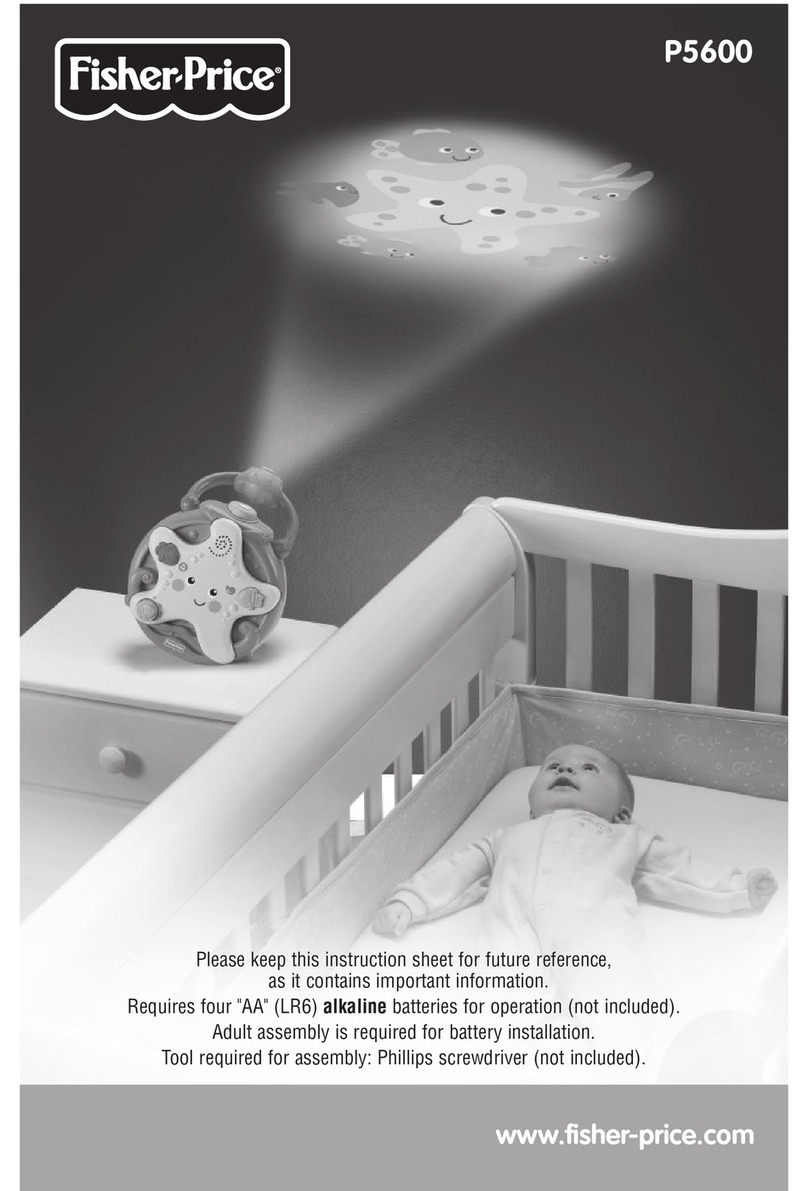

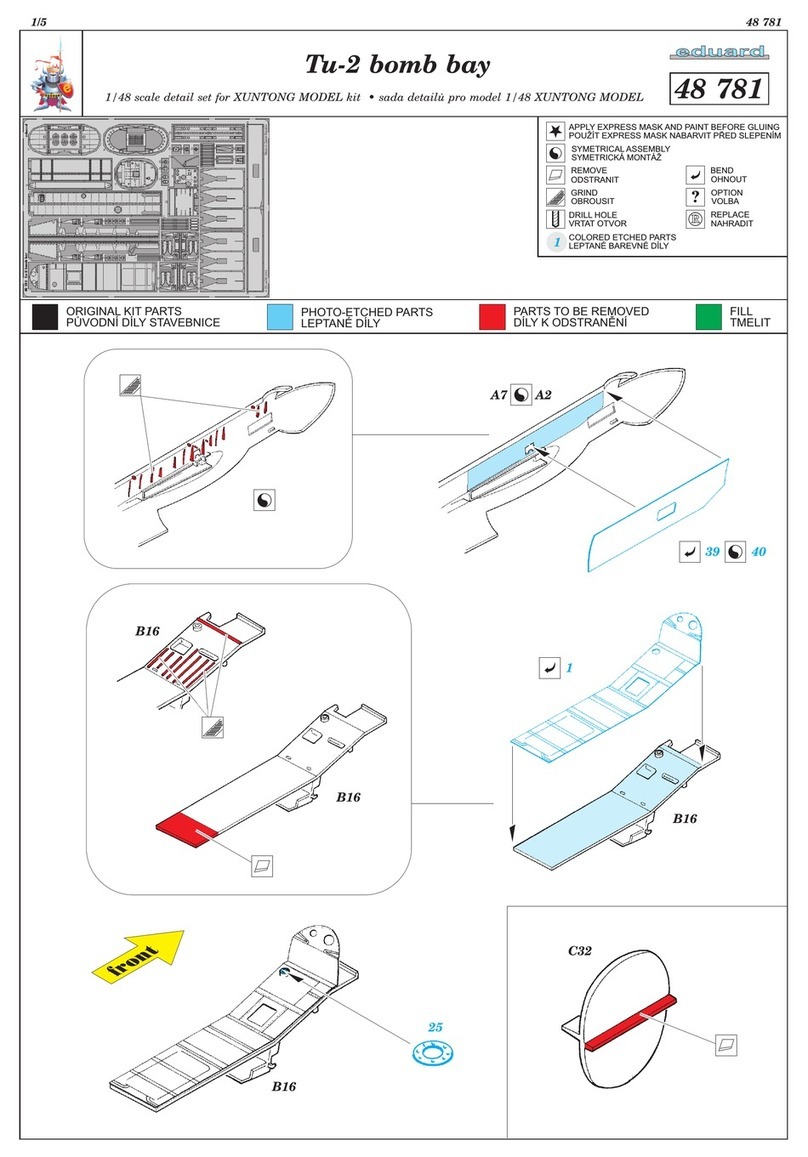

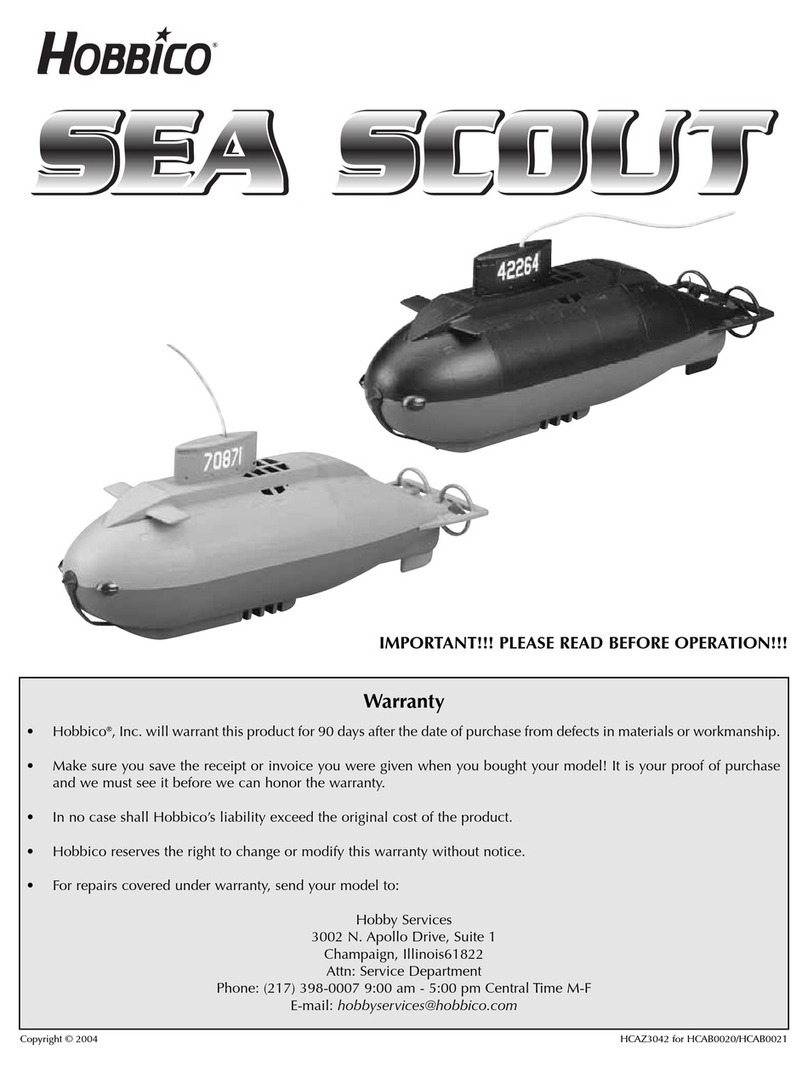

Step 32.1 The CG for your Xtreme Stick is located at 3-

1/8“ to 3-1/2" (80 - 90 mm) back from the leading edge of

the wing when the wing has been attached to the fuselage

as per illustration 33A.

Step 32.2 For the initial flight, the CG should be located at

3 1/8” (80mm) back from the leading edge of the wing when

the wing has been attached to the fuselage.

Step 32.3 The CG is measured with the engine, radio gear

and all other components installed but WITH NO FUEL IN

THE TANK.

Step 32.4 Set up the CG as it will be when you fly it BUT

WITH NO FUEL IN THE TANK.

Step 32.5 It is very important to have the CG correct.

Flying your model with the CG too far back will likely lead

to loss of control and a crash. If you discover that after you

have assembled your model and installed your radio and

engine that the CG of your model is incorrect you must

bring the CG to the correct location by doing the following

BEFORE FLYING :

- Move the battery pack fore or aft.

- Move other components fore or aft.

- Change engine to a lighter or heavier model.

- Add weight to the nose or tail. If adding weight to the

nose, try to make it useful by going to a heavier duty engine

or adding a spinner with a heavy metal backing plate. As a

last resort, add stick on “dead” weight where appropriate.

3

Step 2.1 When the epoxy has cured in Stage 1, trial fit the

second wing panel onto the wing joiner first to ensure that

the two panels fit without an excessive gap.

Step 2.2 Now apply plenty of epoxy to the wing joiner and

wing root ribs of both wing panels. Use only 30 minute

epoxy to ensure a strong bond and give yourself plenty of

working time. As described in the Step 1.4, repeatedly

apply epoxy and insert into the wing joiner cavity, the epoxy

should ooze from the joint and the excess should be

cleaned off with a rag or tissue before it cures.

Step 2.3 Use low tack masking tape to hold the two wing

panels together until the epoxy cures. See 2C

1E - Carefully insert the joiner all the way to the center line

Step 3.1 Once the epoxy has cured completely (allow sev-

eral hours at least), the tape can be carefully removed from

the wing panels. Peel the tape back on itself… do not pull

upright away from the wing. To seal and finish the joint in

the wings, a roll of wing joiner tape has been supplied.

Starting on the bottom side of the wing, stick the tape cen-

trally over the joint ensuring that it is pressed down firmly

as you work around the wing. Wrap the tape all the way

around the wing joint in one piece, starting and finishing at

the servo mounting cavity in the bottom of the wing.

Center line

80mm - 90mm

3-1/8 in. - 3-1/2 in.

BACK FRONT

1F - Wipe off the excess epoxy then allow to cure

3C- Continue over to the bottom of the

wing & along to the servo cable cavity

and trim off the excess tape

3B- Continue applying the tape over

the top of the wing, pressing down

firmly as you go

3A- Apply tape over the joint starting

here on the bottom at the servo cavity

WING ASSEMBLY - JOINING THE WING HALVES (Cont.)

WING ASSEMBLY - JOINING THE WING HALVES (Cont.)

STAGE

3

STAGE

2

2C - Use low tack masking tape to

hold tightly together

2B - Align the two wing panels and

slowly close the gap until the

wing root ends are firmly in

contact with each other

2A - Apply plenty of 30 minute epoxy

glue to all surfaces

14

INSTALLING THE RECEIVER

STAGE

30

CONFIRM RADIO OPERATION

STAGE

31

BALANCING THE AIRCRAFT

STAGE 32

CONFIRM MECHANICAL INTEGRITY

STAGE

33

Step 30.1 Consult your radio manual for instructions about

hooking up your receiver.

Step 30.2 Plan where you are going to put the receiver

with consideration for routing the antenna safely.

Step 30.3 Wrap the receiver securely in foam suitable for

RC equipment and wrap the foam insulated receiver in a

plastic bag or cling wrap.

Step 30.4 Generally in the absence of specific instructions

from the radio manufacturer, it is recommended that the

receiver should be placed where it is least likely to have

impact during a crash. Keep the battery pack and other

heavy loose items ahead of the receiver.

Step 31.1 Consult your radio manual for instructions about

testing and operating your radio system.

Step 31.2 Pay particular attention to charging your radio

system batteries and range testing the system before and

after each flight.

Step 31.3 Check that all controls are working correctly

before and after each flight.

Step 33.1 Once you have confirmed that the

CG is correct, you should do a thorough review

of the entire model before your first flight.

Check everything twice! Every hook up, every

coupling, everything! Do it twice!!

Step 33.2 Before your first flight, have an

experienced flyer review your work. Do not fly

your model until it has been checked out by a

third party who knows how to fly and how to

set up a model aircraft. Do not fly alone. Seek

experienced help.

Step 33.3 Once you have completed your first

flight, get in the habit of checking your model over

before and after each flight! Don’t fly if you find

something that is not right!

33A - CG location

WE RECOMMEND MEDIUM GRADE THREAD LOCKER BE APPLIED

SPARINGLY TO ALL METAL TO METAL SCREW FASTENERS. DO

NOT APPLY TO PLASTIC