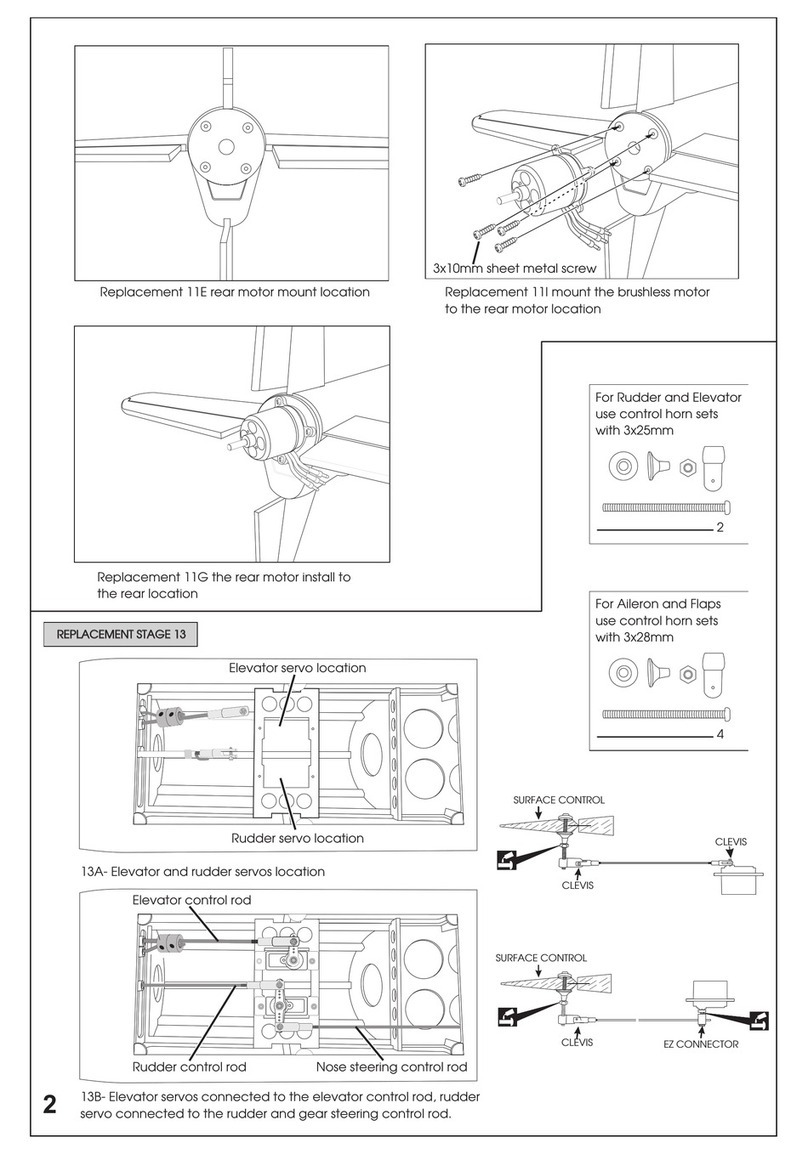

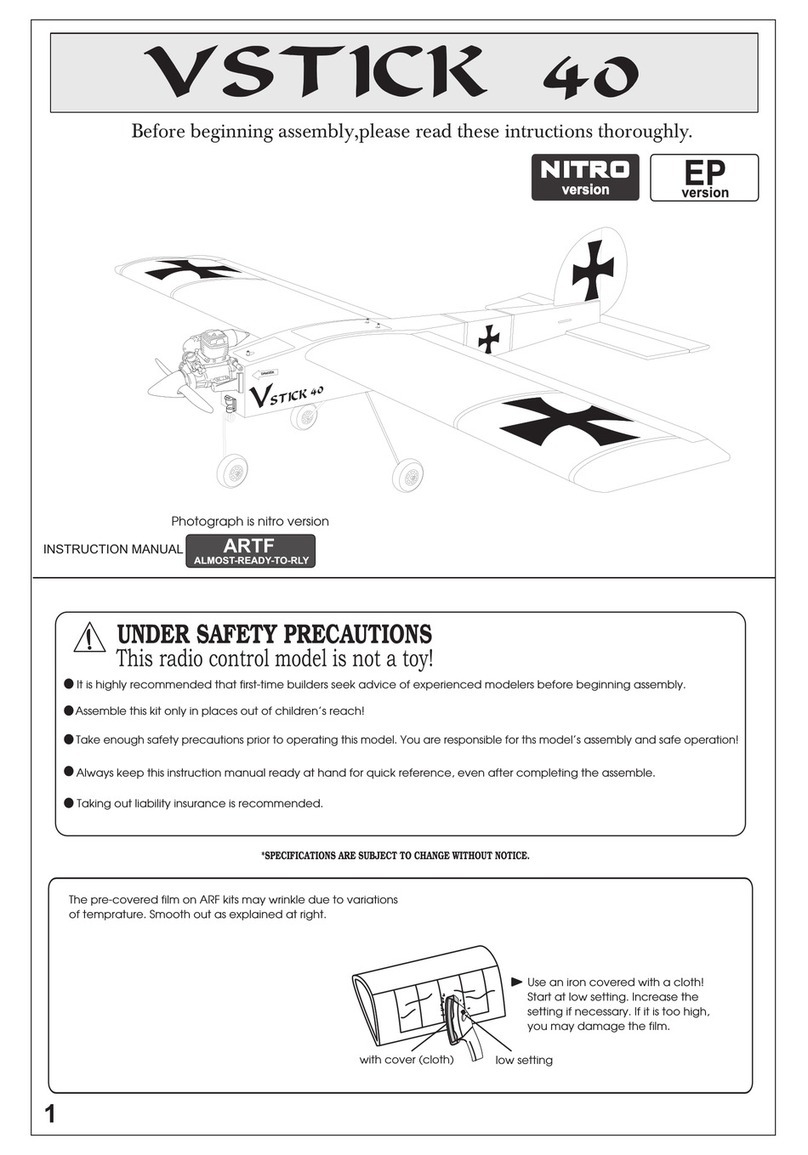

WING ASSEMBLY - JOINING THE WING HALVES (Gont.)

2A- Apply plenty of30 minuta epory 2B-Align the two wing panels and 2C- Use low tack masking tape to hold

gluetoall surfac6 slowly close the gap until the tightly together

:ilg",'iil "11f"."31" rirmr' in

Step 2.4 Once the epoxy has cured completely (allow sev- supplied.Starting on the bottom side of the wing, stick the

eral hours at least), the tape can be carefully removed from tape centrally over the joint ensuring that it is pressed down

the wing panels. Peel the tape back on itself... do not pull firmly as you work around the wing. Wrap the tape all the

upright away from the wing. To seal and finish the joint in way around the wing joint in one piece, starting and finish-

the wings, a roll of wing joiner tape has been ing on the bottom.

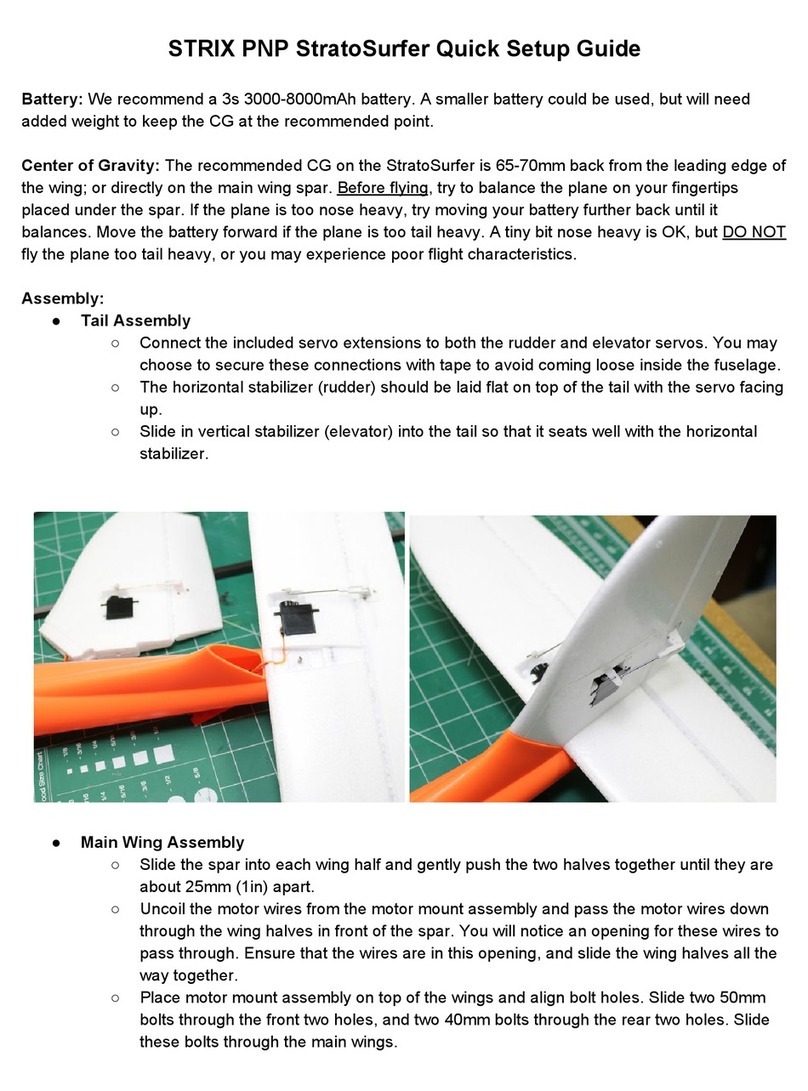

Step 2.1 When the epoxy has cured in Stage 1, trial fit the

second wing panel onto the wing joiner first to ensure that

the two panels fit without an excessive gap.

Step 2.2 Now apply plenty of epoxy to the wing joiner and

wing root ribs of both wing panels. Use only 30 minute

epoxy to ensure a strong bond and give yourself plenty of

working time. As described in the Step 1.3, repeatedly

apply epoxy and insert into the wing joiner cavity, the epoxy

should ooze from the joint and the excess should be

cleaned off with a rag or tissue before it cures.

Step 2.3 Use low tack maskilg tape to align the wing sur-

faces and hold the two panels together until the epoxy

cures.

3A- Prepare the servos by fitting the

rubber grommets & ferrules supplied

with your seryos

2D- Apply tape over the joint starting

here on the boftom as shown

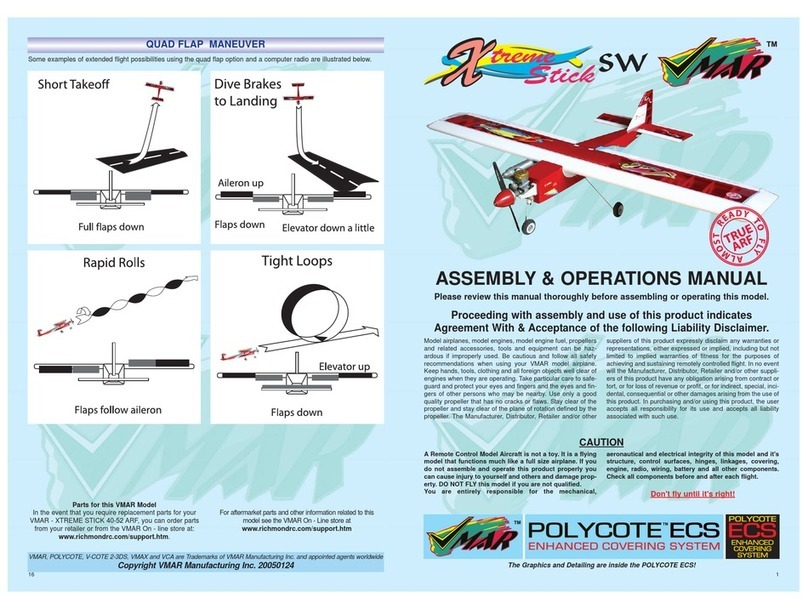

To install the aileron servos into the wing you will need the following items:

- 2 micro servos (with mouting screws control arms and grommets)

- Two aileron control rod assemblies with a clevis screwed onto both ends

- Low tack masking tape

- 2 aileron control horn assemblies

- 2 aileron extension cables 12 in (30 cm)

Step 3.1 Turn the wing upside down.

Step 3.2 Trial fit the aileron servo into the servo mounting cavity. You may have

to modify the cavity slightly to provide clearance for the servo and servo wires.

Step 3.3 Use a hobby knife to modify the cavity as required. Most servos have

their output shaft closer to one end than the other. Mount the servo so that the

output shaft is closer to the leading edge of the wing.

Step 3.4 Securely attach an aileron extension cable to the servo. Thread the

cable through the wing tube to the center of the wing. Screw the servo into place

with the screws and grommets supplied. lt is important to install the grommets

and screws correctly. See the manual that came with your radio for intructions

about your paticular servo grommets.(Note that in some type servo installation

without the grommets)

Step 3.5 Fasten the screws down according to the seryo manufacturers recom-

mended tightness.

Step 3.6 Repeat step 3.2 to 3.5 for the other wing panel.

2E-Continue applying the tape over 2F- Gontinue back around to the bgttom

the top of the wing, pressing down of the wing & overlap the tape where you

firmly as you go stafted. Trim off excess tape

INSTALLING THE AILERON SERVO INTO THE WING

38- Aileron servo location