Page 4 | Stellar®TM4110 TireMan Owner’s Manual

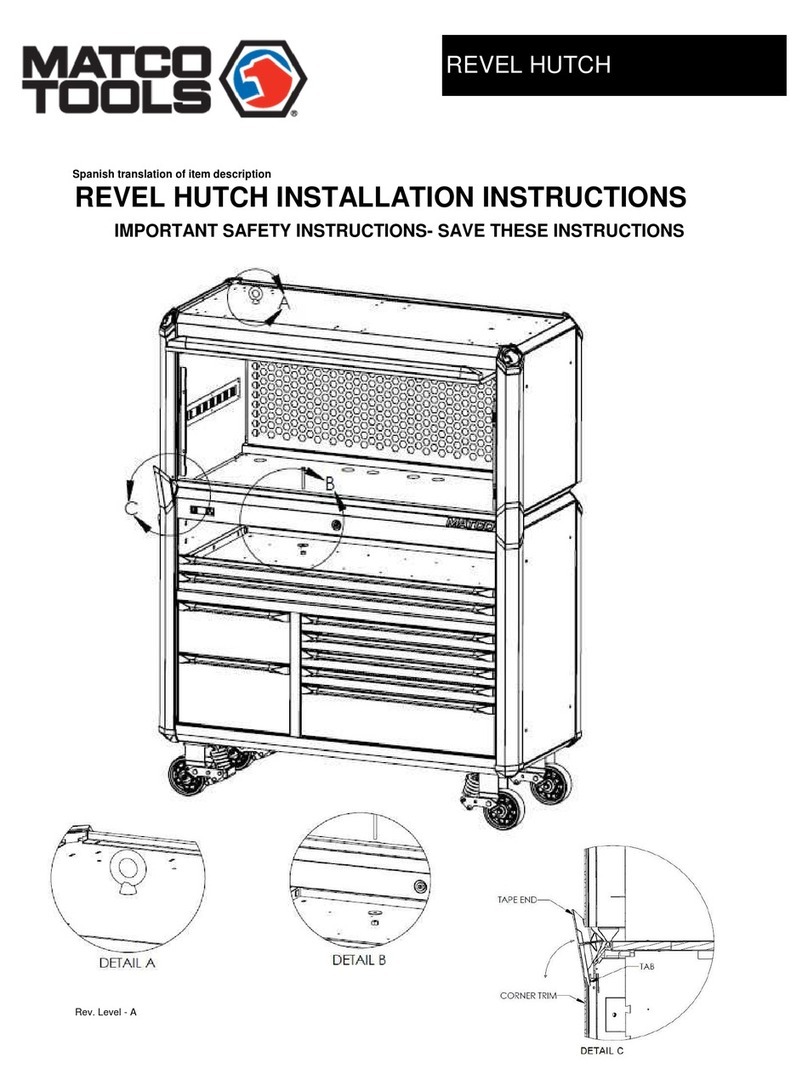

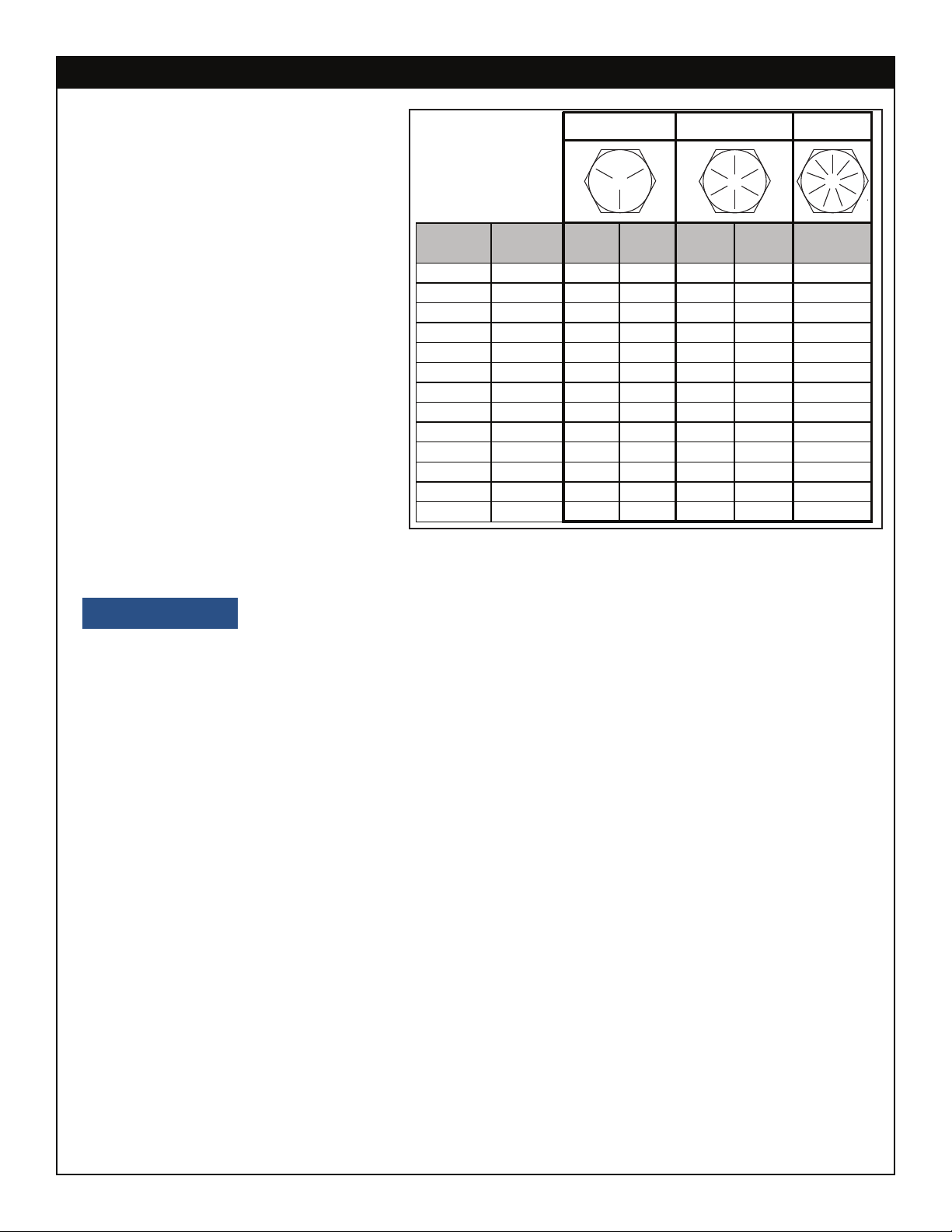

When using the torque data in the

chart, the following rules should be

observed:

• Bolt manufacturer’s particular

specifications should be consulted

when provided.

• Flat washers of equal strength

must be used.

• All torque measurements are

given in foot-pounds. To convert

to inch-pounds, multiply by 12.

• Torque values specified are for

bolts with residual oils or no special

lubricants applied.

• Torque values for socket-head

capscrews are the same as for

Grade 8 capscrews.

• Do not use these values if a different torque value or tightening

procedure is given for a specific application. Torque values listed are for general use

only. Check tightness of fasteners periodically.

• Shear bolts are designed to fail under predetermined loads. Always replace shear bolts

with identical grade.

• Fasteners should be replaced with the same or higher grade. If higher grade fasteners

are used, these should only be tightened to the strength of the original.

• Tighten plastic insert or crimped steel-type lock nuts to approximately 110 percent of the

dry torque values shown in the chart below, applied to the nut, not to the bolt head.

Tighten toothed or serrated-type lock nuts to the full torque value. Note: “Lubricated”

means coated with a lubricant such as engine oil, or fasteners with phosphate and oil

coatings. “Dry” means plain or zinc plated without lubrication. Tighten lubricated bolts

to approximately 80% of dry bolts.

Size Bolt DIA Plain Plated Plain Plated Plated

(DIA-TPI) (Inches) (Ft-Lb) (Ft-Lb) (Ft-Lb) (Ft-Lb) (Ft-Lb)

5/16-18 0.3125 17 13 25 18 22

3/8-16 0.3750 31 23 44 33 39

7/16-14 0.4375 49 37 70 52 63

1/2-13 0.5000 75 57 105 80 96

9/16-12 0.5625 110 82 155 115 139

5/8-11 0.6250 150 115 220 160 192

3/4-10 0.7500 265 200 375 280 340

7/8-9 0.8750 395 295 605 455 549

1-8 1.000 590 445 910 680 823

1 1/8-7 1.1250 795 595 1290 965 1167

1 1/4-7 1.2500 1120 840 1815 1360 1646

1 3/8-6 1.3750 1470 1100 2380 1780 2158

1 1/2-6 1.500 1950 1460 3160 2370 2865

GRADE 5 GRADE 8 GRADE 9

Torque Data Chart