Voith DSG-B03212 User manual

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 1 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

7

I/H Converter

Type: DSG-B03212

Type: DSG-B07212

Translation of the original version

Installation and Operating Manual

Version 4.1

ATTENTION!

Please make sure to read this instruction manual prior to transport, installation,

commissioning, operation, etc. and keep it for further use!

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 2 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

If you have any questions concerning the I/H converter,

please contact J.M. Voith SE & Co. KG, Crailsheim,

After-Sales Service of Product Group Division Digital

Ventures in Crailsheim, indicating the article number and

the serial number of the I/H converter.

J.M. Voith SE & Co. KG

P.O. Box 15 55

D-74555 Crailsheim

Switchboard: +49 - 7951 / 32 - 0

Fax No.: +49 - 7951 / 32 - 500

After-Sales Service of Product Group

Division Digital Ventures

Direct dial: +49 - 7951 / 32 - 470

Direct fax: +49 - 7951 / 32 - 605

Email: turcon@voith.com

Address for deliveries of goods:

Voith Group │ Division Digital Ventures

J.M. Voith SE & Co. KG

Voithstraße 1

D-74564 Crailsheim

This instruction manual describes the design standard of

the I/H converter types DSG-B03212 and DSG-B07212

delivered as of 2019 / 02.

It does not consider any alterations or modifications on

the I/P converter which have not been performed by J.M.

Voith SE & Co. KG. Any such alterations or modifications

are exempted from all warranty claims.

J.M. Voith SE & Co. KG 2019

This Instruction Manual are protected by copyright laws.

It must not be translated, duplicated (mechanically or

electronically) in whole or in part, or passed on to third

parties without the publisher's written approval.

Revised on: 2019 / 02

Order No. 918 3626018861 en

Version: 4.1

Printed in Germany

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 3 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

Contents

Installation and Operating Manual

Page

1Technical Data ............................................................................................................................... 4

1.1 I/H converter............................................................................................................................. 4

2Safety Information......................................................................................................................... 6

2.1 Definition of symbols and warnings ......................................................................................... 6

2.2 Proper use................................................................................................................................ 6

2.3 Important information............................................................................................................... 6

2.4 Warranty................................................................................................................................... 8

3Function.......................................................................................................................................... 9

4Packing, Storage and Transportation........................................................................................ 12

5Installation.................................................................................................................................... 13

5.1 Assembly................................................................................................................................ 13

5.2 Hydraulic connection.............................................................................................................. 14

5.3 Electrical connection.............................................................................................................. 14

6Commissioning............................................................................................................................ 15

6.1 Test Run................................................................................................................................. 15

6.2 Parameter setting................................................................................................................... 15

6.2.1 Potentiometer effect.................................................................................................. 16

6.2.2 Factory setting........................................................................................................... 16

7Operation...................................................................................................................................... 17

7.1 Operation with manual operation knob.................................................................................. 17

7.2 Normal operation ................................................................................................................... 17

7.3 Troubleshooting ..................................................................................................................... 18

8Maintenance, Servicing, and Inspections................................................................................. 19

8.1 Maintenance and servicing.................................................................................................... 19

8.2 Inspections............................................................................................................................. 20

8.3 Spare parts information.......................................................................................................... 20

9Decommissioning........................................................................................................................ 21

10 Annex............................................................................................................................................ 22

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 4 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

1 Technical Data

1.1 I/H converter

I/H converter

DSG-B03212

DSG-B07212

Article number

9 186827 0

9 186826 0

Instruction Manual No. 918 3626018861

Marking II 2G IIC T4

Protection IP 65 as per EN 60529

Ambient temperature TA

-30 ... +60

°C

Ambient temperature (storage)

-40 ... +90

°C

Installation conditions Indoor installation

Outdoor installation Offshore

Industr. atmosph.

Hydraulic Data

Supply pressure P max.

40

bar

Supply pressure P min. PA max + 1.5 bar

Pressure adjusting range PA (output pressure)

See Chapter 6.2.1

Flow rate P → A at ∆P = 1 bar

17

l/min

Flow rate A → T at ∆P = 1 bar

18

l/min

Return pressure on T1 and T2

0

bar

Leakage at T1 (Toil = 50 °C and P=10 bar) < 4 l/min

Leakage at T2

< 1

l/min

Operating medium

Type

Hydraulic oil as per DIN 51524

Turbine oil as per DIN 51515

High-flash point fluid1)

oil temperature during operation +10 … +60 °C

Cleanliness grade (ISO VG 4406) - / 19 / 16

Viscosity (DIN 51519)

ISO VG 32 … ISO VG 46

Mechanical Data

Weight approx. 12 kg

Installation position

See Chapter 10

Dimensions, fastening See Chapter 10

Hydraulic connection

See Chapter 10

Sealing material

FPM2)

Special design4)

NBR3)

1) according to the customer's specification and consultation with J.M. Voith SE & Co. KG │ Division Digital Ventures

2) Fluor-caoutchouc

3) Acrylnitril-Butadien-caoutchouc

4) According to customer's request or especially for high-flash point fluids

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 5 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

Electrical Data

Supply voltage 24 (+10% / -15%)

V DC

Current consumption

approx. 0.7, max. 3 for t < 1 sec

A

Control Parameters

Setpoint w

for pressure adjusting range PA min….PA

max w = 0/4 … 20 mA

Input load 25 Ω

Input configuration

E360 Electronics

E503 Electronics

Applied, related to GND

Isolated (500 kΩ)

Setpoint limitation

E360 Electronics

E503 Electronics

w > 35

w > 90

mA

mA

Adjustment ranges X0 and X1

See Chapter 6.2.1

Magnetic force switch-off at

(only with E503 electronics) w < 3 mA

Voith Control Magnet (VRM)

marking with cable end

II 2G Ex db IIC T4

Protection IP 65 as per EN 60529

Ambient temperature TA at T4 -30 … +60 °C

… in connection with components

Cable entry

(cable end design) II 2G Ex db IIC T4-T6

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 6 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

2 Safety Information

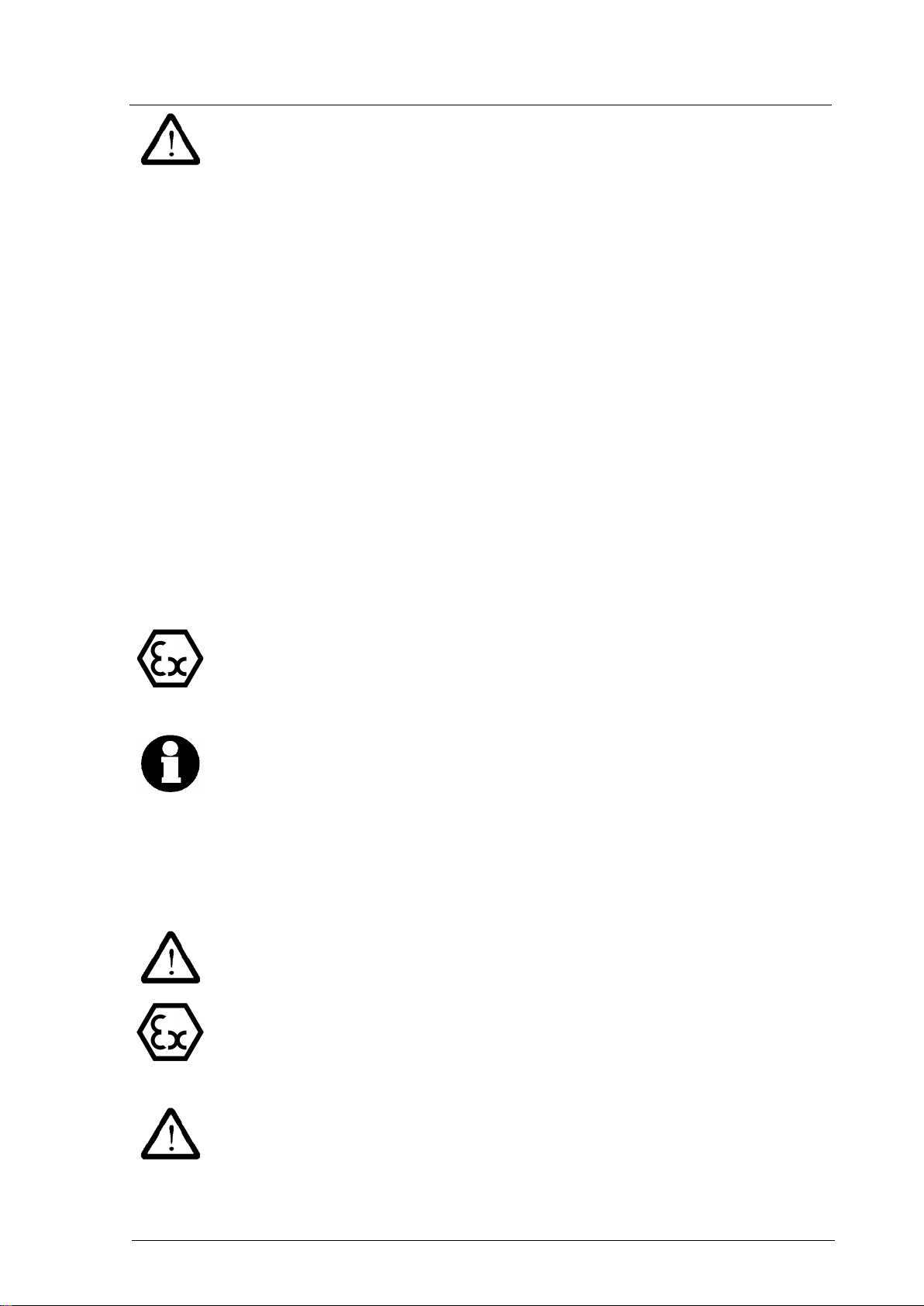

2.1 Definition of symbols and warnings

Symbol Damage/harm

to ... Signal word Definition Consequences

Persons,

property EX-

PROTECTION! Indication for Ex-protection

Explosion hazard

Persons DANGER! Imminent danger Fatal or most

serious injuries

(crippling)

Persons WARNING! Dangerous situation possible Fatal or most

serious injuries

possible

Property ATTENTION! Harmful situation possible Possible damage to

- the product

- its environment

– Note!

Information! Application details and other

useful information Efficient in operation

2.2 Proper use

The I/H converter is provided to convert an electric set signal, e.g. 4 - 20 mA, to the

corresponding hydraulic output pressure reduced to the supply pressure. This allows, for

example, remote-controlled, infinitely variable adjustment of control pistons on hydraulic

cylinders positioning valves of steam turbines.

The permissible temperature of the hydraulic oil is +10 °C … +60 °C.

The max. surface of the device is significantly determined by the temperature of the

hydraulic oil.

For the operation it is therefore vital to ensure that the max. permissible oil temperature

will not be exceeded!

2.3 Important information

The following information refers to the entire instruction manual and is to be observed in

addition to the individual instructions.

Accident prevention

It is imperative to observe the requirements of the relevant standards and regulations

when connecting an I/H converter in explosion-proof design.

There must not be any potentially explosive atmosphere during all works performed,

such as e.g. transportation, storage, installation, electrical connection, commissioning,

test run, maintenance and servicing!

Operating medium leaving/leaking from the I/H converter may get in contact with hot

machine parts, posing a risk of fire.

When working on the I/H converter, it is vital to wear protective clothing.

On commissioning or operation of the I/H converter, spraying hydraulic oil may get

into

the eyes causing blindness. Wear protective glasses for all works performed on the I/H

converter.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 7 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

The I/H converter is a hydraulic unit.

Any improper use may lead to the leakage of

operating medium under pressure, posing a

risk to the health and life of the operating

staff. Prior to performing any work on the I/H converter, switch off the hydraulic auxiliary

energy.

During operation, the outer surfaces of the I/H converter and the hydraulic connecting

lines may become hot d

ue to the operating medium. Any contact may cause injuries by

burning. Prior to performing any work on the I/H converter, let the I/H converter cool

down.

On commissioning or operation of the I/H converter, the end of the piston rod directly or

indirectly driven by the I/H converter may move uncontrolled in case of failure of the

hydraulic or electric energy, due to malfunctions in the master control or on the I/H

converter. This movement may pose a risk to both individuals and property. Prior to

performing any work on the I/H converter, switch off the hydraulic and electric auxiliary

energy.

Electric components are integrated in the I/H converter which may be destroyed, e.g.

during electric welding near the I/H converter. Prior to performing electric welding near

the I/H converter, remove all electric connecting lines.

Environmental protection

On assembly, disassembly or improper use of the I/H converter, operating medium may

leak out. Operating oil getting into the sewage system or open soil causes severe

environmental damages. Collect leaking operating medium and dispose of it in

accordance with the national statutory provisions.

Painting

In case of repaints or mendings of the paint on a device, please ensure that the

maximal permissible total f

ilm thickness will not be exceeded. For devices of Gas

Groups IIA and IIB, it is 2 mm and for devices of Gas Group IIC it is 0.2 mm.

Instruction Manual

The instruction manual contains important information regarding proper handling of the

I/H converter. Prior to installation and commissioning of the I/H converter, carefully read

the entire instruction manual and make sure you fully understood its content.

Keep the instruction manual in a place constantly accessible to the operating staff.

In addition to this instruction manual, have the rules governing accident prevention and

environmental protection available and observe the same.

Please keep for later reference.

Staff qualification

Only trained and instructed personnel are allowed to work on the I/H converter. These

personnel must be sufficiently trained, instructed and authorized to properly mount,

operate and maintain the I/H converter in accordance with the safety standards.

Installation, commissioning and operation have to be performed by a certified electrician

with experience and knowledge in the field of explosion protection.

Constructional modification

Mounting work and structural modifications are not permitted.

The screw fitting of the cable entry on the control magnet (VRM) is secured against

distortion. Do not distort or slacken the screw fitting.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 8 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

2.4 Warranty

The terms and conditions stated in the General Terms and Conditions of Sale

for Industrial Engineering of J.M. Voith SE & Co. KG │ Division Digital Ventures,

Crailsheim, shall apply. Warranty claims are excluded if these are due to one or several of

the following causes:

•Improper transportation, storage, installation, connection, commissioning, operation,

maintenance and repair of products of the I/H converter.

•Failure to observe the operational and product safety regulations included in this

instruction manual.

•Use of spare parts not approved by J.M. Voith SE & Co. KG │ Division Digital Ventures,

Crailsheim.

During the warranty period, repairs to the I/H converter are only to be performed with

the approval of J.M. Voith SE & Co. KG │ Division Digital Ventures, Crailsheim.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 9 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

3 Function

The I/H converter is an electro-hydraulic, remote controllable current-to-pressure converter.

With a setpoint of w = 0/4 mA to 20 mA, the requested output pressure PA can be set

quickly and hysteresis-free. For instance, a pilot piston or a hydraulic cylinder may be

positioned against a restoring spring.

For the operation of the I/H converter, electric and hydraulic auxiliary energy is required. All

electric components necessary for the I/H converter operation are integrated in the I/H

converter and protected against environmental influences. The controllers with connections

for setpoint limitation and magnetic force control are installed in the Voith control magnet

(VRM). With potentiometers X0 and X1 which are accessible from outside, the output

pressure PA can be allocated to setpoint w.

Function of manual operation knob

The control magnet of the I/H converter is provided with a manual operation knob. Same

can be used instead of the magnetic force FMag to define a spring force, adjustable via the

manual operation knob, which controls the piston via the magnet armature and the tappet.

The hydraulic force FHyd being proportional to the output PAacts against this spring force.

Thus adjustment of the output pressure is possible without electric connection.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 10 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

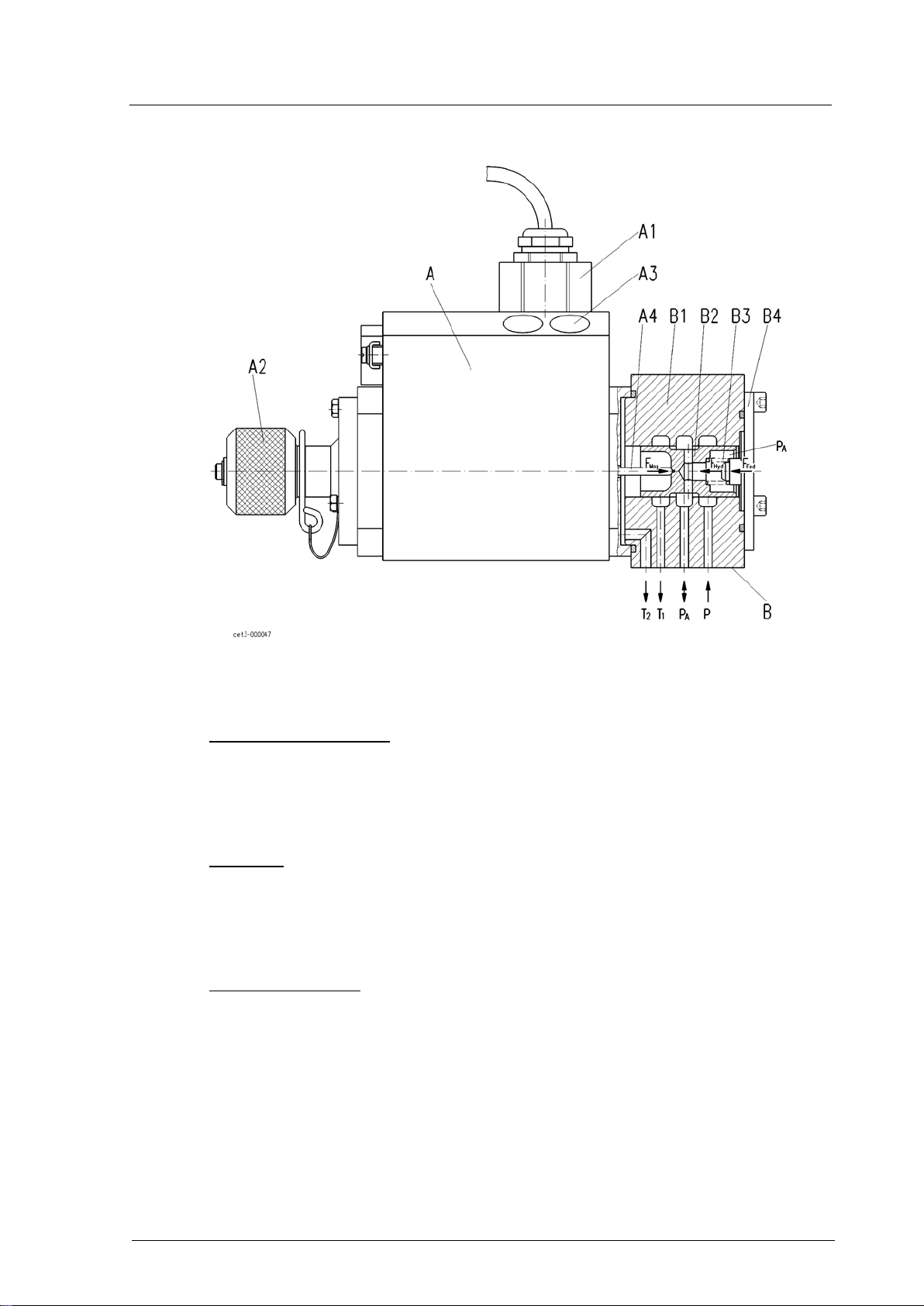

View of I/H converter

Fig. 1: Sectional view of I/H converter

Voith control magnet VRM (A)

With integrated magnetic force control

Electrical connection (A1)

Manual opertion knob (A2)

Potentiometers X0 and X1 (A3)

Tappet for power transmission (A4)

Slide valve (B)

With pressure-reducing arrangement

Control housing (B1)

Control piston (B2)

Control spring (B3)

Cover (B4)

Hydraulic connections

Supply pressure P

Output pressure PA

Tank return line T1

Tank return line of leakage T2

Magnetic force FMag

Spring force FFed

Hydraulic force FHyd

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 11 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

Block diagram - I/H converter

Fig. 2: Block diagram of I/H converter

Pressure control

The control system controls the I/H Converter by an electric signal w = 4…20 mA for the

power setpoint UMag. The actual value in the magnetic system is measured by a Hall

probe and returned to the magnetic force controller as UHall. The magnetic force FMag

assigned to the setpoint w by potentiometers X0 and X1 is transmitted to the control piston

via a tappet. The hydraulic force FHyd being proportional to the output pressure PA acts

against the magnetic force. In balanced condition, the control piston is in center position

and the output pressure PA corresponds to setpoint w.

Spring force FFed of the control spring generates a force offset in order to ensure the I/H

converter function also with output pressures near 0 bar.

Limitation of maximum value

In case of incorrect connection of the setpoint, e.g. by unintentional connection of 24 VDC

to the plus-port of the setpoint input, the setpoint current is limited to an uncritical value by

means of an overload protector integrated in the VRM, thus protecting the I/H converter

control against damage.

I/H Converter

Voith control magnet

Magnetic force controller

Control

stadion

Magnetic system

Hydraulic part

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 12 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

4 Packing, Storage and Transportation

Packing

The I/H converter is supplied in special packaging. All hydraulic connection openings are

sealed with protective plugs.

Storage and preservation

The outer surfaces of the I/H converter are electro-plated. On delivery, the inner parts of

the I/H converter which are not surface-coated are moistened with preservation oil.

Within Europe, this preservation is sufficient as corrosion protection for about 8 months,

provided the I/H converter is stored in a dry location.

If it is intended to store the I/H converter for a longer period of time, special precautions

have to be taken. Coordinate such precautions for each individual case with J.M. Voith SE

& Co. KG │ Division Digital Ventures, Crailsheim.

The ambient conditions for storage must be within the limits indicated in Chapter 1.

Transportation

It is not allowed to transport the I/H converter in an explosive atmosphere! This also

applies to the transportation of spare parts!

Improper transportation or lifting of the I/H converter module may cause damage to

property and persons.

Observe, in particular, that constraining forces do not act on the cable entry of the

control magnet (VRM) and that the connecting line is not damaged.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 13 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

5 Installation

Installation and operation of the I/H converter is only allowed for the conditions stated in

Chapter 1.

Do not install the I/H converter in an explosive atmosphere!

During operation, explosive atmosphere may get into the way valve via the tank.

Therefore, the hydraulic tank must not be set up in zone 0.

Only personnel satisfying the qualifications according to Section 2.3 are allowed to work

on the I/H converter.

Improper ins

tallation of the I/H converter module may cause malfunctioning and

premature failure of the I/H converter.

Cleanliness is imperative during both installation and connection. Prevent any impurities

(dust, metal chips, etc.) from getting into the interior of the I/H converter or into the

piping system. Any such impurities may cause damage to the I/H converter.

During the installation period, cover and protect the I/H converter and, in particular, the

electric and hydraulic connections.

5.1 Assembly

Wear protective glasses when connecting the I/H converter hydraulically.

Pay attention to the correct pressure stage when selecting pipes,

flexible tubes, unions

and flanges.

Immediately replace any damaged pipes and flexible tubes.

Mount the I/H converter in accordance with the permissible installation position

indicated in Chapter 1.

Recommended fastening bolts

2 M10 hex. screws,

Property class 8.8 with washer

Tightening torque MA= 35 Nm, thread oil-moistened.

Select the screw length according to the installation situation.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 14 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

5.2 Hydraulic connection

When assembling the pipes, ensure that they are not fastened to any moving equipment,

but rather to fixed structures free from vibration.

Alterations in length caused by temperature variations must not apply constraining forces

to the I/H converter.

Fixing and hydraulic connection to a connecting flange is made via the hydraulic part.

O-rings

are used for sealing. The customer's connecting surface must correspond to Ra

≤ 1.6 µm and Rmax ≤ 6.3 µm.

To guarantee proper functioning of the I/H converter, external pressure variations must

not affect tank return line T2. In practice, the tank return l

ines T1 and T2 can be brought

together, provided the joint pipe is laid to the tank in descending position and with a

nominal width ≥ 20 mm.

Residual oil (up to 0.2 l) may leak when removing the screw plugs. Collect the oil in a

suitable container and dispose of it properly.

Do not use fibrous or hardening sealing compounds, such as hemp or mastic, for

sealing the connections and pipe unions.

Prior to installation, clean pipes from dirt, cinder, sand, chips, etc.

Pickle welded piped. Clean and flush carefully the pipes and the whole hydraulic system

before installing the I/H converter.

A flushing plate can be supplied for the flushing process. See Chapter 10, Annex.

An adapter can be supplied to connect the I/H converter to the piping system. See

Chapter 10, Annex.

5.3 Electrical connection

Only a certified electrician with experience and knowledge in the field of explosion

protection is allowed to connect the servomotor electrically in accordance with the

electro-technical rules and legal provisions of the country of manufacture.

Signal and supply lines provided by the customer to the I/H converter need to be

screened and laid separately from each other.

When connecting the customer's lines, please avoid parallel running of way valve lines

with the lines of the current converter assemblies.

Poor connecting points do not guarantee a reliable operation of the I/H converter.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 15 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

6 Commissioning

Prior to delivery, the I/H converter has been tested and adjusted at J.M. Voith SE & Co.

KG │ Division Digital Ventures

. The settings are documented in the supplied test report.

Potentiometers X0 and X1 are covered with a cap for protection against unintentional

maladjustment and entry of dirt.

On commissioning, please check all connections of the hydraulic and electric supply

systems. Commissioning must only be continued after ensuring that all hydraulic and

electric connections have been properly wired (Chapter 5).

6.1 Test Run

How to de-aerate the hydraulic system

Make sure that there is no explosive atmosphere during the test run and the de-

aeration

process!

•Switch on the power supply.

•Switch on the oil supply and check the supply pressure P.

•Enter setpoint w = 0 mA.

•After 5 minutes, switch on setpoint w = 4 mA.

•Operate the I/H converter for a period of min. 10 minutes at a setpoint sine rhythm (4

mA to 20 mA). Alternatively, it is possible to run the setpoint via a ramp (attention:

longer de-aeration time!). If it is not possible to specify a setpoint sine rhythm, a setpoint

w = 20 mA can be directly connected and disconnected via a setpoint source.

During the test run, check all hydraulic connections for leaks. In case of leaks, immediately

switch off the hydraulic supply system and remedy the leakage.

6.2 Parameter setting

Due to unintentional maladjustment of the parameters or changed operating conditions,

one or both parameters may have to be readjusted. We recommend documenting the

adjustment of the parameters as well as the set values.

The parameters are adjusted by means of potentiometers X0and X1. For position of

potentiometers, please see Chapter 10.

Prior to the test run, please ensure that the

pipes and the hydraulic system have been

cleaned. Cleanliness of the operating medium must correspond to the cleanliness grade

stated in Chapter 1. Cleaning and flushing operations essential to the operating medium

must not be performed with the I/H conve

rter hydraulically connected. Operation of the

I/H converter with contaminated operating medium is not permitted and may damage

the I/H converter.

During the test run, air pockets in the hydraulic piping system may cause temporary

pressure variations at output pressure PA. In such cases, please de-aerate the system.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 16 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

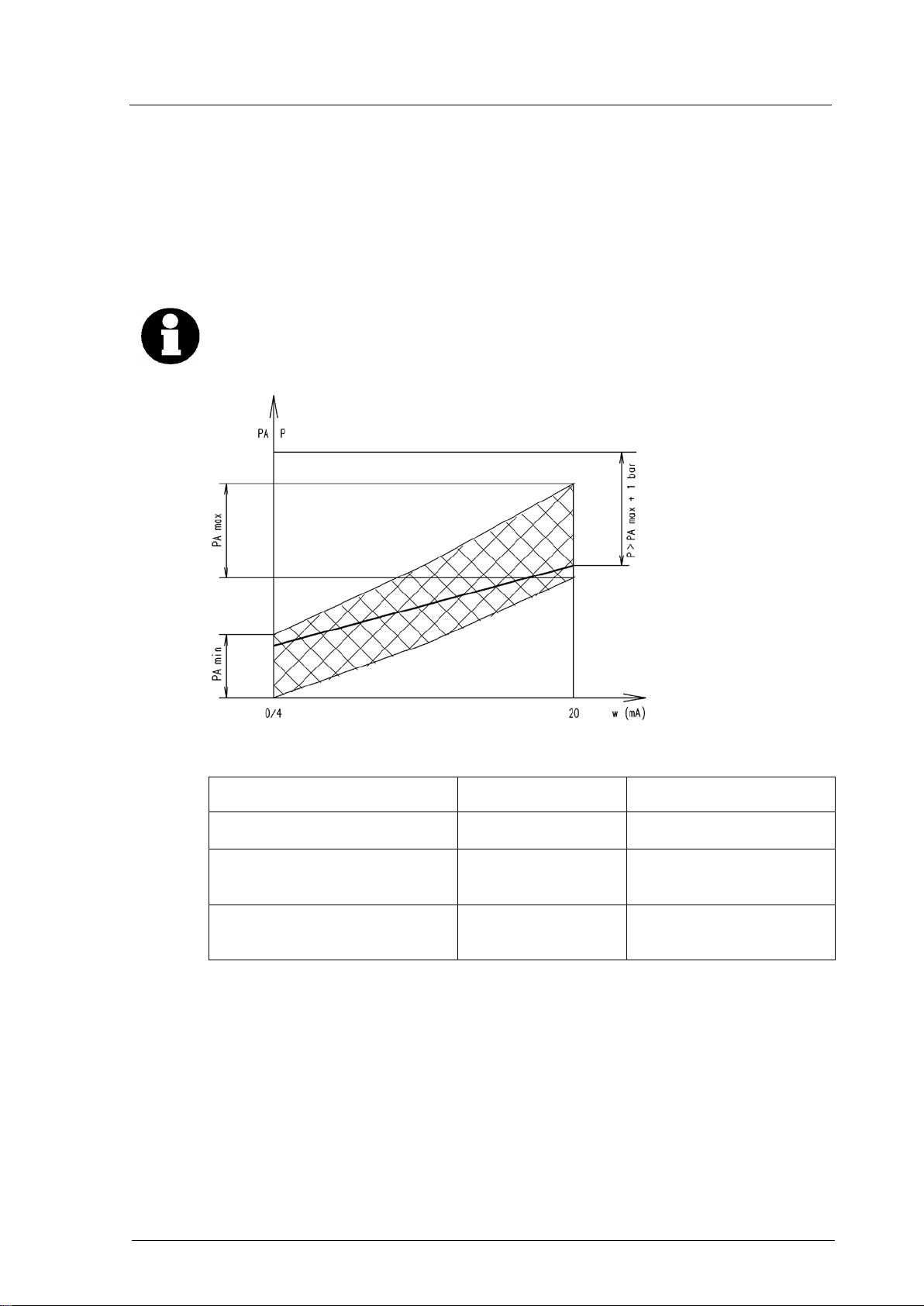

6.2.1 Potentiometer effect

Set X1 at setpoint w = 20 mA before setting X0.

Fig. 3: Adjusting range PA of I/H converter

I/H converter type DSG-B03212 DSG-B07212

Pressure adjusting range

PA [bar]

0..3 1..7

Adjusting range approx.

PAmax [bar]

at setpoint w = 20 mA

1..35..7

Adjusting range approx.

PAmin [bar]

at setpoint w = 4 mA

0..0.8

0..2 1..3

1.5..5

The bold data for PAmin refer to the maximum set pressure PAmax.

6.2.2 Factory setting

The adjusting range of PA is assigned to the setpoint range 0/4...20mA according to the

order data.

X

0

Potentiometer X

0

is used to adjust the minimum output pressure PAmin at a

setpoint w of 0 mA or 4 mA. The output pressure increases by turning the

potentiometer clockwise.

X1Potentiometer X1

is used to adjust the maximum output pressure PAmax at a

setpoint w of 20 mA. The output pressure increases by turning the potentiometer

clockwise.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 17 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

7 Operation

Working on the I/H converter is only allowed when using suitable tools intended for

hazardous areas!

7.1 Operation with manual operation knob

Operation with manual operation knob is possible without electrical auxiliary power.

Manual operation is only possible when the retaining clip on the ma

nual operation knob

was removed before.

On completion of operation with manual operation knob, move the manual operation

knob to its end position by turning it counterclockwise and lock it with the circlip.

•Remove circlip.

•Slowly turn the manual operation knob clockwise and observe the output pressure. The

output pressure PA increases. Its maximum corresponds to input pressure P.

7.2 Normal operation

During normal operation, the I/H converter is operated with an external setpoint. If the I/H

converter does not work as expected, normal operation is interrupted. To remedy the

malfunction, troubleshooting activities are required.

On operation with manual operation knob, uncontrolled stroke movements of the

components that are controlle

d by the I/H converter output may occur due to the

increase of the output pressure.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 18 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

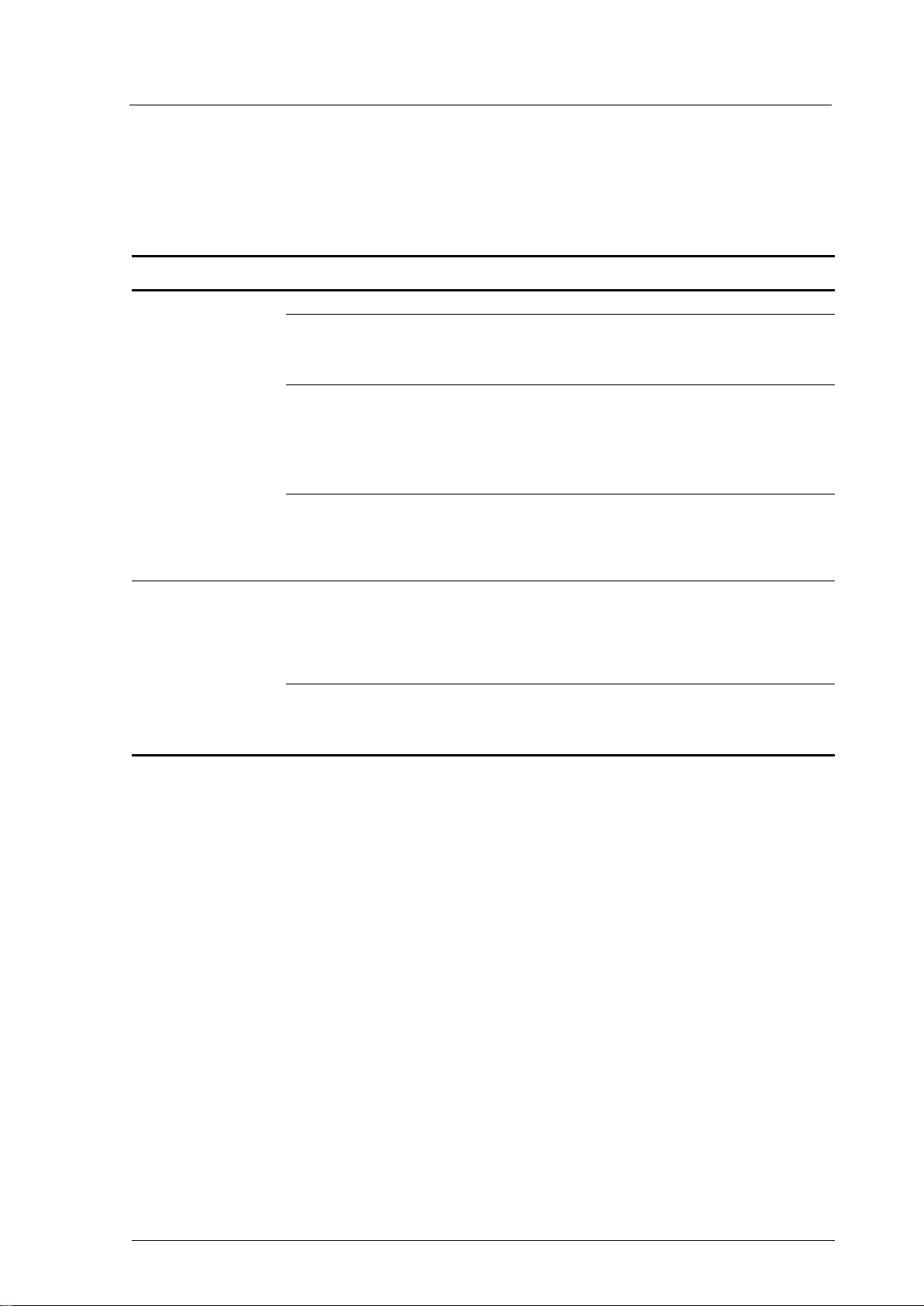

7.3 Troubleshooting

Malfunction

Possible cause(s) Remedy

Pressure variations

Supply pressure too low Check supply pressure

Air pockets in

I/H converter Dur

ing first commissioning, air pockets in the control

magnet may cause pressure variations. De-

aerate the

I/H converter according to the information provided in

Chapter 6.1.

Impurities in

hydraulic component

Contaminated operating medium causes increased

f

riction at the control piston resulting in hysteresis and

pressure variations.

Open hydraulic component and clean inner parts. If

necessary, consult

J.M. Voith SE & Co. KG │ Division

Digital Ventures.

Pressure variations

in tank return line T2 Pressure v

ariations are not allowed in tank return line

T2. If other consumers are connected to this line,

ensure that these do not generate any pressure in the

line. If necessary, consult

J.M. Voith SE & Co. KG │

Division Digital Ventures.

Output pressure does

not

follow setpoint w:

PA = 0 bar or

PA ~ P

Blocking of control piston

The control piston may be blocked by a particle. The

blocking may connect the outlet with T1 or P, thus the

output pressure PA equals 0 bar or corresponds to

the input pressure. Open hydra

ulic component and

clean inner parts. If necessary, consult

J.M. Voith SE

& Co. KG │ Division Digital Ventures.

Defect in the control magnet

VRM

The control magnet is defective if the control piston

can be moved and the output pressure can be

adjusted with the manual operation knob (see

Chapter 7.1). Replace the I/H converter.

Please kindly contact J.M. Voith SE & Co. KG │ Division Digital Ventures if any type of malfunctioning

occurs which is not included in this table.

Prior to starting work, make sure that the I/H converter was installed electrically and

hydraulically according to the information provided in Chapter 5 and properly

commissioned according to the information provided in Chapter 6.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 19 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

8 Maintenance, Servicing, and Inspections

Any maintenance, servicing and inspection work is only allowed in non-hazardous

atmosphere.

For trouble-

free and reliable operation of the I/H converter, inspection, maintenance and

servicing are necessary and need to be performed in certain intervals.

The intervals indicated apply to I/H converter operation and proper use within the

permisible operating conditions. For continuous operation in extreme ranges, shortening

of the intervals is recommended.

8.1 Maintenance and servicing

Combustible dusts may cause fire or explosion. Therefore, immediately remove any

deposit of combustible dusts on the I/H converter!

Maintenance intervals

Maintenance work

Routine inspection

Check pipes, pipe unions and connections on the I/H converter for leaks,

impurities and damage.

Remedy any leaks, impurities and damages detected , as required, during

appropriate operating phases.

Monitor the I/H converter operating behavior for any changes (e.g. noise).

Analyze and eliminate the causes, as required, during appropriate

operating phases.

Inspection after approx. 740

operating hours or 1x per month

Take an oil sample from the oil tank and check it for solid and suspended

matters, water content, change of color and air bubbles. Check the oil

sample for oil cleanliness.

Check and change the oil, as required, during appropriate operating

phases.

Inspection afte

r approx. 8000

operating hours or 1x per year

Take an oil sample from the oil tank and analyze it chemically.

Check and change the oil, as required, during appropriate operating

phases.

Check the electrical connections of the I/H converter and retighten them,

if necessary.

These inspection works can be performed by the operator's expert personnel, provided

they meet the relevant criteria stated in Chapter 2.3.

Installation and Operating Manual

I/H Converter DSG-B03212

DSG-B07212

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 20 / 22

918 3626018861 en

D – 74564 Crailsheim

Version: 4.1

8.2 Inspections

Inspection intervals

Inspection work

Within the scope of the regular

plant inspection

Check I/H converter, pipes, pipe unions and connections on the I/H

converter for leaks, impurities and damage.

Remedy any leaks, impu

rities and damages detected , as required, during

appropriate operating phases.

Monitor the I/H converter operating behavior for any changes (e.g. noise).

Eliminate the causes, as required, during appropriate operating phases.

Inspection works after 60,000

operating hours, 7 years after first

commissioning at the latest

Remove the I/H converter from the machinery and disassemble same in

an appropriate workshop. Inspect the inner parts and replace

conspicuous parts. Replace all seals.

Perform a test run on a suitable test stand; check and document the I/H

converter operational behavior.

Inspection works after another

60,000 operating hours, 7 years

after the l

ast inspection at the

latest

Remove the I/H converter from the machinery and have it inspected and

completely overhauled at J.M. Voith SE & Co. KG │ Division Digital

Ventures, Crailsheim. All the conspicuous parts will be replaced. By

performing a test run, the operating behavior will be checked and

documented.

8.3 Spare parts information

It is only allowed to install original Voith parts.

The manufacturer only is able to guarantee an expert repair and/or maintenance.

These inspection works

can be performed by the operator's expert personnel, provided

they meet the relevant criteria stated in Chapter 2.3.

These inspection works must only be performed by the operator's trained expert

personnel in an appropriate workshop or by Voith personnel at the Voith workshop.

(See Section 2.3.)

Only J.M. Voith SE & Co. KG │ Division Digital Ventures expert

personnel are

exclusively allowed to perform these inspection works. Removal of the I/H converter is

performed by the operator's expert personnel according to Chapter 2.3.

For del

iverable spare parts, please refer to the spare parts catalog of the outline

drawing (see Chapter 10). In case that required parts are not included, please contact

J.M. Voith SE & Co. KG │ Division Digital Ventures, Crailsheim.

Storage of spare parts is only allowed if these are protected against corrosion. The

storage area has to be dry and free from dust. Prior to installing the parts, remove the

corrosion protection.

Do not store the elastomere seals together with chemicals, solvents, fuels, acids, etc.

They need to be packed airtight and protected against light with a high content of UV

rays. The storage time until the I/H converter gets used must not exceed 6 years (for

NBR) and 10 years (for FPM).

This manual suits for next models

3

Table of contents

Other Voith Media Converter manuals

Popular Media Converter manuals by other brands

TR-Electronic

TR-Electronic Profibus 582 Series user manual

Korenix

Korenix JetCon 1100 Series user manual

Brook

Brook Super Converter Firmware update

Phoenix Contact

Phoenix Contact QUINT4-PS/12-24DC/24DC/1.3/PT manual

Blonder tongue

Blonder tongue CV HDMI2 QAM IP user manual

ADF Web

ADF Web HD67B18-B2 user manual