2 3

VMAR and POLYCOTE are Trademarks of VMAR Manufacturing and

authorized VMAR Agents worldwide. Copyright Richmond RC Supply Ltd

TM

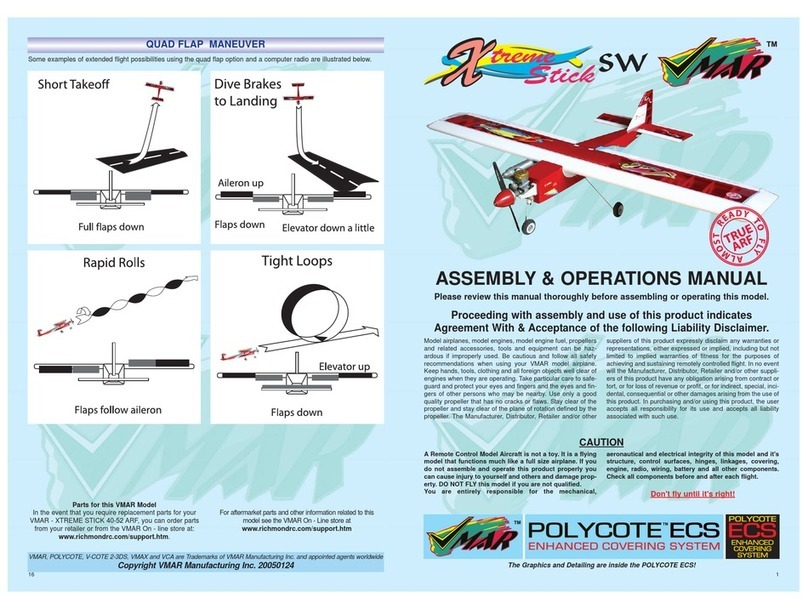

CARE & MAINTENANCE OF POLYCOTE ECS.

POLYCOTE ECS is a proprietary Enhanced Covering System engineered in Canada &

available only from VMAR. With POLYCOTE ECS the graphics are inside the covering... not

stuck on top. No Decals! No Layers! No Strips! No Stripes! POLYCOTE ECS utilizes ULTRA

TOUGH polyester and our SURE SEAL system to ensure that the seams stay down! Best of all POLYCOTE is totally fuel

proof! Quite simply... POLYCOTE ECS leads the pack in ARF covering systems!

By putting the graphics inside the POLYESTER covering... we've reduced the need for maintenance to a minimum. No

seams to pick up, very few edges, extraordinary fuel proofing etc. With POLYCOTE ECS you will spend more time flying

and less time reworking the covering! Polyester offers the best in covering performance and as with any POLYESTER

covering here are a few tips to make it even easier to keep POLYCOTE ECS looking it's best!

CARE: Avoid puncturing. Avoid leaving your model in a closed car exposed to direct heating from the sun for lengthy

periods. Temperatures under such conditions can exceed 50C (122F) and sagging may occur.

TIGHTENING: To tighten POLYCOTE ECS we recommend using a medium-high temperature heat iron on the seams, edges, around

perimeters and over solid surfaces. Use a heat iron "sock" on the iron and push down firmly on the covering over solid areas to bond

the covering to the underlying substrate. Work with the iron set at 250-300F. You may also work with a heat gun over solid surfaces

provided that all edges and seams are set with a heat iron first. If using a heat gun over solid surfaces, make sure the edges are firmly set

with a heat iron first then use the heat gun to heat about 1 square foot of area at a time, then rub the warm covering down firmly with a soft

cotton cloth to bond the covering to the underlying substrate. DO NOT USE A HEAT GUN NEAR EDGES & SEAMS. Higher tempera-

tures may assist with complex curved surfaces. Use a medium-high temperature heat gun on POLYCOTE ECS applied over open

bays. Always practise on the bottom of a less noticable section first. Be patient and work systematically... you will likely only have to tighten

POLYCOTE once or twice to accomodate any shrinkage of the airframe in dry hot conditions.

RESEALING SEAMS: POLYCOTE ECS seams are sealed with our SURE SEAL system and will not normally lift. If you

find a loose edge, clean any oil residue from the area and the edge and reseal with thin CA.

PATCHING: If you puncture POLYCOTE ECS, clean any oil residue from the area of the puncture. We clean using Fantastic and

then a paper towel moistened with Pacer De-Bonder or alcohol or water to remove any remaining residue from the surface. The

patch should be 1/2" bigger than the hole on all sides. We recommend using POLYCOTE patch sheets if provided with your model

or polyester covering such as POLYCOTE, ULTRACOTE or ORACOVER and the use of a heat iron and soft cloth. Monokote,

SolarFilm or V-COTE covering material will also work. Cut the patch with rounded corners. Seal the patch in place with a heat iron set

at 250F first and then tighten the patch and the original covering around the patch as outlined in the tightening section above. To repair

larger more extensive damage areas, you may wish to obtain the appropriate POLYCOTE ECS covering set for this model.

CLEANING AFTER FLYING: To clean POLYCOTE ECS after flying we recommend Fantastic household cleaner and

disposable paper towels. You can use just about any cleaner and we are not aware of any cleaner that will damage

POLYCOTE but it is a good idea to always test a small out of the way spot first. Wipe along seams, not across. To really

show off your POLYCOTE ECS covering, after cleaning wtih Fantastic... use a bit of Armorall and buff dry & shiny.

CLEANING INITIALLY: POLYCOTE ECS has very few seams and we use our SURE SEAL system to really lock the

seams down. Upon initial inspection if you see a thin streaky film on any of the POLYCOTE ECS when looked at under

bright light this is a residue from the SURE SEAL process. It is easily removed using Minerial Spirits (Paint Thinner,

Varsol). If you've ever painted with oil base paints you probably have Mineral Spirits on hand already, if not, it is readily

available at a paint or hardware store. It is recommended that you work with Mineral Spirits outdoors and follow the

directions on the container. Use a paper towel and wipe a slightly wet film of Mineral Spirits over 1/4 of a wing or half a

fuselage at a time. Rub gently while still wet. Change towels frequently. Use a clean towel to buff dry. If you want to

accentuate the deep "clear coat" gloss of POLYCOTE ECS even more, use a bit of Armorall and buff shiny with a clean

paper towel. Discard all soiled paper towels into a metal garbage can stored outdoors.

TM

Check for updates and more

information about

POLYCOTE ECS at

www.richmondrc.com/polycote.htm

CUTTING: POLYCOTE ECS is made from ULTRA TOUGH POLYESTER.

Where possible, use scissors to cut POLYCOTE. Scissors work well.

Otherwise use a new sharp #11 Blade. The blade must be SHARP.

For more information that may be relevant to

this model please visit us at

www.richmondrc.com/support.htm

Copyright Richmond RC Supply Ltd

VMAR is a Trademark of VMAR Manufacturing Inc. and authorized VMAR Agents worldwide

TM PLEASE READ EVERYTHING BEFORE ASSEMBLY!

REMOVING & USING TAPE: Tape may been used to hold control surfaces or other parts in place during shipping. When

removing tape from POLYCOTE ECS, peal the tape back on itself so that the pulling is parallel to the surface of the

covering. If the tape is near or across a seam or an edge, peal towards the edge or seam. Do NOT pull the tape up at right

angles to the covering or away from a seam or edge. If you use tape during the assembly process use a low tack masking

tape and remove it using the procedure noted above.

HINTS & TIPS

P21ES_Important_Info_20030222.pmd

P21ES_Important_Info_20030222.pmd

PILATUS PC6B

ELECTRIC ARF

1. During construction use Low Tack Masking Tape only. The

green painters masking tape works well. When removing tape

from your model, peal the tape back carefully upon itself.

Do not pull the tape at right angles to the surface to which

the tape has been applied or you run the risk of pulling the

coveirng away from the substrate to which it has been

applied.

2. On Page 3, Step 1.2 refers to various items that are not

included but are required to complete this model.

Extensive testing at elevations up to 2000 feet above sea

level has resulted in the following specific

recommendations.

2.1 Use an RC Radio intended for Electric Flight. These

systems usually come with a ligh weight receiver, smaller

servos etc. We recommend the Airtronics #AIR-VG407FM

system that comes with a lightweight 4ch FM receiver and 3

super micro lite servos (#AIR-94091Z). For this model you

will need only 2 of the 3 Airtronics servos supplied in the

system. The 94091Z servo provides 18oz of Torque at 4.8V

and 23 oz of Torque 6.0 and weights only 9 grams. Best of

all the receiver and servos have the new Z connector to

ensure compatibility with a wide range of new Airtronics,

Fubaba and JR components.

2.2 Use a good Electronic Speed Control (ESC) such as the

Airtronics Super Micro ESC #AIR-96334Z which is perfect

to control the motor speed of this model.

2.3 Note that you must use the 7.2 volt version of Speed

400 motor not the 6.0 volt version. We recommend VMAR's

400 motor (#VME-0400M072) along with an appropriate

prop adapter (#VME-0400PA) and a good quality electric

propeller such as the APC-6x4 Electric.

2.4 For good performance we recommend a 9.6 volt battery

pack NOT the 8.4 volt battery pack referred to in the

instructions. You can begin with a 9.6V (8 cell) 500AR nicad

pack and upgrade later to a 9.6V/1100mAh NiMH pack for

much longer flight times. The 500AR nicad pack will give

you flight times of approximately 3 minutes at full throttle.

The 1100mAh NiMH pack will give you approximately 7

minutes of flight time at full throttle.

3. Before beginning Step 2 on Page 3, remove any lockdown

material and/or foam pads from the wing. Be careful when

removing tape. Pull tape strips back on themselves... do not pull

tape away from the wing. Be very careful when removing tape

that crosses a seam or edge in the covering. Remove any Tape

Residue with alcohol or other not abrasive solvent. Test a small

area first.

4. Please review the "Care and Maintenance of POLYCOTE

ECS" page within this document. Pay particular attention to the

section entitled "Cleaning Initially". We recommend that you

clean the surfaces initially in order to maximize the appearance

of your new model. Remove any plastic plates before cleaning

and test all cleaners on painted surfaces.

5. On Page 3 in several of the wing pictures you can see the

wing bolt holes cleared of covering. Before clearing the holes.

wick a bit of ZAP (thin) CA into the covering area from inside the

hole, externally press the covering around the hole, let the CA

dry, then trim the covering clear of the mounting holes

with a sharp #11 blade.

6. When installing the motor as described in Phase 4 on

Page 5, we strongly suggest opening up some cooling air

inlets on the front nose ring plate. The factory has tapped

two holes for the motor retaining screws. Use a cutting

knife or a dremel tool to open up some air inlet slots in the

nose ring to match the venting slots on the front of your

particular motor. Cool motors produce more power!

7. Plan to use an Electronic Speed Control ESC such as

the recommended Aitronics #AIR-96334Z. Mount the ESC

where it is in the airflow away from the motor. Mount the

components facing into the air circulation.

8. To properly cool your motor, electronic speed control

and your battery we recommend cutting some vents into

both bottom hatches. Examine the inside (uncovered side)

of both hatches and plan any cutouts to avoid structural

members. Cut the sheeting and covering only. The

Hatches are for cosmetic purposes and some modellers

will fly without them. We do recommend using the hatches

but strongly suggest cutting some vents into both bottom

hatches to provide an exit for hot air coming from the

motor and for cooling air to pass over the ESC & battery.