Voith DSG-BXX113 User manual

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 1 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

I/H Converter

Type DSG-BXX113

Translation of the original version

Installation and Operating Manual

Version 3.3

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 2 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

Should you have any questions concerning the

I/H converter, please contact the Service

Department of the product group Division Digital

Ventures, J.M. Voith SE & Co. KG, Crailsheim,

indicating article number and serial number of

the I/H converter.

J.M. Voith SE & Co. KG

P.O. Box 15 55

D-74555 Crailsheim

Switchboard: +49 – 7951 / 32 - 0

Fax: +49 – 7951 / 32 - 500

Service department of the product group

Division Digital Ventures

Direct dial: +49 – 7951 / 32 - 470

Direct fax: +49 – 7951 / 32 - 605

E-mail: turcon@voith.com

Address for goods supplied:

Voith Group │ Division Digital Ventures

J.M. Voith SE & Co. KG

Voithstr. 1

D-74564 Crailsheim

This instruction manual describes the technical

condition of the I/H converter on delivery from

2019/02. Any modifications following the delivery

are not considered in this operating manual.

J.M. Voith SE & Co. KG 2019

This instruction manual is protected by copyright.

It may not be reproduced or translated in any

form or by any means (mechanical or electronic)

or submitted to third parties, without the

publisher’s written approval.

Amendment: 2019 / 02

Order No.: 918.3626018884 en

Version: 3.3

Printed in Germany

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 3 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

Contents

1. Technical data

2. Safety Information

2.1 Definition of notes and symbols

2.2 Proper use

2.3 Important notes

2.4 Warranty

3. Functional Description

3.1 Design

3.2 Operating characteristics

4. Packing, Storage and Transport

5. Installation

5.1 Mounting

5.2 Hydraulic connection

5.3 Electric connection

6. Commissioning

6.1 Test run

6.2 Parameter setting

7. Operation

7.1 Operation with manual operation knob

7.2 Operation with set signal

7.3 Trouble shooting and remedial action

8. Maintenance and Repair

9. Shutdown

10. Outline drawing with Wiring Diagram

11. Annex

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 4 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

1. Technical Data

Ambient conditions:

Ambient temperature for storage -40 °C ... +90 °C

Ambient temperature: -20 °C …+85 °C

Protection IP 65 to EN 60529

suitable for internal installation in industrial air

Electric Data:

Supply voltage 24 VDC ±15%

Power consumption approx. 0.7 A for DSG-B05..

DSG-B10

approx. 1 A for DSG-B30

max. 3 A, for t <1 sec

Setpoint input 0/4...20 mA

input resistor approx. 80 Ω with

suppressor circuit.

Hydraulic data:

Input pressure Pin min 1.5 bar + PA max for B05.. B10

5 bar + PAmax for B30

Input pressure Pin max see table

Pressure fluid mineral oil or hydraulic oil (hardly

combustible fluids on request)

Viscosity pressure fluid ISO VG 32... ISO VG 48 to

DIN 51519

Temperature pressure fluid: +10 °C...+70 °C

Oil purity recommended purity class:

To NAS1638 class 10

To ISO4406 class -/19/16

Leakage at Pin=10 bar ≤3 l/min for DSG-B05… DSG-B10

Leakage at Pin=40 bar ≤5 l/min for DSG-B30

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 5 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

Type

DSG- BXX 113

B05...

B07...

B10...

B30...

Output pressure

regulating range

PA[bar]

0..5 1..7 0..10 0..30

Input pressure

Pin max [bar]

40 40 40 70

Flow rate line P →A

Q1 [l/min]

at ∆P = 1 bar

24 24 23 24

Flow rate line A →T

Q2 [l/min]

at ∆P = 1 bar

30 30 28 30

Regul. range approx.

PA max [bar]

at setpoint 20 mA

3..53,5..75..10 10..30

Regul. range approx.

PAmin [bar]

at setpoint 4 mA

0..1,5

0..3 0,5..3

1..5 0..2

0..6 0..5

0..18

The regulating range of PAmin depends on the set pressure PAmax.

The regulating range of PAmin indicated above refers to the minimum adjustable

pressure PAmax.

Mechanical data:

Dimensions, fitting see chapter 10

Hydraulic connection see chapter 10

Type-depending installation position see chapter 10

Mounting position see chapter 10

Sealing material FPM

Weight approx. 12 kg

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 6 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

2. Safety Information

2.1 Definition of notes and symbols

Danger !

This symbol signals an imminent danger to the life and

health of individuals.

If this note is not observed, injury to health and even most

serious injuries may be the consequence.

Warning !

This symbol signals a harmful situation.

If this note is not observed, the product may be damaged.

Note !

This symbol refers to proper handling of the product. It does not refer to

or indicate a dangerous situation.

2.2 Proper use

The I/H converter serves to transform an electric set signal

into a related hydraulic output pressure reduced to feed-in pressure. This

allows, for example, adjusting control pistons at hydraulic cylinders which

are used to position the valves of steam turbines.

2.3 Important notes

The following notes refer to the entire instruction manual and have to be

observed in addition to the individual notes.

Accident prevention

•Improper use may cause operating agent under pressure to leak

at the sealing surfaces. There is a risk of fire around hot components.

•

Isolate the hydraulic supply prior to working on the I/H converter.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 7 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

•Failure of electric power or disturbance of the control electronics

integrated in the I/H converter may cause strong variations of the

output pressure when operating the I/H converter. Thus e.g. the

piston rod of a hydraulic cylinder may move uncontrolled, causing

danger to individuals or equipment.

•During operation, the outer surfaces of the I/H converter may heat up

due to the pressure fluid. Contact may cause skin burns. Make sure

to cool down the I/H converter prior to working on it.

•Electrical components are installed in the I/H converter. These

components can be destroyed by e.g. electric welding in its

surrounding. Therefore make sure to disconnect all electric

connections prior to electrical weldings in the surrounding of the I/H

converter.

Environment protection

•During mounting, dismounting or improper use of the I/H converter

pressure fluid may leak out. Operating agent reaching the sewage

system or open soil, causes severe environmental damages. Leaking

pressure fluid has to be collected and deposited in accordance with

the national legal regulations.

Instruction manual

•The instruction manual contains important information for proper

handling of the I/H converter. Prior to installation and commissioning

of the I/H converter, read the manual carefully and make sure it is

completely understood.

•Keep this manual in a location convenient to the operating staff.

•In addition to this operating manual: Have the relevant regulations for

prevention of accidents and environmental protection available and

observe these.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 8 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

Staff qualification:

•Only trained and instructed staff is allowed to perform any work on the

I/H converter. This personnel has to be trained and authorized to

mount I/H converters professionally.

•Installation, commissioning and operation have to be effected by an

electronic expert.

Constructional modifications:

•Mounting and constructional modifications are not permitted.

2.4 Warranty

The terms and conditions mentioned in the General Conditions

of Sale of J.M. Voith SE & Co. KG │ Division Digital Ventures,

Crailsheim, are applicable. Warranty claims are excluded, if these are

due to one or several of the following causes:

•Improper transportation, storage, mounting, set-up, commissioning

and operation of the I/H converter.

•Not observing the safety instructions and guidelines included in this

instruction manual.

•Use of spare parts not approved by

J.M. Voith SE & Co. KG │ Division Digital Ventures, Crailsheim.

Repair works on the I/H converter are to be performed or approved by

J.M. Voith SE & Co. KG │ Division Digital Ventures, Crailsheim.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 9 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

3. Function

3.1 Design

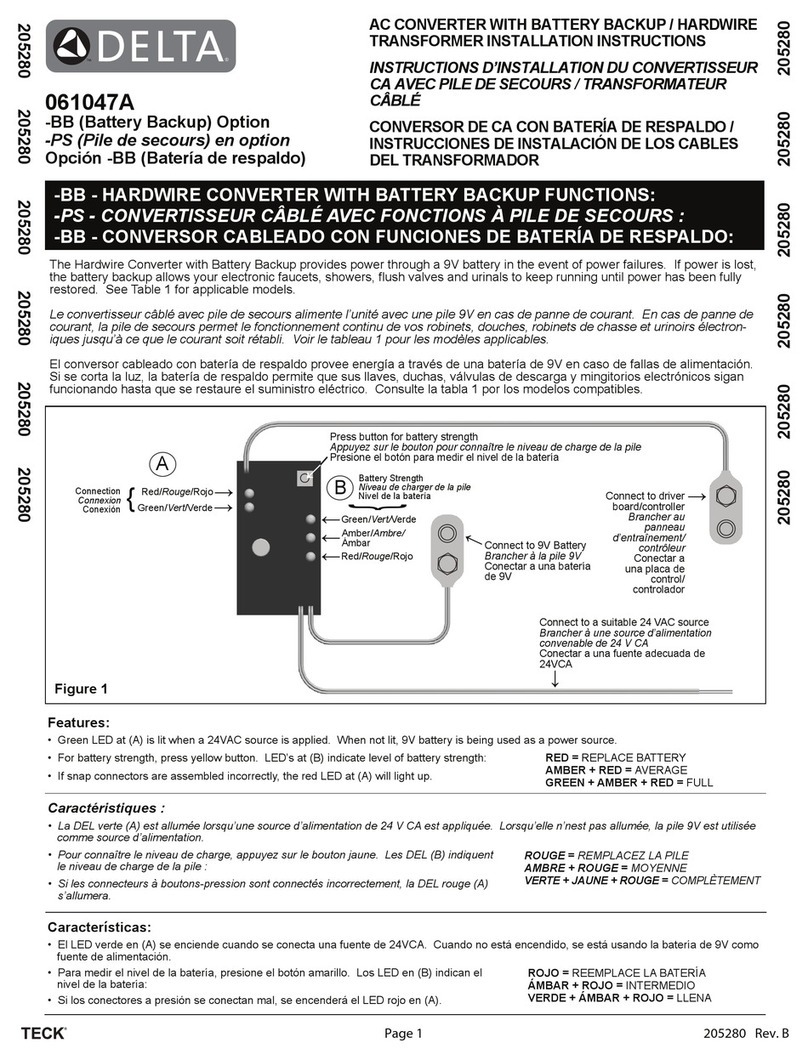

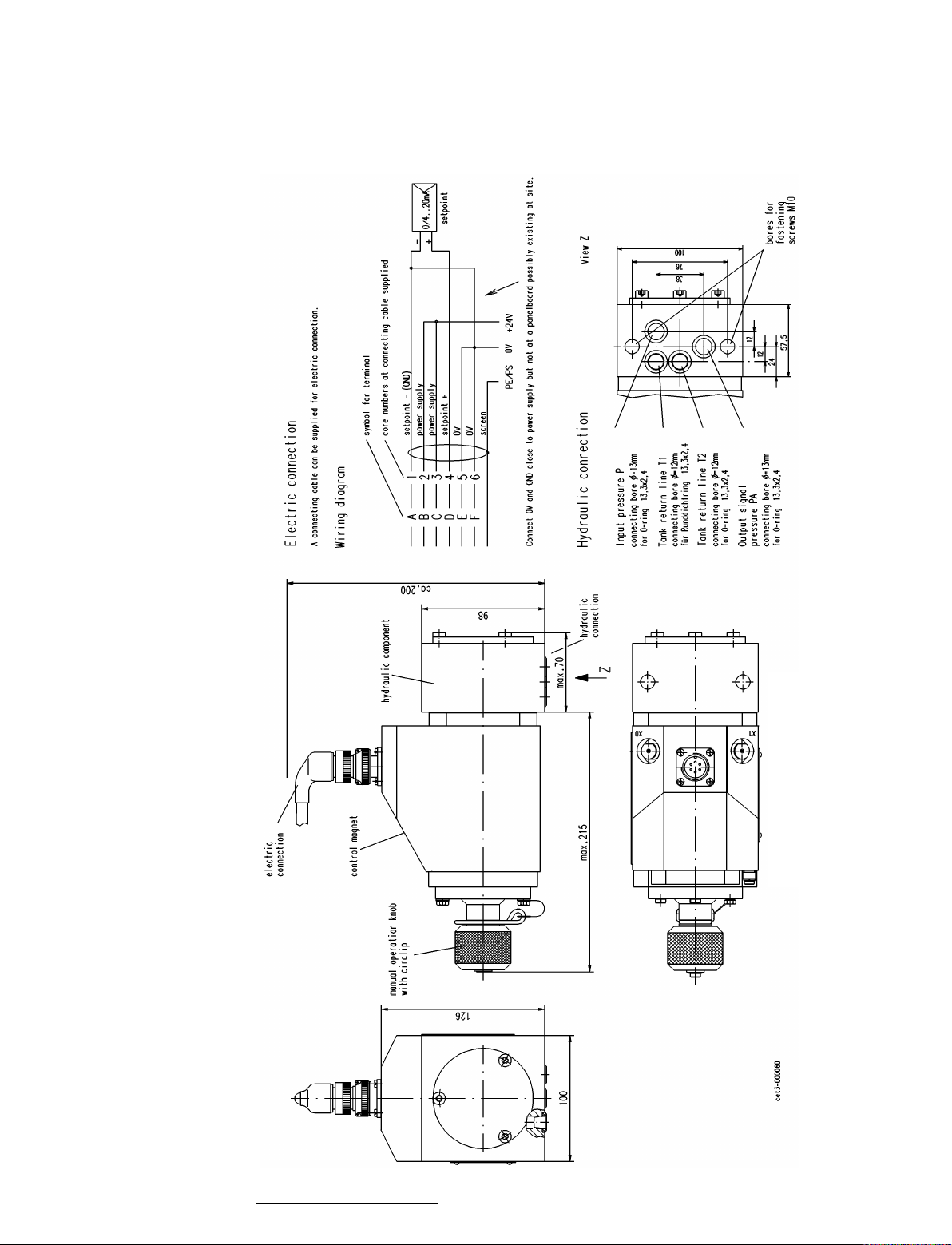

Fig.: 3.1.1

1 - Control magnet VRM Pin - Input pressure

2 - Tappet for power transmission PA- Output signal pressure

3 - X0 and X1 potentiometers

4 - Manual operation knob T1- Tank return line

5 - Electric connection T2- Tank return line with int. leakage

6 - Control housing FMag - Magnetic force

7 - Control piston with damping piston FHyd - Hydraulic force

8 - Cover FFed - Spring force

9 - Control spring

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 10 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

3.2 Operating characteristics

(see fig. 3.1.1)

A set signal w = 4...20 mA generates a magnetic force FMag in the VRM,

the limits of which can be adjusted by means of the X0 and X1

potentiometers and which is then transmitted onto the control piston via

tappet.

The hydraulic force FHyd being proportional to the output signal pressure

PAacts against this force.

In the case of the two forces being equal, the control piston is positioned

in the “hydraulic center” as shown in fig. 3.1.1 and the output signal

pressure PAcorresponds to the set signal. In the “hydraulic center“

position the control piston performs minimum oscillating movements in

the area of the guiding edges P→PAand PA→T, in order to keep the

output pressure PAon the value set by FMag.

When increasing the set signal and thus FMag from this condition, the

control piston position changes and thus connects the output pressure PA

to the feed pressure P and blocks PAtowards the tank return line T1and

T2. Now pressure PAwill increase until the same has returned the control

piston to the “hydraulic center“ and PAcorresponds to the new set signal.

The spring force FFed of the control spring generates a force-offset in

order to guarantee the I/H converter function for output pressures of

approx. 0 bar, too.

The internal leakage is fed back into tank return line T2.

Function of manual operation knob:

The control magnet of I/H converter is provided with a manual operation

knob, by means of which an adjustable spring force can be set instead of

the magnetic force FMag . This spring force affects the control piston via

magnet armature and tappet. The hydraulic force FHyd , being

proportional to the output signal pressure PAalso acts against this spring

force here. Thus adjustment of output pressure is possible without

electric connection.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 11 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

4. Packing, Storage and Transport

Packing

The I/H converter is delivered in a special packing.

The openings for the hydraulic connections are sealed with plugs to

prevent penetration of impurities and humidity.

Storage and preserving

The outer surfaces of the I/H converter are protected by means of a

preserving surface coat.

The internal parts are preserved by oil.

Within Europe the anticorrosion protection is sufficient for approx. 8

months in industrial air, presuming storage of the I/H converter in a dry

location.

In case the I/H converter is supposed to be stored for a longer period of

time, special precautions will have to be taken.

In each specific case, these precautions have to be agreed with J.M.

Voith SE & Co. KG │ Division Digital Ventures, Crailsheim.

The storage ambient conditions have to be within the limits as indicated

in chapter 1.

Transport

Improper transport may cause personal injuries and damages to

property. Pack the I/H converter in a way that prevents damages of

housing and electric connection during transport.

5. Installation

•Improper installation of the I/H converter may cause malfunctions and

premature failure of the operation of the I/H converter.

•Cleanliness is imperative during installation and connection. Prevent

that any impurities ( dust, metal chips etc.) can get into the I/H

converter. These impurities impair its function and may cause

damage to the I/H converter.

Cover and protect the I/H converter and in particular the electric lines

during construction time.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 12 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

5.1 Mounting

Perform any work on the I/H converter only when it is in deenergized

condition and with switched off oil supply system.

Protect oil and power supply against unintentional switching-on during

mounting.

Install the I/H converter in accordance with the permissible installation

position as shown in chapter 10.

Recommended fastening bolts:

2 pieces hexagonal screws M10, strength category 8.8.

tightening torque MA=35 Nm, thread slightly oiled.

Select screw length according to mounting situation.

5.2 Hydraulic connection

The hydraulic connection on the I/H converter is made by means of

connection bores at its bottom. The connecting flange is sealed with

O-rings. Please refer to chapter 10 for position and dimensions of the

connections.

Surface roughness of connecting flange:

Ra = 1.6

µ

m, Rmax = 6.3

µ

m

Only pressure-less return of the operating medium through return line T2

to the tank, ensures proper work of the I/H converter.

In practise the tank lines for the connections T1 and T2 are joined

together and laid downgrade towards the tank in one common pipe line.

Requirements to this pipe line:

Nominal size 20 mm or bigger for I/H converters with an output pressure

up to 10 bar.

Nominal size 30 mm or bigger for I/H converters with an output pressure

of more than 10 bar.

Observe the correct pressure range when selecting pipes, hoses,

screwings and flanges.

Immediately replace damaged pipes and hose lines.

When assembling the pipe lines, ensure that it is fastened to fixed

structures, free from vibration and not to moving equipment. Temperature

variations of the piping (thus alterations in length) must not apply

constraining forces to the I/H converter.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 13 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

Clean pipe lines from dirt, cinder, sand, chips etc. prior to installation.

Pickle or flush welded pipes.

Clean and flush carefully all pipe and hose lines prior to attaching the

I/H converter.

=> For flushing, a flushing plate (Art. No. 43.8565.10) is available.

See chapter 11.

=> To connect the I/H converter to the piping system an adapter (Art. no.

43.9300.11) is available. See chapter 11.

•Residual oil may leak when removing the plug (max. 0.1 l). Collect the

oil in a suitable container and deposit it properly.

•Do not use fibrous or hardening sealing compounds, such as e.g.

hemp or mastic to seal the connections and screwings.

5.3 Electric connection

The electric system has to be connected by an electric expert in

accordance with electrical engineering standards and legal regulations of

the manufacturing country

When connecting customer’s lines, avoid parallel run of the I/H converter

lines with the lines of current converter assemblies.

The customer’s signals and supply lines running to the I/H converter

must be screened.

=> A connecting cable with Art. No. 91876100XX can be supplied for

electric connection.

Please refer to chapter 10 for the wiring diagram.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 14 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

6. Commissioning

The I/H converter was adjusted and tested at J.M. Voith SE & Co. KG │

Division Digital Ventures works by means of the potentiometers X0 and

X1. The test result is documented in an attached test certificate.

The potentiometers are provided with a protective cap to avoid

unintentional maladjustment and impurities.

6.1 Test run

Make sure that pipe lines and hydraulic system are cleaned prior to

performing a test run. The operating fluid has to be in accordance with

the purity class as indicated in chapter 1. Do not flush or clean the

pressure fluid with the I/H converter being hydraulically connected.

Operation of the I/H converter with contaminated pressure fluid is not

permitted, the I/H converter may be damaged.

•Check the line mounting, connection and flow direction to and on the

I/H converter.

•Check the electric connection.

•Switch on oil supply system and check input pressure.

•After waiting approx. 5min. switch on supply voltage 24VDC. (the

waiting period is necessary for auto-ventilation of the system during

first commissioning and after longer standtstill periods.)

The minimum input pressure has to be 1.5 bar more than the maximum

output pressure required at 20 mA.

•Set the signal w = 4.. 20mA and check output pressure.

During the test run, check all hydraulic connections for leakages. In case

of leakage, immediately switch off the hydraulic supply and eliminate

leakages.

6.2 Parameter setting

Due to unintentional maladjustment of the parameters or changed

operating conditions, new setting of one or both parameters may become

necessary.

We recommend to document adjustment of the parameters as well as the

set values.

The parameters are adjusted by means of potentiometers X0 and X1.

Please refer to chapter 10 for the position of the potentiometers.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 15 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

Potentiometer effects:

X0 - With help of potentiometer X0 the minimum output pressure

PA min is adjusted at a setpoint of 4 mA.

Pressure increase by turning the potentiometer clockwise.

X1 - With help of potentiometer X1 the maximum output pressure

PA max is adjusted at a setpoint of 20 mA.

Pressure increase by turning the potentiometer clockwise

X1 should be adjusted before X0.

The X1- adjustment influences the adjustment of X0.

Manufacturer-provided adjustments:

At the works, the I/H converter has been adjusted as indicated in the

order.

7. Operation

7.1 Operation with manual knob

Operation with manually controlled rotary knob is possible without electric

energy.

On operation with manually actuated rotary knob, uncontrolled stroke

movements of the hydraulic components controlled by the I/H converter

output might occur due to the increase in the output signal pressure.

Manual operation is only possible when the circlip is removed from the

manual operation knob.

On completion of operation with manual operation knob, move the

manual operation knob in its final position by turning it counter clockwise

and pushing in the circlip in its final position.

•Remove the circlip.

•Slowly turn the manual operation knob clockwise and observe the

output pressure.

Effective direction: Output pressure increases by clockwise rotation.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 16 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

7.2 Operation with set signal

When the supply voltage is switched on, the output signal pressure can

be adjusted continuously by the set signal 4...20 mA within the limits set

by the potentiometers X0 und X1.

7.3 Trouble shooting and remedial action

Prior to all works, make sure that the I/H converter was commissioned

according to chapters 5 and 6.

Malfunction: Pressure variations

The output signal pressure PAmay vary now and then or

periodically with low or high frequency and amplitude.

Cause: 1. air inclusions in the hydraulic component

2. low or considerably varying input pressure.

3. dirt particles in the hydraulic component

4. pressure on return line

Remedy: 1. On first commissioning or after longer periods of

stand still air inclusions in the hydraulic component may

cause pressure variations. Therefore, when setting into

operation again, observe to first connect the input pressure

and then, after waiting five minutes, the supply voltage. This

supports the auto-ventilation of the system.

2. Under load and in particular in case of higher output

signal pressure, low input pressure may lead to pressure

variations.

Increase and / or stabilize the input pressure by taking

appropriate measures (e.g. accumulator).

3. Contaminated pressure fluid results in increased friction at

the control piston, thus causing hysteresis and pressure

variations.

Open hydraulic component and clean the inner elements. In

case of damaged surfaces and guiding edges replace the

I/H converter.

4. The dimensions of the return line have to be sufficient.

In case of additional consumers of the output pressure

connected to this line, make sure they do not create any

pressure in the return line. See also chapter 5.2.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 17 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

Malfunction: Output pressure PA

→

0 bar or

→

P (input pressure)

Due to a defective control valve VRM or blockage of the

control piston the output pressure may fall to 0 bar or

increase to the input pressure.

Remedy: The function of the component part can be checked using the

manually controlled knob with the supply voltage being

switched off. See chapter 7.1.

If the output pressure cannot be adjusted manually, the control

piston, e.g., may be blocked by particles.

Open hydraulic component and clean inner parts.

If the surfaces and guiding lines are damaged, exchange

the I/H converter.

Should output pressure adjustment be possible with manual

operation knob, but not with the control magnet, the control

magnet VRM is defective.

8. Maintenance and Repair

For trouble-free and reliable operation of the I/H converter, it is

necessary to perform inspection, maintenance and repair work in

certain intervals.

Routine inspection:

Check the pipes, screw connections and connections on the

I/H converter for leakage, impurities and damage.

Eliminate any leakage, impurity and damage noticed, if required, during

appropriate operating modes.

Monitor the control behavior of the I/H converter for any changes.

Analyse and eliminate the causes, if required, during appropriate

operating modes.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 18 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

Inspection after approx. 740 operating hours / max. 1 month:

Take an oil sample from the oil tank and analyse it for solid and

suspended matters, water content, shadings and air bubbles.

Analyse oil purity of the oil sample. Clean or exchange the oil, if

required, in an appropriate operating mode.

Inspection after approx. 8000 operating hours / max. 1 year:

Take an oil sample from the oil tank and analyse it chemically.

If required, clean or change the oil during an appropriate operating mode.

Check and retighten, if necessary, the electric connections of the I/H

converter.

9. Shutdown

If the I/H converter is switched off for reasons of repair, inspection or

unit shutdown, switch off the oil supply system and relieve all pressure

reservoirs, if effective. Switch off the 24 VDC supply voltage and

remove the lines as well as piping and hose connections. Doing so, a

considerable oil quantity may leak out. Collect the oil in a suitable

container and deposit it properly. Close all holes. Now clean and pack

the I/H converter.

Disposal

In the event of disposal of the I/H converter, observe the local applicable

regulations regarding the environmental protection. The I/H converter

essentially contains steel, copper, synthetic materials, electronic

components and residual oil.

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 19 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

10. Outline Drawing with Wiring Diagram

Installation position B05, B07 and B10 vertical

B30 vertical, control magnet on top

Installation and Operating Manual

I/H Converter DSG-BXX113

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 20 / 20

918.3626018884 en

D – 74564 Crailsheim

Version: 3.3

11. Annex

Flushing plate 43.8565.10

Adapter plate 43.9300.11

Connecting cable 91876100XX

This manual suits for next models

5

Table of contents

Other Voith Media Converter manuals