OWNERS MANUAL

PAGURO 2000

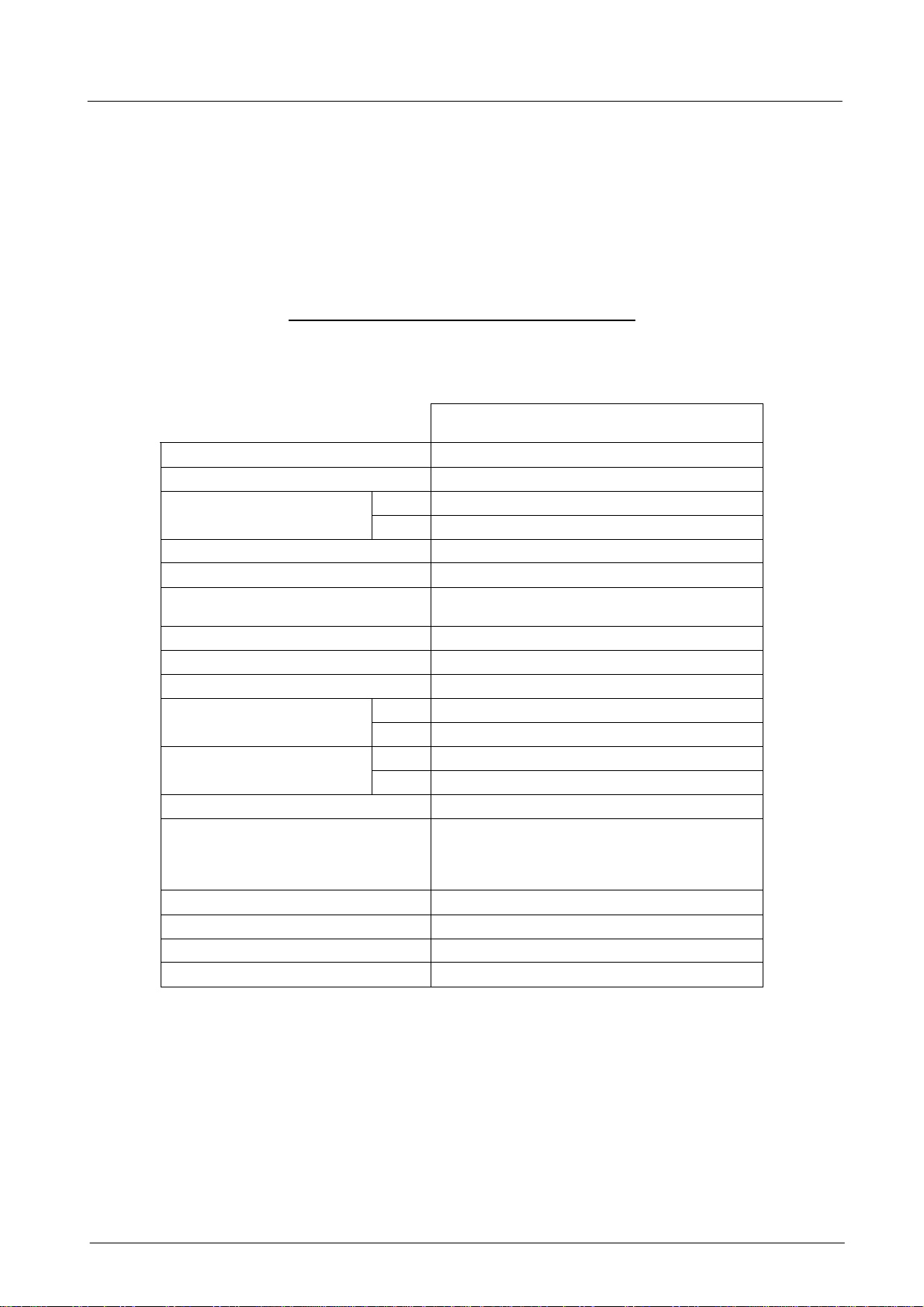

TABLE OF CONTENTS

GENERAL INFORMATIONS …………………………………………………………………………………………………………………………….... 3

SAFETY INSTRUCTIONS ………………………………………………………………………………………………………………………………. 5

INTRODUCTIONS / RECOMISSIONINGS ……………………………………………………………………………………………………………… 10

1. INSTALLATION ……………………………………………………………………………………………………………………………………………….. 11

EXTERNAL CONNECTIONS ………………………………………………………………………………………………………………………………. 12

VENTILATION ……………………………………………………………………………………………………………………………………………….. 12

LOCATION AND MOUNTINGS ………………………………………………………………………………………………………………………………. 13

FUEL LINES (Fuel Supply Line, Fuel return Line) …………………………………………………………………………………………..... 13

EXHAUST SYSTEM ………………………………………………………………………………………………………………………………………………… 14

RAW WATER COOLING SYSTEM (Siphon break, Raw Water Intake) …………………………………………………………… 15

INVERTER INSTALLATION ……………………………………………………………………………………………………………………………….. 16

STARTING BATTERY CONNECTION ………………………………………………………………………………………………………………. 16

MAIN OUTPUT VOLTAGE (230 V AC) ………………………………………………………………………………………………………………. 17

CONTROL PANEL ………………………………………………………………………………………………………………………………………………… 18

2. PREPARATION FOR INITIAL START-UP ………………………………………………………………………………………………………………. 22

DIESEL FUEL ………………………………………………………………………………………………………………………………………………… 22

ENGINE OIL SPECIFICATION ……………………………………………………………………………………………………………………………….. 22

PRE-START INSPECTION ……………………………………………………………………………………………………………………………….. 22

3. STARTING/STOPPING PROCEDURE ………………………………………………………………………………………………………………. 23

ELECTRIC START ………………………………………………………………………………………………………………………………………………… 23

PRE-HEATING ………………………………………………………………………………………………………………………………………………… 23

STARTING OPERATION ……………………………………………………………………………………………………………………………….. 23

OPERATING THE GENERATOR ……………………………………………………………………………………………………………………………….. 23

INITIAL START UP CHECK LIST ……………………………………………………………………………………………………………………………….. 23

STOPPING THE GENERATOR ……………………………………………………………………………………………………………………………….. 23

4. BREAK-IN PROCEDURE ……………………………………………………………………………………………………………………………….. 24

CHECK LIST ………………………………………………………………………………………………………………………………………………… 24

STOPPING THE GENERATOR ……………………………………………………………………………………………………………………………….. 24

5. MAINTENANCE SCHEDULE ……………………………………………………………………………………………………………………………….. 25

6. EXHAUST SYSTEM ………………………………………………………………………………………………………………………………………………… 27

EXHAUST SYSTEM PRECAUTIONS ………………………………………………………………………………………………………………. 27

7. COOLING SYSTEM ………………………………………………………………………………………………………………………………………………… 28

RAW WATER PUMP (inspecting/changing the raw water pump impeller) …………………………………………………………… 28

RAW WATER INTAKE STRAINER ……………………………………………………………………………………………………………………………….. 28

8. LUBRICATION SYSTEM ……………………………………………………………………………………………………………………………….. 29

ENGINE OIL ………………………………………………………………………………………………………………………………………………… 29

OIL PRESSURE ………………………………………………………………………………………………………………………………………………… 29

OIL COOLER ………………………………………………………………………………………………………………………………………………… 29

OIL FILTER ……………………………….………………………………………………………………………………………………………………. 29

CHECKING THE OIL ………………………………………………………………………………………………………………………………………………… 29

CHANGING THE OIL ………………………………………………………………………………………………………………………………………………… 29

DRAINING THE USED OIL ……………………………………………………………………………………………………………………………….. 29

ADDING NEW OIL ………………………………………………………………………………………………………………………………………………… 30

9. FUEL SYSTEM ………………………………………………………………………………………………………………………………………………... 30

DIESEL FUEL ………………………………………………………………………………………………………………………………………………… 30

FUEL ADDITIVES ………………………………………………………………………………………………………………………………………………… 30

CARE OF THE FUEL SUPPLY ……………………………………………………………………………………………………………………………….. 30

FUEL LIFT PUMP ………………………………………………………………………………………………………………………………………………… 30

FUEL FILTER ……………………………………..…………………………………………………………………………………………………………. 30

FUEL SUPPLY LINE ………………………………………………………………………………………………………………………………………………... 31

FUEL FILTER OF THE WATER-SEPARATING TYPE ……………………………………………………………………………………………... 31

FUEL INJECTION PUMP ……………………………………………………………………………………………………………………………….. 31

FUEL SHUT-OFF SOLENOID ……………………………………………………………………………………………………………………………….. 31

BLEEDING THE FUEL SYSTEM ……………………………………………………………………………………………………………………………….. 31

SPARE PARTS ………………………………………………………………………………………………………………………………………………... 31

10. ENGINE TROUBLESHOOTING ……………………………………………………………………………………………………………………………..... 32

11. DC ELECTRICAL SYSTEM ……………………………………………………………………………………………………………………………….. 33

12 VOLT DC CONTROL CIRCUIT ……………………………………………………………………………………………………………………………….. 33

BATTERY (Battery Care, Checking the service Battery) ……………………………………………………………………………………………… 33

ELECTRICAL SCHEME ………………………………………………………………………………………………………………………………………………... 34

12. GENERATOR INFORMATION ……………………………………………………………………………………………………………………………….. 35

GENERATOR MAINTENANCE ……………………………………………………………………………………………………………………………….. 35

13. GENERATOR TROUBLESHOOTING ………………………………………………………………………………………………………………. 35

14. SHORE POWER TRANSFER SWITCH ………………………………………………………………………………………………………………. 36

15. LAY UP AND RECOMISSIONING ……………………………………………………………………………………………………………………………….. 37