Page 5/39

1.2 Correct handling and usage

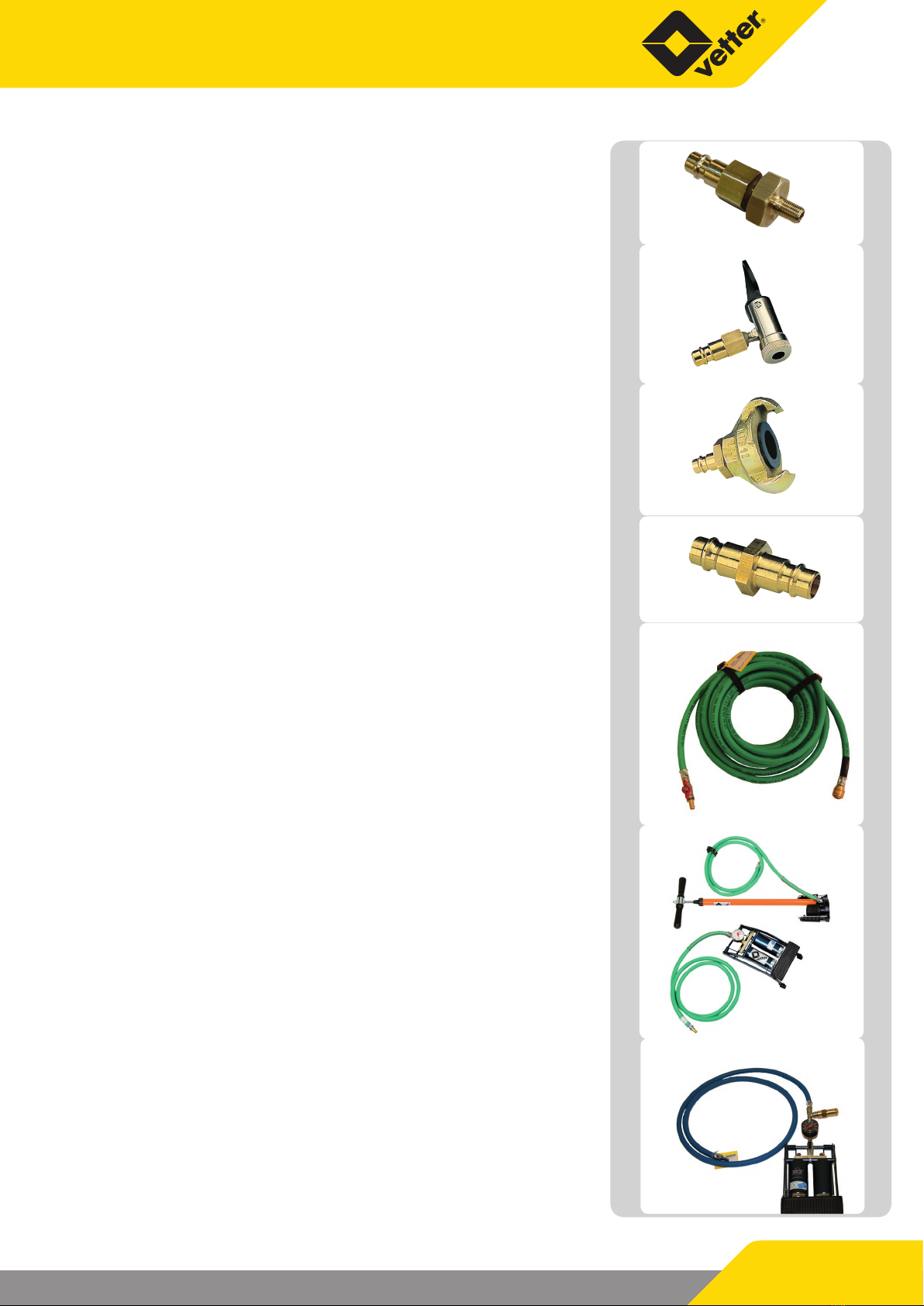

Depending on the application, Vetter leak sealers must only be

used with compressed air and only inated to the corresponding

pressure with original ination ttings.

They are exclusively used for sealing leaks on containers and

pipes.

Incorrect application of Vetter leak sealers includes the following:

9Incorrect use, operation or maintenance of leak sealers.

9Use of the leak sealers with defective safety devices or inati-

on ttings which have been either incorrectly installed or are

non-functional.

9Non-observance of the instructions contained in the opera-

ting instructions with respect to storage, operation and main-

tenance of the leak sealers.

9Insucient monitoring of accessory parts which are subject

to wear.

9Incorrectly carried out maintenance work.

The following also belong to correct application:

9Observance of all information contained in these operating

instructions.

9Compliance to the periods for maintenance and care contai-

ned in the Chapter“Maintenance and Care”.

2. Safety instructions

The use of Vetter Leak Sealers is made under the precondition that

there is a knowledge of this application and that the operating

instructions are observed.

2.1 General information

The observance of all pertinent regulations with respect to work

protection, safety and accident prevention (e.g. DGUV) as well as

generally recognized technological regulations is a precondition.

Leak sealers must be tested before application to see whether

they are resistant against hazardous materials. For this, refer to the

resistance chart!

The PVC acid protection cover for the leak sealing bag oers incre-

ased protection against acid spray.

Observe the pertinent regulations concerning handling with dan-

gerous liquids.

Protection equipment, such as protection clothing, gloves, hel-

met, face and eye protection, breathing protection and inherent

protection, are to be used onsite depending on the degree of

danger and the situation.