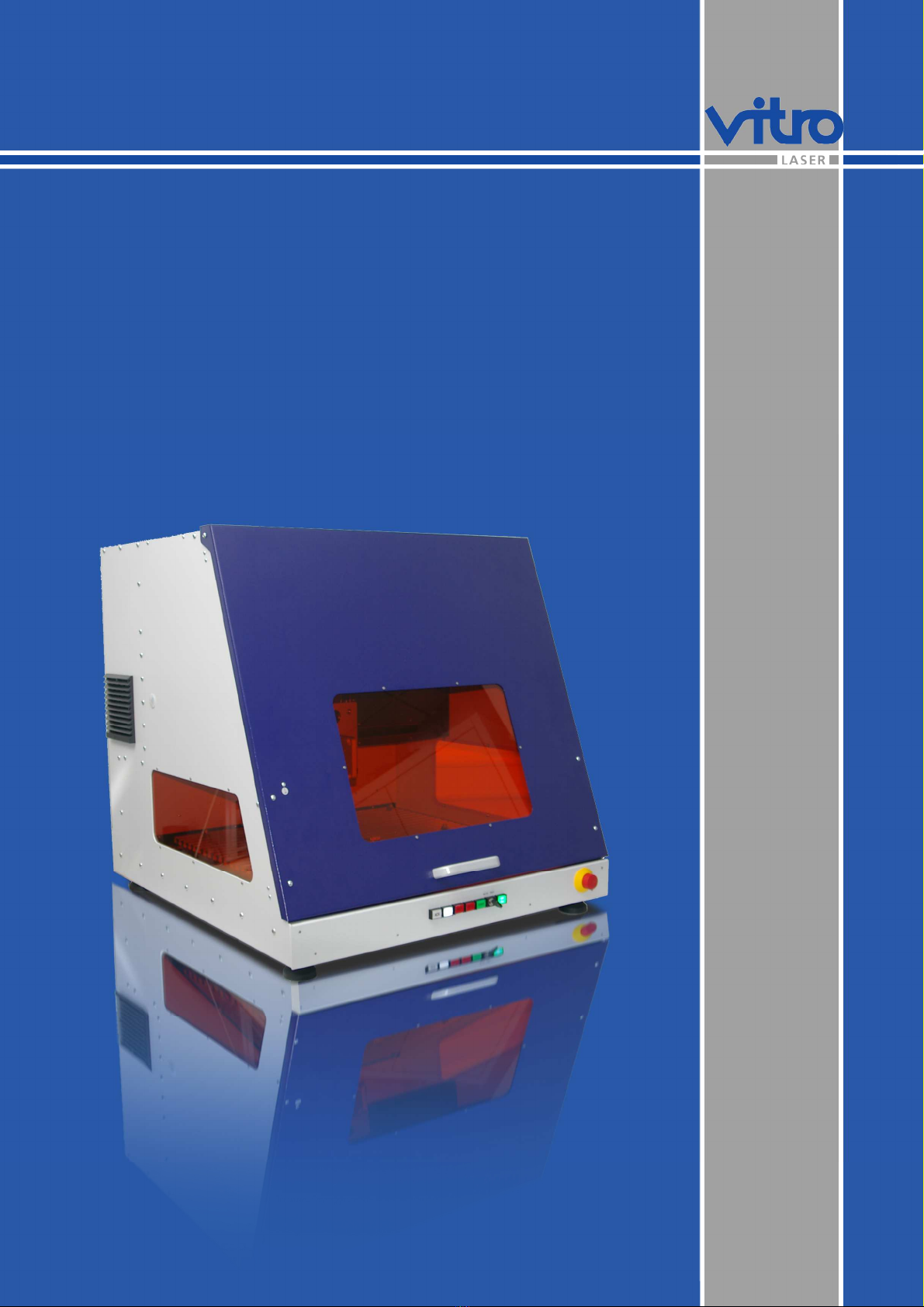

Vitrolux H

V2

Preface

Stand 5/12

Page 1 of 57

User Manual

Vitrolux H

V2

Vitrolux H

V2

User Manual

Stand 5/12

Page 2 of 57

Note

Always keep the serial number shown on this page close to hand when contacting Vitro

Laser Solutions UG

Vitro Laser Solutions UG reserved the right to make technical changes to improve the

product

All measures have been taken to ensure this documentation is correct Please inform Vitro

Laser Solutions UG if you find any mistakes in the documentation

Copyright

The documentation is the Copyright of Vitro Laser Solutions UG

It is only intended for the proprietor and operating personnel T>he instructions and

information contained may not be copied in full or part, distributed or transferred by any

electrical data transfer methods or used for competitive purposes without authorized

approval Offenders will be liable to prosecution

Declaration of Conformity

We

Vitro Laser Solutions UG

llerbusch 28

D-32429 Minden

assume the sole responsibility that the product

Typ : Vitrolux H

Serial Number:

fulfills the requirements stipulated in:

the relevant safety and health protection laws set out in the EEC machinery safety guidelines

89/392/EEC, 89/336/EEC and 73/23/EEC and amedments 91/368/EEC (20 06 91),

93/44/EEC (14 06 93), 93/68/EWG (22 07 93) as well as the 9

th

ordinance regulating safety

(Ordinace Regulating Machines, 9

th

GSGV),

the other appropriate EU guidelines, DIN EN 292 Part 1 and 2 (safety of machines), EN

60204 (equipping of machines), EN 60825 (radiation safety concerning laser equipment), EN

55011 (radio interference of electrical resources) EN 50082-2 (electromagnetic compatibility),

the accident prevention regulations concerning laser radiation (BGV B2), E DIN 5335 on

screening workplaces, safety related requirements and tests and national standards VDE

100 (directive for erecting high voltage systems) and VDE 0105 (operating high voltage

systems)

Minden,

A Sperling

Board of Managers

Vitrolux H

V2

Preface

Stand 5/12

Page 3 of 57

Preface

This operating instruction manual provides detailed information on using the Vitrolux laser

system for subsurface engraving It contains safety information which ensures safe use of

the laser

It also contains instructions on installation, maintenance, fault location and troubleshooting

The spare parts list enables spare parts for the laser system to be ordered simply

The aim of this manual is to help you exploit the full potential of the laser system

The laser system will provide years of satisfaction when it is used and cared for properly

The documents provided should help to ensure this

Always keep the documentation available in the direct vicinity of the laser system Observe

all the information, notes, instructions and guidance contained in it This will prevent

accidents through incorrect operations, secure rights to claim under the full terms of

manufacturers guarantee and ensure that your laser system is always full functional

Vitro Laser Solutions UG constantly aims to improve its products For this reason it reserves

the right to make modifications and improvements which it deems necessary

However this does not involve any obligations to make reconstructions to laser systems

already supplied

The following symbols appear at important sections of this manual Observe the information

precisely and take particular care in such cases

Used symbols:

Warning

This symbol indicates the risk of fatal or severe personal injury if certain

behavioural regulations are ignored Where this symbol appears, ensure all the

relevant safety precautions are met

Caution

This notice warns you against material damage as well as financial and criminal

disadvantages (such as loss of the warranty rights, liability cases, etc )

Information

Here you will find important information and details on the effective, economic

and environmentally safe management of the system

Warning

You have to read the operating manual and understood the safety information

contained in it before starting up the laser system

Vitrolux H

V2

Table of contents

Stand 5/12

Page 4 of 57

Table of contents

1. Safety ........................................................................................... 7

1.1 For your safety .................................................................................... 8

1.1.1 General information ........................................................................ 8

1.1.2 Obligations of the proprietor ............................................................. 8

1.1.3 Obligations of operating personnel .................................................... 9

1.2 Liability ........................................................................................... 10

1.3 Accident prevention regulations ........................................................... 11

1.3.1 General information ...................................................................... 11

1.3.2 Laser system ............................................................................... 11

1.3.3 Protective measures from the operator ............................................. 13

1.3.4 Assembly and disassembly ............................................................ 14

1.3.5 Transport and assembly ................................................................ 14

1.3.6 Storage ...................................................................................... 14

1.3.7 Maintenance and repair .................................................................. 15

1.3.8 Safety when out of service .............................................................. 15

1.3.9 lectrics ..................................................................................... 15

1.3.11 Other points of danger ................................................................. 16

1.4 Intended use ..................................................................................... 17

1.5 Operation ......................................................................................... 18

1.6 Information labels and rating plates ....................................................... 18

2. Transport and installation ............................................................... 21

2.1 General information ............................................................................ 22

2.2 Transport ......................................................................................... 22

2.2.1 Transport vehicles ........................................................................ 22

2.2.2 Notes on the packaging ................................................................. 22

2.2.3 Tilt and shock monitoring ............................................................... 23

2.3 Installation ....................................................................................... 24

3. Product description ....................................................................... 25

3.1 Components comprising the laser system ............................................... 26

3.1.1 Overview .................................................................................... 26

3.1.2 View of the components ................................................................. 27

Vitrolux H

V2

Table of contents

Stand 5/12

Page 5 of 57

3.2 Laser head ....................................................................................... 28

3.3 Scanner ........................................................................................... 29

3.4 Laser optics ...................................................................................... 30

3.5 Motor axis ........................................................................................ 31

3.6 Laser system switches ........................................................................ 33

3.7 Components in the rear part of the system .............................................. 35

3.7.1 Control unit ................................................................................. 35

3.7.2 Axis controller ............................................................................. 35

3.8 Computer ......................................................................................... 36

4. Operation .................................................................................... 37

4.1 Power-on routine ............................................................................... 38

4.2 Load / ngrave .................................................................................. 38

4.3 Shutdown procedure .......................................................................... 39

5. Maintenance ................................................................................ 40

5.1 General information ............................................................................ 41

5.2 Maintenance work and intervals ............................................................ 41

5.2.1 Fixed intervals ............................................................................. 41

5.2.2 Mantenance work as necessary ....................................................... 41

5.3 Lubricate motor axles ......................................................................... 42

5.3.1 Guide rails .................................................................................. 42

5.3.2 X-axis ........................................................................................ 42

5.3.3 Y-axis ........................................................................................ 43

5.3.4 Z-axis ......................................................................................... 44

5.4 Clean air filter ................................................................................... 45

5.5 Clean interior of the system ................................................................. 45

5.6 Clean the optics ................................................................................ 46

6. Troubleshooting ........................................................................... 47

6.1 General information ............................................................................ 48

6.2 rrors .............................................................................................. 48

6.2.1 System can't be switched on ........................................................... 48

6.2.2 „Power" button does not work ......................................................... 48

6.2.3 Laser does not engrave ................................................................. 48

6.2.4 Software works incorrectly ............................................................. 48

Vitrolux H

V2

Table of contents

Stand 5/12

Page 6 of 57

6.2.5 Software massage „Door open“ in closed .......................................... 49

6.2.6 ngraving moved in glass .............................................................. 49

6.2.7 Motives with defects always in the same place .................................... 49

6.2.8 Motives with streaks or strips .......................................................... 49

6.2.9 Motive rare to see ......................................................................... 50

6.3 Changing the lens .............................................................................. 50

6.4 Replacing the laser diode module ....................................................... 50

7 Technical Data .............................................................................. 51

7.1 General Data ..................................................................................... 52

7.2 nvironmental conditions .................................................................... 52

77.3 lectrical installations ....................................................................... 52

7.4 Laser............................................................................................... 52

8 Spare parts, special equipment ......................................................... 53

8.1 Grease for the axes bearings ................................................................ 54

8.2 Warning labels .................................................................................. 54

8.3 Diode module .................................................................................... 55

8.4 Lens ............................................................................................... 55

8.5 Laser safety glass .............................................................................. 55

8.6 Protection goggles ............................................................................. 55

8.7 Glass tension tester ........................................................................... 56

9 Warranty ...................................................................................... 57

Vitrolux H

V2

Safety

Stand 5/12

Page 7 of 57

1. Safety

Contents

This operating manual for your laser system contains important information on installation,

operation, maintenance, fault conditions and ordering spare parts We provide this

information to ensure safe, reliable operation of your laser system

All the safety information are necessary for safe use of the laser system and terms of liability

are contained in this chapter It also provides information on the intended use

Organization

___________________________________________________________

1 1 For your safety

1 1 1 General information

1 1 2 Obligations of the proprietor

1 1 3 Obligations of the operating personnel

1 2 Liability

1 3 Accident prevention regulations

1 3 1 General information

1 3 2 Laser System

1 3 3 Protective measures from the operator

1 3 4 Assembly and disassembly

1 3 5 Transport and assembly

1 3 6 Storage

1 3 7 Maintenance and repair

1 3 8 Safety when out of service

1 3 9 Electrics

1 3 10 Other points of danger

1 4 Intended use

1 5 Operation

1 6 Information labels and rating plates

___________________________________________________________

Objective

This chapter points out the potential dangers involved when using the laser system It

provides information on recognizing dangerous situations and should help to ensure you

operate the system in a safe, proper way

Read this operating manual, paying particular attention to this chapter, before starting

to use the laser system!.

Vitrolux H

V2

Safety

Stand 5/12

Page 8 of 57

1.1 For your safety

1.1.1 General information

In addition to safety information, this operating manual provides:

a general description of the product

information on installing the laser system

instructions on operating the laser system

instructions on maintenance and upkeep

instructions on fault location and elimination

technical data

an overview of special optional equipment

a spare parts list

Always keep this operating manual and other documents related to the laser system close to

hand in the vicinity of the operating unit Operation of the system was explained when the

system was handed over Read this manual before operating the system for the first time,

paying particular attention to the safety information Sections marked by a symbol are of

special importance

Your laser system was tested at the factory However, risks are present in the case of

incorrect operation or misuse:

risk of fatal injury to operators, third-parties and animals in the vicinity of the laser system

risk of damage to the laser system and other property damage of the proprietor and third-

parties

for the efficient operation of the laser system

1.1.2 Obligations of the proprietor

The proprietor is obliged to ensure personnel working on the laser system:

are familiar with the basic regulations on safety and accident prevention and who have

received instruction on operating the laser system

has read the operating manual, the chapter on safety and the warning symbols, has

understood them and confirmed this with their signature

The proprietor is accountable for selecting operating personnel During selection, he or she

must pay attention to the suitability of personnel for using the laser system

The laser system operator must observe and maintain the following regulations:

the appropriate accident prevention laws

company laws on laser systems

the functional limits and safety regulations stipulated in the technical manuals

Vitrolux H

V2

Safety

Stand 5/12

Page 9 of 57

The proprietor must instruct users regularly (at least once a year) on the dangers of laser

radiation

Warning

The proprietor is finally accountable for safety

This responsibility cannot be delegated to others

1.1.3 Obligations of operating personnel

All persons involved in operating the laser system are obliged:

to constantly ensure the safety of the laser system and third-parties

to read the operating instructions, the chapter on safety and the warning symbols, and to

confirm they have understood it by applying their signature

operate the laser system only when they are familiar with the laser system functionality,

its safety and emergency equipment and are in full control of it

Operating personnel must devote their full attention to working with the laser system

Warning

This not only concerns your safety but also that of colleagues and others in the

vicinity of the laser system!

Vitrolux H

V2

Safety

Stand 5/12

Page 10 of 57

1.2 Liability

Principally, our »General Terms of Business« apply Claims under the terms of warranty and

liability in the case of personal injury or property damage are excluded when they are the

result of one or more of the following causes:

Non-intended use of the laser system

Unauthorized assembly, starting up, operation and maintenance of the laser system

Operation of the laser system with defect safety equipment or when safety or protection

equipment is incorrectly mounted or not functional

Failure to observe the information in the documentation in respect of laser system

operation, maintenance, upkeep and fault location

Unauthorized constructional modifications on the laser system

Insufficient monitoring of parts subject to wear

Improperly completed repairs

Catastrophes caused by foreign bodies and Acts of God

Note

The manufacturer only assumes the full terms of warranty for spare parts ordered

from him

Caution

No modifications, refitting or reconstruction may be made on the laser system

without authorization from the manufacturer All reconstruction work requires

written approval from Vitro Laser Solutions UG

Caution

Only use original spare parts and parts subject to wear It cannot be guaranteed

that parts obtained from other sources have been constructed and produced

according to the applicable load and safety requirements

Vitrolux H

V2

Safety

Stand 5/12

Page 11 of 57

1.3 Accident prevention regulations

1.3.1 General information

Before starting the equipment up for the first time following assembly (new installation or

assembly after transport), a safety check must be made All the load-bearing and machine

parts must be checked that they are in perfect condition

Check that the laser system is operationally safe before starting up each day! Apart from the

information in the operating manual, the generally applicable and any local safety and

accident prevention regulations must also be observed

The warning and information labels attached provide important information on safe operation

Observe this information in the interest of third-parties as well as your own

Any faults which occur that affect safety must be cleared immediately

Damaged parts must be replaced immediately The laser system may not be operated again

until the fault has been cleared

All mentioned directions are viewed from the operating side

Direction of rotation is defined as follows:

Turn right = clockwise

Turn left = anticlockwise

The turning of screws, nuts, etc , is always viewed from the operating side

1.3.2 Laser system

The laser system can be delivered as Laser Class 1 (with cover and doors) or as Laser Class

4 (as shown on front page of this manual)

The system complies to Laser Class 1 under normal working conditions with cover and doors

fully closed

The laser system may only be operated under the following conditions in Normal mode:

The housind and doors are fully closed (Laser Class 1)

All persons located in the same room as the system wear safety-glasses (Laser Class 4)

The laser head, scan head and laser beam path to it’s intended outlet at the lens are fully

closed

The operating personnel has been instructed and has read and understood the operating

manual

The fiber optics are not damaged

Warning

The laser may only set to production mode when the protective guards and cover

flaps are closed, the laser head and scan head are closed and the laser beam

path is covered The optical waveguide must not be damaged Risk of accident

Warning

If the beam guide is not mounted, the laser beam escapes at the side of the laser

head

Risk of accident

Vitrolux H

V2

Safety

Stand 5/12

Page 12 of 57

Caution

Do not open the laser head, scan head and diode module Particles can enter

and damage the high performance optics Opening these components annuls

rights to claims under the terms of warranty

In Maintenance, Set-up and Repair modes (the laser beam can be accessed) the Vitrolux C

laser system complies to Laser Class 4

The laser system may only be operated in Maintenance, Set-up

and Repair modes under the following conditions:

1 The proprietor must contract a specialist for laser protection in writing

2 The operator has submitted the requirements for operating laser equipment

complying to Laser Class 4 to the relevant localauthority department prior to

commissioning the

3 The laser zone is clearly identified and the entrance to the laser zone is equipped

with a warning lamp

4 The operator and all those in the laser zone must wear protective goggles which

provide protection from direct, specular reflected or diffuse radiated laser beams It is

recommended to wear protective gloves

Warning

Prevent the possibility of unauthorized persons accessing the laser zone

Risk of accident!

Warning

If the beam guide is not mounted, the laser beam escapes at the side

of the laser head Risk of accident

Note

The order numbers for appropriate protective goggles is provided

in Chapter 8 Special Equipment

Danger from laser beams

The laser beams radiated by the Vitrolux laser system are (in)visible They can cause severe

damage to the eyes and cause skin burns

Diffuse leakage radiation or reflected radiation can also be dangerous

Warning

Never expose yourself to direct or reflected laser beams

Never look directly into the laser beams Risk of injury

Vitrolux H

V2

Safety

Stand 5/12

Page 13 of 57

Warning

While the material is being processed, aggressive UV radiation is

generated Risk of injury

Warning

Remove all objects from the laser zone which could put you or others

at risk through uncontrolled reflection Risk of injury

Warning

The viewing window of the sliding door must not be in a damaged

condition Risk of accident through escaping laser beams

Laser beams can increase the risk of fire and explosion Remove all flammable

and easily combustible gases, liquids and substances from the laser zone

Warning

The laser system must not be operated in environments in which there is a

risk of fire or explosion Risk of accident

When processing metals or plastics, poisonous gases or dusts can be produced

Note

The rating plate and information in Chapter 7 Technical Data provides

specifications on the maximum laser power, pulse energy, pulse duration and

wavelengths

1.3.3 Protective measures from the operator

The laser system door is equipped with protective switches which are part of a protection

circuit The laser beam is switched off when a protective switch is opened

Warning

Never bridge or manipulate protective switches that has the consequence

that the warranty expires Risk of accident

In addition to these constructional protective measures for the laser system, Vitro Laser

Solutions UG also recommends equipping the entrance doors to the laser zone with such

switches

Keep all unauthorized persons away from the laser zone

This can be archieved by installing self-closing doors which can only be opened using a key

or similar protective equipment

Vitrolux H

V2

Safety

Stand 5/12

Page 14 of 57

1.3.4 Assembly and disassembly

Only personnel involved with the assembly and disassembly work may be in the vicinity of

the laser system during assembly and disassembly Others (e g spectators) must be kept

outside the laser zone

Ensure the load-bearing capacity of the ground is sufficient

During assembly and disassembly work, also ensure the stability of the laser system and its

components

Following assembly, check all the parts are properly connected and that all connection

cables and lines are correctly attached When the cable and line layout is on the floor, ensure

it is done in a way to minimize the risks of tripping

Before starting the laser system, the personnel responsible for switching it on must be sure

that the system is in perfect condition by carrying out the prescribed checks and controlling

sample production!

1.3.5 Transport and assembly

Only transport the Vitolux E / F in a standing position Observe the transport and storage

information provided on the laser system packing material

Caution

Transport the laser system carefully without the packing Avoid vibrations

and the use of force The cooling water must be drained off Risk of damage

Before transporting the laser system, pack the components carefully (e g applicable sea

freight cases, drying agents) The following transport systems are permitted:

Rail

Ship

Truck with pneumatic suspension

Fork-lift truck (for transporting the laser system and components on pallets)

The base must have a load-bearing capacity of at least 300 kg/m²

²

The laser system may only be installed in locations which:

are not exposed to extreme vapors from oils, solvents or cleaning agents

are free of dust

are not potentially explosive

are clean

are not subject to vibration

1.3.6 Storage

The laser system must be kept dry and in an upright position when stored

Vitrolux H

V2

Safety

Stand 5/12

Page 15 of 57

1.3.7 Maintenance and repair

Carry out all the prescribed maintenance work according to the maintenance schedules

Disconnect the power supply before beginning any maintenance or repair work (switch the

main switch in the to OFF and unplug the mains connector)

If maintenance work must be carried out with the system in operation, the operating panel

must be supervised by an additional person Damaged parts must be replaced immediately

by perfect, original parts

Check the functionality of all the safety equipment after completing maintenance and repair

work Handle and dispose of materials and substances used properly, particularly lubricants

and solvents

1.3.8 Safety when out of service

Secure the laser system against unauthorized activation during periods out of service (e g

by inserting a padlock in the main switch)

Ensure that children have no access to the laser system Never allow children to play on or in

the laser system

1.3.9 lectrics

A voltage up to 5 kV is required to generate laser pulses

Parts conducting high voltage are electrically insulated

Warning

Never remove or damage the insulation Never touch electrically conductive

parts Never access parts conducting high voltage Risk of fatal injury

The following parts conduct such high voltage:

Q-switch laser connections in the laser head,

High voltage power lines in the laser power supply,

Connection lines between laser head and laser power supply

Other system components (e g control, scanner, power supply) have a 230 V power supply

Warning

Never touch parts conducting voltage Risk of fatal injury

Work on the power supply system and control may only be carried out by a suitably trained

electrician Observe locally applicable safety regulations when working on equipment

conducting mains power or high voltage

Always disconnect the power supply before starting work on the electrical System!

Do not simply rely on the fact that the power supply is disconnected, check for yourself by

taking the necessary measurements

Vitrolux H

V2

Safety

Stand 5/12

Page 16 of 57

When plugs are disconnected, keep them dry

Always keep the doors closed (protect from damp and dirt)

Check the laser system’s electrical equipment regularly Tighten loose connections and

replace damaged or scorched cable

1.3.11 Other points of danger

There are other points of danger on or around the laser system which are not immediately

obvious Safety information on these areas is provided below

High performance laser diodes (HP laser diodes)

The control unit is equipped with HP laser diodes They serve to excite the laser in the laser

head The beam emitted from the HP laser diodes has a wavelength of 800 to 850 nm and is

not normally accessible to the user

Warning

Damaged or loose cable between the laser head and laser power supply unit can

cause laser beams to escape from the HP laser diodes Risk of accident

If the connection between the laser head and laser power supply unit is damaged (e g the

optical waveguides in the spiral protection hose are broken), the laser system must be shut

down immediately and a specialist contacted

UV radiation

When processing material using a laser, UV radiation may occur which could damage the

eyes and skin

Warning

Never operate the laser with the protective equipment open door Risk of

accident

Warning

Protective laser goggles do not protect against UV radiation

Risk of accident

If operation with open protective equipment is necessary for maintenance, set-up or repair

work, the user and others in the laser area must wear special protection goggles

Pilot-laser

The pilot laser complies to Laser Class 2 requirements and protects the eyes through the

natural eyelid reflex (visible light)

Warning

Never look directly into the pilot laser beam using optical instruments

Risk of accident

The pilot laser represents no risk to the skin

Vitrolux H

V2

Safety

Stand 5/12

Page 17 of 57

Risk of crushing

The laser system is equipped with strong motor drives to position the working table There is

a risk of crushing limbs within the movement range of the laser head

Warning

Never operate the laser with the protective equipment open (access flaps)

Risk of accident

If operation with open protective equipment is necessary for maintenance, set-up or repair

work, the user must be particularly careful

Warning

During operation with the protective equipment open, hands or other limbs must

not be held within the area of movement of the motor axes Risk of accident

Workpieces

Too high workpieces can damage the optics, control the height of scanner head When

processing mirror glass watch the spezial instructions

Caution

When processing mirror glass, the optics in the scan head (lens, mirror) can be

damaged by reflection Put the mirror glass into a little diagonal position before

you begin to laser

1.4 Intended use

The laser system is intended exclusively for processing material (inner engraving) The laser

operates as a source of a beam for the processing system Only appropriate materials may

be processed

Any other use is considered unintended use The company Vitro Laser Solutions UG is not

considered liable for any damage resulting from unintended use

The following are also considered part of the intended use:

observation of all information provided in the operating manual and manufacturer’s

documents supplied, and

maintaining all the maintenance and servicing conditions and intervals stipulated by the

manufacturer

Observe all the applicable accident prevention regulations and other generally accepted

safety and health protection regulations

Vitrolux H

V2

Safety

Stand 5/12

Page 18 of 57

1.5 Operation

Warning

In the case of functional faults, operation must be stopped immediately!

The cause of functional faults must be located immediately If necessary, operating

personnel must calling experts Operation may only be restarted when there is absolutely no

doubt about the safety of the laser system

Operation may be resumed when the operating personnel is convinced that the maintenance

work has been properly completed (as described in this manual)

If it becomes apparent during operation that the necessary maintenance measures have not

been performed, operation must be shut down immediately

1.6 Information labels and rating plates

Caution

Real safety infer that you are familiar with all the safety information and

regulations This relates to the type and location of the specific dangers and,

particularly, to the safety measures necessary Always be alert and remain

conscious of the danger(s) involved

This laser system is equipped with information labels and rating plates Keep the information

on the labels and plates on the laser system in a legible condition

Caution

Always observe the information, instructions and operating values provided on

the labels and rating plates

Rating plates

The following components have rating plates:

Control unit / Axles control unit / laser system with serial number

Note

Always refer to the laser system’s serial number in the case of queries, orders

and contracts This simplifies communication with the manufacturer and helps

prevent errors when processing your inquiries

Vitrolux H

V2

Safety

Stand 5/12

Page 19 of 57

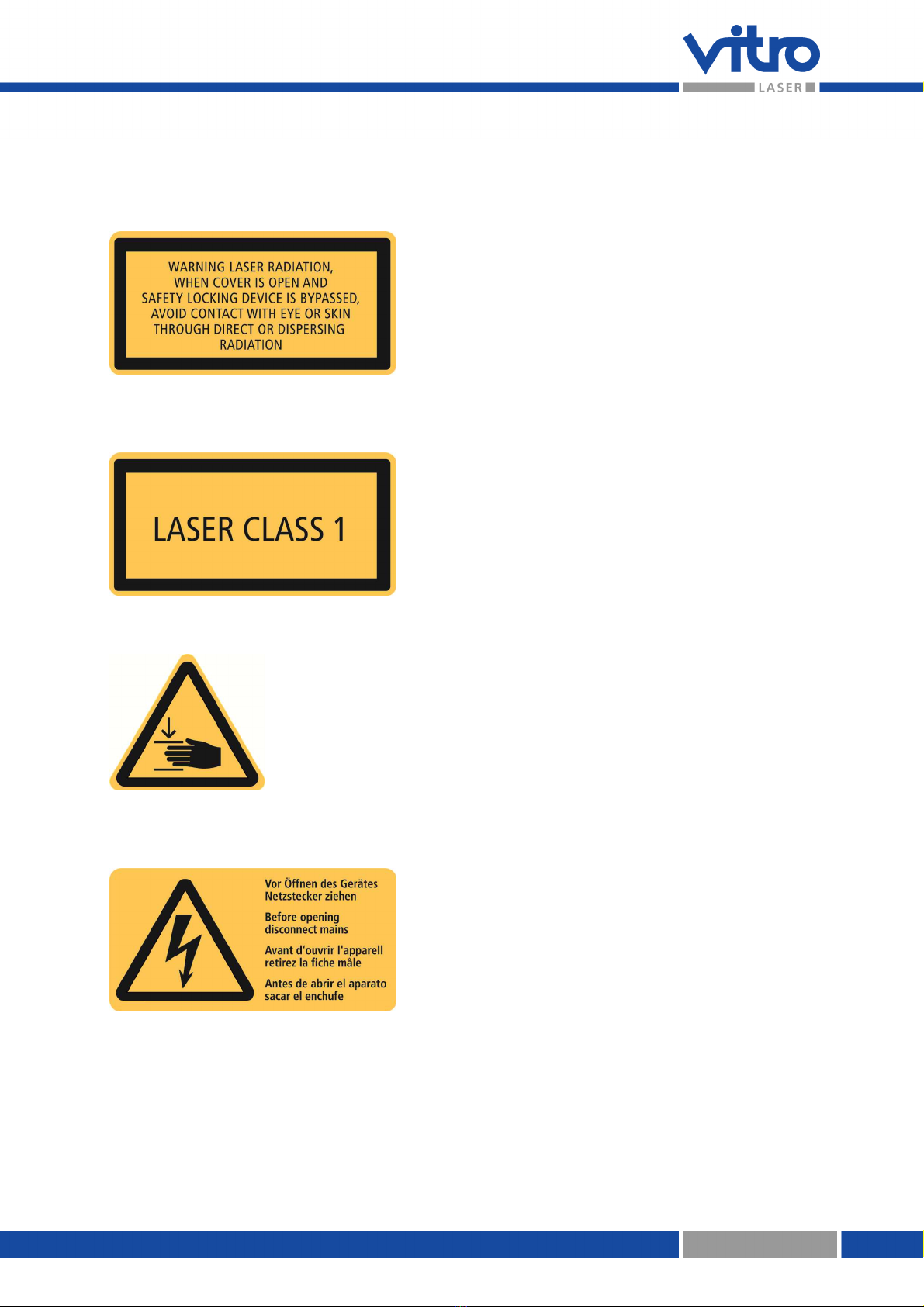

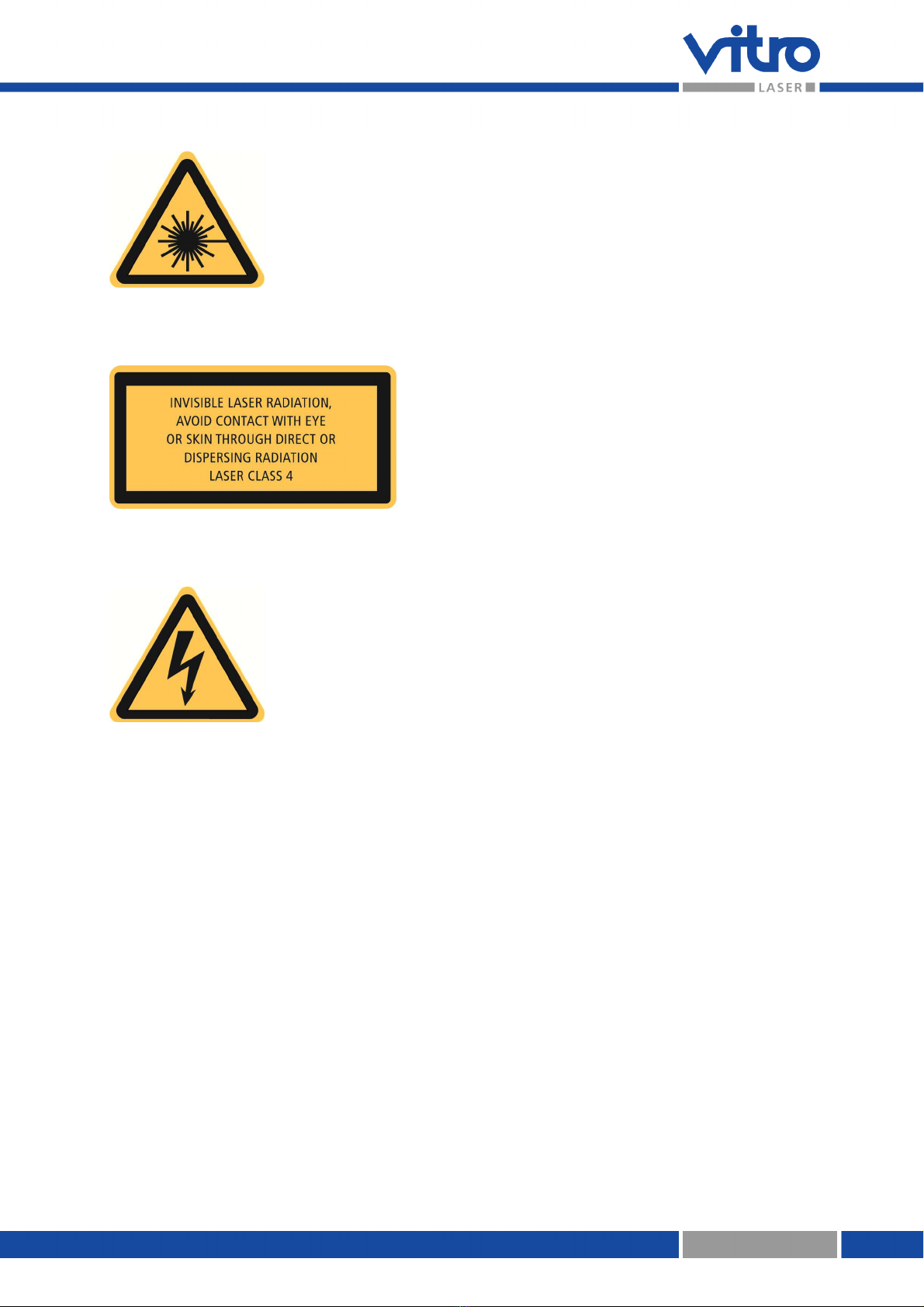

Warning labels

Different warning labels are provided for example at the following points:

Examples of warning labels

(1) laser irradiation with open cover / bridged safety loc

(2) laser class specification of entire system

(3) Warning at points with risk of crushing

(4) Warning at points with a general risk of electric shock

Vitrolux H

V2

Safety

Stand 5/12

Page 20 of 57

(5) Warning - dangerous laser irradiation

(6) Warning laser irradiation with Laser Class 4 (laser diode, laser head)

(7) Warning at points with a general risk of electric shock

Table of contents

Other vitro Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual