viZaar INVIZ BIG User manual

www.vizaar.com

The device identification “INVIZ” stands

for a series of latest inspection cameras,

which are constructed strictly according

to the instructions of the users.

The video endoscope at hand,

”INVIZ BIG”, is currently the simplest and

at the same time most hard wearing

camera technology for the inspection and

documentation of weld seams and pipe

inner walls in the 30 mm – 300 mm

category. Expect high resolution, impres-

sive colours, highest light sensitivity, full

image, digital image and video memory

as well as a smart text generator option.

irst models of the INVIZ BIG series and

previous are in the market since about 10

years and have been proved to be one of

the most ‘ruggedized’ inspection cameras

in the world. The percentage rate of

failure during the first two years of

operation is less than 5% - not reached

through any other RVI video - equipment

in today’s market place.

By continually and consistently not

including the electrical conductors of the

KEVLAR – reinforced main cable inside

one epoxy-glass fibre pushing pole, the

system keeps difficult flexibillity of tur-

ning multiple corners and bends without

breaking the main camera supply.

The immense amount of options and

custom made accessories will allow the

operator to reach any point of the

application:

:: Simple rotating and maneuvering of the

probe with attached NEW side view optics.

:: Waterproofness up to 50 meter.

:: Longterm-tested durability of the entire

probe through high wall thickness of

the probe.

:: Extremely light sensitive 40mm camera

head, interchangeable with 29mm

standard head.

:: Manoeuverability through many pipe

bends. A widest range of pushing- and

centering tools are supporting the

operator to accomplish his task.

:: Easy focusing of the optics within a

wide range of applications.

:: New several hours lasting

battery-operation option.

In order to obtain the economic advantages

of your endoscope even in the long run,

you ought to read and follow the following

advice, tips and warnings carefully. The

observance of these instructions serve

the purpose of your own safety as well as

the safety of those in the work field of the

endoscope as well as that of the

corresponding control device.

All tips, code of behaviour, suggestions

for measures to be undertaken, advice,

warnings and instructions are exclusively

valid for the operation of “INVIZ” BIG

videoscopes and not for devices by other

manufacturers.

or questions, which have not been

answered by this instruction manual,

your dealer and/or the manufacturer are

gladly available for advice. Kindly contact

us even if you have suggestions for the

improvement of this manual or the product.

We wish you success during your inspections!

Preface

:: Status / Revision: 10 / 2007

Warning against risk of injury or

loss of life to humans

Warning against significant risk of

damage to device and plant

Warning against fatal electric shock

Warning against life-threatening

explosion risk

Warning against life-threatening fire risk

Before the initial operation, this instructions

manual must be completely read and

understood by the user in order to

exclude damage to life and property

through the operation of the video

camera system (the device) with the

greatest degree of safety. The operation

of the device without the understanding

of the instructions manual is not allowed

under any circumstances. The device has

been conceived exclusively for industrial

application exclusively through personnel

trained in all technical questions and

must never be operated by private users.

or a generally non-destructive operation

of the device, beside the safety of the

personnel and environment, an extensive

knowledge of the device, the inspection

technology, the safety instructions as well

as the industrial field of application are

absolutely necessary!

or compulsory attention:

Compulsory instructions

for a safe start-up in

accordance with regulations.

Reading before the initial

operation is an absolute must!

The device must never be connected to

electric mains, if you have not understood

this instruction including safety warnings

or even if you have not understood

individual sections or if you cannot or do

not wish to use the device in accordance

with the regulations.

viZaar is not liable under any circumstances

for the consequences of faulty inspection

results, which were achieved with the device.

viZaar shall not be liable under any

circumstances for the loss of inspection

data.

viZaar shall not be liable under any

circumstances if device parts are left

behind in the inspected plant inadvertently.

Operating precautions

www.vizaar.com

The device or parts thereof must never be

inserted into human body openings

and / or used for (veterinary) medical

analyses.

The device must never be opened by the user

at any place other than the camera housing.

Life-threatening electric voltage are used or

generated in the device; in particular, the

device must never be used with the

The video probe of the device must never

be used in or in the vicinity of apparatus

or equipment, which are partly or fully

energized by electric current of any type

(e.g. transformers, motors, generators,

switchboards etc.). The metallic housing of

In case an exchange of the lamp becomes

necessary, one must proceed according

to the procedure in the instructions!

The device must never be operated in

moist environment (e.g. during

precipitation) nor must the control device

Before start-up, the device must be

acclimatized according to the ambient

temperature. This is valid in particular for

cooled devices, wherein condensate

The device must never be operated with

damaged video probe. There is a risk of

damage to hand due to the metallic

protective mesh (Suggestion: Always

wear work gloves for protection). At the

same time, there is a danger that liquids

might penetrate the probe and thereby

impair the functioning permanently or

might cause a life-threatening electric

shock to the operator! Even the use of a

Never operate the probe without working

gloves! Considerable risk of getting

adjusted!

Never operate the device under conditions

which do not comply with the operating

conditions or storage conditions described

in the instructions manual!

housing open. The device must never be

used when there are audibly loose parts

inside the device.

the camera conducts electricity and dange-

rous currents are transmitted during every

contact or even short-circuits can be trig-

gered in the plant.

or the operating pendant be submerged

in water – there is a risk to life due to

electric currents!

accumulation during warm-up can lead to

destruction and damage due to electric

sparkover.

slightly damaged probe can quickly lead

to the total destruction of the probe due

to the electric conductors lying inside.

The operation of a damaged probe is

impermissible within the area of jurisdic-

tion of the European Union, since the

regulations on emission of electro-

magnetic radiation can no longer be

adhered to with safety.

At the same time, protective glasses must

always be worn while operating the probe.

www.vizaar.com

The device must never be operated in

operating environments which are vulne-

rable to explosion or fire risk. The device

is not equipped with safety devices or

acceptance for operation in environments

vulnerable to explosion or fire risk. An

impermissible employment in

The device must be checked annually by

the manufacturer or an authorized third

party for compliance with the electrical

safety instructions obligatory at the usage

site and conformance with the as-delivered

condition of the device. The device must

not be connected to the electric supply

Never allow the device to be operated

without supervision. or safety reasons,

it is necessary to switch-off the machine

during pauses.

Never operate the device in radio-actively

contaminated environment! Never expose

the probe to ionizing radiation of any type!

Never bring the probe in contact with

corrosive substances of any kind (acid or

alkali). Risk of damage and injury while

manipulating the probe.

Never insert the probe in plant parts the

contents of which are unknown!

or increasing your own safety against

electric shocks with risk of injury or loss

of life, the device must always be connec-

ted and operated via a residual current

circuit breaker system or an isolating

transformer.

This can in any case be a compulsory

The device must be transported exclusive-

ly in the transport case conceived for it by

the manufacturer. The device and the

corresponding accessories must be

environments susceptible to explosion or

fire leads unavoidably to a device-induced

life-threatening explosion and to a fire in

the plant. The operator is obliged

to check the plant for substances vulne-

rable to explosion or fire before every

new start-up of the device.

mains or otherwise operated after the

ascertainment of a defect or any deviation

from the as-delivered condition. This is

valid, in particular, if the device has tumbled

or fallen down or was exposed to a liquid.

Never bring the probe in contact with

solvent containing liquids! Risk of

Damage!

condition depending upon the operating

environment. or this, consult your

responsible safety in-charge or the

accident protection measures in force in

your respective country.

packed in the transport case only

according to the instructions at hand.

www.vizaar.com

The use of too long power extension

cords is life-threatening and forbidden

(max. 25 m in case of a supply line made

of copper 3 x 1.5 mm2). Hereby, a

life-threatening loss of the protective

function of the upstream safety element

is possible. At the same time, voltage

differences of the earth potential as

Always ensure that the respectively

inspected metallic pipeline systems

conform exclusively to a homogenous

earthing potential; electrically insulated

transition points (e.g. sealings, plastic

line sections) can exhibit different electric

earth voltage potentials depending upon

The endoscope system can be connected

to the public electric supply mains through

a ‘IEC-plug lead’ included in the delivery

or a ‘IEC-plug lead’ which complies with

the local socket standards. The system

accepts faultlessly all power supplies

known worldwide with alternate currents

of 96 VAC to 246 VAC at 46 to 60 Hz.

Never insert the probe in plant parts, if

weld or cutting work is being undertaken

simultaneously or soon. Likewise, the

probe must never be inserted if further

inspection procedures like eddy current

or radiography tests are being undertaken

Exclusively the viZaar accessory articles

or spare parts described in this instructions

manual may be used in connection with

the device.

Never look directly at the light emission

in the camera head. There is danger of

lasting eye injury or at least a long-lasting

eye irritation with accidental consequen-

ces through a temporarily restricted

power of vision.

When operating the device outside the

permissible operating conditions or with

destruction caused by usage which deviates

from the instructions, non-compliance with

the operating conditions or through the

usage

The different options / accessoires

require handling which is different each

time and deviate from each other signifi-

cantly even in the technical specifications.

compared to the displaced reference

point of electric output (bridged by a too

long extension cord) could cause dange-

rous electric currents on contact with the

device housing or impermissibly high

equalizing currents at the probe. In case

of uncertainties, consult your on-site

electrical expert.

the plant, which could build up very high

electric currents with sparking and

substance burn-out in case of bridging

through the metallic, electrically

conducting probe. Kindly consult your

on-site expert in advance.

or safe operation, the device needs a

reliable potential earth (PE) connection.

In case of doubt, an expert or the

manufacturer must be consulted. The

minimum output supplied by the power

connection can be derived from the devi-

ce specifications contained in the instructi-

ons.

on the same plant part. Never insert the

probe in plant parts, which are not fully

switched-off (e.g. danger from rotating

plant components) or cooled down.

of non-original spare parts or accessories as

well as through impermissible opening of

the device, the guarantee obligation or the

guarantee commitment by the supplier or

manufacturer lapses, in principle.

The enclosed operating and application

instructions of the respective option must be

compulsorily adhered to.

www.vizaar.com

Never insert the probe in pressurized

containers or pipelines via sluices! The

entire probe is watertight up to the length

of the probe in most devices but is not

designed for fluid or general gas

pressure higher up. Beside the danger of

destruction through pressure forces,

Using the optional pushing poles and / or

pushing reel causes additonal endanger-

ment of the operator: Glass-fibre epoxy

poles may have splices on the surface

and can cause heavy injury of your hand

during handling. Always use rugged wor-

king gloves when operating with epoxy –

glass fibre pushing poles

Using the optional pushing poles and / or

pushing reel causes additonal endanger-

ment of the operator and facility: Endless

push poles on a reel are winded under a

enormous spring force – in the case you

open the reel break without keeping the

Using the optional pushing poles and / or

pushing reel causes additonal endanger-

ment of the facility: Defective or false

operated push poles may get stuck inside

the application without a chance of easy

retrieval. Never push the poles too

strongly, always inspect poles before

starting the inspection.

Using the optional pushing poles cause

additonal endangerment of the facility:

Always approve 100% push poles are

connected properly to each other ( exten-

sion) or to the camera before inserting

the probe. Not correctly linked pole-con-

Be careful employing centering tools to

the probe. aulty operated or wrong

chosen centering trollies or rings can

cause the probe getting stuck inside

tubes and affiliated bends behind

obstacles, bends and weldings etc.

there is the danger of uncontrolled exit of

pressure medium into the control device

via a leaky probe. Depending on the pro-

perties of the pressure medium, there is

significant risk of injury or accident.

open end of the push pole under control,

the reel will unwind very fast and can

cause heavy injury to the operator and

persons nearby. Also any neighboring

material can be destroyed through a push

pole moving uncontrolled and fast.

nectors / locks will cause the fatal situa-

tion to open immediately when starting to

retrieve the probe after inspection (during

pulling). This will disable the operator to

retrieve the probe if one or more bends

have been inspected (getting stuck).

www.vizaar.com

1 Structure and start-up

1.1 Removal from the transport case

1.2 Accessories

1.3 Initial operation

1.4 urther functions of the basic system

1.5 ocusing

2 Product specifications

3 Supplementary equipment

3.1 Option push poles and pushing rods

3.2 Option centering tools and trollies

3.3 Option side view prism

3.4 Option motorized side view mirror

3.5 Option battery operation

3.6 Option cable counter

3.7 Option 40mm head adapter

4.1 Image recorder

4.2 Integrated text generator

5 Getting Started

6 Care, maintenance and repair

6.1 Cleaning of the system

6.2 Maintaining of the O-ring

6.3 Maintenance by the manufactorer

6.4 Transport

6.5 Customer service

7 Guarantee, technical data and conformity

7.1 Guarantee

7.2 General device specifications

7.3 Disposal of the device after end of life-expectancy

01

01

04

05

07

08

09

10

10

12

14

15

16

17

19

20

28

32

33

33

33

33

33

33

34

34

34

34

Contents

www.vizaar.com

1.1 Removal from the transport case

Before opening the optional transport

case, check the container for possible

transport damages.

DIM:

H 635 x W 510 x D 365; PE;

Weight empty 12,25 kg

’

1 Structure and start-up

www.vizaar.com 01

‚Open here’

‚Push center and lift to unlock’

Pull-out lever

Press the tab for sliding

the lever

‚Wheels’

1.1a

1.1b

1.1c

Pull the device on both sides of the reel

and remove. It appears to be sensible to

note the location of each accessory part

during removal and to proceed later in

reverse sequence while packing.

www.vizaar.com 02

1 ‚Lift here’

2 ‚LCD Control

Pendant’

3 ‚Watch alignment

when packing’

4 ‚Umbilical cord for

LCD’

1 ‚Mini-keyboard

under holding plate

2 ‚Magic arm’

dismembered

3 ‚Accessory pouch’

4 ‚Card Reader’

5 ‚Remote control’

6 ‚Accessory box’

7 ‚Packing drawers

opened for remo-

valt

1 ‚ ix magic arm

here’’

2 ‚Handle for

carrying’

3 ‚ eet’

4 ‚Transport position

for scope camera’

1

1

3

3

4

4

5

6

3

2

2

1

7

7

1

4

2

33

1.1d

1.1e

1.1f

insert

www.vizaar.com 03

1 ‚Power cord’

2 ‚On / off main switch’

1 ‚Reel brake’

2 ‚Mount for accessory pouch’

or battery

1 ‚Counter operation hrs’

2 ‚PS2 keyboard for option text generator’

3 ‚S-Video video out (only in combination with

option data display modul’

4 ‚BNC composite video out’

5 ‚Connector umbilical to LCD’

6 ‚Date of manufacturing, SN’

2

1

3

4

5

6

1

2

2 2

1

1.1g

1.1h

1.1i

4.2 4.3

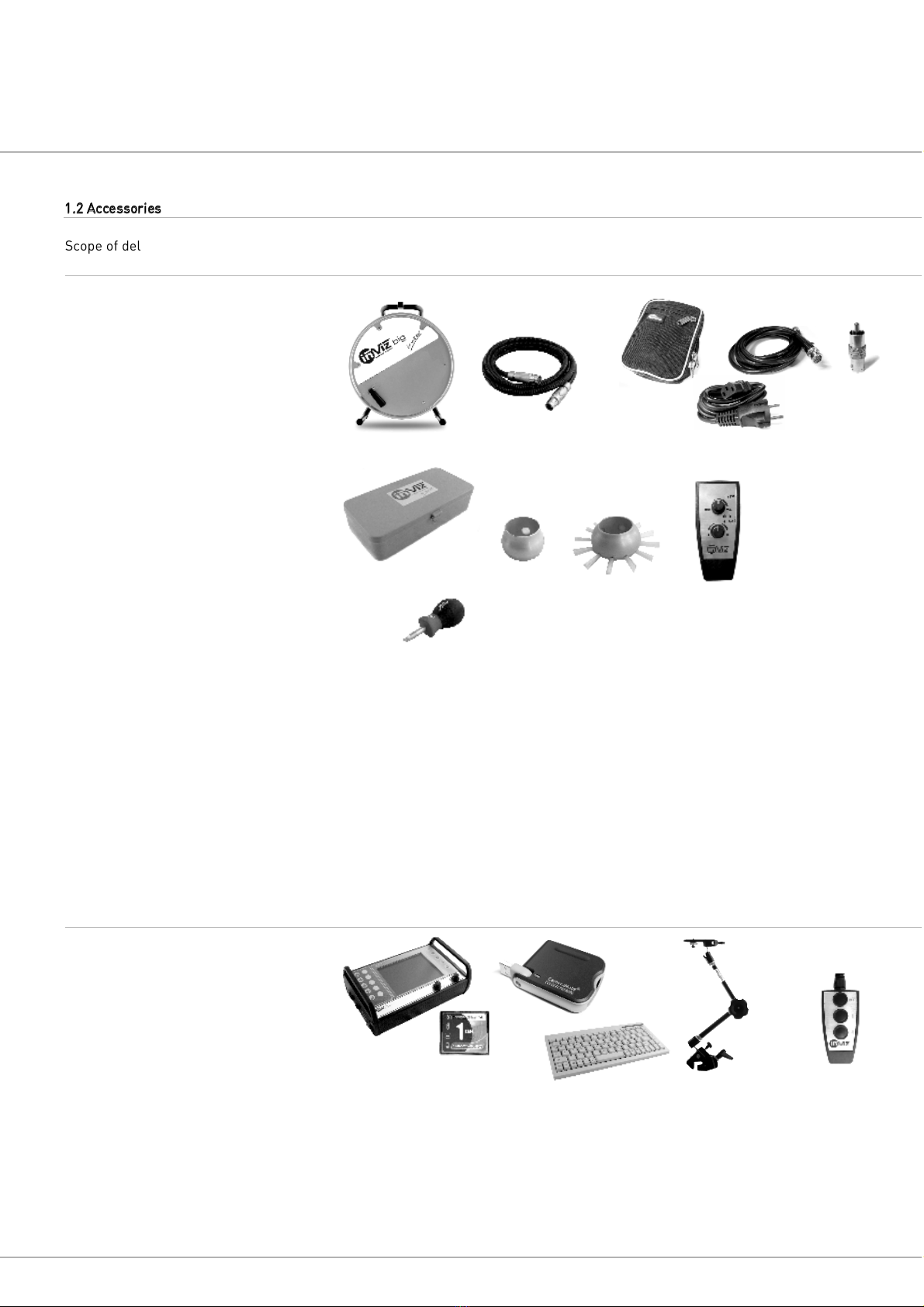

1.2 Accessories

Scope of delivery version basic device in

optional transport:

1 INVIZ big

2 Umbilical cord for LCD or

of the simple operation pendant

3 Accessory pouch with

3.1 Power cord D, UK or US

3.2 BNC Video cord

3.3 BNC to RCA video adapter

4 Accessory box

4.1 Screwdriver

4.2 Protection ring (Ø 40mm)

4.3 Centering brush (Ø 65mm)

5 Light control

Scope of delivery optional accessory

packed in optional transport case:

1 LCD operating pendant with digital

image video recorder and actual high

speed “ lash Card” Memory Card

2 lash Card reader with USB connector

3 Mini PS2 keyboard US or D

4 Magic Arm

5 Remote control for recording of

picture and video

www.vizaar.com 04

Connection and operation of the text

generator is represented in the following

chapters.

Optional pushing aid tools cannot be

accommodated in the transport case. The

usage is explained separately.

Connection and operation of the optional

LCD imaging recorder represented separate-

ly.

1

2

33.2

3.1

4

4.1

5

12

3

45

3.3

1.3 Initial operation

After connecting the power cord, the

device can be started with the red main

switch. The camera LED will be started. or

visualization of the camera image, at least

a conventional monitor or the imaging

recorder must be connected to the video

output of the device.

The device must be operated exclusively

in environments, which guarantee that

the in-built ventilator supplies the lamp

with sufficient fresh air for cooling. In

case of insufficient cooling, there can be

damage to the LED.

Example

The following is recommended for visualization:

:: Standard studio monitor, type CRT

(best results) 10” to 21”

::

INVIZ

image recorder

:: LCD monitors

:: ast laptop / Notebook via high-value

framegrabber (Status 2006 USB

framegrabber cannot be recommended)

:: Head up display

or storage of image and video, the

following are recommended given the

current state of technology:

:: VHS recorder (adequate quality only in

S-VHS operation)

:: DVD / hard disc recorder

:: Mini DV Camcorder with AV input

:: ast laptop / notebook via high value

framegrabber (s per status 2006, USB

2.0 framegrabber cannot be

recommended), e.g. ire Wire / PCMCIA

::

INVIZ

image recorder

www.vizaar.com 05

Please contact your viZaar representant for any further question to this important issue.

or avoiding possible damages to the

monitor, it is recommended to operate

the inspection camera or external periphe-

real devices like monitor or video recor-

der via the same main power potential.

This is ensured for all participating users

through the use of a multiplug. In case

very long video cords are used, there can

be disturbing equalizing current via the

shielding of the cable.

The video image of the camera head can

now be captured as so-called Composite

Signal (“video signal” in common parlan-

ce) via the lateral BNC video output

through every conventional televisionwith

Scart/AV input. The S-VHS (Y/C) output lying

thereunder offers a visibly improved quali-

ty in the detail of the image signal and

can be used with accordingly higher value

devices.

In order to use the full image quality of

the high-resolution camera quality, we

recommend that accordingly high resoluti-

on special monitors from a screen size of

10” onwards be used exclusively for

inspection tasks in the material test, which,

also possess an S-VHS input.

All video connection cords to periphereal

devices must exhibit a resistance of 75

Ohm and are characterized by the identi-

fication RG 59. Beside the industrial BNC

connector, the so-called CGA / RCA /

Cinch connectors are widely popular; corre-

sponding adapter and/or adapter cable

can be ordered in the trade.

As a rule, recording device and monitor

are switched in series, for being able to

control the recording results easily. Older

video devices do not terminate the video

line automatically with a 75 Ohm terminating

resistance. This must be placed in the

correct position manually by means of a

switch. You may refer to the instructions

of the respective devices. A wrongly set

or missing terminating resistor and/or

the parallel operation of several termina-

ted users at one output can lead to signifi-

cantly dark or overexposed pictures, it

can lead to colour distortions and can

lead to so-called ghost images in extre-

Video out Video inVideo out Video in

Monitor

DVD recorder

Option:

Image recorder Light control

INVIZ

camera system

1.3a

me cases.

However, the S-VHS output (if available),

the composite output and the LCD

tableau can be operated simultaneously.

The result and the correct interpretation

of an inspection are dependent to a high

degree on the selection of adequate

sighting and documentation medium a too

low resolution, like in case of normal TV

sets, cheap LCD head-up displays or

standard VHS recorders as well as a

faulty colour settings as a rule lead to the

missing of small material errors like e.g.

tears. The same can occur with so-called

digital systems, which partly exhibit

significant detail errors through data

compression or falsify the finest pixels of

the camera during digitalization. The

manufacturer or your dealer will gladly

advise you.

Avoid visual inspections under the

influence of sunlight on the screen.

The connection of any kind of power

supply units at the video outputs can

destroy your video endoscope.

BNC connectors and cables are widely

popular in all industrialized countries

with the most diverse signals and voltage

ranges – before start-up, confirm the

compatibility with your device by

consulting an expert.

Always consider the videosignal-norm of

your

INVIZ

system (PAL or NTSC), which

should comply to the video standard of

your country. Only NTSC or PAL monitors

/ VCR’s will allow to correctly operate

with your INVIZ scope. The INVIZ LCD

image

recorder will allow to run on NTSC and

PAL through it’s integrated auto-detect

function.

www.vizaar.com 06

1.4 urther functions of the basic device

With the delivery of an

INVIZ

system

without imaging recorder, there is a

remote control serially delivered for the

manual control of light emission

strength, or the revolving speed of the

motorized side view mirrors. The remote

control is connected to the the basic devi-

ce by means of the enclosed cord, while

the device is in off mode.

Manual light intensity adjustment

In most of the cases, it is sufficient to

leave the light emission at maximum setting,

since the automatic exposure time con-

trol of the camera (“shutter”) ensures an

optimally exposed picture. In case of spe-

cial applications, like e.g. polished metal sur-

faces, a manual intervention and/or

reduction of the light emission output

becomes necessary.

Motorised regulator “Speed”

All necessary information pertaining to

this can be found in the special section of

instructions manual option +motorized

head’.

Operating hours counter

The operating hours counter cannot be

reseted to zero. Its gives you an indication

of the progressive ageing of the probe.

Through the operating hours counter, you

shall obtain objective values for a realistic

estimate of the economic success of your

inspection work with the system.

PS2 connection socket in the control device

To the extent that the optional text generator

is integrated, the mini keyboard included

with the delivery or another keyboard can

be connected here with PS2 interface.

Alternatively, there is another interface

available in the optional imaging recorder;

but only one of the two connection points

can be occupied for trouble-free operation.

Reel brake

or transport, the reel brake ought to be

pulled carefully, in order to prevent an

unintentional rolling away of the endosco-

pe. Pulling it too hard can damage the

reel axis or the brake itself. or optimum

work, the brake can be pulled slightly or

completely during operation.

Mount for the accessory pouch

The accessory pouch can be simply hung

from the two mounting points and for

local transport, it ought to be fitted with

everything which would be needed for the

next inspection (centering tools, side view

optics, cable etc.). Remove the pouch

before storage in the case and pack

separately.

astening axis for the

variable mounting arm

At this point, the “magic arm” for

fastening the LCD imaging recorder can

ideally be fastened securely. Watch out,

since during a too great deviation of

theadjustable centre of gravity, it is

possible that the entire unit topples and

the device is damaged.

www.vizaar.com 07

1.4b

1.4a

1.4d

1.4c

1.4c

www.vizaar.com 08

1.5 ocusing

:: Rotate front housing until desired

focus is set.

:: Hold back section, while rotating

front housing.

:: Do not remove front housing

unnecessarily. LED will shut-off at

nearest fokal point.

1.5a

:: Clockwise:

focus farther

:: Conter clockwise:

focus near

INVIZ big

:: CCD push camera for visual

inspections of tube, pipes and other

cavities.

:: PAL or NTSC composite video out

(see product label).

:: Probe length 30 meter, 50 meter,

80 meter (see product label).

:: Camera head diameter 29,0 mm.

:: Weight incl. 30 meter probe

15,7kg (incl. monitor 1,4kg).

:: Recommended area of application:

40mm tubing up to 400mm pipes.

:: CCD image resolution:

NTSC: vertical 512 / horizontal 492 Pixel,

PAL: vertical 500 / horizontal 582 Pixel,

380 TV lines.

:: Min. illumination requirement: 1,5 lux.

:: Automatic white balance modus.

:: Ambient operation temperature:

-25°C – 55°C / -13° – 131° .

:: Ambient storage temperature:

-25°C – 55°C / -13° – 131° .

:: Max. operation temperature range of

the probe in air:

-10°C – 65°C / 14° – 145° .

:: Adjustable focus range:

Straight view 18mm to infinity.

:: ield of view OV:

Diagonal 72°.

:: Watertight up to 50 meter

(

CAUTION:

When using 80 meter probe!)

2 Product specifications

www.vizaar.com 09

:: big

3.1 Option push poles and pushing rods

The inspection push camera INVIZ big

usually can’t be operated within tubes

and pipes when not employing 1,5 meter

push poles with connector or endless

push rods stored on a reel.

The epoxy – fibre poles will allow the

operator to push the camera head to

most of the regions of interest of an indu-

strial device without opening it.

Even the poles and rods will provide

excellent handling advantage during the

inspection, a few precautions must be

observed to guarantee working safety and

keep the device / facillity undamaged.

Push poles and rods are hard-wearing, however will

not withstand any pushing or pulling force. The epoxy

fibre material will break when bended too much. The

allowed maximum bending depends on the design

(stiff , medium , soft ). Epoxy fibre poles are aging

rapidly through high temperatures, chemicals, sol-

vents and frequent usage. The older they are, the

more they have to be exchanged by new material.

viZaar rejects any damage compensation in the descri-

bed case of damage. In case of doubt, please send in

the pushing-aid material for evaluation to the

viZaar service.

10mm stainless steel pole connecting clutches are

especially glued onto the fibre epxoxy material, and

can be pulled-off when mistreated or worn out. Pulled

off / damaged connectors or clutches will cause

tremendous trouble to the facility, when camera head

and other poles may left in a pipe after a 90° bend.

Always check the pole connectors before employing

them to the camera. viZaar rejects any damage

compensation in the described case of damage.

In case of doubt, please send in the pushing-aid

material for evaluation to the viZaar service.

Always confirm when using the 10mm stainless steel

pole connectors, that the clutches are truly locked,

liked described in the below pictures. Open connectors

will cause the same impact as broken / defective

connectors to the object of inspection.

Damaged epoxy – fibre material can cause heavy injury

to your hand, when the PE- outside coating is worn or

damaged!

When using endless push poles stored on a reel be

aware of unexpected force trying to unwind the reel

itself when just opening the reel-break. The rod will

unwind itself in a fast and powerful way, causing injury

to people or damage to the facility!

Even without breaking, the employment of push poles

can disable you to retrieve the camera – head with the

poles from the inspected piping. viZaar rejects any

damage compensation in this case. Employing epoxy

fibre poles and rods is an issue of experience and

training. In case of doubt, please ask viZaar for further

training or technical assistance. Never push the

probe / fibre epoxy pole into the pipe applying high

force, especially through 90° bends!

3 Supplementary equipment

www.vizaar.com 10

3.1

3 Supplementary equipment

www.vizaar.com 11

3.1e 3.1f

3.1a

confirm pin locked

3.1b

3.1d

3.1c

Employing the poles or rods extremely

depends on the experience of the

operator. The different flexibility of the

rods / poles may be used depending on

the application length and number of

bends. Rods and poles can be combined,

also poles of different flexibillity may be

combined to reach the area of interest. If

the probe or camera head needs to be

rotated, 1,5 meter poles need to be used

instead of the reel.

The poles / rod can be connected to the

camera head or to the centering tool.

use screwdriver to unlock

connect to camera head

break

store connector

here

disconnect from camera head

3.1

www.vizaar.com 12

3.2 Option centering tools and trollies

Centering tools are necessary to perform

inspections with the INVIZ big in larger

tubes and pipes, nevertheless, a side view

or a straight view is employed. Centering

tools prevent the probe from lying on the

tube/pipe-sole, creating diffculties because

of unacceptable illumination and focusing

situations. Also centering tools prevent

the probe optics to get dirty through

debris in the empty pipe.

or good inspection results, always try to

attach a corresponding centering tool to

each tube diameter.

Two different centering tools technics are

available: ‘Sliding’ centering discs and

brushes for small diameters and larger

centering trollies with wheels reducing

friction. Pushing aids like epoxy fibre

rods or poles are attached to the bigger

trollies or directly to the probe when

using smaller discs only.

Standard centering tools

3 Supplementary equipment

Custom made centering tools

3.2a 3.2b

tighten 2 worm-screws

tighten 2 worm-screws

3.2g

3.2h

3.2i

3.2j

tighten 3 worm-screws

29mm head

open screws to attach or remove centering tool

3.2

When choosing a centering

tool always consider

obstacles, big weldings,

damaged (oval) pipes, dirt

etc. which decreases the

nominal inner pipe diame-

ter. Ignoring the rule to

choose centering tools at a

maximum of 75% - 85% of

the inner tube diameter may

end into the impact of the

probe get stuck inside the

inspection application.

Always assure all

components screws of the

centering tools are perfectly

tightened to not get lost

inside the application.

Heavy centering tools can

cause damage to delicate

tube surfaces.

Table of contents

Other viZaar Analytical Instrument manuals

Popular Analytical Instrument manuals by other brands

DART SYSTEMS

DART SYSTEMS MINI DARTEYE user guide

Parkside

Parkside PKIK 4.3 A1 Operating instructions and safety instructions

Parkside

Parkside PMML 5 A1 Operation and safety notes

LaserLiner

LaserLiner DistanceMaster Compact manual

Bosch

Bosch Professional GIC 12V-5-27 C Original instructions

Whistler

Whistler IC-3409PX user manual