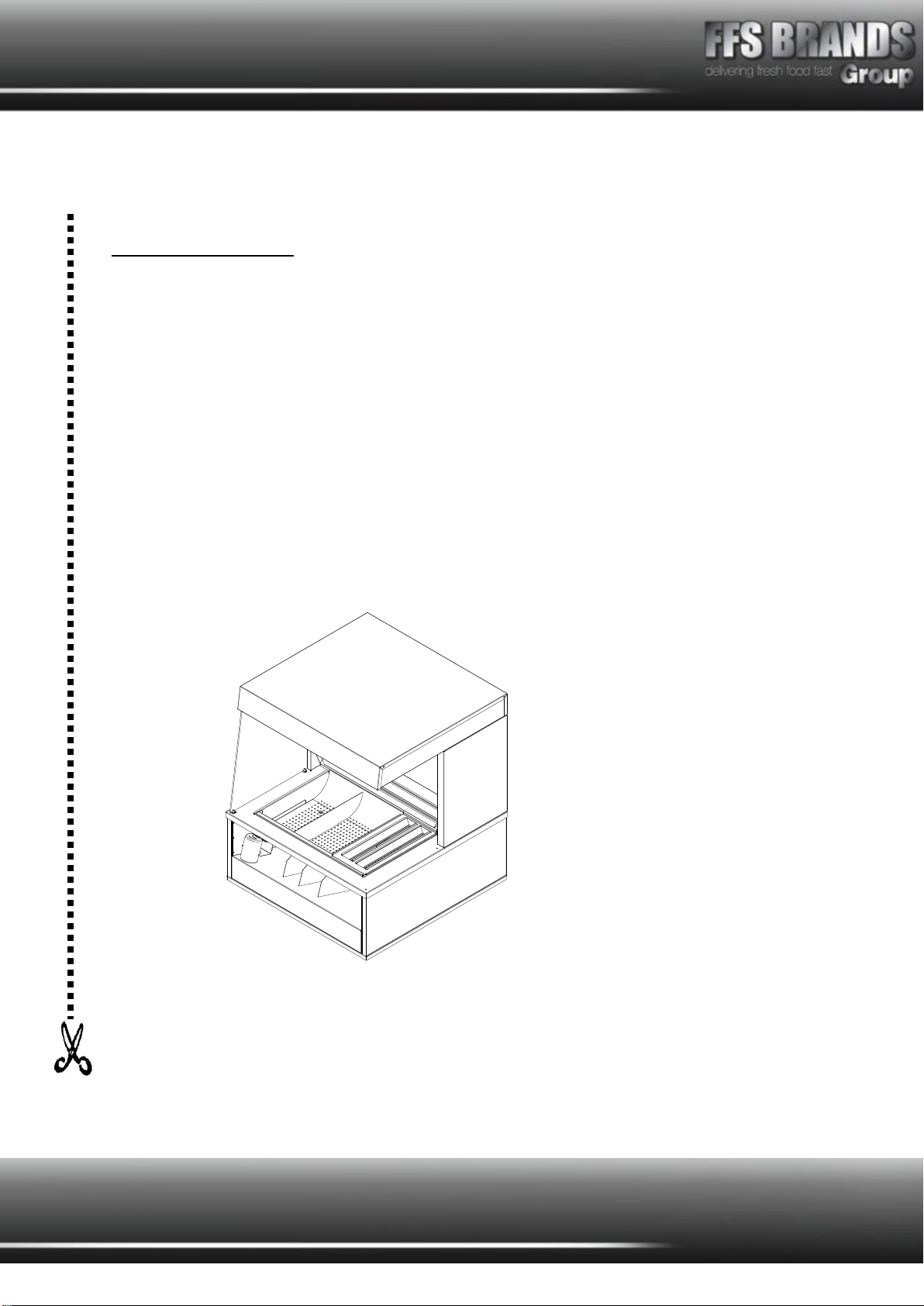

VIZU Mega Fries Topper User manual

1

Featuring tilt and clear bagging rack

Optional product rack for LH or RH use

Removable chip rack and ump for easy cleaning

Designed to fit on top of the ‘Adande’ cooling unit (shown in image)

Mega Fries Topper

VIMFTOPPER

2

MEGA FRIES TOPPER SPECIFICATION PAGE

MODEL VIMFTOPPER

Dimensions

Height

Width

Depth

Machine

1015mm

885mm

915mm

Weight

68kg

Electrical

Running Amps

Connection Type

International Option

1 phase, 50Hz AC, 230v, 2.6Kw

13 Amps

BSCHUKO 2/3 PIN PLUG

N/A

3

Assembly Instructions

Remove all packing from the unit.

Peel off all protective plastic covering from metal

Wash all removable parts in warm, soapy water and dry them thoroughly.

Installation

Your

Vizu Mega Fries Topper

unit can be set up to work either to the left or right hand side

of your fryer(s).

1. Check both heat switch and light switch are in the OFF position.

2. Firstly position the Mega Fries Topper unit in the desired position and lock both front

castors in position. Connect this to the power supply.

3. In order to be able to load the Mega Fries Topper unit with fries the side glass needs

to be on the opposite side of the machine to the fryer(s). If the glass needs to be

moved this is possible by unscrewing the grub screws and sliding the glass out, to

re-fit simply slide back in and tighten screws.

Operating Instructions

1. Use the switch with the red LED to start heating of the under pan element and rear

pair of heat lamps.

2. Use the switch with the green LED to light front row heat lamps.

3. Allow 20 minutes to reach operating temperature.

4. When fries are cooked lift out of oil and allow to drain.

5. When draining is complete move basket across to Mega Fries Topper serving area

and tip contents carefully into tray.

6. Take the salt shaker from its holder and add salt as desired.

7. Now using the fry scoop slide a bag/box over the bottom and scoop chips.

8. The bags full of fries can now be placed in the bagging rack prior to sale.

Note: It is important that fries are held for no longer than 10 minutes. After this time the

quality of the fries will deteriorate.

4

Additional equipment, to suit Mega Fries Topper

As well as the equipment supplied the Mega Fries Topper is fitted with two handles inside

the chip draining plate that can double up as a chip scoop holder.

1. Chip Bagging Scoop holder & handle

Cleaning: Every Day

1. ‘Switch OFF’ and remove electrical cord from power supply. Allow unit to cool

2. First of all remove the bagging rack and wash in warm soapy water

3. Next remove the chip chute and again wash in warm soapy water

4. Finally remove the perforated serving tray, wash in warm soapy water

5. Wipe the inner tray and all exterior surfaces of machines with a soft damp cloth

6. Remove side glass by unscrewing the grub screws and sliding the glass out, to re-fit

simply slide back in and tighten screws. Should be cleaned with warm soapy water

7. Dry all parts thoroughly and refit in order they were removed

5

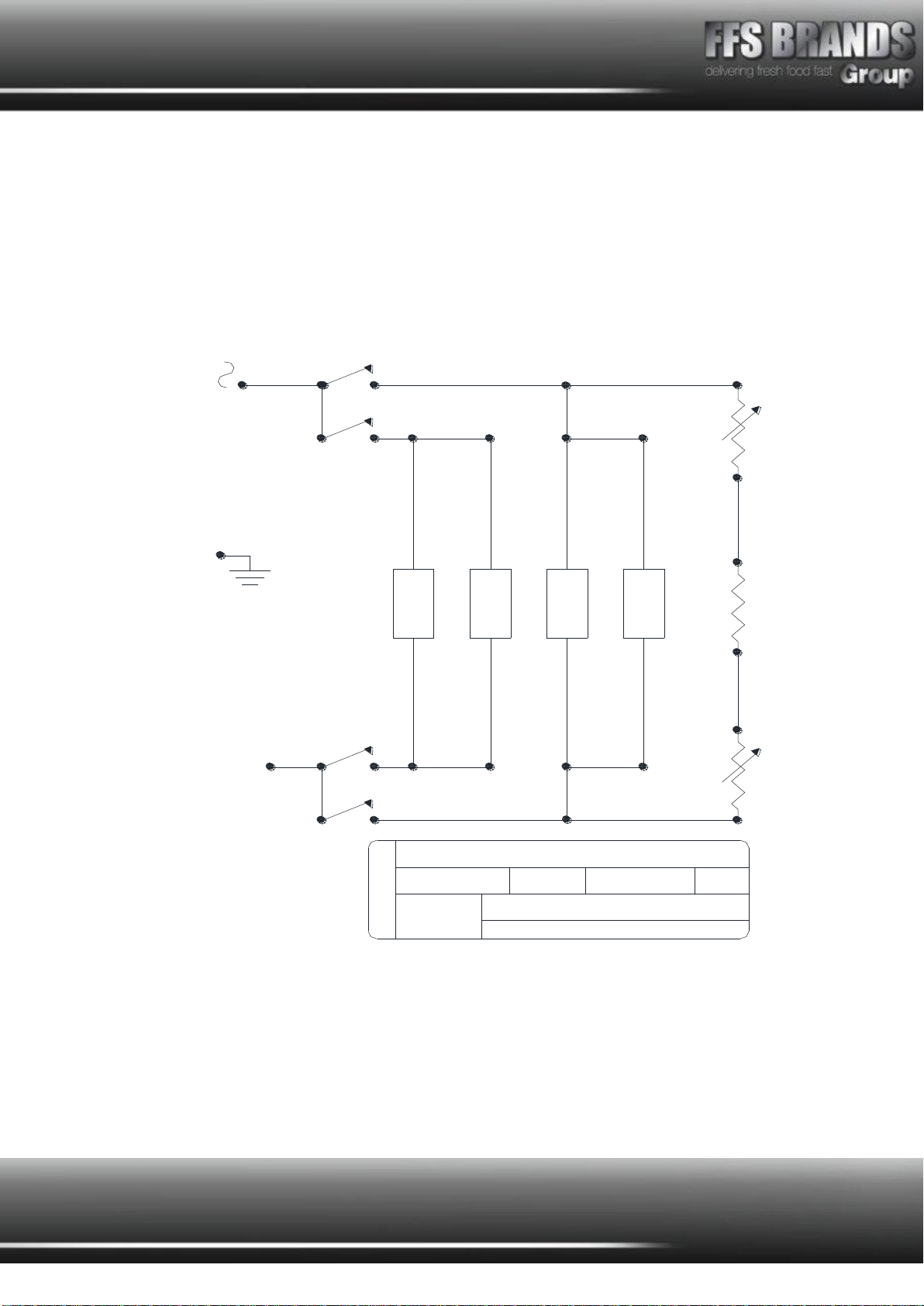

MAT ELEMENT, 500W

230V

GREEN ON/OFF

ROCKER SWITCH

48 MEGA FRIES

WIRING DIAGRAM

PROTOTYPE CODE

11/09/2014

DATE

PROTOTYPE NAME

EQVIMF 05

BUILD NO.

DRAWN DESIGNED

RT

Property of Fast Food Systems Ltd. May not be reproduced or used for

purposes other than those for which it is supplied, without written permission.

Unit 1, Headley Park 9, Headley Road East, Woodley, Reading, Berkshire. RG5 4SQ.

ENERGY REGULATOR

500W

HEAT LAMP

500W

HEAT LAMP

500W

HEAT LAMP

500W

HEAT LAMP

ENERGY REGULATOR

RED ON/OFF

ROCKER SWITCH

GREEN ON/OFF

ROCKER SWITCH

RED ON/OFF

ROCKER SWITCH

6

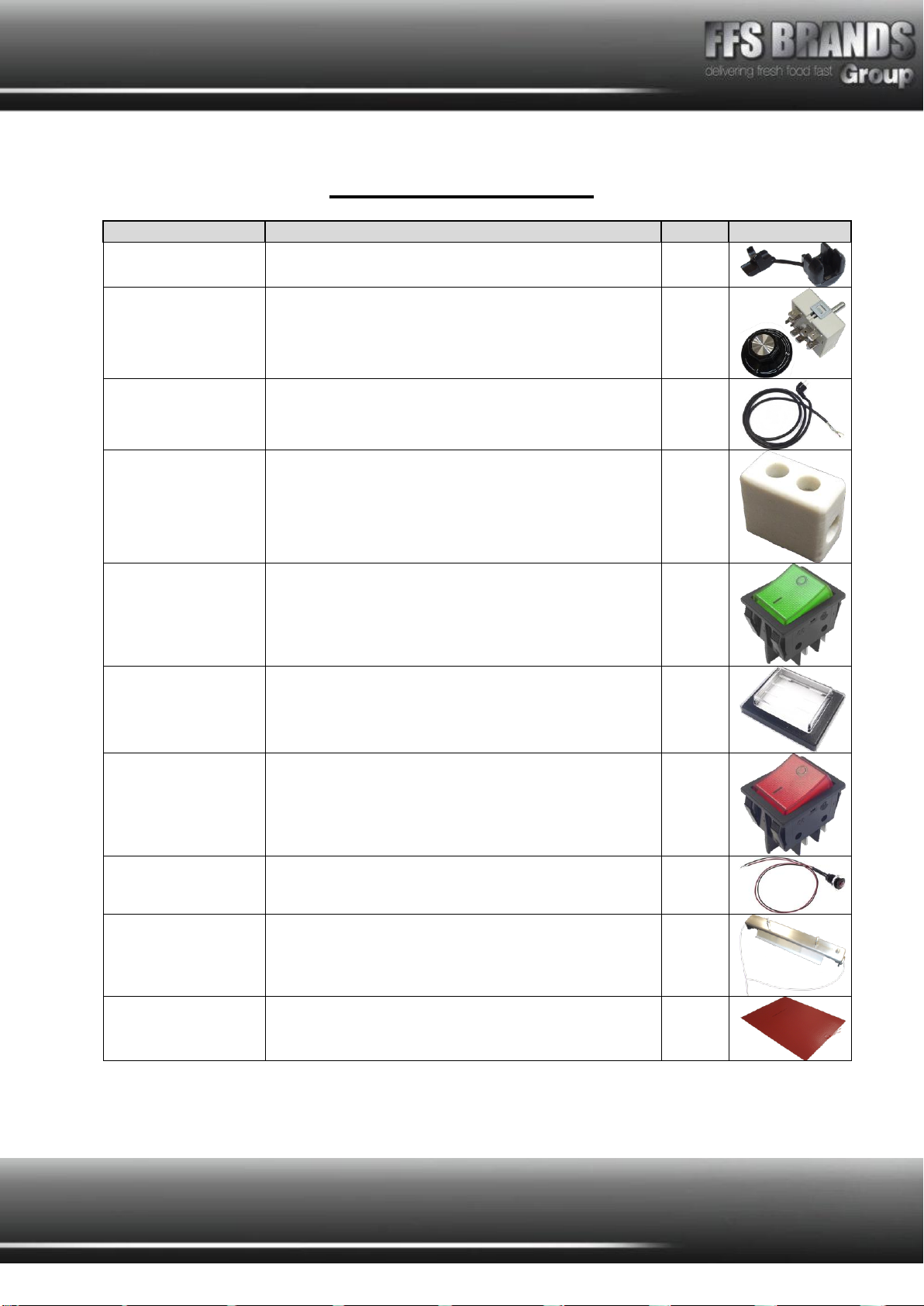

Spare Parts Listing

PART NO.

DESCRIPTION

QTY.

IMAGE

MF817-8877

Black Nylon 66, strain relief cable bush

1

MFE5057071010

50.57071.010 regulator + 524.010 knob

1

BESCHUKO

H05Rr-F 2Mtr. Rubber C032

1

MF88161720

Single Pole Ceramic Blocks 88161720

2

VISW15

Green neon rocker Vizu Burger/Passthru

1

VILE14

Switch cover / bezel HD2/HD4 MFF1025 / MF1026

2

VISW17

Rocker switch HD2 Revolva HD4 MFC1553ALR

1

MF374-1029

100mm low profile lens indicator 230VAC

1

MF500HOLDER

IRL500Phr Holder+Reflector For 500W Bulb

4

MFELBCE600W

590mm x 450mm 230V 500W limiter mat

1

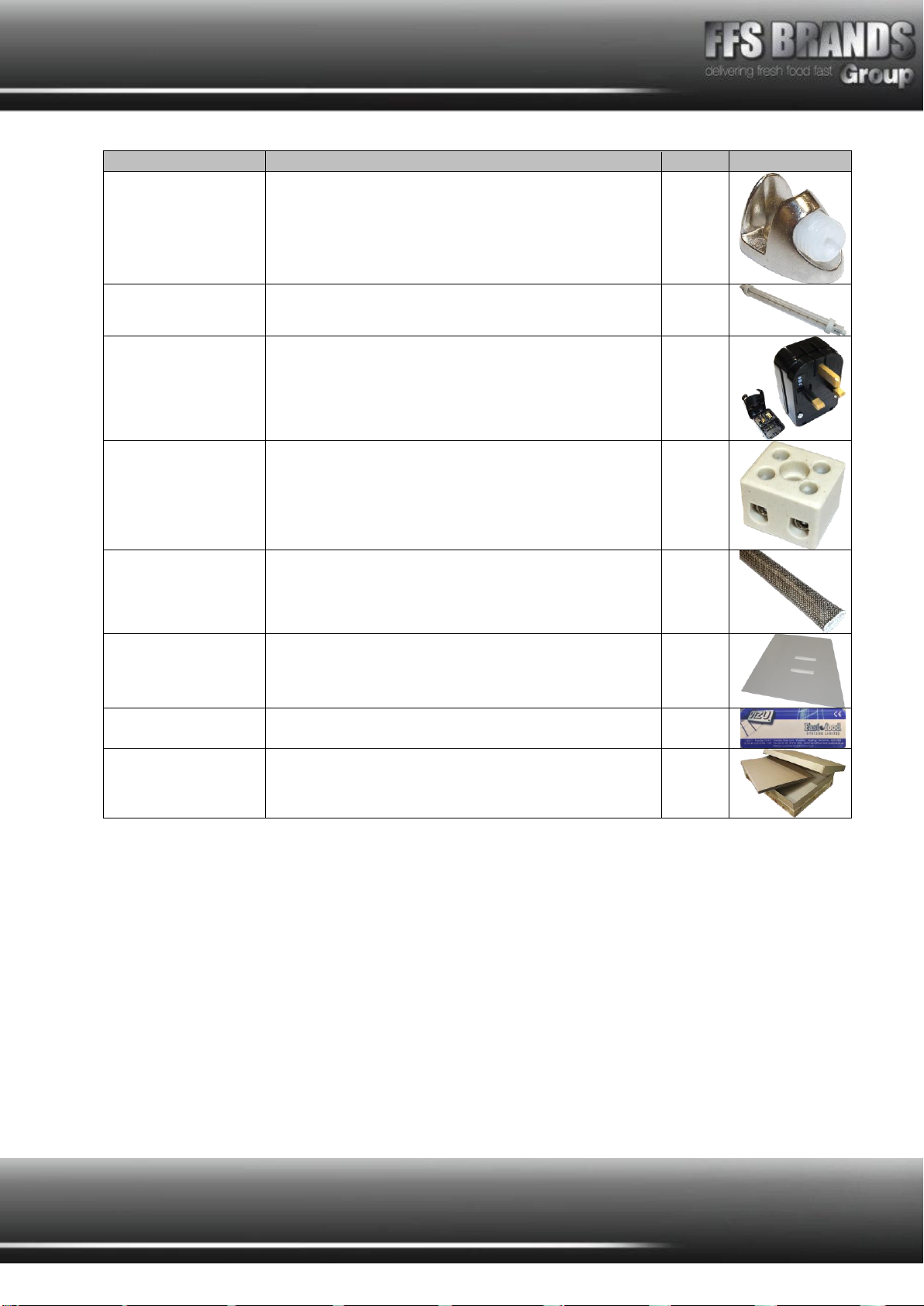

7

PART NO.

DESCRIPTION

QTY.

IMAGE

MFCOB-CR

Cob-Cr shelf support

8

MF500PLUGIN

IRL500PJ 500W JKT Lamp Plug In

4

MFEUROCONVERT

Euro to UK converterplug In black 19-1032

1

MF354Z

2 Pole 5amp term block TB06

8

MFOHSL01

High temperature sleeving

1

MFMEGAGLASS2

New Mega Fry Side Glass

1

MFCOMMON1

Label 5 140mm x 53mm

1

LPMEGACARTON

820X720X1430 0200 150K/T D/Wplain Carton

1

8

Fault Finding

Any servicing must only be carried out by qualified personnel. Machine must be removed

from electrical supply before any servicing.

Problem

Probable Cause

Solution

1. Indicated

ON/OFF switch

does not light up

No power to machine.

ON/OFF switch off

ON/OFF switch faulty

Check machine is plugged in and switched on.

Check fuse in 13a plug.

Check circuit breaker at main supply board is in

(ON).

Check Switch

Replace switch.

2. Unit will not

heat up.

No power to machine.

Red indicator switch

OFF

Red indicator switch

faulty

Thermostat faulty.

Heat element faulty

See section 1

See section 1

See section 1

Check and replace if necessary

Check and replace if necessary

3. Lights do not

illuminate

No power to machine

Green indicator switch

off

Green indicator switch

faulty

Heat lamp broken

Check machine is plugged in and switched on.

Check fuse in 13amp plug.

Check circuit breaker at main supply board is in

(ON)

Check switch

Replace switch

Replace heat lamps

9

Terms and Conditions

Claims

No claim shall be entertained by the Company unless made in writing. Claims arising from

damage or partial loss in transit must reach the Company within 7 days from the date of

delivery. Claims for non-delivery must reach the Company within 10 days from the date of

dispatch. All other claims must reach the Company within 7 days. Damaged goods must be

retained for inspection/collection.

Returns

The Company does not operate a returns policy unless the goods are defective:

In circumstances where the Company agrees to accept return of goods, a charge of 25% of

the invoice value will be made.

10

Damage claim form

Machine: MEGA FRIES TOPPER

Product code: VIMFTOPPER

Customer name……………………………………………………………

Date of delivery……………………………………………………………

Machine serial number…………………………………………………

Damage comments………………………………………………………

……………………………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………

Please indicate on the picture where the unit is damaged.

Courier name…………………………………………………………………

Please cut this page out and post to

Fast Food Systems

(The address is on the back of this manual)

11

Warranty

UNITED KINGDOM AND REPUBLIC OF IRELAND

Excepting where otherwise specified all products are subject to 12 months parts and labour

warranty. Goods found defective will be repaired, credited or replaced without charge

according to the terms of the Company’s standard warranty, provided written notice is given

within the guarantee period. In no case will the company be liable for repairs made without

it’s knowledge or sanction, or for indirect damage, or any consequential loss or expense

incurred by purchasers.

Fast Food Systems Ltd, warrants to the original purchaser that the equipment supplied to be

free from defective materials or workmanship for a period of 12 (twelve) months.

The following are NOT covered by warranty:

1. Failure or breakdown caused by incorrect installation.

2. Adjustment or calibration of controls - this is a routine maintenance function.

3. Abuse or misuse, including cleaning.

4. Warranty labour is only carried out during normal working hours, calls out of hours

may be subject to surcharges.

5. The warranty will commence either on installation or 1 (one) month from date of

dispatch - whichever is the sooner.

7. Warranty on spare parts purchased for equipment outside of the warranty period is 3

(three) months from date of sale.

8. Any faulty spare parts replaced under warranty must be returned with 7 days of

supply.

9. Warranty is non-transferable.

Fast-Food-Systems Ltd

will not be held responsible, financially or otherwise, for any loss

of business as a result of equipment breakdown.

12

Fast Food Systems Limited

Manufacturer & Distributor of Catering Equipment

Unit 1 Headley Park 9 Headley Road East

Woodley Reading Berkshire RG5 4SQ

Tel: 0118 944 1100 Fax: 0118 944 0350

Website: www.fast-food-systems.com

ISSUE 6: 14.06.17

MODEL NUMBER………………………………

ORDER ID/JOB NO……………………………

MACHINE SERIAL NUMBER……………………

DATE OF MANUFACTURE ……/………/………

DATE OF DELIVERY……/………/……

DATE OF COMMISSIONING……/………/……

Table of contents