Application Assistance 1.800.234.8731 (847.662.6633)

Page 1

Encoder Installation Manual

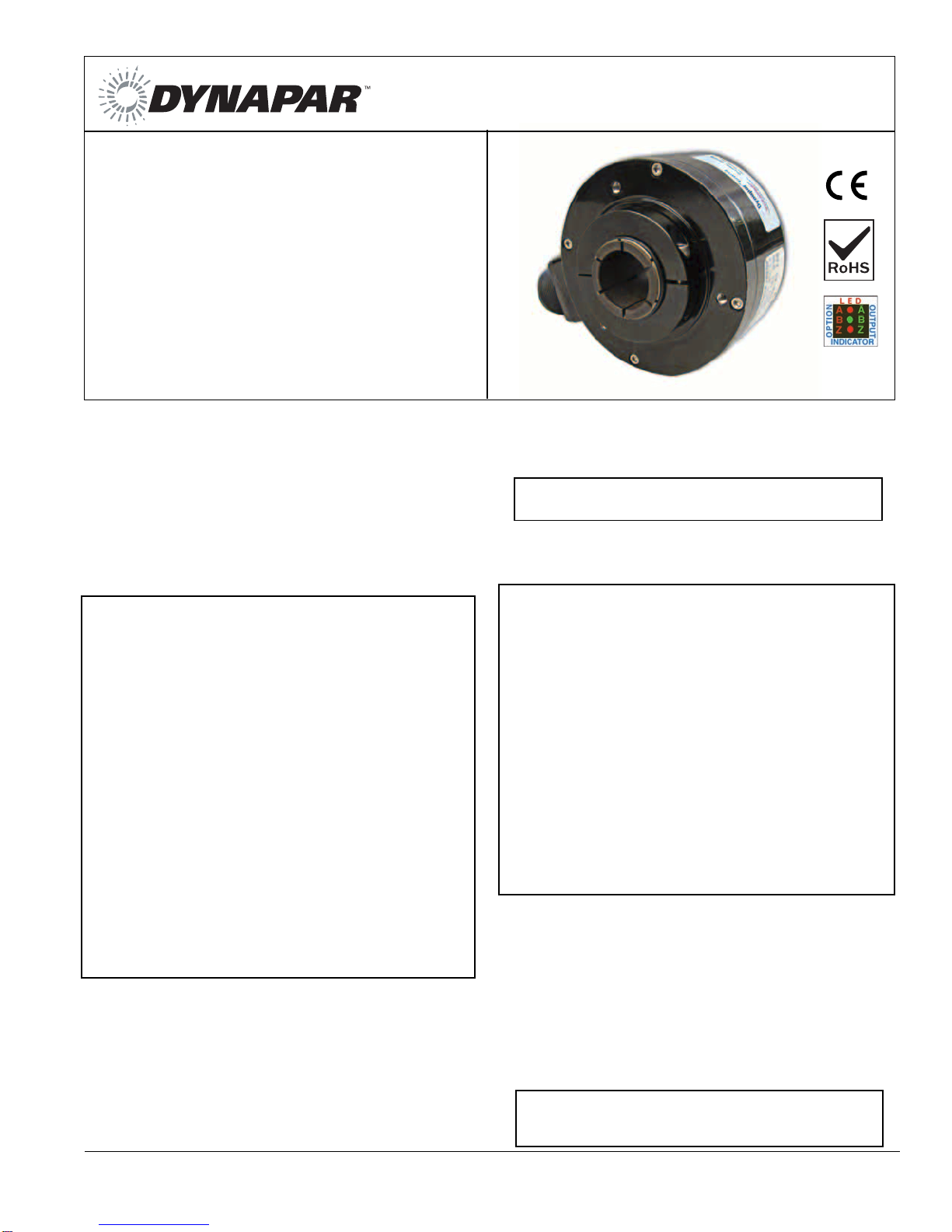

Dynapar™ brand

SERIES HS35R

Heavy Duty Hollowshaft Encoder

Document No.: 702761-0001

Revision Level: S

Sept. 16, 2013

DESCRIPTION

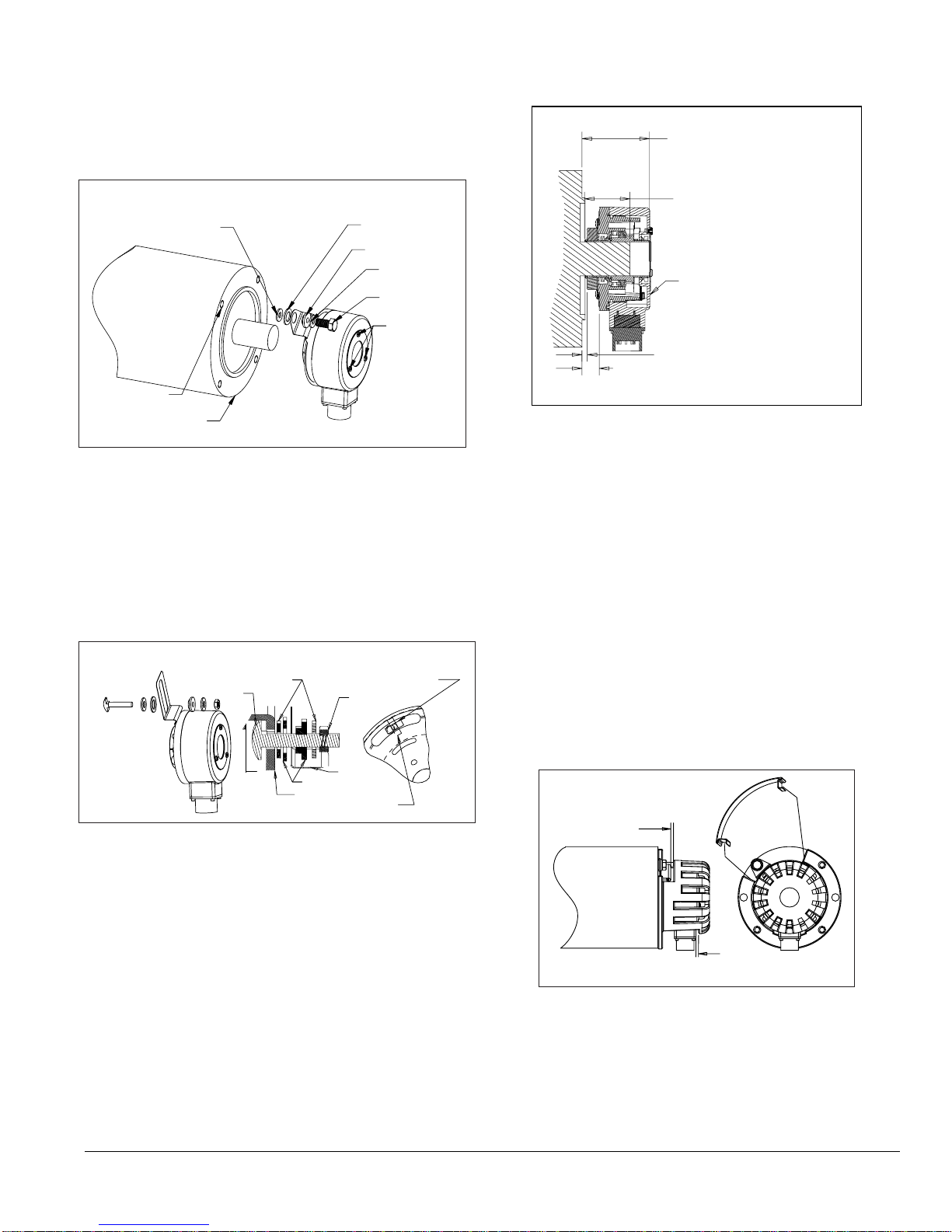

The Series HS35R Sealed Hollowshaft encoder is equipped with an

unbreakable disk that handles the most severe shock and vibration. Its

hollow shaft mount and anti-rotation tether reduce bearing wear and

maintenance. Series HS35R has electrical protection from overvolt-

age, reverse voltage, and output short circuits when ordered with

standard operating temperature configuration.

Series HS35R is not only electrically & thermally isolated (for shaft

sizes 1.125” and under) but also environmentally sealed with shaft

seals at both ends.

APPLICATION ENVIRONMENT

The encoders can be provided with optional hazardous location

certification that allows use in environments stated in:

Class I, Division 2, Group A: atmospheres such as

acetylene;

Class I, Division 2, Group B: atmospheres such as

hydrogen;

Class I, Division 2, Group C: atmospheres such as

ethyl ether and ethylene;

Class I , Division 2, Group D: atmospheres such as

acetone, ammonia, benzene, butane, cyclopropane,

ethanol, gasoline, hexane, methanol, methane, natural

gas, naphtha, and propane.

Class II, Division 2, Group F & G.

Classifications of hazardous locations are subject to the approval of

the authority having jurisdiction. Refer to Article 500 of the National

Electrical Code (NEC) or Section 18 of the Canadian Electrical Code

(CEC).

Note: For CSA Division 2, Group F & G certification, Dynapar

Adapter Kit P/N 114064-0001 must be used.

IMPORTANT INSTALLATION INFORMATION

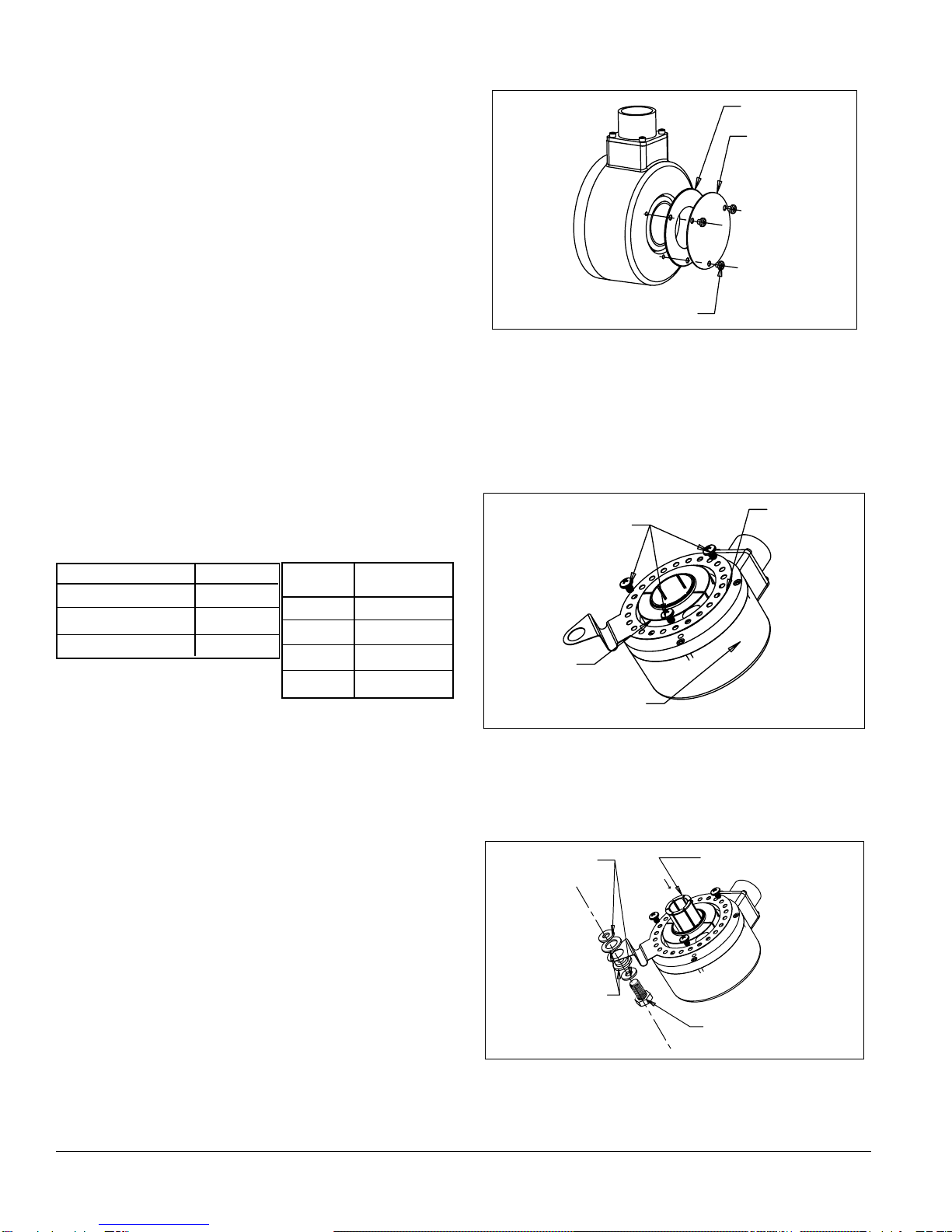

Mounting the Encoder: Before Installation, ensure power is discon-

nected from encoder and motor or machine.

CAUTION: The loads applied to the encoder shaft must be in

accordance with the specificatios of this device.

Important Wiring Instructions: Use of shielded cable is recom-

mended for all encoder installations. The shield should be connected

to signal-ground at the receiving device only.

Grounding: For applications with high ground potential differ-

ences, DO NOT ground the encoder through both machine and

controls end. Connect the shield at the controls end only. NOTE:

If the shield is connected at both ends, grounding problems that

degrade system performance can result.

CE Grounding Measures – For best EMC immunity the cable

screen must be grounded on both encoder and controls end. For

cable lengths longer than 30m or outdoor applications, additional

measures must be implemented to comply with CE require-

ments. Connection of the encoder to DC power supply network is

prohibited if CE compliance is required. CE-compliant products

are tested to EN61326-1 EMC.

In all cases, system CE compliance is ultimately the responsibil-

ity of the manufacturer integrating the encoder.

Connecting the shield at both ends can cause grounding

problems that degrade system performance.

If possible, run the encoder cable through a dedicated conduit (not

shared with other wiring). Use of conduit will protect the cable from

physical damage and provide a degree of electrical isolation. Do not

run the cable in close proximity to other conductors that carry current

to heavy loads such as motors, motor starters, contactors, solenoids,

etc. This practice can induce electrical transients in the encoder

cable, potentially interfering with reliable data transmission.

Refer to Electrical Connections table for wiring information.

To avoid possible damage, do not connect or disconnect the encoder

connector or wiring while power is applied to the system.

CAUTION: Unused encoder signal wires must be individually

insulated and under no circumstances be in contact with

ground, voltage sources, or other signal lines.

•

Phased Array Sensor for Reliable Signal

Output

•

Rugged Design Withstands up to 400g

Shock and 20g Vibration

•

Unbreakable Code Disc up to 5000PPR

•

Heavy Duty Design Rated for IP67

•

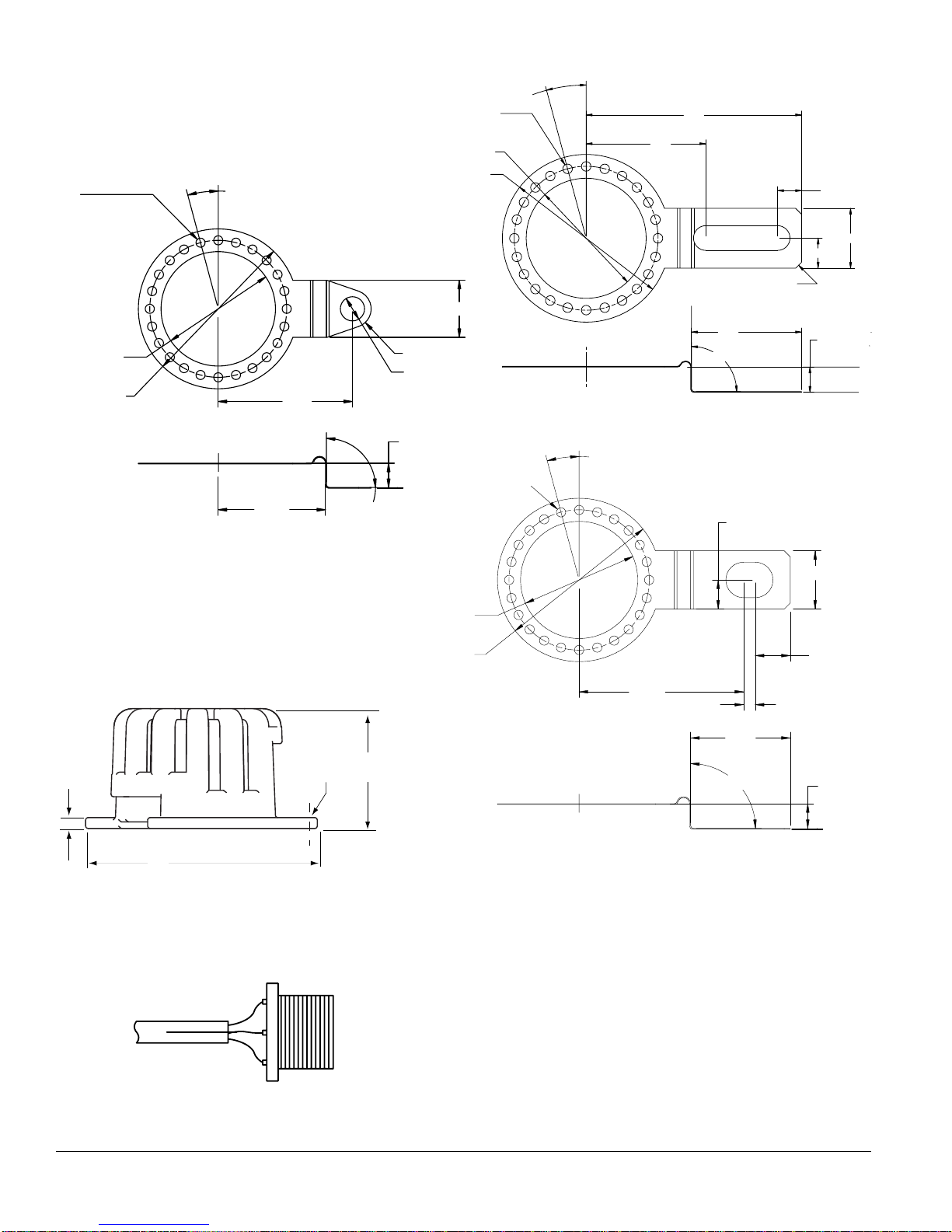

Customizable Mounting Options including

Torque Arm with Optional Grounding

Strap

KEY FEATURES