v

RULES OF THE ROAD

ln the interest of safe cycling, make sure you read and understand the owner's manual.

Throughout this manual you will find WARNING, CAUTIONS, and NOTES or NOTICES.

WARNINGS: Pay special attention to these since failure to do so could result in injury to the rider or others.

CAUTIONS: lf not followed these could result in mechanical failure or damage.

NOTES or NOTICES: These specify something that is of special interest.

Before you ride this bicycle, read this RULES OF THE ROAD section and check that all parts are installed as per.this instruction manual.

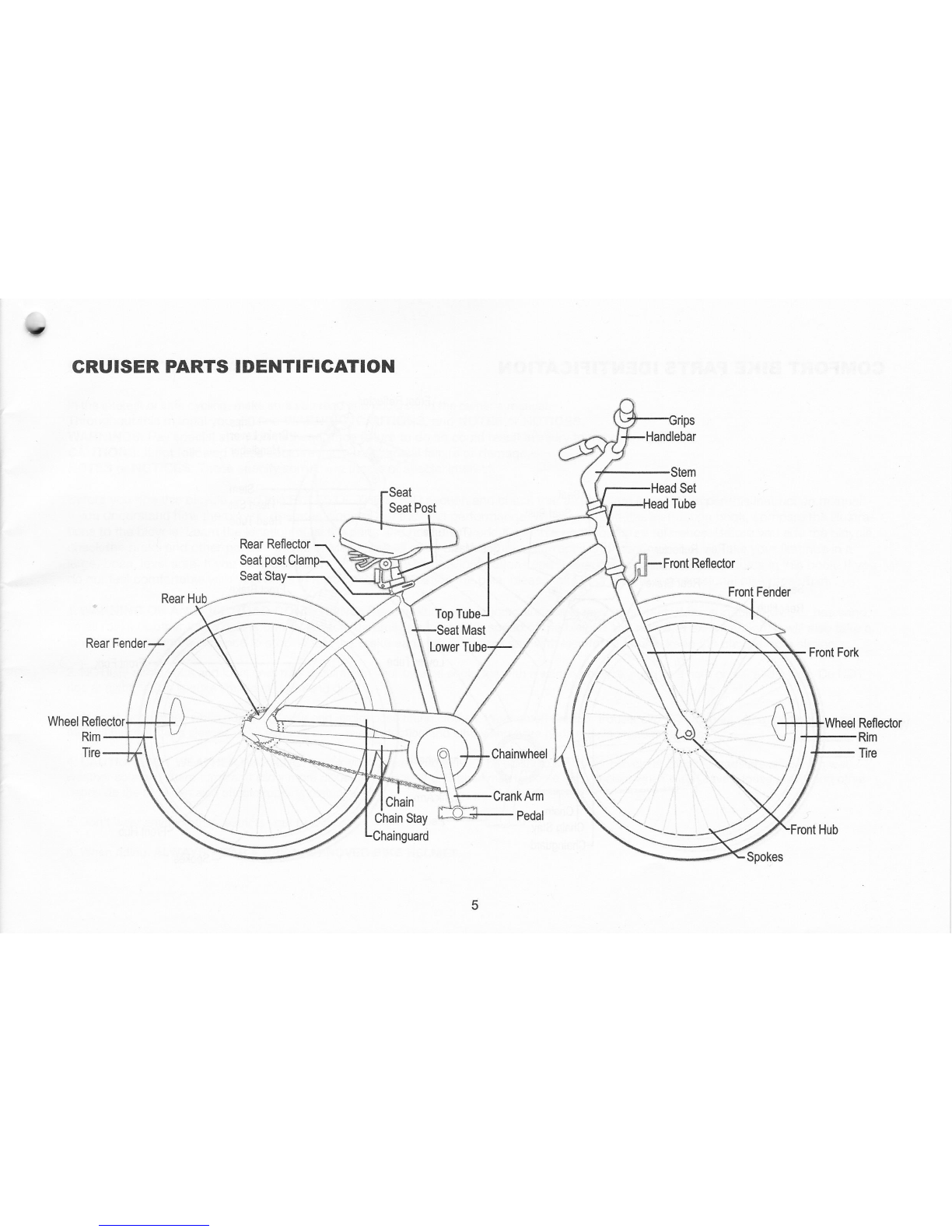

lf you understand how the bicycle operates, you will get the best performance. When you read this instruction book, compare the illustra-

tions to the bicycle. Learn the location of all the parts and how they work. Keep this book for future reference. Before you ride the bicycle,

check the brake and other parts of the bike. Make sure all pads are assembled correctly and working properly. Take your first ride in a

large, open, level area. lf you have a problem, check the assembly instructions and follow the maintenance procedures in this book. lf you

do not feel comfortable with your skills in assembling or adjusting the bike, please take your bike to a professional bike repairman.

1. WARNING ON AND OFF ROAD CONDITIONS: The condition of the riding surface is very important. lf the surface is wet, or has sand,

small rocks or other loose debris on the surface, carefully decrease the speed of the bicycle and ride with extra caution. lt will also take a

longer time and more distance to stop. Apply the brake earlier than normal and with less force to help keep the bicycle from sliding.

2. NOTICE: some state and local laws may require that your bike be equipped with a warning device, such as a horn or bell and a light. Do NOT

ride at night. Vision is quite limited at dawn and dusk.

3..Always wear shoes when riding a bicycle and avoid loose fitting clothes. Wear a cuff band or trouser clip to keep pants from getting caught in

the chainwheel. Long sleeves, long pants, gloves, eye protection and elbow and knee pads are also recommended.

4. CAUTION: WET WEATHER WARNING: Check your brakes frequently. The ability to stop your'bicycle is critical. Roads are slippery in wet

weather so avoid sharp turns and allow more distance for stopping. Brakes may become less efficient when wet. Leaves, loose gravel and other

debris on the road can also effect stopping distance.

5. Don't wear anything that restricts your hearing.

6. When riding, ALWAYS WEAR A CPSC APPROVED BIKE HELMET.