Vivax Metrotech vLoc3-DM Instruction Manual

vLoc3-DM (Defect Mapper)

User Handbook

(English Edition)

Version 1.0

P/N: 4.04.000171

Who Can Use This Equipment

•This equipment must only be used by people suitably trained in the use of pipe and

cable locators.

Work-site Safety

•Use your company’s, or other applicable safety codes and rules when using this

equipment.

•Unless having the required authorization, license and appropriate training – do not

make connections to any pipe, cable or conductor.

•The equipment should not come in contact with corrosive or hazardous chemicals,

or gases or dust.

•Do not directly connect this equipment to cables or pipes that have a potential

difference to ground of greater than 25V AC.

Equipment Safety

•Do not open the enclosures (housings) of either the transmitter or receiver.

•Place the ground stake firmly in the ground before connecting the cable from the

transmitter.

•Do not hold any uninsulated portion of the connection leads & clips when the

transmitter is switched on.

Batteries and Environmental Safety

Vivax-Metrotech products use four types of batteries:

• Alkaline batteries

• Ni-MH (Nickel-Metal Hydride) batteries – rechargeable

• Lithium-Ion batteries – rechargeable

•Lithium-Metal batteries – (small non-rechargeable button cells for “clock”

applications)

1. Alkaline Batteries (Non-Rechargeable)

•When replacing the alkaline batteries – use only the size and type specified – do

not mix battery types (rechargeable and alkaline).

•Do not mix partially discharged and fully charged cells in the same battery pack –

do not mix old with new.

• Never attempt to charge alkaline batteries.

2. Nickel-Metal Hydride Batteries (Rechargeable)

•When using rechargeable batteries, use only the correct charging device supplied

or specified by the manufacturer. The battery pack or the battery charger will contain

circuitry to manage the charging process – other chargers (even if they have the

same connector, polarity, voltage & current rating will not have the same control

circuitry and can cause damage to the product, overheating, and in extreme cases

fire or harm to the individual.

•Do not assume that if the plug fits, it is the correct charger – a charger with the

correct part number must be used – just because it is a Vivax-Metrotech charger,

and the plug fits does not mean it is the correct charger.

•Before using for the first time, charge rechargeable batteries for six hours. If at any

time the rechargeable batteries do not last as long as anticipated – discharge fully

and then charge for six hours.

•Care should be taken when charging batteries – Never repeatedly recharge batteries

(or turn power off & on) without using the instrument. If used with an inverter in a

vehicle – charge the product then unplug the charger and do not charge again until

the rechargeable batteries have been used for at least ten minutes. Failure to do

this could result in the overcharging of the battery which will shorten the life of the

battery and could in some circumstances cause overheating or fire.

•If ever the product becomes hot during the charging process, immediately unplug

the charger and use the rechargeable batteries for at least ten minutes before

recharging. If this reoccurs the next time the unit is charged – return immediately to

Vivax-Metrotech for repair.

•Do not charge batteries for prolonged periods of time without using the locator for

at least ten minutes. Charging for prolonged period of time could overcharge the

battery, reduce the battery life and in extreme circumstances cause damage to the

locator and fire.

3. Lithium-Ion Batteries (Rechargeable)

•Lithium-Ion Batteries – some products use Lithium-Ion batteries – the requirements

for marking and transportation are still developing. Please contact Vivax-Metrotech

before shipping products containing Lithium-Ion batteries or Lithium-Ion battery

packs on their own for any “special instructions”.

4. Lithium-Metal Batteries (Non-Rechargeable)

•Commonly known as “button cells” these are small – non-rechargeable batteries

used to power internal “clocks” within some units (similar to computers). Generally,

they have a life of three to five years.

• Under no circumstances should any attempt be made to charge these batteries.

•Dispose of to your company’s work practice/environmental standards, the prevailing

laws, or recognized best practice. Always dispose of batteries responsibly.

5. General Rules regarding Disposal of Batteries

•Never disassemble a battery, or battery pack.

•Never dispose of in a fire or water.

•Dispose of batteries in accordance with your company’s work practice/environmental

standards, the prevailing laws, or recognized best practice. Always dispose of

batteries responsibly.

6. Transportation of Lithium-Ion and Lithium-Metal Batteries

•The Lithium-Ion and Lithium-Metal batteries used in Vivax-Metrotech products meet

the required safety standards and include the designated protection circuitry.

•Recent regulation changes require that when batteries with Lithium-Ion and Lithium-

Metal batteries are transported, the packaging must include specified warning

labels.

•Please contact Vivax-Metrotech Customer Service (USA 1-800-446-3392,

International +1-408-734-1400 (USA Pacific Time Zone)) for more details.

•Regulations have also changed regarding the shipping of spare battery packs

(battery packs that are not inside a product). There are limitations on the weight of the

package, and the packaging must be marked with the appropriate warning labels.

•Please contact Vivax-Metrotech Customer Service (USA 1-800-446-3392,

International +1-408-734-1400 (USA Pacific Time Zone)) for more details.

•Vivax-Metrotech vLoc Series 3 products using Lithium-Ion battery are classified as

“not restricted” they can be shipped normally by road/rail/sea & air (passenger &

freight aircraft) without restrictions.

IMPORTANT

Remember – Batteries contain dangerous chemicals –

They can be aected by many things such as water ingress

or heat – In some circumstances they can explode. They

also can cause electric shocks!

Care of Equipment

• Use equipment only as directed in this User Handbook.

•Do not immerse any part of this equipment in water.

• Store in a dry place.

• Keep equipment in the case provided when not in use.

• If left for prolonged period of time – remove alkaline batteries.

• Keep unit clean and free of dust and dirt.

• Protect against excessive heat.

Care when Interpreting the Information provided by the Locator

•Like all locators – this instrument is locating and providing depth and current

readings based on electromagnetic signals that radiate from the buried cable or

pipe. In most cases these signals will enable the locator to pinpoint both position

depth and current correctly.

•Beware – in some cases other factors will distort electromagnetic fields radiating

from cable or pipe being located, resulting in incorrect information.

•Always locate responsibly and use information learned during your training to

interpret the information provided by the locator.

•Do not provide information regarding depth of cable or pipe to anyone unless

authorized to do so by your company.

•Remember that depth measurements are to the center of the electromagnetic field or

pipe – In the case of pipes this may be significantly deeper than the top of the pipe.

American & Canadian Safety Notices

USA

•This transmitter and receiver comply with the general conditions of operation,

pursuant to part 15 of the FCC Rules.

οCFR 47 Part 2

οCFR 47 Part 15

•Changes or modifications not expressly approved by the manufacturer could void

the user’s authority to operate the products.

CANADA

•Equipment is for use by trained operators only, and not for general household or

consumer use.

•Operation is subject to the following two conditions: (1) this device may not cause

interference, and (2) this device must accept any interference that may cause

undesired operation of the device.

EUROPE

•Vivax-Metrotech confirms that the location system is compliant with relevant

provision of European directive 1999/5/EC.

οEN 55011

οEN 61000-4-2: A1 & A2

οEN 61000-4-3

οEN 61000-4-8: A1

οETSI EN 300 330-2

οETSI EN 301 489-1

οETSI EN 301 489-3

General Safety & Care Information

™

Table of Content

1. Service & Support..................................................................................................................................................................... 1

1.1 Serial Number and Software Revision Number .............................................................................................................. 1

1.2 Distributors and Service Centers Closest to You: ........................................................................................................... 2

2. Introduction ............................................................................................................................................................................... 3

2.1 About this Manual............................................................................................................................................................ 3

2.2 Overview of vLoc3-DM System....................................................................................................................................... 3

2.3 Planning a Survey........................................................................................................................................................... 3

3. Loc-150Tx, 150Watt Transmitter Functions and Operations .................................................................................................... 5

3.1 Transmitter Overview ...................................................................................................................................................... 5

3.2 Display ............................................................................................................................................................................ 6

3.3 Power Supplies and Connections ................................................................................................................................... 6

3.4 Connecting to the Pipeline .............................................................................................................................................. 6

3.4.1 Connecting at a CP (Cathodic Protection) Station.............................................................................................. 6

3.4.2 Connecting to the Pipe when there is No Access to a CP Station...................................................................... 8

3.5 Selecting the Correct Frequency..................................................................................................................................... 8

3.6 Output Current Select ..................................................................................................................................................... 9

3.7 Alarms ............................................................................................................................................................................. 9

3.7.1 Over Voltage ....................................................................................................................................................... 9

3.7.2 Over Temperature ............................................................................................................................................... 9

3.7.3 Overpower .......................................................................................................................................................... 9

4. vLoc3-DM Receiver Functions and Operations ...................................................................................................................... 10

4.1 Receiver Overview........................................................................................................................................................ 10

4.2 DM Low-Frequency Sensor Foot .................................................................................................................................. 10

4.2.1 Removing the DM Low-frequency Sensor foot ..................................................................................................11

4.3 Charging the Receiver Batteries ....................................................................................................................................11

4.4 vLoc3-DM Receiver Main Display (Locate Screen) ...................................................................................................... 13

4.5 Pushbuttons .................................................................................................................................................................. 13

4.6 User Menu..................................................................................................................................................................... 14

4.7 Self-Test ........................................................................................................................................................................ 18

4.8 Warnings ....................................................................................................................................................................... 18

4.8.1 DM current warning........................................................................................................................................... 19

4.8.2 Signal Overload ................................................................................................................................................ 19

4.8.3 Shallow Cable .................................................................................................................................................. 19

4.8.4 Swing Alert........................................................................................................................................................ 19

4.8.5 Overhead cable ................................................................................................................................................ 19

4.9 Locate Modes................................................................................................................................................................ 19

4.10 Classic Locating Modes (Response) .......................................................................................................................... 20

4.10.1 Peak Response Mode ........................................................................................................................... 20

4.10.2 Broad Peak Mode ................................................................................................................................. 20

4.10.3 Null Mode ............................................................................................................................................... 20

4.10.4 Delta Null ............................................................................................................................................... 20

4.10.5 Peak with Arrows Response Mode ....................................................................................................... 21

4.10.6 Omni Peak Response Mode .................................................................................................................. 21

5. Using the vLoc3-DM Receiver ................................................................................................................................................ 25

5.1 Locating a Pipeline........................................................................................................................................................ 25

5.2 Pinpointing .................................................................................................................................................................... 25

5.3 Taking Depth and Current Readings (Information Screen) ........................................................................................... 26

5.4 Storing the Results........................................................................................................................................................ 27

™

5.5 Clearing the log............................................................................................................................................................. 27

5.6 Graphing results on the screen..................................................................................................................................... 27

5.7 The Walk-back feature .................................................................................................................................................. 28

5.8 Signal Direction Precision Identication........................................................................................................................ 29

5.9 Using the A-frame Fault Finder .................................................................................................................................... 31

5.9.1 Fault Finding Method ........................................................................................................................................ 32

5.9.2 Using the A-frame where there are Many Defects Such as Porous Coating .................................................... 33

6. Using External GPS................................................................................................................................................................ 35

6.1 Compatible GPS and GPS Data Loggers ..................................................................................................................... 35

6.2 Bluetooth....................................................................................................................................................................... 35

6.2.1 Fitting the Bluetooth Module ............................................................................................................................. 35

6.3 Pairing with external GPS/Dataloggers......................................................................................................................... 35

6.4 Transferring Data from the Locator to a Computer ....................................................................................................... 36

6.4.1 MyLocator3 ....................................................................................................................................................... 36

6.4.2 MyLocator3’s Basic Operation.......................................................................................................................... 36

6.4.2.1 Updates Page .................................................................................................................................... 37

6.4.2.2 Application Update............................................................................................................................. 37

6.4.2.3 Locator Firmware update................................................................................................................... 37

6.4.3 Toolbar .............................................................................................................................................................. 37

6.4.4 Data Logging .................................................................................................................................................... 38

6.4.5 Splash Screen................................................................................................................................................... 39

6.4.6 Frequencies Page............................................................................................................................................. 39

6.4.7 Menu Settings................................................................................................................................................... 40

6.4.8 Advanced Features........................................................................................................................................... 40

6.4.8.1 Supervisor Lockouts .......................................................................................................................... 40

7. Interpreting Results................................................................................................................................................................. 41

7.1 Introduction ................................................................................................................................................................... 41

7.2 Sources of Error............................................................................................................................................................ 41

7.2.1 Operator Error................................................................................................................................................... 41

7.2.2 Interference (Distorted Fields) .......................................................................................................................... 41

7.2.2.1 Source of Interference (Distorted Fields)........................................................................................... 41

7.2.2.2 Checking for Distorted Fields............................................................................................................. 42

7.3 Viewing Data ................................................................................................................................................................. 43

7.3.1 Viewing. xls Files .............................................................................................................................................. 43

7.3.2 Viewing .kml Files ............................................................................................................................................. 44

7.4 Interpreting Graphs ....................................................................................................................................................... 44

8. Care and Maintenance............................................................................................................................................................ 46

8.1 Cleaning........................................................................................................................................................................ 46

8.2 Checking Functionality.................................................................................................................................................. 46

9. Glossary.................................................................................................................................................................................. 47

™

Page 1 of 47

1 Service & Support

1. Service & Support

1.1 Serial Number and Software Revision Number

Always quote your receiver or transmitter model, serial number, and software revision number when requesting product support.

They can be found as follows:

1

1

1 Model & Serial Number

NOTE

The software revision number, for both receiver and transmitter, is displayed on the LCD during the

startup sequence or can be found in the “About” section of the user menus.

™

Page 2 of 47

1 Service & Support

1.2 Distributors and Service Centers Closest to You:

Worldwide Sales Offices and Service Centers

World Headquarters, United States of America

Canada

Vivax-Metrotech Corporation

3251 Olcott Street,

Santa Clara, CA 95054, USA

Website : www.vivax-metrotech.com

Sales & Sales Support:

T/Free : 800-446-3392

Tel : +1-408-734-1400

Fax : +1-408-734-1415

Service & Repairs:

T/Free : 800-638-7682

Tel : +1-408-962-9990

Fax : +1-408-734-1799

Vivax Canada Inc.

41 Courtland Ave Unit 8,

Vaughan, ON L4K 3T3, Canada

Tel : +1-289-846-3010

Fax : +1-905-752-0214

Website : www.vivax-metrotech.com

Ventas para América Latina

3251 Olcott Street,

Santa Clara, CA 95054, USA

T/Free : 800-446-3392

Tel : +1-408-734-1400

Fax : +1-408-743-5597

Website : www.vivax-metrotech.com

Central/South America and the Caribbean

Vivax-Metrotech SAS

Technoparc ‐1 allée du Moulin Berger,

69130 Ecully, France

Tel : +33(0)4 72 53 03 03

Fax : +33(0)4 72 53 03 13

Website : www.vivax-metrotech.fr

Vivax-Metrotech Ltd.

Unit 1, B/C Polden Business Centre,

Bristol Road, Bridgwater,

Somerset, TA6 4AW, UK

Tel : +44(0)1793 822679

Website : www.vivax-metrotech.com

Email : [email protected]

Vivax-Metrotech AUS

Unit 1, 176 South Creek Road,

Cromer NSW 2099, Australia

Tel : +61-2-9972-9244

Fax : +61-2-9972-9433

Website : www.vivax-metrotechaus.com

Leidi Utility Supply (Shanghai) Ltd.

No. 780, Tianshan Rd,

Shanghai, China 200051

T/Free : 4008-206-719

Tel : +86-21-5235-3001

Fax : +86-21-5235-8365

Website : www.leidi.cn

France

Germany

United Kingdom

ChinaAustralasia

International Distributors and Service Centers

Metrotech Vertriebs GmbH

Am steinernen Kreuz 10a

D-96110 Schesslitz

Tel : +49 954 277 227 43

Website : www.vivax-metrotech.de

™

Page 3 of 47

2 Introduction

2. Introduction

2.1 About this Manual

This handbook assumes some understanding of Cathodic Protection techniques, It covers the operation of the Loc-150Tx

transmitter and the vLoc3-DM receiver.

2.2 Overview of vLoc3-DM System

The vLoc3-DM (Defect Mapper) has been designed to:

• identify the position of coating defects

• identify shorts to other structures

• help categorize the faults

• help plan and prioritize remedial work

• operate as a long line pipeline locator

The vLoc3-DM uses the latest locating and signal processing techniques to plot the current gradient of an industry-standard low

frequency (3Hz or 4Hz) proling current. The current is typically applied at CP stations so the disruption of the pipeline can be

minimized.

The Loc-150Tx, 150W transmitter (DM transmitter), is used to apply a signal current to the anode bed. The pipeline returns

the signal via coating faults back to the transmitter. The transmitter is designed to be powered from CP (Cathodic Protection)

stations, AC or external batteries, eliminating the need for internal batteries.

The non-intrusive measuring device, the vLoc3-DM receiver, takes measurements along the pipeline and plots the results

directly onto the screen of the receiver. There is no need to carry extra logging and display devices. All the data is displayed and

logged into the receiver and can be downloaded to a spreadsheet or dedicated analysis program.

An internal +/- 3m accuracy GPS antenna is included with the system. Alternatively, a Bluetooth enabled GPS device can be

linked to the vLoc3-DM receiver via Bluetooth radio link. The GPS enables the user to generate real-time current gradient

graphs and guides the user back to the point of interest by highlighting the user’s position on the graph. This feature is called the

“walk back” feature. The system can also be integrated with other high accuracy GPS systems and software packages.

Storing the results also has the benet of facilitating the technique of comparative tests. Comparing the results from previous

surveys of the same length of the pipe allows the Cathodic Protection engineer to establish trends of coating deterioration.

The A-frame fault-nding accessory is used to accurately locate the position of a fault. An arrow points the user to the position

of the fault whilst quickly and eciently graphing the characteristic shape and magnitude of the fault signal on the receiver's

display. This ensures the user minimizes the chances of misidentication.

The A-frame is also used to undertake full ACVG surveys along a pipeline route. Results are stored with GPS data and real-time

graphs generated on the vLoc3-DM screen.

Setting the vLoc3-DM to simultaneous mode allows the user to simultaneously take ACVG and current proles during just one

survey of the pipeline.

2.3 Planning a Survey

Surveys will vary greatly depending on the type of terrain, accessibility, condition of the pipeline, type of pipeline and coating

type.

The rst step of undertaking any survey should be to obtain information about the stretch of the pipeline to be surveyed. More

work at this stage may well save time and eort later. Obtaining maps showing route information, CP stations, sacricial anodes

and cross bonding points will be of great help.

™

Page 4 of 47

2 Introduction

The transmitter should be capable of transmitting from one CP station to another, so although not absolutely necessary, plan

to have the previous and after CP stations disconnected from the stretch of the pipeline to be surveyed. Remember that the

pipeline is not protected whilst the survey is being undertaken, so unnecessary downtime of CP stations should be avoided.

Choose the survey interval to match the condition of the pipeline. In areas where the coating is particularly poor, a survey

interval of as little as 10m may be desirable. However, if the coating is in very good condition and the distance between CP

stations is many km, it may be better to choose a survey interval of as much as 200m. Taking measurements at large intervals

will enable the surveyor to quickly asses the condition of the pipeline and subsequently identify areas that require further

inspection at closer survey intervals or detailed analyses using the A-frame Fault Finder accessory.

WARNING

Parts of the pipeline may be crossing road junctions and may even follow the route of roads.

Obtaining accurate results from the vLoc3-DM requires full concentration from the operator. It is,

therefore, essential that correct traffic management is undertaken at these points to avoid poor

results or injury to the operator. Safety should always be the first concern.

™

Page 5 of 47

3 Loc-150Tx, 150Watt Transmitter Functions and Operations

3. Loc-150Tx, 150Watt Transmitter Functions and

Operations

3.1 Transmitter Overview

3

4 5

1

21Loc-150Tx Transmitter

2AC power cord

*one of supplied based on geographical location

3 Ground stake

4Signal Output Cable,

with clamps & Signal Output Connector

5 DC power cord

2

1

3 4

Ref. Control Function

1 Power To power on/o the unit

2 LCD Display View menu status and information from the transmitter

3 Output Current/Active-Standby - Rotate rotary switch to select output current

- Press and hold to power on or standby

4 Frequency/Status - Rotate rotary switch to select a frequency

- Press momentarily to view status (refer to status screen in the section below)

™

Page 6 of 47

3 Loc-150Tx, 150Watt Transmitter Functions and Operations

3.2 Display

2.35 A

ELF3-4Hz/8Hz/98Hz

3000 mA

VOLTAGE LIMIT!

POWER LIMIT!

ELF3-4Hz/8Hz/98Hz

P:

I OUT: 2339 2339 mA

DC: 30 V

PWR IN: 165 W

V OUT: 33 V

3000 mA 0

855 935 85

Main Screen Status Screen

NOTE

Power Limit = The Overpower alarm will be shown on the display when the output power rating of the

transmitter is reached. (150W or 50W if 12-28Vdc input is used.)

Voltage Limit = The output voltage limit is 100V. If the current cannot be stabilized with a voltage less

than 100V, it will display an overvoltage alarm.

3.3 Power Supplies and Connections

1

234

5

1 Mains Input

2 Mains Input Fuse (5A, 250V)

3 12 - 60V DC Input

4 Output Fuse (10A, 250V)

5 Output Socket

3.4 Connecting to the Pipeline

3.4.1 Connecting at a CP (Cathodic Protection) Station

WARNING

Connecting to the CP station involves removing connections from the CP transformer rectifier and

should only be performed by authorized personnel. Always make connections before switching on the

unit. Switch off before disconnecting the transmitter.

Method:

1. Make a note of the CP settings (output current and voltage settings). This is important as the settings must be checked to

ensure they return to the original settings when the connections are re-made.

2. Switch o the CP transformer rectier and allow the residual voltage to dissipate. This may be a few seconds or a few

minutes, depending on the pipe condition.

™

Page 7 of 47

3 Loc-150Tx, 150Watt Transmitter Functions and Operations

CP

Station

-Ve +Ve

Mains Socket

DC Output

To Anode Bed

Standard CP

Station Connections

3. Disconnect the output wires connecting the CP station to the pipeline and anode bed. If there is an earthed mains socket at

the station, connect the transmitter mains power lead to the socket.

CP

Station

-Ve +Ve

Mains

Socket

Mains

Input

Disconnect Leads

from CP station

To Anode Bed

Red

Black

Making connections to CP

station using DC output as

a power source

4. If there is no mains socket, it is possible to use the DC output of the transformer rectier. See the diagram below.

CP

Station

-Ve +Ve

Disconnect leads

from CP station

Red

Black

To Anode Bed

Black

Red

12-60V DC

input socket

Making connections to CP

station using DC output as

a power source

5. Adjust the transformer output to approximately 40V DC (although the unit will function from 12V DC to 60V DC) and use the

DC input lead to connect the transmitter to the transformer terminals.

™

Page 8 of 47

3 Loc-150Tx, 150Watt Transmitter Functions and Operations

6. With the output lead connected to the transmitter, connect the red wire to the lead connecting to the pipeline. Connect the

Black wire to the lead connecting to the anode bed. See the diagram above.

NOTE

If the output leads are white and green, the white cable should be connected to the pipe.

3.4.2 Connecting to the Pipe when there is No Access to a CP Station

Sacricial Anode

Very often the cable connecting a sacricial anode to a pipe is fed through an above-ground connection box. If this is the case

the anode can be disconnected, and these cables used to connect the transmitter to the pipe. The Red connection lead needs to

be connected to the pipe side and the black to the sacricial anode.

It will be necessary to power the transmitter either from a portable 110V AC mains generator or from a vehicle car battery or

external 12V DC power source.

NOTE

It may not be possible to attain high current from the transmitter, as a sacrificial anode will not

provide as good a ground as a system anode bed.

Connecting at a Point where Access to the Pipe is Possible

It is possible to connect the transmitter at any point along the pipe length where an electrical connection is possible. If this

is the case, a good independent ground will need to be generated by driving a ground stake into the ground a few meters

perpendicular to the pipe. The ground needs to be low impedance, so the copper ground rod needs to be at least 0.5 meters

long. In some cases, multiple stakes may be necessary.

A poor ground will result in the transmitter showing the overvoltage alarm even at low currents. If this occurs, add further ground

rods connected in parallel and dampen the surrounding soil.

WARNING

Use a cable locator to ensure the area is clear of services before the rod is driven into the ground.

3.5 Selecting the Correct Frequency

The available frequency options are:

• 98Hz

• 128Hz

• 512Hz

• 640Hz

• ELF1-3Hz/6Hz/98Hz

• ELF2-3Hz/6Hz/128Hz

• ELF3-4Hz/8Hz/98Hz

• ELF4-4Hz/8Hz/128Hz

• SD EUR (640/320Hz)

• SD USA (512/256Hz)

Note that some frequencies may be missing depending on age and software revision of the transmitter. Vivax-Metrotech reserve

the right to change this frequency list without notication.

3Hz/6Hz/98Hz or 3Hz/6Hz/128Hz are the most commonly used frequencies. They provide the low-frequency 3Hz component

required for current mapping and a low frequency (98Hz or 128Hz depending on local mains frequencies) used to pinpoint the

position and is used to determine the pipe depth. The 6 or 8Hz enables the locator to calculate the DM current direction.

The other frequency options can be used to improve reception in areas of high interference.

SD signals are explained in the section: Signal Direction Precision Identication

™

Page 9 of 47

3 Loc-150Tx, 150Watt Transmitter Functions and Operations

3.6 Output Current Select

There are seven current settings:

• 100mA

• 300mA

• 600mA

• 1A

• 2A

• 3A

• 4A (when a single locate frequency is selected)

Choosing the correct setting for a particular application depends on many factors, but as a general rule, the higher the setting

the better. The higher the current the more stable the readings at long distance and larger currents create larger current changes

at faults. However, it will not always be possible or desirable to apply the maximum current.

With the transmitter connected as above, select the 3A position. Wait to see if any alarms are displayed, such as over-voltage,

overpower, over-temperature. If after 20 seconds, no alarms are shown, note the return current reading. This should be 3A+/-

0.1A. Now note the output voltage. This should be less than 100V. The transmitter stabilizes the output current by altering the

output voltage. The output voltage limit is 100V. If the current cannot be stabilized with a voltage less than 100V, it will display

an overvoltage alarm. The transmitter is not damaged if this is displayed but the output will not be stabilized. To overcome this,

select a lower current setting.

Other causes of overvoltage alarms are:

1. Pipeline in very good condition (Small high impedance faults will require higher voltages to achieve the requested current).

2. Poor anode bed -poor anode beds will require a high voltage drop across them to create the requested current.

3. Poor pipe connections.

3.7 Alarms

3.7.1 Over Voltage

Output exceeds 100V. (also see Output Current Select)

3.7.2 Over Temperature

The over-temperature alarm will show on the display when the temperature of the output amplier exceeds a predetermined

level. At this temperature, the unit will shut down and cannot be switched on until the unit has cooled down.

After the unit has been cooled down, it may be necessary to place the unit in a position where the ambient temperature is less

such as a shaded position. Alternatively, select a lower current output.

3.7.3 Overpower

The Over Power alarm will be shown on the display when the output power rating of the transmitter is reached. The unit will shut

down until the output power is reduced.

This can be doing either:

1. Reduce the output current setting.

2. Improve the ground and pipe connections. (this may be the case where the ground used is not an anode bed. For instance,

where a ground rod is used because access to a CP station is not possible.)

™

Page 10 of 47

4 vLoc3-DM Receiver Functions and Operations

4. vLoc3-DM Receiver Functions and Operations

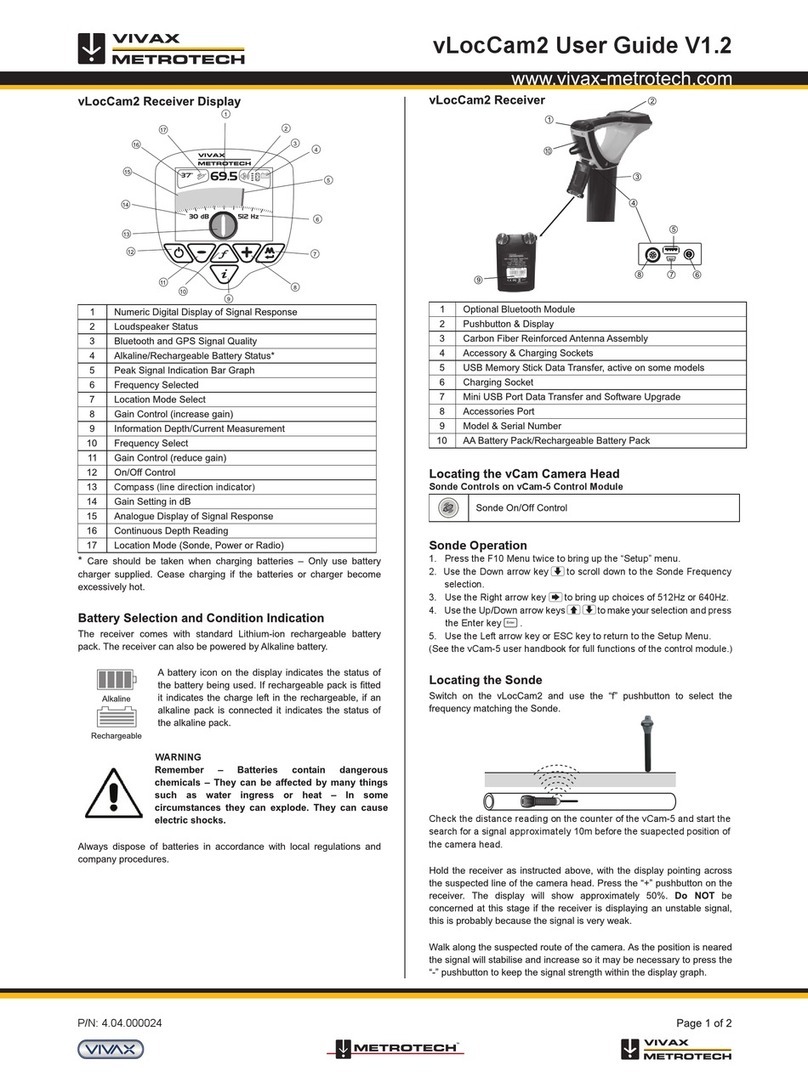

4.1 Receiver Overview

1

2

3

4 5 6 8 9 10 117

1vLoc3-DM Receiver

(with DM Foot attached)

2 Mini-USB cable

3 Li-ion battery

4 Charger

5AA Alkaline batteries

6 Alkaline battery holder

7Power cable for charger

*one of supplied based on geographical location

8 vLoc3-DM Foot

9 Receiver Blanking Plate

10 User manual

11 Soft carry bag

1

2

3

4

5

6

7

8

9

10

11

1 Pushbutton keypad and display 7 Accessory socket and charging point

2 Model number & serial number

8Expansion sockets for additional features such as the

Bluetooth module

3 Battery retaining cover

4 AA Alkaline battery pack/rechargeable battery pack 9 Receiver stem

5 Mini-USB port for data transfer and software updates 10 Sensor retaining screw

6 Battery compartment cover 11 Low-frequency sensor

4.2 DM Low-Frequency Sensor Foot

The device at the bottom of the locator tube is the DM low-frequency sensor foot. This device is used to detect the low-

frequency component (frequencies between 3Hz and 8Hz). These are the vLoc3-DM current mapping frequencies. When the

low-frequency mapping is not required, for instance, if the equipment is being used for pipeline locating but not defect mapping,

the DM foot can be removed.

™

Page 11 of 47

4 vLoc3-DM Receiver Functions and Operations

Removing the DM sensor foot will help reduce the weight of the locator and also change the way the logging is done. The

logged frequency will then be the locate frequency selected, and graphing will also use this frequency.

4.2.1 Removing the DM Low-frequency Sensor foot

Rotate the retaining screw on the bottom of the receiver stem counter-clockwise for ¼ turn.

Grasp Low-frequency sensor and rotate it counterclockwise until it releases.

Now t the blanking plate supplied by following the above instructions in reverse order.

IMPORTANT

Always install the blanking plate when the low-frequency sensor foot is not attached. There are critical

contacts within the antenna tube that require protection. Not doing so will void the warranty.

NOTE

When setting the retaining screw on the side of the antenna tube, hand tighten only.

4.3 Charging the Receiver Batteries

The vLoc3-DM can be used with either alkaline batteries or an interchangeable rechargeable battery pack.

The central illuminated section within the battery icon indicates the amount of charge remaining.

• Blue center indicates alkaline batteries

• Green center indicates rechargeable batteries

• When batteries are low, the remaining charge section becomes red and will flash

• Just before the shutdown, the following symbol will be shown:

Rechargeable batteries are supplied with a mains charger. This is specic to the batteries, avoid the use of other manufacturers’

chargers as these may damage the battery pack and may result in overheating of the battery pack.

To charge the rechargeable batteries, rst make sure the pack is inserted in the receiver battery compartment as charging is

done with the battery inside the receiver.

™

Page 12 of 47

4 vLoc3-DM Receiver Functions and Operations

Connect the charger to the charging/accessory socket of the receiver. Connect the charger to the mains and switch on. The LED

indicator on the charger will illuminate red until the batteries are fully charged, at which time the LED will change to green.

WARNING

Rechargeable batteries are supplied with a mains or 12V DC charger. These are specific to the

batteries. Only use the charger that is appropriate for the batteries in the product. If in doubt, call

the Vivax-Metrotech customer service department at +1(800) 446-3392. Failure to use the appropriate

charger could result in damage to the battery pack, locator, and in extreme cases, cause a re.

Avoid charging the unit in extreme temperature conditions, i.e., below 0ºC and above 45ºC.

Although Vivax-Metrotech batteries include all the required safety-related features, immediately

discontinue the use of the charger and battery pack if the battery pack becomes excessively warm.

Return both to where they were purchased for investigation.

Always ensure batteries have at least a partial charge if storing for long periods without use.

Dispose of all batteries in accordance with your company procedures and or Federal/State and local

regulations.

Never dismantle batteries, put them in a re, or get wet.

Status bar:

All the screens have a status bar at the top, which indicates various settings of the locator. The bar is shown below:

50.3

4

’

2

”

21 3 764 5

1Antenna configuration (meter response) described

later in the manual. 4

Bluetooth status: Grey indicates a module is not tted.

Black indicates tted but not active.

Blue indicates active and paired.

2This icon is shown in this position when the low-

frequency sensor is tted and active. 5 GPS status (Green indicates GPS signal lock).

3Depth to the target line. This can also be set to display

signal current online or both.

6 Speaker volume setting.

7 Battery type and remaining charge.

™

Page 13 of 47

4 vLoc3-DM Receiver Functions and Operations

4.4 vLoc3-DM Receiver Main Display (Locate Screen)

69.9

98Hz25dB

419mA

4

’

7

’’

575’8’’

1

2

3

4

5

6

7

8

9 10 11

1 Locate frequency

2 Left/Right locate arrows

3Distance from last recorded reading (requires

GPS option active)

4 Compass Line direction indicator

5 Left/Right arrows

6

Locate signal bar graph:

Green indicates low distortion, Blue indicates minor

distortion, and Red indicates excessive distortion.

7 Depth to the center of the pipe

8 Peak level indication

9Locate tone current (not to be confused with DM

current)

10 Numeric signal strength reading

11 Gain setting

4.5 Pushbuttons

Pushbuttons Locate Screen Measure Screen Graph screen

13.5

98Hz11dB

80.8mA

0.27m

0.00m

27.50m

0.19m

79o59’55.95961’’N

179o59’55.95961’’W

0.00m

425

506mA

4+8Hz

Log

7

1.09mA

345.05m

+37.03m

On/O On/O On/O

Change frequency, long press

shows frequency list Not active

Auto scale when this icon

is shown

Delete when this icon is

shown

Short press for measure and long

press for the user menu Jump back to Locate Screen Return to the locate screen

Increase gain Save and go to the graph Increase scaling

Decrease gain Reject and go to graph and long

press to delete log in memory Reduce scaling

Change antenna mode Save a record and return to Locate

Screen

Change scaling aspect (see next

chart)

™

Page 14 of 47

4 vLoc3-DM Receiver Functions and Operations

When in the graphing Mode/Screen the soft key operated by the key has the following functions as indicated by the

changing icon:

Softkey icon in Graph mode Function

Scales the horizontal axis

Scales the vertical axis

Allows the horizontal axis to be zoomed

Allows the vertical axis to be zoomed

This is the review mode. Use left/right soft keys to highlight a point of interest, as

indicated by the blue line.

Data is displayed on the left-hand side of the screen example:

Log

4

781mA

212.50m

+37.03m

Pressing the “f” key deletes the highlighted point.

Note, press the “i” button to return to the locate screen.

4.6 User Menu

The vLoc3-DM has several features that can be switched on and o. These features are accessed through the user menu.

Switch on the unit by pressing and holding the on/o key until the start-up screen appears. The start-up screen can be congured

to the user’s preference and is described later in the manual. Otherwise, the start-up screen will default to the one below:

Access to the User Menu is via the “i” button. Press and hold down the button until the menu appears.

Menu

About

Speaker Volume

Sound Configuration

Backlight

Frequency

DM Frequency

DM Current

Medium

3Hz + 6Hz

Live

Menu

DM Simultaneous Info

DM Current Warning

DM Pipe Diameter

Locate Perspective

Language

Imperial / Metric

Continuous Information

Disabled

Disabled

English

Meter

Off

Menu

Auto Power Off

GPS Source

Satellite Information

Buletooth Pairing

Diagnostics

Self Test

Regulatory Labels

Never

Internal

Menu

Auto Power Off

Warning

GPS Source

Satellite Information

Bluetooth Pairing

Self Test

New Survey

Never

Internal

Other manuals for vLoc3-DM

1

Table of contents

Other Vivax Metrotech Receiver manuals

Vivax Metrotech

Vivax Metrotech vLoc3-Pro Installation guide

Vivax Metrotech

Vivax Metrotech vLocCam2 User manual

Vivax Metrotech

Vivax Metrotech vLoc3-Pro Instruction Manual

Vivax Metrotech

Vivax Metrotech vLoc3 Series User manual

Vivax Metrotech

Vivax Metrotech vLoc3-Pro Instruction Manual

Vivax Metrotech

Vivax Metrotech vLoc3 Series User manual

Vivax Metrotech

Vivax Metrotech vLoc-5000 Instruction Manual

Vivax Metrotech

Vivax Metrotech vLoc3 Series Instruction Manual

Vivax Metrotech

Vivax Metrotech vLoc3 Series User manual