FCM 300 PROFIBUS / VLT 2800 PROFIBUS

MG.90.A2.02 – VLT is a registered Danfoss trademark 5

The PROFIBUS Interface

■Master controlled Variable Speed Drives (VSD)

The PROFIBUS Field-bus was designed to give you

unprecedented flexibility and command over your

VSD controlled system. The PROFIBUS will perform

as an integrated part of your VLT VSD, giving you

access to all parameters relevant to your application.

The VSD will always act as a slave, and together with

a master it can exchange a multitude of information

and commands. Control signals such as speed

reference, start / stop of motor, reverse operation,

etc. are transmitted from the master in the form of a

telegramme. The VSD acknowledges receipt by

transmitting status signals, such as running, on

reference, motor stopped and so on to the master.

The VSD may also transmit fault indications, alarms

and warnings to the master, such as Overcurrent or

Phaseloss.

The PROFIBUS communicates according to the

PROFIBUS Protocol Standard DIN 19245 parts 1 and

3. This means that it can communicate with all

masters that comply with this standard, but it does

not necessarily mean that all services available in the

PROFIBUS standard are supported. The VDI / VDE

3689 PROFIBUS Profile for Variable Speed Drives is a

subset of PROFIBUS which only supports the

services relevant to speed control applications.

PROFIDRIVE is an implementation of VDI / VDE 3689

profile created by DANFOSS and a number of other

companies.

Communication partners

In a control system the VSD will always act as a slave,

and as such it may communicate with a single master

or multiple masters depending on the nature of the

application. A master may be a PLC or a PC that is

equipped with a PROFIBUS communication card.

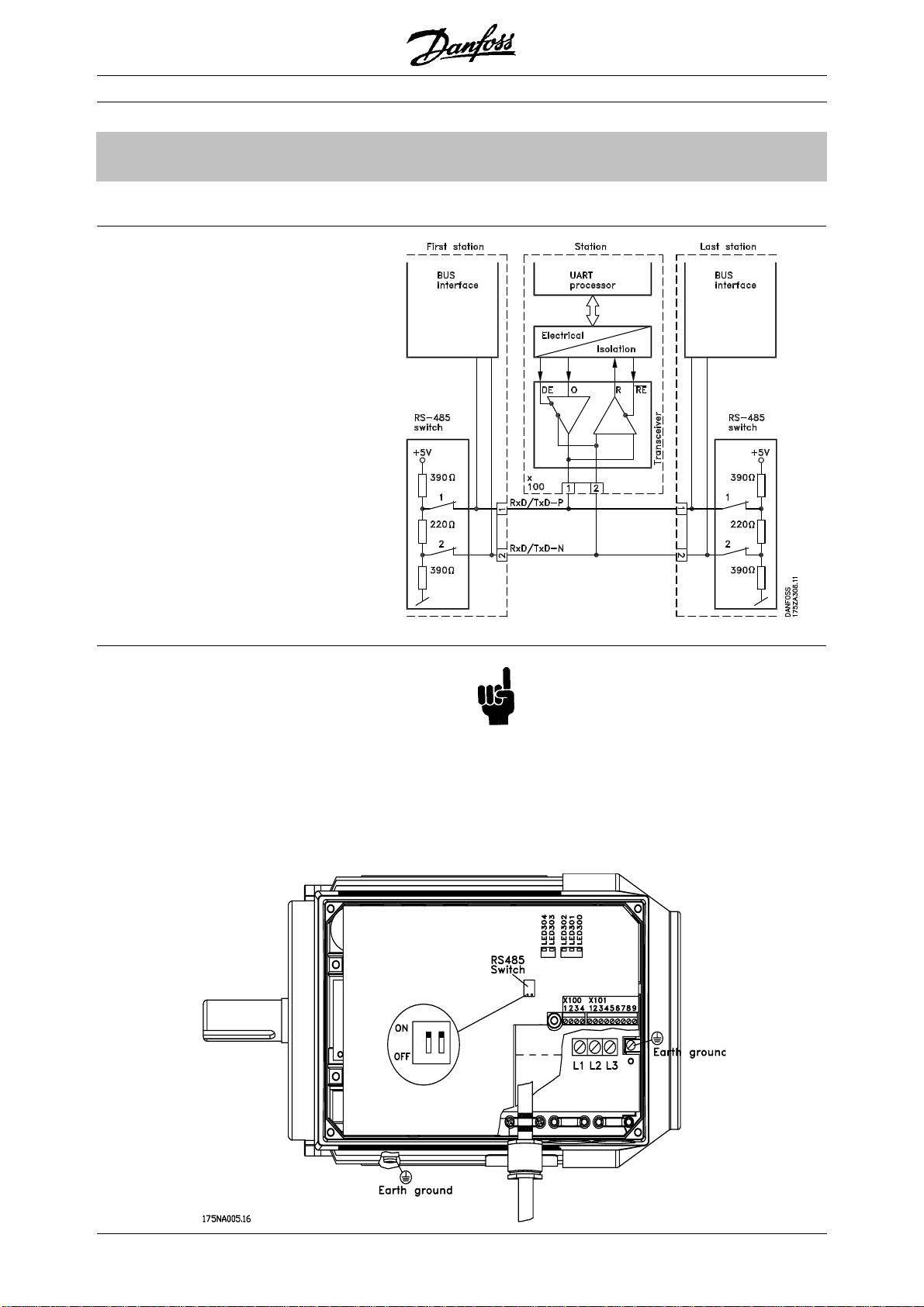

■Physical layer

The field of application of a field-bus system is

primarily determined by the transmission media and

the physical bus interface selected. The type of bus

cable required for the application and its installation

(physical layer) are particularly important factors, in

addition to the required transmission reliability of the

physical level.

Though a fundamental feature of the PROFIBUS stan-

dard is the possibility of specifying several different

physical interfaces, the standard, at the time of

printing, has allowed for one universal specification

only, namely the EIA Standard RS 485-A, which has

found acceptance both in the field of factory automa-

tion and in several areas of the processing industry.

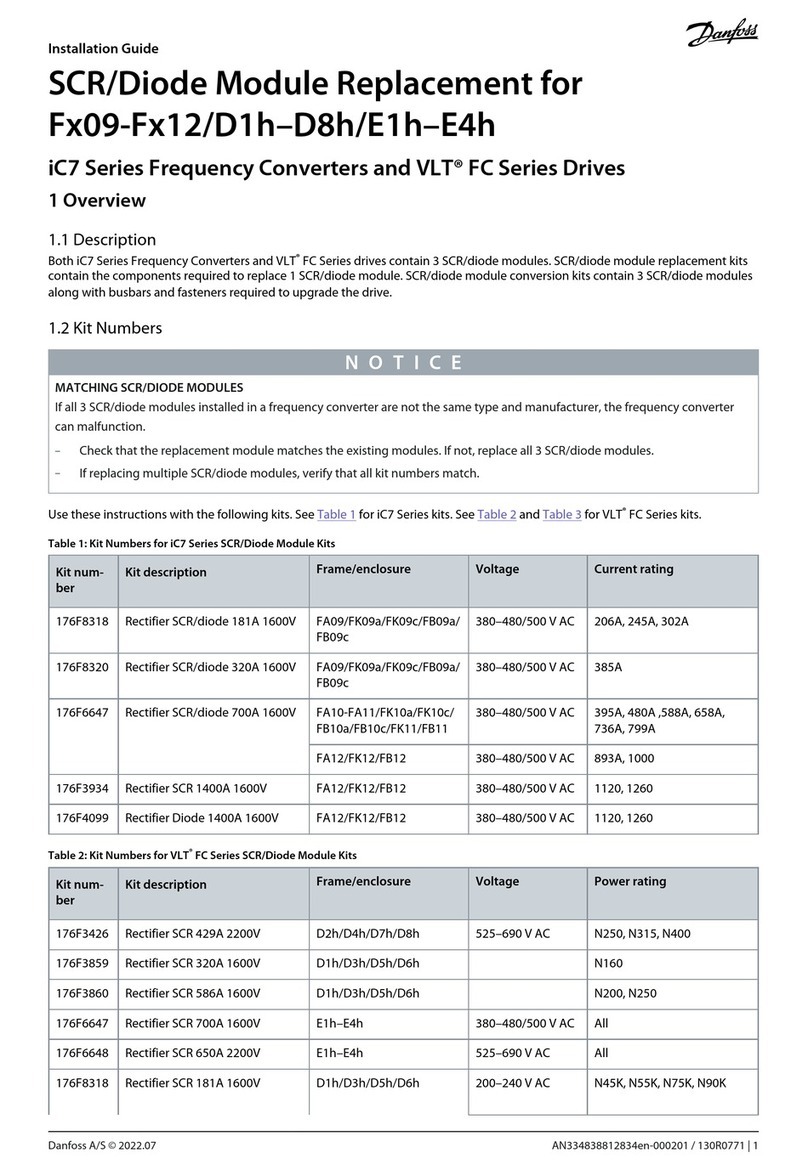

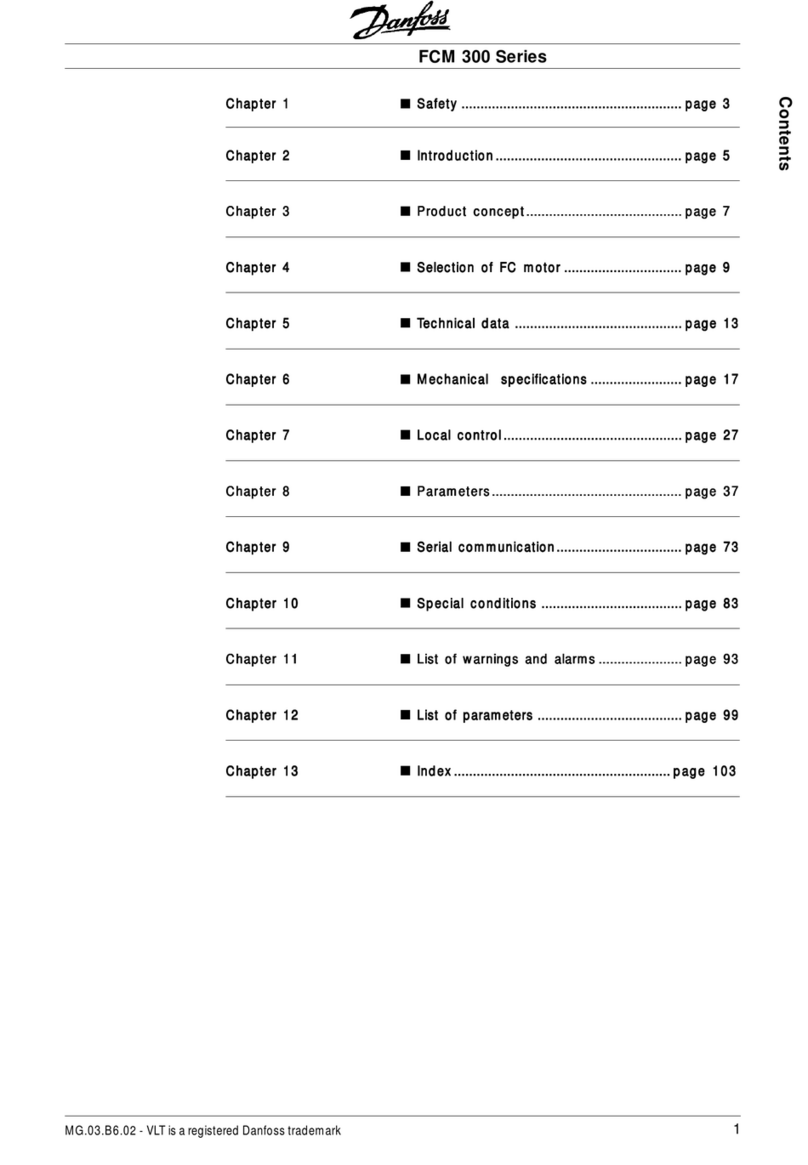

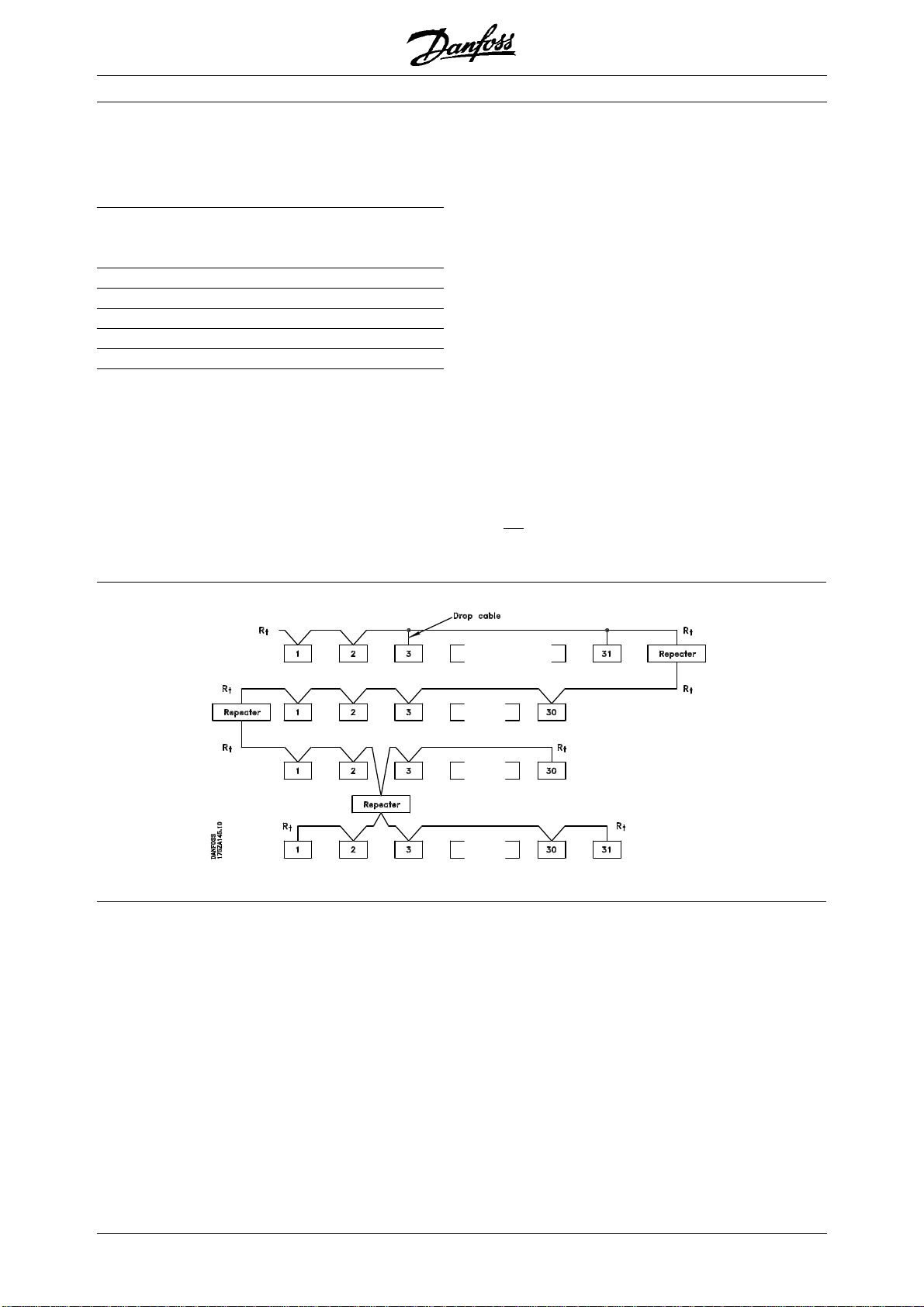

■Cable lengths/number of nodes

The maximum cable length in one segment is

depending on the transmission speed. The total cable

length includes drop cables if any. A drop cable is the

connection from the main bus cable to each node if a

T-connection is used instead of connecting the main

bus cable directly to the nodes, see drop cable

length. The table below shows the maximum allowed

cable length and maximum number of nodes/VLT’s

with 1, 2, 3 and 4 bus segments.

Note that a repeater is a node in both of the two

segments it connects. The number of VLT is based on

a single master system. If there are more masters the

number of VLT must be reduced correspondingly.

Max. total bus cable lenght

1 segment: 2 segments: 3 segments: 4 segments:

32 nodes 64 nodes 96 nodes 128 nodes

Transmission (31 VLT) (1 repeater, 61 VLT) (2 repeaters, 91 VLT) (3 repeaters, 121 VLT)

speed [m] [m] [m] [m]

9.6-187.5 kBaud 1000 2000 3000 4000

500 kBaud 400 800 1200 1600

1.5 MBaud 200 400 600 800

3MBaud 100 200 300 400