VIVI TT2020-Z2 User manual

ELECTRIC BICYCLE

User Manual

[ VIVI TT2020-Z2]

READ THIS MANUAL CAREFULLY BEFORE USE – FAILURE TO DO SO MAY RESULT IN INJURY, PROPERTY DAMAGE AND

MAY VOID WARRANTY. • KEEP THIS MANUAL FOR FUTURE REFERENCE. • Products covered by this manual may vary in

Made in ChinAfter-sale Email: service.viviebike@gmail.com a

Table of Contents

Safety.......................................................................................................................... 1

Parts assembly............................................................................................................ 2

Front Wheel................................................................................................................ 2

Handlebars..................................................................................................................4

Seat..............................................................................................................................5

Front ligh.....................................................................................................................6

Pedals.......................................................................................................................... 7

Operation....................................................................................................................7

Operation and use...................................................................................................... 9

Using Gears............................................................................................................... 11

Guidelines for Using Gears....................................................................................... 11

Using Brakes..............................................................................................................12

Guidelines for Using Brakes......................................................................................12

Batteries and Battery Charging................................................................................ 13

To charge the battery:.............................................................................................. 13

Removing the Battery Pack...................................................................................... 14

Maintenance.............................................................................................................15

Battery Storage.........................................................................................................16

Battery Fuse.............................................................................................................. 17

Tyre Pressures...........................................................................................................17

Chain Care.................................................................................................................17

Torque Settings.........................................................................................................17

Frequently Asked Questions.................................................................................... 18

Troubleshooting........................................................................................................18

Record Your VIVI bike Info........................................................................................21

Safety

Safety messages are designed to alert you to possible dangers or hazards that could cause death, injury or equipment or

property damage if not understood or followed.

You WILL be KILLED or SERIOUSLY INJURED if you do not follow instructions

It is vital that you read and understand this user manual before using the product, including safety warnings, and any

assembly and operating instructions. Keep the manual for future reference. Safety precautions and recommendations

detailed here must be fully understood and followed to reduce the risk of injury, fire, explosion, electrical hazard, and/or

property damage. Safety information presented here is generic in nature – some advice may not be applicable to every

product. The term "equipment" refers to the product, be it electrical mains powered, battery powered or combustion

engine powered.

Before Use - If you are not familiar with the safe operation/handling of the equipment or are in any way unsure of any

aspect of suitability or correct use for your application, you should complete training conducted by a person or

organization quafied in safe use and operation of this equipment, including fuel/electrical handling and safety.

Do NOT operate the equipment in flammable or explosive environments, such as in the presence of flammable liquids,

gases or dust. The equipment may create sparks or heat that may ignite flammable substances.

Keep clear of moving parts.

Equipment may be a potential source of electric shock or injury if misused.

Do NOT operate the equipment if it is damaged, malfunctioning or is in an excessively worn state.

Do NOT allow others to use the equipment unless they have read this manual and are adequately trained.

Keep packaging away from children - risk of suffocation ! Operators must use the equipment correctly. When using the

equipment, consider conditions and pay due care to persons and property.

General Personal Safety

Wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment to

help protect from eye and ear injury, poisoning, burns, cutting and crush injuries. Protective equipment such as safety

goggles, respirators, non-slip safety footwear, hard hat, hearing protection etc should be used for appropriate equipment

/ conditions. Other people nearby should also wear appropriate personal protective equipment. Do not wear loose

clothing or jewellery, which can be caught in moving parts. Keep hair and clothing away from the equipment.

Stay alert and use common sense when operating the equipment. Do not over-reach. Always maintain secure footing

and balance.

Do not use the equipment if tired or under the influence of drugs, alcohol or medication.

This equipment is not intended for use by persons with reduced physical, sensory or mental capabilities.

General Equipment Use and Care

The equipment is designed for domestic use only.

Handle the equipment safely and carefully.

Before use, inspect the equipment for misalignment or binding of moving parts, loose components, damage or any

other condition that may affect its operation. If damaged, have the equipment repaired by an authorised service centre

or technician before use.

Prevent unintentional starting of the equipment - ensure equipment and power switches are in the OFF position before

connecting or moving equipment. Do not carry equipment with hands or fingers touching any controls. Remove any tools

or other items that are not a part of the equipment from it before starting or switching on.

Do not force the equipment. Use the correct equipment for your application. Equipment will perform better and be

safer

when used within its design and usage parameters.

Use the equipment and accessories etc. in accordance with these instructions, considering working conditions and the

work to be performed. Using the equipment for operations different from those intended could result in hazardous

situations.

Always keep equipment components (engines, hoses, handles, controls, frames, housings, guards etc) and accessories

(cutting tools, nozzles, bits etc) properly maintained. Keep the equipment clean and, where applicable, properly

lubricated.

Store the equipment out of reach of children or untrained persons. Toavoid burns or fire hazards, let the equipment

cool completely before transporting or storing. Never place or store the equipment near flammable materials,

combustible gases or liquids etc.

The equipment is not weather-proof, and should not be stored in direct sunlight, at high ambient temperatures or

locations that are damp or humid.

Do not clean equipment with solvents, flammable liquids or harsh abrasives.

For specific equipment safety use and care, see Equipment Safety.

1

Parts assembly

Carefully place the bicycle assembly on a flat surface so that it rests on the front fork and rear wheel.

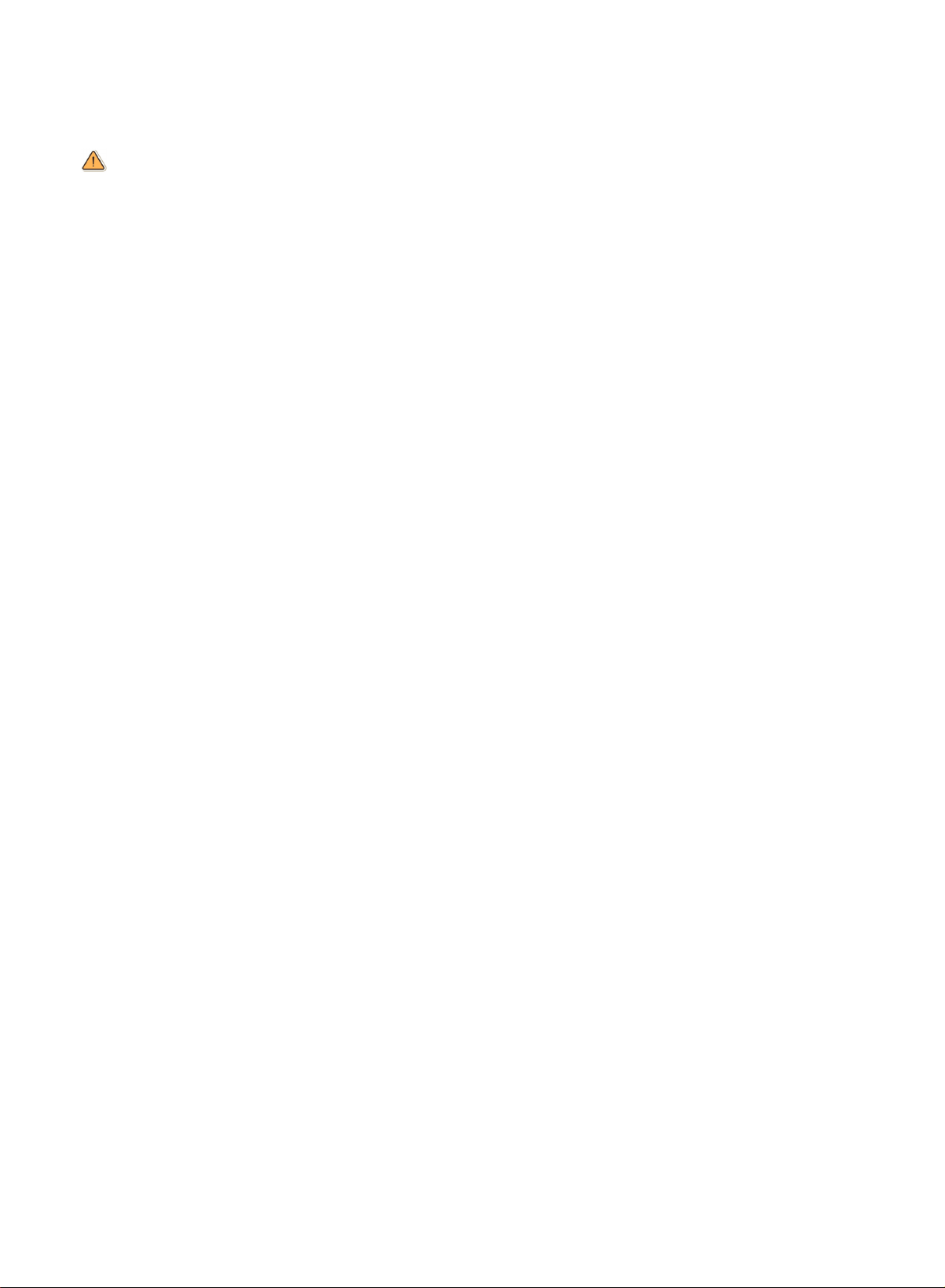

Front Wheel

1. Remove the front fork protector from the front fork. (Please note: front fork protector is used to prevent

the fork from being deformed during transport. It belongs to the packing material. You can throw awayit!)

2. Take out the front wheel fixed axis, according to the picture installed in a good direction: thick washer is on the

right side of the thin washer is on the left (disc brake) direction;First remove the left direction of the nut washer

gasket, etc., put the shaft through the front wheel hole, and then put the left direction of the nut washer gasket,

etc., back on the shaft

2

3. When the front wheel is mounted on the fork, the washer is on the inside, and a gasket is added on the

outside and a safety hook is added.

Thin gasket Thick gasket

Safety hook

Safety hook

3

4. Use your thumbto measure the distancebetween the tires on bothsides and the front fork. Hold the front hub

with your right hand and lock the left nut and then the right nut until both sidesare locked

Handlebars

1. Insert the "T" tube into the folding handle, which can be determined according to the height of

the individual, and finally lock the quick release handle,If it feels too loose or too tight, adjust the nut

on the other side of the handle.

2. Tighten the head screws with a "6"# hex wrench;

4

3. lock the quick release handle with the palm of your hand until it is completely locked, preferably

with the safety plastic latch (this is very important!!)

4.Release the handlebar quick release handle, turn the handlebar hand, adjust the brake handle to the

plane or Angle you want about 15-30 degrees, and finally lock the quick release handle with your palm

until the lock is tight.If it feels too loose or too tight, adjust the nut below.

Seat

comfortable, but also safe. You should be able to remain stable and properly handle the bicycle when at

and comfortably and safely operate the handlebars and all controls. A good reference height for the seat is

at hip height. Do NOT have the seat raised enough so you can see the maximum height marker on the

seat post. • Ensure that when the seat is clamped, you cannot rock it back and forth orrotate it.

1.Insert the seat post/seat assembly into the bicycle frame and adjust it to a comfortable position-do NOT

have the seat raised enough so you can see the maximum height marker on the seat post.

2.Rotate the clamp lever from the unlock position to the lock position.It the seat post is not clamped

firmly,increase pressure by unlocking the clamp,then rotating the adjustment knob right(clockwise) a¼turn,

then re-test and adjust as necessary.

The seat angle can also be adjusted, again for best comfort. To adjust angle, using a 13mm spanner, loosen

(rotate left) the seat clamp nuts (CC) on either side of the seat until the front of the seat can be moved

up/down. Set the angle as required, then tighten the5nuts securely

adjust nut

5

Note that small changes in seat position can have a substantial effect on comfort. It is

recommended to make seat adjustments in small increments and test the position, then re-

adjust as necessary.

Front light

1.Use the "5"# hexagon tool to loosen the screw on the front fork, then screw through the

headlight rack hole to lock the screw

6

Pedals

It is critical that you follow the pedal to crank arm attachment procedure carefully to ensure correct

assembly. During assembly, do NOT use excessive force to screw the pedals into the crank arms – this may

indicate misalignment of the pedals or mis-matched threads. If the pedal does not

"feel right" when being screwed in, STOP immediately and check that it is the correct pedal and that it is

aligned properly with the crank arm. Failure to follow the instructions here or take due care may damage

the equipment and void any product warranty.

1.Starting with the rigat-hand crank arm,identify the right-hand pedal assembly,which is idsntified by having

the pedal bolt stamped "R".

2.Very carefully begin screwing the pedal bolt into the crank arm (rotate right / clockwise). If the bolt does

not "feel right" when being screwed in, STOP immediately and check that it is the correct bolt and that it is

aligned properly with the crank arm . Screw the pedal bolt in fully,then tighten to the specified torque using a

15mm spanner and torque wrench.

3.Repeat the above procedure for the left-hand crank arm,noting that the pedal bolt and crank armthread

is left-hand(rotate left/anti-clockwise to tighten)and that the pedal bolt is stamped “L”.

Operation

Before riding, ensure that all required fasteners are tightened to the correct torque.

Charge the battery prior to use.

Ensure that the pedal assistance system is switched OFF when the bicycle is not in use.

Always wear a helmet and appropriate safety equipment and always keep both hands on the handlebars

and both feet on the pedals whilst riding. Read, understand and follow all safety recommendations before

riding.

Avoid riding in damp conditions, rain etc. as this may affect operation or possibly damage the bicycle

electronics.

7

8

Ⅱ.Product components

1、Saddle

2、Seat tube

3、Battery box

4、Brake lever

5、Valve

6、Mudguard

7、Controller box

8、Front Fork

9、Freewheel

10、Brake disc

11、Motor

12、Rear derailleur

13、Quick lock

14、Folding system

15、Chain

16、Chain wheel

17、Crank

18、Pedal

19、Handle bar

20、Quick lock

21、Stem

22、Headlight

1

2

3

4

5

6

6

7

8

9

10

11

13 14

14

15

16 17

18

19

20

21

22

12

Saddle

Brake lever

Freewheel

Rear derailleur

Front Fork

9

Operation and use

("pedal power") alone can be used. It is recommended to use pedal assistance when necessary, and not

rely on it solely. When using pedal assistance, also pedal for best efficiency.

The bicycle must be moving,or have enough pressure placed on the pedals (in a forward direction) to

activate pedal assistance.

If you apply the brakes when pedal assistance is active,the drive provided by the motor reduces in

proportion to how much braking pressure you appiy.

Once hebicycle reaches a sufficiently slow speed or stops completely,pedal assistance automatically

deactivates.

The bicycle pedal assistance system comprises an electric motor built into the rear wheel hub, a

battery pack with key security and charging port (on the other side of the battery pack),pedal assist

throttle,and display.

10

-2-

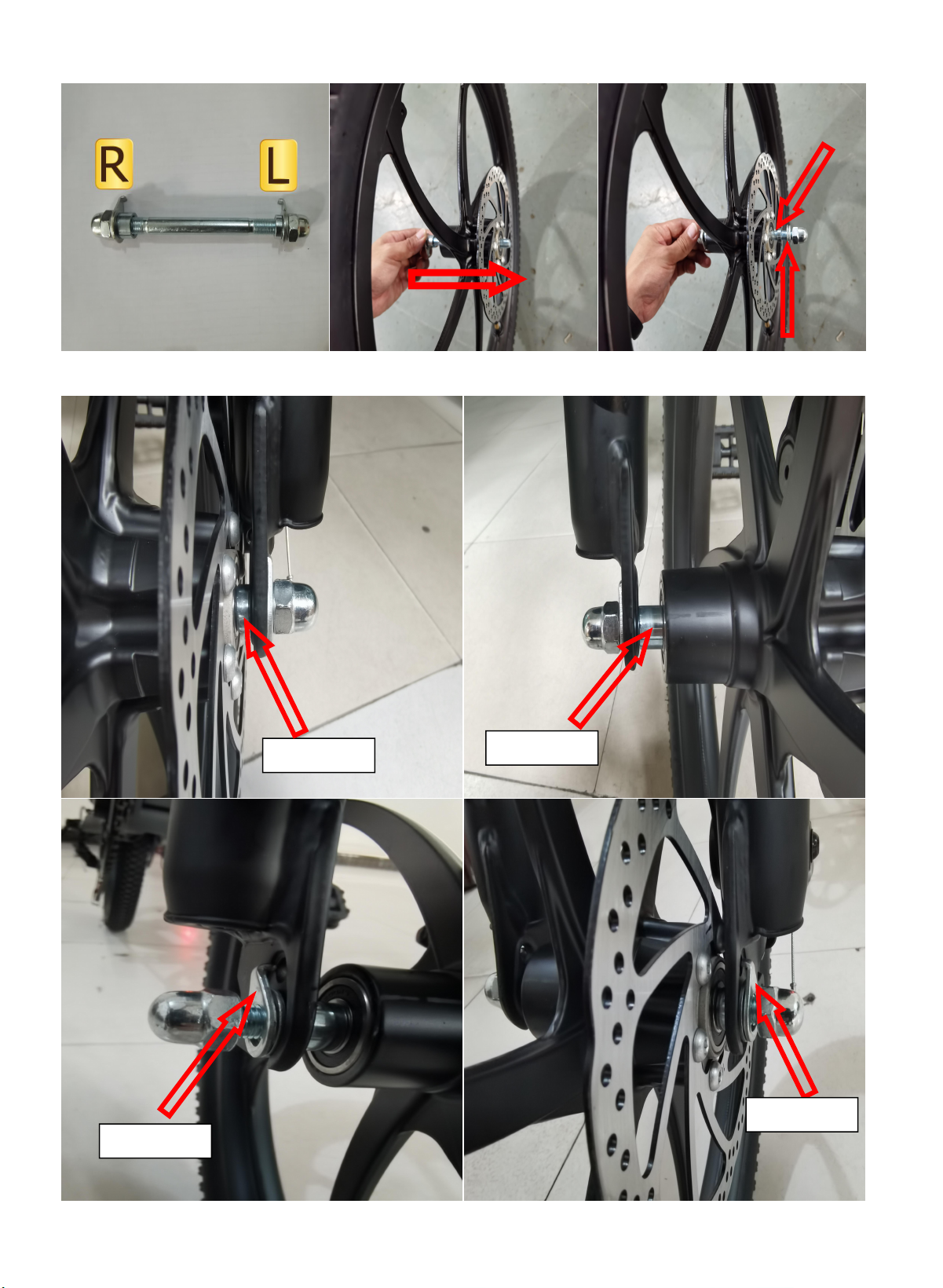

3.Meter operation

3.1

Meter instruction

3.2

Meter operation

a, Please kindly note that the key must be fully pushed in for the bolt,and

must stay in to operate the ebike (there are 3 key spots - unlock, lock, and

lock on where you operate the ebike).

b, In the pedal assist mode,you need to step on the pedal so that the bike will

be moved.

c, In the pure electric mode,you can turn the right handle (throttle) to start

moving the bike.

Operating instructions

①Pedal Assist

Mode-Low

To switch on/off

the E-Bike

system, hold the

M button for 2s.

The default

value is “low”

pedal assist

level.

②Pedal

Assist

Mode-Middle

Press “+” to

crease into

pedal assist

level “Mid”. - 2 -

③Pedal Assist

Mode-High

Press “+”

again to move

into pedal

assist level

“High”. “High”

is the

maximum

power of PAS.

④Pure

Electric Mode

Press”-“, until

first row

indicators are

off.Then low

power mode

directly

convert to

pure electric

mode.

11

Using Gears

Some model bicycles are equipped with gears. Gears are used to change the ratio between rotations of

the rear wheel and the crank set. This enables you to pedal less and travel faster on flat or downhill

sections, or pedal faster and travel slower to climb hills. Gearing is independent to pedal assistance, so

pedal assistance operates the same regardless of selected gear. Remember, however, that pedal

assistance is "governed" by overall speed.

The selectable gears are located on the rear wheel, known as a "gear cluster" or "cassette". The larger

the gear, the smaller number of rotations per rotation of the crank. The largest gear is the "lowest" and

is referred to as "1". As each gear becomes smaller, it is a "higher" gear then the previous and is

numbered sequentially. The number of gears may vary between different models. Beneath the gear

cluster is the derailleur mechanism, which moves the chain, so it runs on different gears. The derailleur

is operated by the rider using controls mounted on the handlebars. The gear change is "indexed" so

each gear selection positively engages – this is factory set and should require no adjustment. There may

be slight variations between bicycle models in method to change gear "up" (from a lower gear to a

higher gear), or to change gear "down" (from a higher gear to a lower gear).

The image shows a "6-speed" type that uses a button for changing up gears (push button to activate

derailleur), and a lever for changing down gears (rotate lever forward to activate derailleur)

Guidelines for Using Gears

To get the best performance and service life from the gear change system, understand and apply the

following techniques:

You MUST be pedalling during gear changes.

Do not attempt to change multiple gears in a single action.Allow each gear change to complete fully

before the next change.

Always use an appropriate gear for your speed, the terrain and incline. This helps you ride most

efficiently.

Keep the chain and gears properly lubricated and clean.

If you notice noise after changing gear or an ability to select a gear or the chain not running

smoothly,have the gear system inspected and adjusted by a b1ic2ycle mechanic or suitably qualified

person.

12

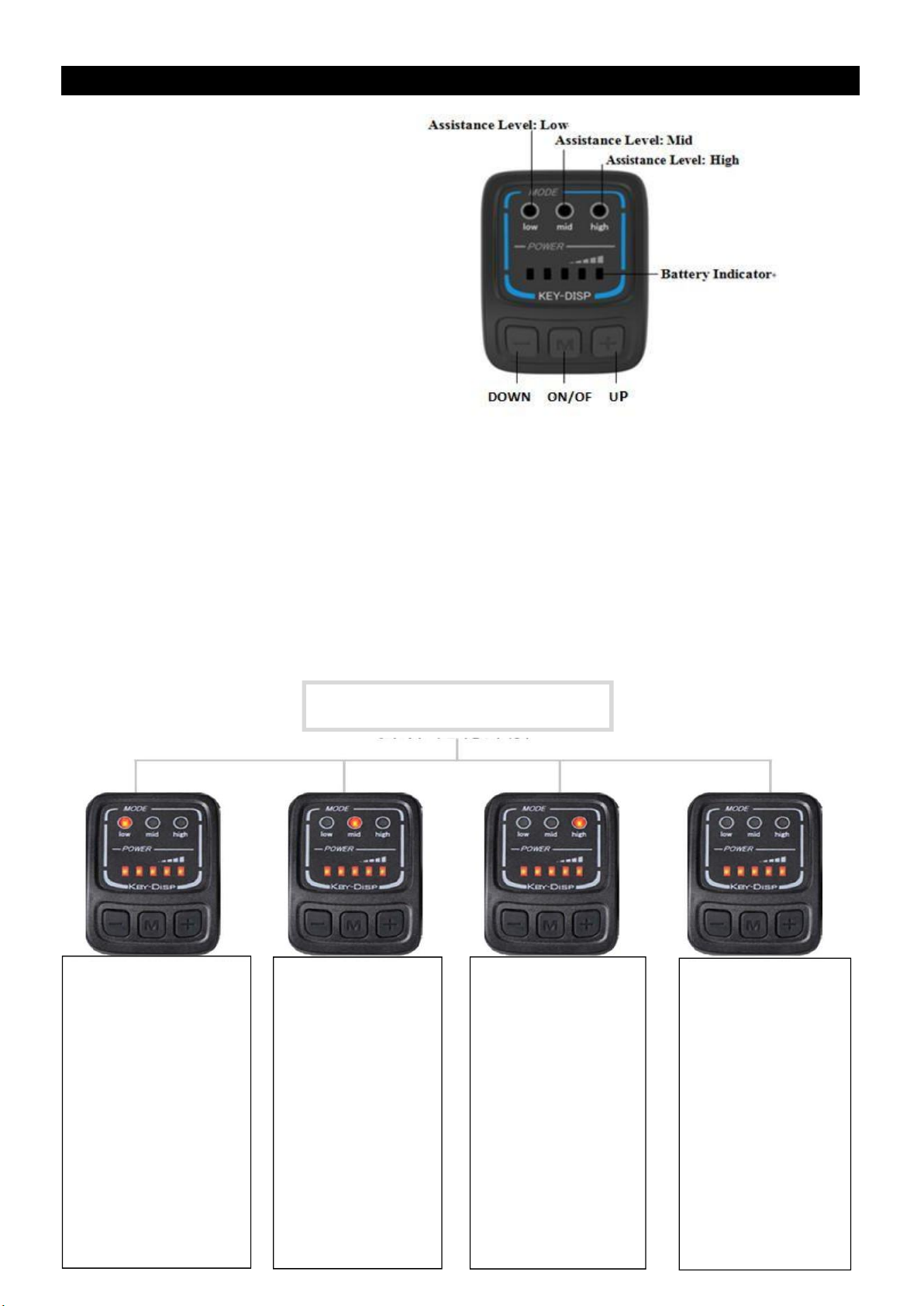

Using Brakes

All bicycle models are equipped with a front and rear wheel braking system. Brakes are used to slow the

bicycle down. The braking systems may use different mechanics; however,the functionality is the same,

and that is to change the energy of the moving bicycle into heat energy(“friction”):

For disc brakes, this means pads made from a special friction material pinching against a disc mounted to

the centre of the bicycle wheel.

The brakes are operated by the rider through levers mounted to the handlebars,The left-hand lever

operates the rear brake,the right-hand lever operates the front brake. The ability of the rider to adequately

slow and/or stop the bicycle depends largely on the skill of therider, the surface being ridden on and other

factors such as rain, tyres,adjustment and condition of the brake parts etc.

Guidelines for Using Brakes

To get the best performance and service life from the brake system, understand and apply the following

techniques:

In wet conditions, which reduces friction, always provide additional distance for braking and adjust

how quickly you apply the brakes.

When applying the brakes, particularly the front brake, use a lower pressure to start with until you

feel the brakes starting to “bite”, then increase pressure as required.Do NOT over-apply the brakes

and cause the wheel to stop rotating - this may result in loss of control.

Maintain the brake friction components (pads, shoes, rubbers) in good condition and replace when

they reach the wear limit.

Maintain brake adjustment so that the brakes perform effectively, the levers are comfortably

positioned, and there is not excessive play in adjustable components.

If the brakes are not performing effectively, making abnormal noise or any part is not serviceable or

cannot be adjusted correctly, have the brakes inspected and adjusted by a bicycle mechanic or

suitably qualified person.

If the brake cables become frayed or otherwise damaged, have them replaced by a bicycle mechanic

or suitable qualified person.

13

Batteries and Battery Charging

Never modify the electrical system. Alterations may cause a fire, resulting in serious injury and

could also damage the electrical system.

Charge with the supplied charger only. Use of the wrong charger may cause a fire or explosion,

resulting in serious injury.

Ensure the voltage and

frequency of the charger is compatible with mains electrical supply.

Use the battery charger in dry locations only.

The battery must be charged before first use.

For maximum battery performance and service life, charge the battery after each use, and charge at

temperatures between 0 and 40°C (32 and 104°F).

Battery charging generally takes 4 to 6 hours from discharged to fully charged. Do NOT charge the

battery continuously for more than 24 hours.

If the bicycle has not been used for over 4 weeks, charge the battery before use.

Always switch the bicycle OFF after each use.

The battery pack can be recharged repeatedly. However, rechargeable batteries eventually need to be

replaced. A significantly reduced operating period after charging indicates that the battery is no longer

serviceable and should be replaced. Discard old batteries in an environmentally responsible manner.

The battery charger has a charge status LED indicator:

Red - Battery charging.

Green - Battery fully charged.

To charge the battery:

1. Plug the charger connector into the charging port.

2. Connect the charger to a mains electrical supply and switch ON. The indicator LED on the charger

illuminates red to show the battery is charging.

3. When the battery is charged (approximately 6 hours), the charger indicator LED illuminates green.

Disconnect the charger from the electrical supply, then disconnect it from the bicycle. Lower the

battery pack handle to protect the bicycle chargingport.

14

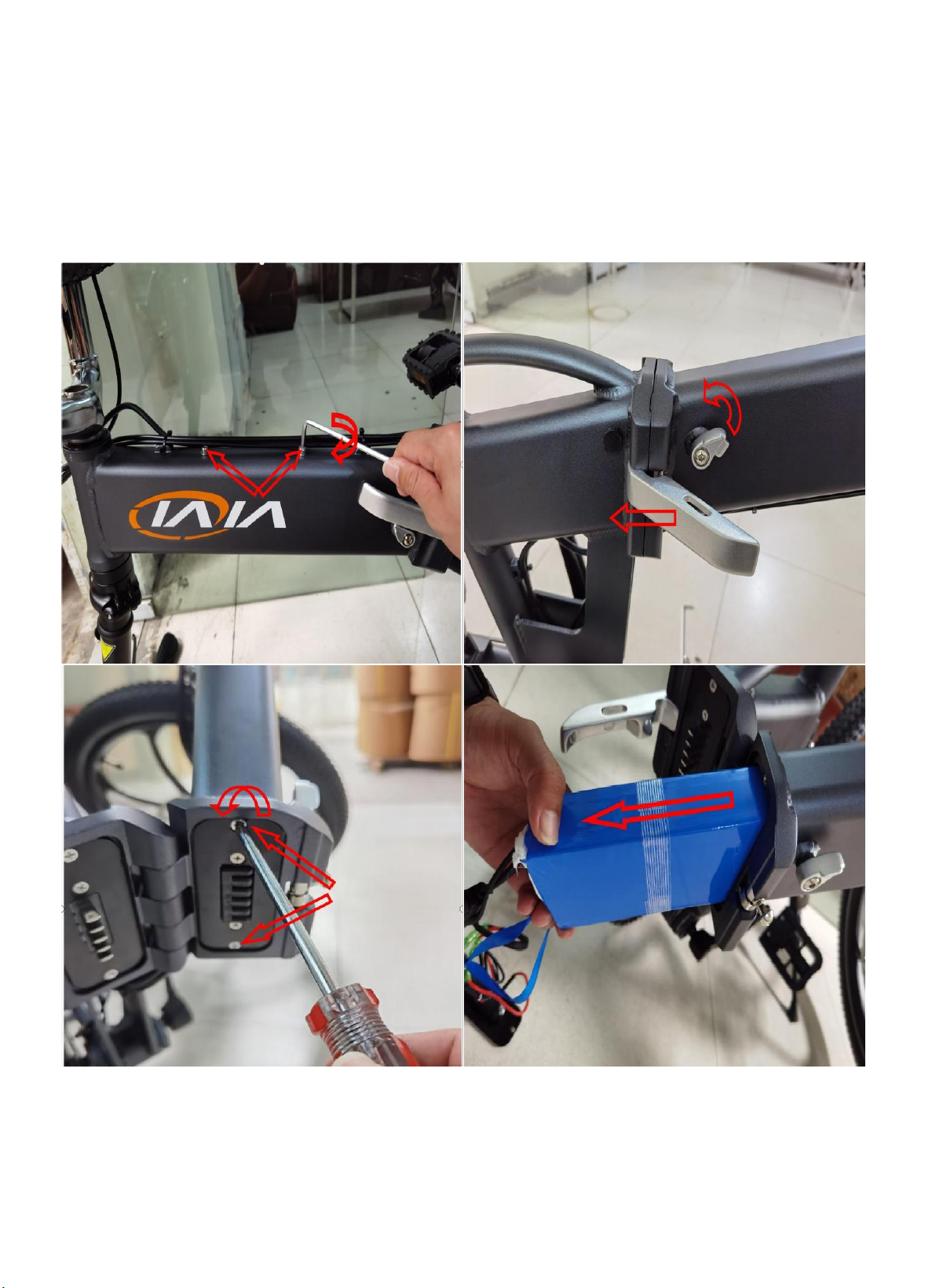

Removing the Battery Pack

Please first remove the two battery fixing screws under the car tube with the "4" # inner hexagon tool,

and then open the safety buckle and folding handle of the frame folding machine. After folding, you can

see the battery cover plate and remove the two screws with a Phillips screwdriver, and finally pull out

the battery.Install back to send steps in reverse order on the way.

15

Maintenance

Some maintenance activities described may be beyond the scope of some users. Do NOT attempt

procedures that you are not comfortable with, or do not have the necessary tools, experience or

knowledge for - take the unit to an authorised service centre or qualifed technician for servicing. Items in

the maintenance schedule below that are recommended to be performed by a qualified technician are

highlighted yellow.

Failure to follow the maintenance recommendations, using incorrect or non compatible accessories

or replacement parts, or general negligence may result in making the product warranty void.

Improper adjustment or service may result in damage to the bicycle or make it hazardous.

Maintenance requirements may be affected by any number of factors from your riding style to

geographic location.

When new, parts of the bicycle may "break-in" over the course of the first approximate 100km of

riding, possibly including the stretching of cables, spoke tension changes etc. It is recommended to

have the bicycle inspected and serviced at an authorised service centre or by a qualified technician.

The bicycle components are subject to wear and stress. If a component is weakened through stress,

age etc, it may fail without warning. It is important to regularly inspect the bicycle for any signs of

component fatigue - look for cracks, fraying, discoloration etc, as this may indicate that a part is near

the end of its useful life and should be replaced.

Clean the bicycle with a soft, damp cloth - do NOT use high pressure water cleaners or

hoses,pressurised air, solvents, abrasives etc. For the console, battery and motor, do NOT use any

liquids.

When transporting in a vehicle, it is recommended to have the battery out of the bicycle during

transport.

Store the bicycle where it will be protected from rain, sun etc to help prevent corrosion, fading etc..

For safety, longest possible service life and reliability, maintain the bicycle properly. Use the

components before each ride. The proper condition and function of these Systems is critical to your

maintenance schedule below for guidance. It is very important that you check certain systems and

safety.

16

Maintenance Schedule

Component / Condition Check Before

Every Ride

*Check

Periodically

Clean /

Lubricate

Adjust / Tighten /

Replace as Required

Tyre Pressure

Tyre Wear / Damage

Brake Adjustment

Handlebar Tightness

Controls and Display

Seat Post Tightness

Fasteners / Mounting Hardware

Brake Pads / Shoes

Brake Cable Wear

Chain

Reflectors

Battery / Charger

Steering Head Bearings

Derailleur

Wheel Spoke Tension

Wheel Trueness

Wheel Bearings

Bottom Bracket (Crank) Bearings

* Every 5 to 10 rides depending on ride length and conditions.

Battery Storage

When storing the batteries for a long period of time:

Charge the batteries at least every 30 days to avoid capacity loss. Batteries slowly self-discharge

when unused over a long period. If the battery cells are left at a critically low charge state, the

lifespan and capacity will be permanently reduced.

Always disconnect the charger from the mains electrical supply and battery before storing the

battery.

Avoid storing batteries in extreme temperatures, whether hot or cold. The recommended battery

storage temperature is between 0 and 25 ° C (32 to 77 ° F). Avoid exposing batteries to

temperatures at or above 40°C (104°F) for extended periods.

Batteries are best kept in a cool, dry place. Do not allow batteries to accumulate condensation,

as this may cause shorting or corrosion.

17

Battery Fuse

Use fuses of the same type only - the rating (in Amperes) is printed on the end of the fuse. . If the

fuse"blows" regularly, have the bicycle inspected at an authorised service centre.

The bicycle battery/ electrical system may feature fuse protection to prevent damage in the event of a

short circuit, overload or over current situation. For example, if the electrical system is exposed to

excessive moisture. On some model bicycles, the fuse is accessible and can be easily replaced. If the

fuse is "blown", the bicycle electronics will not be available until the fuse is replaced. To replace the

fuse:

1. Using a suitable screwdriver, remove (rotate left) the fuse holder on the battery pack until fully

unscrewed, then pull the fuse holder and fuse from the bicycle.

2. Discard the blown fuse. Insert the replacement fuse into the fuse holder.

3. Insert the fuse and fuse holder to the bicycle, and re install (rotate right) the fuse holder until fully.

Tyre Pressures

The tyres must always be inflated to the correct pressure (as specified on the tyre sidewall) before every

ride. Riding the bicycle with either too low or too high pressures will affect bicycle performance, may

affect effective electrical assistance range, and may render the bicycle as dangerous. Use an accurate

pressure gauge when checking pressures.

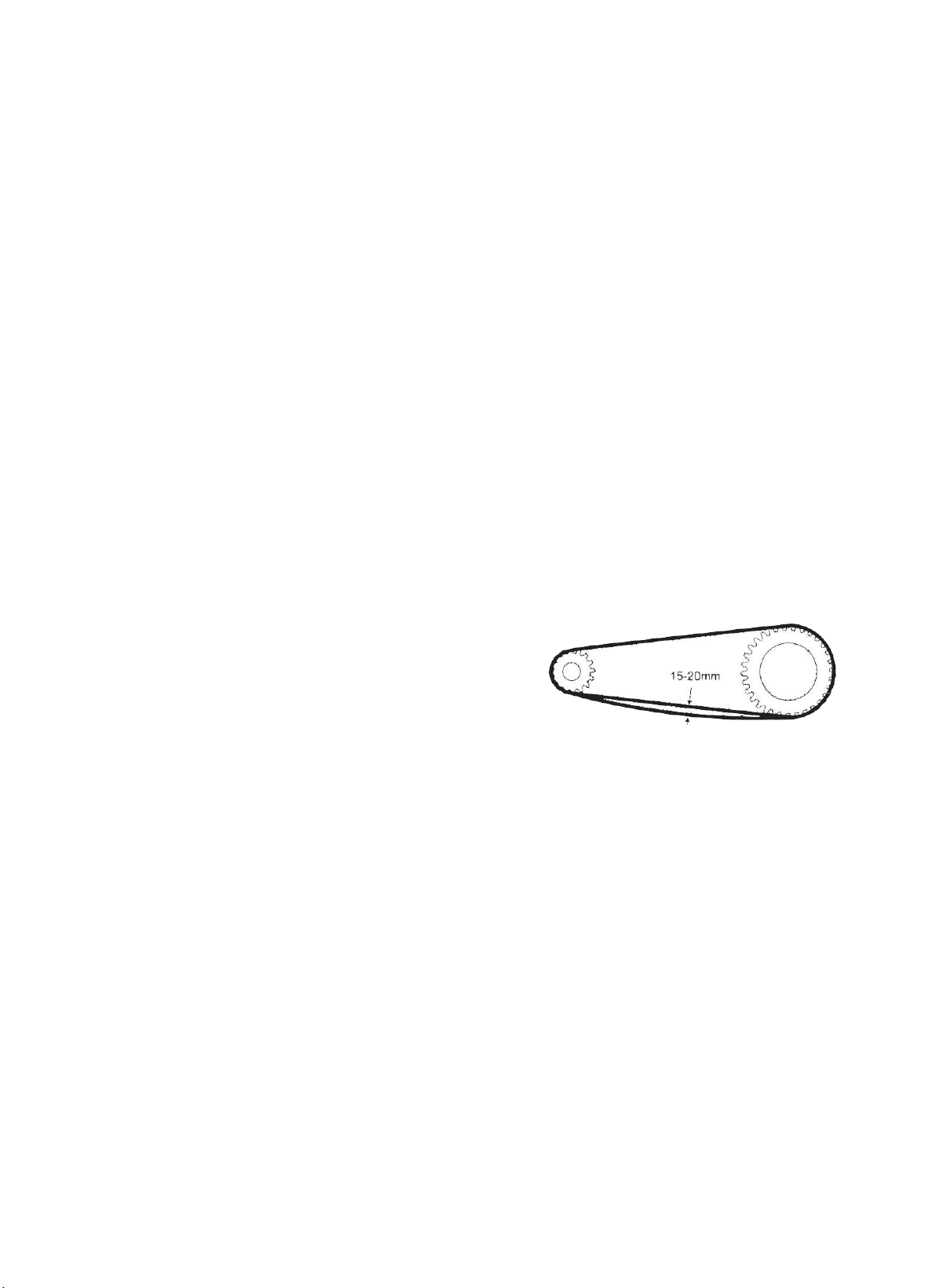

Chain Care

The chain periodically requires lubrication, depending on

frequency of use and conditions etc. If the chain is noisy

or running roughly, lubricate it by applying a small

amount of bicycle chain lubricant to it. Do not allow the

lubricant to get on to the tyres.

Torque Settings

It is important to regularly check all fasteners for adequate tightness. The following are considered

highly important and should be adjusted to the specified torque values using a suitable bicycle torque

wrench, sockets and adaptors. Depending on bicycle model and design, some fasteners listed below may

not be applicable:

• Front Axle Nut – 35Nm

• Rear Axle Nut – 35Nm

• Handlebar Clamp Bolt – 10Nm

• Handlebar Neck Lock Bolt - 15Nm

• Handlebar Stem Bolt – 24Nm

• Pedal Bolts – 35Nm

• Brake Calliper Mounting Bolt – 7Nm

• Brake Cable Anchor Bolt – 7Nm

18

Table of contents

Other VIVI Bicycle manuals