EG4 6500 EX-48 User manual

May 2022 | Rev A | Information subject to change without notice.

6.5KVA 120Vac

6500 EX-48

EG4 Electronics

www.eg4electronics.com

EG4 Inveer Set Up Guide:

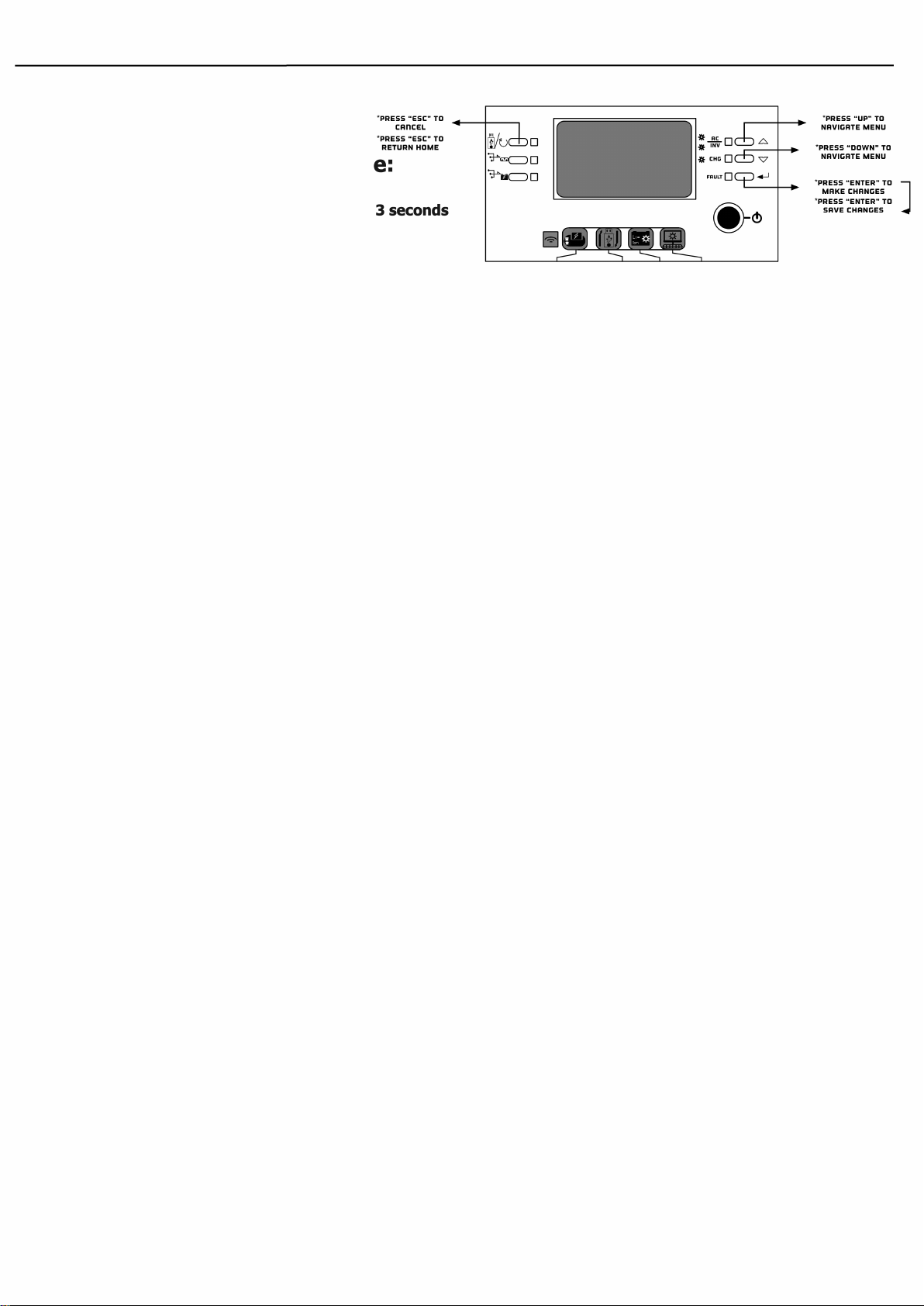

To enter Menu - Press and ENTER for 3 seconds

•Program Setting 0

•Program Seing 2

r = BOA

•Program Seing 3

•Program Seing 4

•Program Seing 5

r =

EG4, for

all other batteries use User Defined Settings.

•Program Seing 6

•Program Seing 7

•Program Seing 9

•Program Seing 10

o

o

o

o

Program Seing 11

•Program Setting 1

Exit Setting Mode

EG4 Electronics

www.eg4electronics.com

•Program Seing 12

•Program Seing 13

•Program Seing 16

•Program Seing 18

•Program Seing 19

•Program Seing 20

•Program Se

tt

ing 22

Beep when primary source interrupted.

default is AON (enabled)

•Program Seing 23

•Program Seing 25

•Program Seing 26

r =

•Program Seing 27

r =

•Program Seing 28

•Program Seing 29

EG4 Electronics

www.eg4electronics.com

•Program Seing 30-3

6

o

Battery Equalization settings

When using EG4 you will not need these settings. If using flooded lead acid or AGM

batteries consult your batteries user manual for recommended Equalization settings.

•

Program Setting 37

o

Rest all stored data for PV generated power and output load energy

•

Program Setting 41

o

Maximum Discharging Current

Use this to set maximum battery discharging current

range is 30A to 150A

unit of change is in 10A increments

o

Note: For EG4 batteries maximum discharge is 100A

•

Program Setting 51

o

RGB LED ON/OFF Control

•

Program Setting 52

o

RGB Brightness Control

•

Program Setting 53

o

Effect Speed of RGB lighting

•

Program Setting 54

o

RGB Lighting Effects Menu

•

Program Setting 55

o

RGB Lighting Color Menu

•

Program Setting 93

o

Erase All Data Logged

•

Program Setting 94

o

Data Log Recorded Interval

Use this menu to determine the interval time (in minutes) that data is logged

•

Program Settings 95- 99

o

Data and Time Settings

EG4 Electronics

www.eg4electronics.com

Table of Contents

ABOUT THIS MANUAL ............................................................................................................................ 1

Purpose ......................................................................................................................................................... 1

Scope ............................................................................................................................................................ 1

SAFETY INSTRUCTIONS .........................................................................................................................1

INTRODUCTION .................................................................................................................................... 2

Features........................................................................................................................................................ 2

Basic System Architecture............................................................................................................................... 2

Product Overview ........................................................................................................................................... 3

INSTALLATION ....................................................................................................................................... 4

Unpacking and Inspection .............................................................................................................................. 4

Installation of Battery Wiring Extension Box and Cable Glands ..........................................................................4

Preparation ................................................................................................................................................... 5

Mounting the Unit .......................................................................................................................................... 5

Battery Connection ........................................................................................................................................ 6

AC Input/Output Connection ........................................................................................................................... 7

PV Connection ............................................................................................................................................... 8

Final Assembly ............................................................................................................................................... 10

Remote Display Panel Installation ................................................................................................................... 10

Communication Connection ............................................................................................................................ 12

Dry Contact Signal ......................................................................................................................................... 12

BMS Communication ...................................................................................................................................... 12

OPERATION ............................................................................................................................................ 13

Power ON/OFF............................................................................................................................................... 13

Inverter Turn-on............................................................................................................................................ 13

Operation and Display Panel ........................................................................................................................... 13

LCD Display Icons.......................................................................................................................................... 14

LCD Setting ................................................................................................................................................... 16

LCD Display ................................................................................................................................................... 30

Operating Mode Description ........................................................................................................................... 35

Faults Reference Code ................................................................................................................................... 38

Warning Indicator .......................................................................................................................................... 39

BATTERY EQUALIZATION ...................................................................................................................... 40

CLEARANCE AND MAINTENANCE FOR ANTI-DUST KIT......................................................................... 41

Overview....................................................................................................................................................... 41

Clearance and Maintenance ........................................................................................................................... 41

SPECIFICATIONS................................................................................................................................... 42

Table 1 Line Mode Specifications..................................................................................................................... 42

Table 2 Inverter Mode Specifications............................................................................................................... 43

Table 3 Charge Mode Specifications ................................................................................................................ 43

Table 4 General Specifications ........................................................................................................................ 45

TROUBLE SHOOTING ............................................................................................................................ 46

Appendix I: Parallel function ................................................................................................................ 47

Appendix II: BMS Communication Installation .................................................................................... 60

Appendix III: The Wi-Fi Operation Guide in Remote Panel ................................................................. 65

EG4 Electronics

www.eg4electronics.com

Appendix IIII: UL Listing ......................................................................................................................74

ABOUT THIS MANUAL

Purpose

This manual describes the assembly, installation, operation and troubleshooting of this unit. Please read

this manual carefully before installations and operations. Keep this manual for future reference.

Scope

This manual provides safety and installation guidelines as well as information on tools and wiring.

SAFETY INSTRUCTIONS

WARNING: This chapter contains important safety and operating instructions. Read and

keep this manual for future reference.

1. Before using the unit, read all instructions and cautionary markings on the unit, the batteries and all

appropriate sections of this manual.

2. CAUTION- Do not disassemble the unit. Take it to a qualified service center when service or repair

is required. Incorrect re-assembly may result in a risk of electric shock or fire.

3. To reduce risk of electric shock, disconnect all wirings before attempting any maintenance or cleaning.

Turning off the unit will not reduce this risk.

4. CAUTION – Only qualified personnel can install this device with a battery.

5. NEVER charge a frozen battery.

6. For optimum operation of this inverter/charger, please follow required spec to select appropriate cable

size. It’s very important to correctly operate this inverter/charger.

7. Be very cautious when working with metal tools on or around batteries. A potential risk exists to drop

a tool that can spark or short circuit batteries or other electrical parts and could cause an explosion.

8. Please strictly follow installation procedure when you want to disconnect AC or DC terminals. Please

refer to INSTALLATION section of this manual for details.

9. Fuses are provided as over-current protection for the battery supply.

10. GROUNDING INSTRUCTIONS -This inverter/charger should be connected to a permanent grounded

wiring system. Be sure to comply with local requirements and regulation to install this inverter.

11. NEVER short AC output and DC inputs. Do NOT connect to the grid with a shorted DC input.

12. Warning!! Only qualified service persons are able to service this device. If errors still persist after

following troubleshooting table, please contact your retailer for further assistance.

13. WARNING: Because this inverter is non-isolated, only three types of PV modules are acceptable:

Mono-crystalline, Polycrystalline with class A-rated, and CIGS modules. To avoid any malfunction, do

not connect any PV modules with possible current leakage to the inverter. For example, grounded PV

modules will cause current leakage to the inverter. When using CIGS modules, please be sure NOT to

ground.

14. CAUTION: It is recommended to use DC breakers for surge protection on PV lines. Otherwise, it will

cause damage to the inverter if lightning strike occurs on PV modules.

EG4 Electronics

www.eg4electronics.com

1

INTRODUCTION

This is a residential self consumption multi-function inverter, combining the functions of an inverter, solar

charger and battery charger to offer uninterrupted power support in a single package. The comprehensive

LCD display offers user-configurable and easy-accessible button operations such as battery charging

current, AC or solar charging priority, and acceptable input voltage based on different applications.

Features

Pure sine wave inverter >3% THD

Configurable color with the built-in RGB LED bar

Built-in Wi-Fi for mobile monitoring (APP is required)

Supports USB On-the-Go function to easily upgrade firmware

Built-in anti-dust kit

Detachable LCD control module with multiple communication ports for BMS (RS485, CAN-BUS,

RS232)

Configurable input voltage tolerances for home appliances and personal computers via LCD control panel

Configurable AC/PV output usage timer and prioritization

Configurable AC/Solar charger priority via LCD control panel

Configurable battery charging current based on applications via LCD control panel

Compatible with the grid or generator power

Auto restart on AC reconnect

Overload / Over temperature / short circuit protection

Smart battery charger design for optimized battery performance

Basic System Architecture

The following illustration shows basic application for this unit - including the below-listed devices needed for

a complete running system:

Generator or Utility

48V Battery

PV modules

Consult with your system integrator for other possible system architectures depending on your

requirements.

This inverter can power various 120v appliances in home or office environment, including motor-type

appliances such as tube light, fan, refrigerator and air conditioners.

Figure 1 Basic PV System Overview

EG4 Electronics

www.eg4electronics.com

2

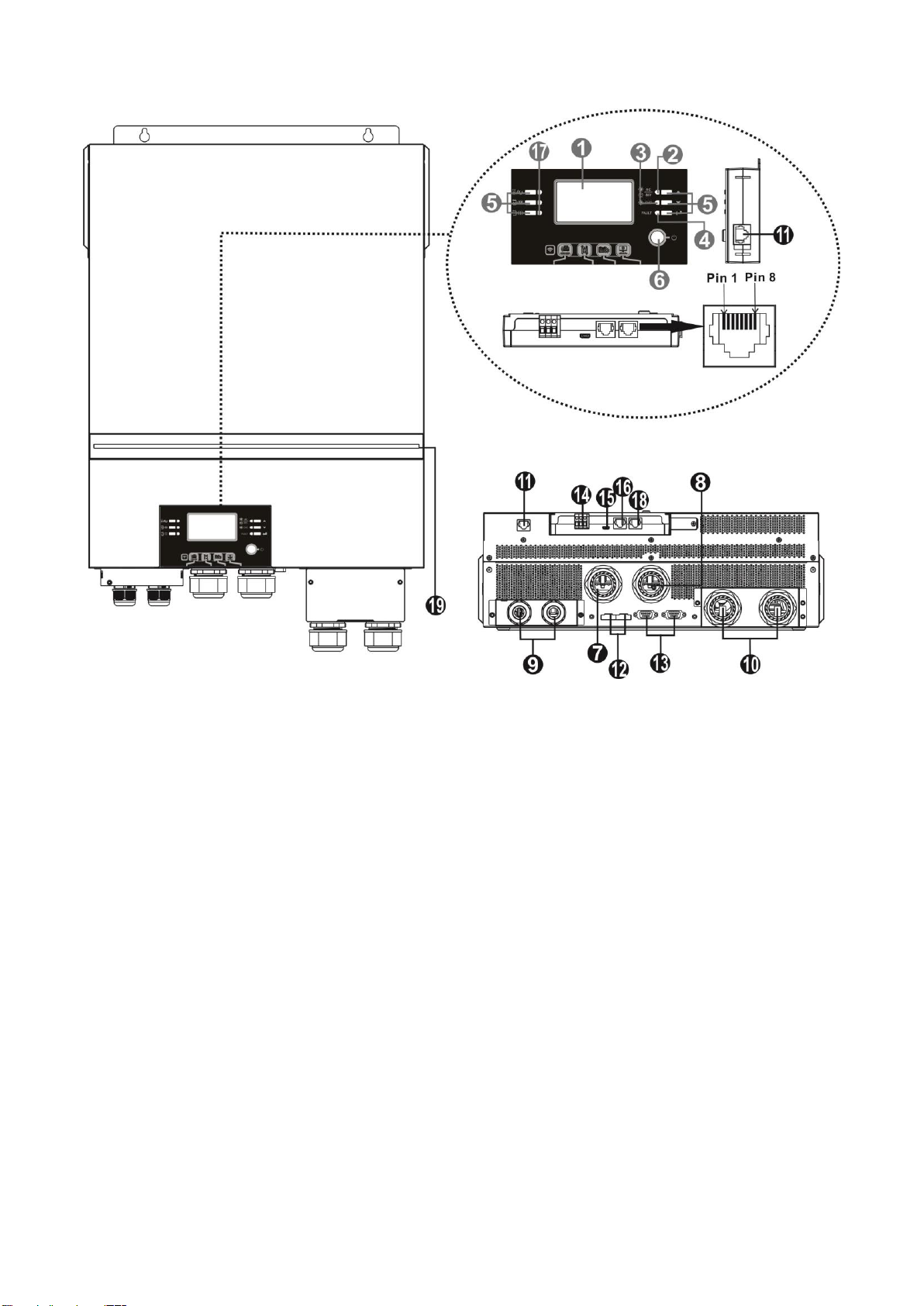

Product Overview

NOTE: 6.5KW is a parallel model. For parallel installation and operation, please check

Appendix I.

1. LCD display

2. Status indicator

3. Charging indicator

4. Fault indicator

5. Function buttons

6. Power on/off switch

7. AC input connectors

8. AC output connectors (Load connection)

9. PV terminal

10. Battery connectors

11. Remote LCD module communication

12. Current sharing port

13. Parallel communication port

14. Dry contact

15. OTG-USB port as USB communication port and USB

function port

16. BMS communication port: CAN, RS-485 or RS-232

17. Output source indicators (refer to OPERATION/Operation

and Display Panel section for details) and USB function

setting reminder (refer to OPERATION/Function Setting for

the details)

18. RS-232 communication port for firmware updates from a

PC

19. RGB LED bar (refer to LCD Setting section for the details)

Port

NOTE: For parallel model installation and operation, please check the parallel installation guide (pg. 47) for details.

EG4 Electronics

www.eg4electronics.com

3

INSTALLATION:

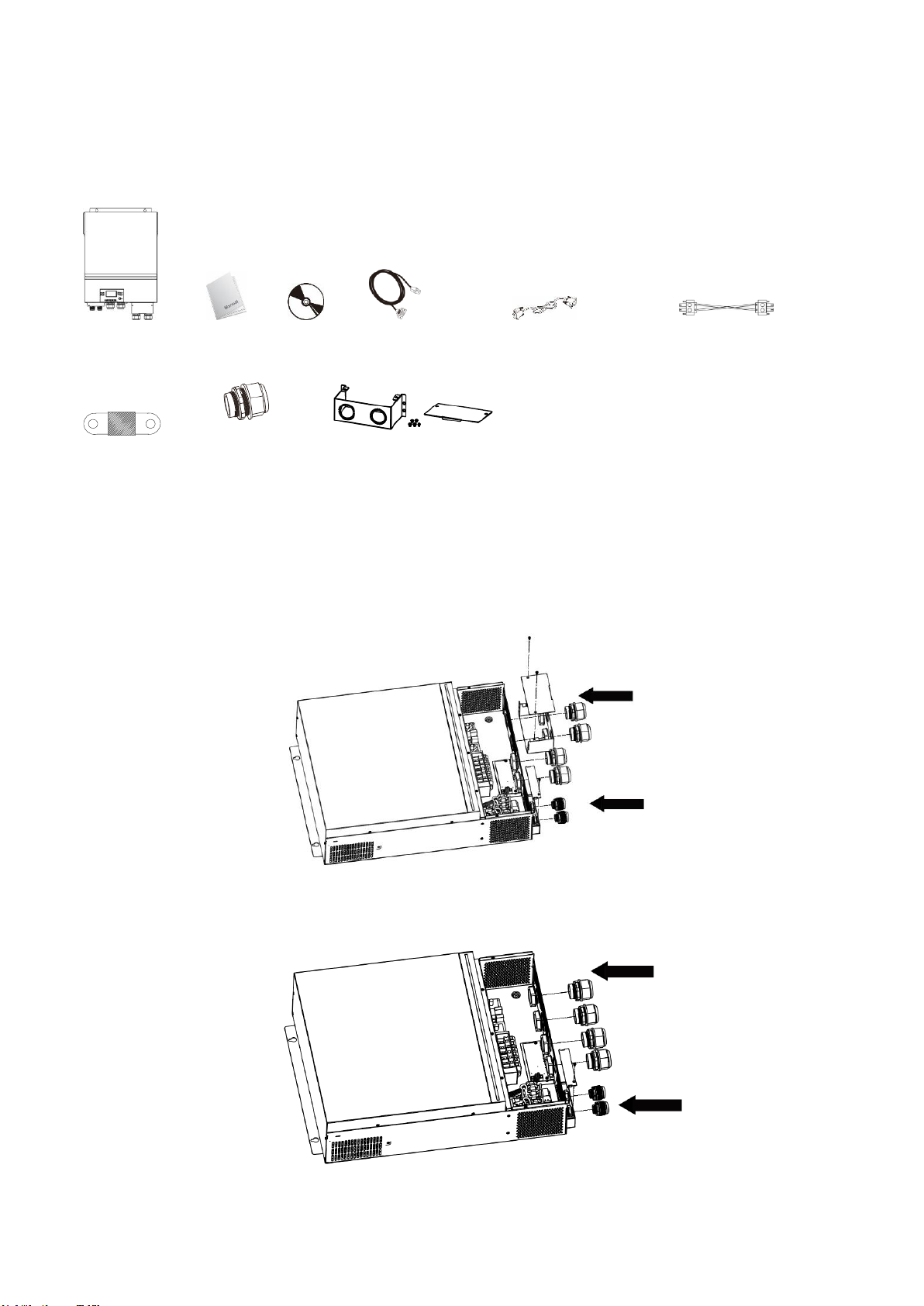

Unpacking and Inspection

Before installation, please inspect the unit. Be sure that nothing inside the package is damaged. You

should have received the following items:

Inverter unit Manual software CD RS-232 cable Parallel communication cable Current sharing cable

DC Fuse Cable gland x 4 pcs Extension Box Kit

Installation of Battery Wiring Extension Box,Cable Glands, and

Conduit Fittings 1/2" or 3/4"

Install two (2) cable glands or conduit fittings on the extension box, then fix the extension box on the

rear panel of the inverter.

Note: Installation of the battery wiring extension box is necessary for UL

conformity. If UL conformity is not required in your region, it is sufficient to only install the cable glands

(Graphic 2) shown below.

Fig.1 6500 with Extension Box

Fig.2 6500 without Extension Box

EG4 Electronics

www.eg4electronics.com

4

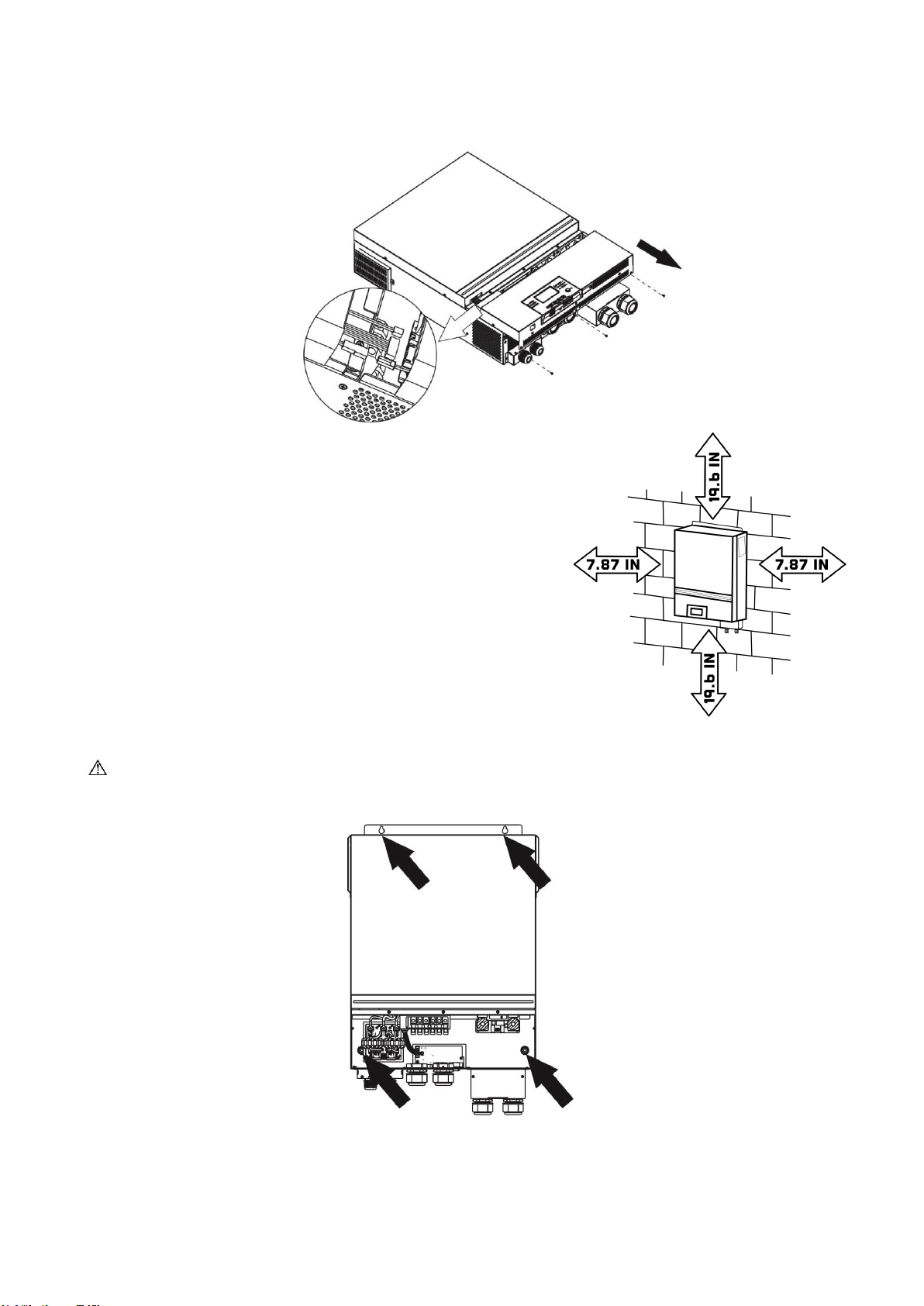

Preparation

Before connecting all wirings, please take off bottom cover by removing five screws. When removing the

bottom cover, be carefully to remove three cables as shown below.

Mounting the Unit

Consider the following points before selecting where to install:

⚫Do not mount the inverter on flammable construction materials.

⚫Mount on a solid surface

⚫Install this inverter at eye level in order to allow the LCD display to

be read at all times.

⚫The ambient temperature should be between 0°C and 55°C to

ensure optimal operation.

⚫The recommended installation position is to be adhered to the wall

vertically.

⚫Be sure to keep other objects and surfaces as shown in the right

diagram to guarantee sufficient heat dissipation and to have

enough space for removing wires.

⚫3ft of space or more on the bottom for servicing unit.

SUITABLE FOR MOUNTING ON CONCRETE OR OTHER NON-COMBUSTIBLE SURFACE ONLY.

Install the unit by screwing four screws. It’s recommended to use M4 or M5 screws.

EG4 Electronics

www.eg4electronics.com

5

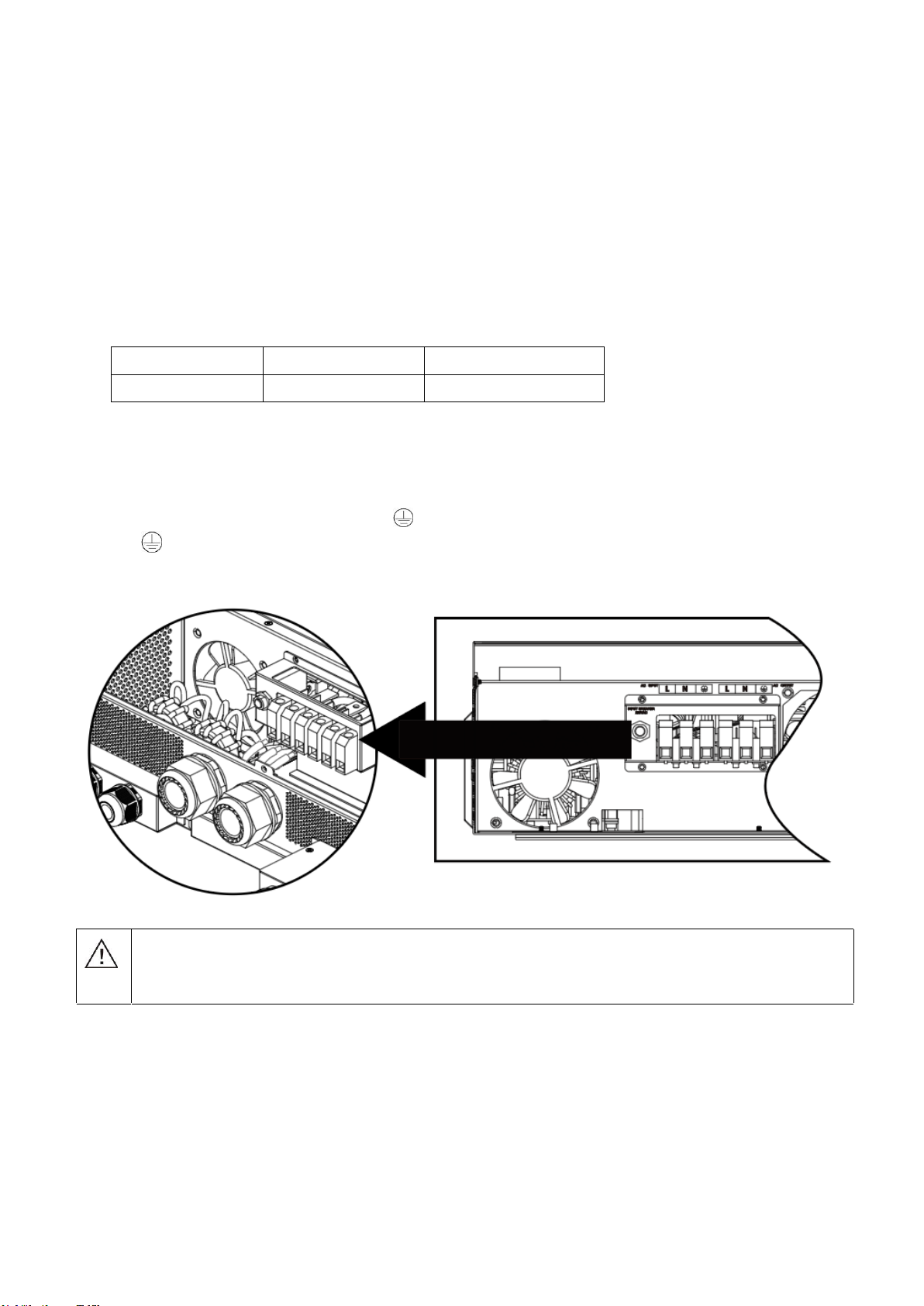

Battery Connection

CAUTION: For safety operation and regulation compliance, it is recommended that a separate DC over-

current protector or disconnect device be installed between the battery and inverter. It may not be

required to have a disconnect device in some applications, however, it is still recommended to have

over-current protection installed. Please refer to the typical amperage in table below for required fuse or

breaker size.

WARNING! All wiring must be performed by qualified personnel.

WARNING! It is very important for system safety and efficient operation

to use the appropriate cable size for battery connection. To reduce risk of

injury, please use the recommended cable and terminal size in the table

below.

Recommended battery cable and terminal size:

Model

Typical

Amperage

Battery

capacity

Wire Size

Cable

mm2

Ring Terminal

Torque

value

Dimensions

D (mm)

L (mm)

6.5KW

153A

250AH

1*2/0AWG

67

8.4

47

5 Nm

Please follow the below steps to implement battery connection:

1. Assemble battery ring terminal based on recommended battery cable and terminal size.

2. Fix two cable glands into positive and negative terminals.

3. Insert the ring terminal of battery cable flatly into battery connector of inverter and make sure the nuts are

tightened with torque of 5 Nm (3.6ft lbs). Make sure polarity at both the battery and the inverter/charge

is correctly connected and ring terminals are tightly screwed to the battery terminals.

WARNING: Shock Hazard

Installation must be performed with care due to high battery voltage in series.

CAUTION!! Do not place anything between the flat part of the inverter terminal and the ring

terminal. Otherwise, overheating may occur.

CAUTION!! Do not apply anti-oxidant substance on the terminals before terminals are connected

tightly.

CAUTION!! Before making the final DC connection or closing DC breaker/disconnector, be

sure positive (+) is connected to positive (+) and negative (-) is connected to negative (-).

Ring terminal:

EG4 Electronics

www.eg4electronics.com

6

AC Input/Output Connection

CAUTION!! Before connecting to AC input power source, please install a separate AC breaker between

the inverter and AC input power source. This will ensure the inverter can be securely disconnected

during maintenance and fully protected from over current of AC input.

CAUTION!! There are two terminal blocks with “IN” and “OUT” markings. Please do NOT mis-connect input

and output connectors.

WARNING! All wiring must be performed by a qualified personnel.

WARNING! It is very important for system safety and efficient operation to use appropriate cable for AC

input connection. To reduce risk of injury, please use the proper recommended cable size below.

Suggested cable requirement for AC wires

Model Gauge Torque Value

6.5KW 4 AWG 1.4~ 1.6Nm

Please follow below steps to implement AC input/output connection:

1. Before making AC input/output connection, be sure to open DC protector or disconnector first.

2. Remove insulation sleeve 10mm for six conductors. And shorten phase L and neutral conductor N 3 mm.

3. Fix two cable glands into input and output sides.

4. Insert AC input wires according to polarities indicated on terminal block and tighten the terminal screws. Be

sure to connect PE protective conductor ( ) first.

→Ground (yellow-green)

L→LINE (brown or black)

N→Neutral (blue)

WARNING:

Be sure that the AC power source is disconnected before attempting to hardwire it to the

unit.

EG4 Electronics

www.eg4electronics.com

7

5. Then, insert AC output wires according to polarities indicated on terminal block and tighten terminal screws.

Be sure to connect PE protective conductor ( ) first.

→Ground (yellow-green)

L→LINE (brown or black)

N→Neutral (blue)

6. Make sure the wires are securely connected.

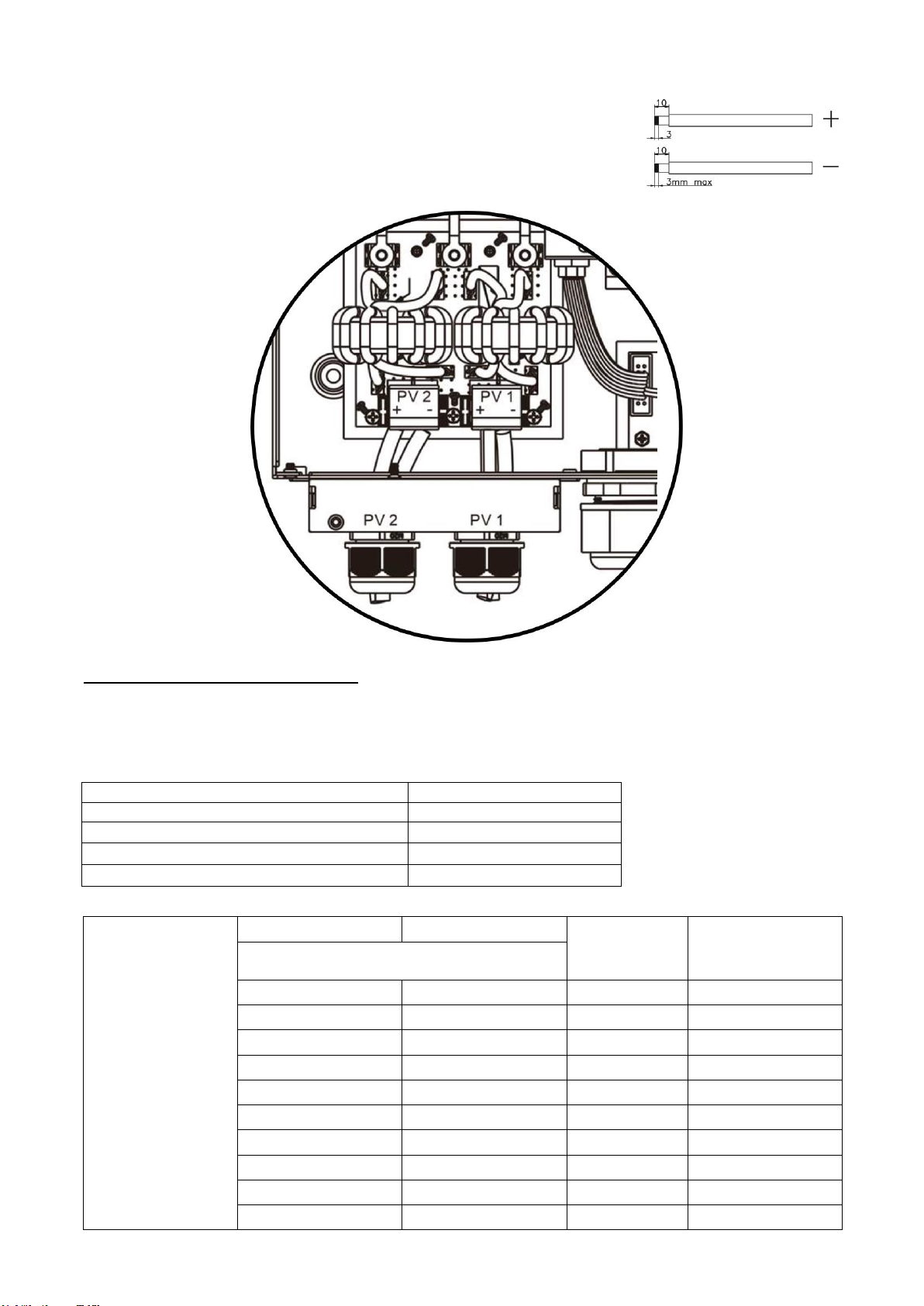

PV Connection

CAUTION: Before connecting to PV modules, please install separate DC circuit breakers between inverter

and PV modules.

NOTE: Please use 600VDC/30A circuit breaker. The over voltage category

of the PV input is

II.

Please follow

the steps

below to

implement PV module connection

Step 1: Check the input voltage of PV array modules. This system is applied with two strings of PV array. Please

make sure that the maximum current load of each PV input connector is 18A.

Step 2: Disconnect the circuit breaker and switch off the DC switch.

CAUTION: Appliances such as air conditioners require at least 2~3 minutes to restart because it’s

necessary to have enough time to balance refrigerant gasses inside of circuits. If a power outage

occurs and recovers in a short time, it may cause damage to your connected appliance. To prevent

damage, please check with the manufacturer of the air conditioner to see if it is equipped with a time -

delay function before installation. This inverter/charger may trigger an overload fault and shut off

the AC output to protect your appliance which may cause internal damage to the air conditioner.

CAUTION: Important

Be sure to connect AC wires with correct polarity. If L and N wires are reversed, it may cause a

short-circuit when these inverters are in parallel operation.

CAUTION: Exceeding the maximum input voltage can destroy the unit!! Check the system before wire connection.

WARNING: Because this inverter is non-isolated, only three types of PV modules are acceptable:

monocrystalline and polycrystalline with class A-rated and CIGS modules.

To avoid any malfunction, do not connect any PV modules with possible current leakage to the inverter. For

example, grounded PV modules will cause current leakage to the inverter. When using CIGS modules,

please be sure NOT to ground.

CAUTION: It is required to use PV junction box with surge protection. Otherwise, it will cause damage

to the inverter when lightning occurs on PV modules.

EG4 Electronics

www.eg4electronics.com

8

Step 3: Assemble PV terminals with PV modules by the following steps.

Please follow below steps to implement PV module connection:

1. Remove insulation sleeve 10 mm for positive and negative conductors.

2. Check correct polarity of connection cable from PV modules and PV input

connectors. Then, connect positive pole (+) of connection cable to positive

pole (+) of PV input connector. Connect negative pole (-) of connection cable

to negative pole (-) of PV input connector.

3. Make sure the wires are securely connected.

Recommended Panel Configuration

When selecting proper PV modules, please be sure to consider the following parameters:

1. Open circuit Voltage (Voc) of PV modules not to exceed maximum PV array open circuit voltage of the

inverter.

2. Open circuit Voltage (Voc) of PV modules should be higher than the start-up voltage.

INVERTER MODEL 6.5KW

Max. PV Array Power 8000W

Max. PV Array Open Circuit Voltage 500Vdc

PV Array MPPT Voltage Range 90Vdc~450Vdc

Start-up Voltage (Voc) 80Vdc

Example solar panel configuration for 6.5KW model:

Solar Panel Spec.

(reference)

-330Wp

- Vmp: 33.7Vdc

- Imp: 9.79A

- Voc: 39.61Vdc

- Isc: 10.4A

- Cells: 60

SOLAR INPUT 1

SOLAR INPUT 2

Q'ty of panels

Total Input Power

Min in series: 3pcs, per input

Max. in series:12pcs, per input

3pcs in series

x

3pcs

990W

x

3pcs in series

3pcs

990W

6pcs in series

x

6pcs

1980W

x

6pcs in series

6pcs

1980W

12pcs in series

x

12pcs

3960W

x

12pcs in series

12pcs

3960W

6pcs in series

6pcs in series

12pcs

3960W

6pcs in series, 2 strings

x

12pcs

3960W

x

6pcs in series, 2 strings

12pcs

3960W

6pcs in series, 2 strings

6pcs in series, 2 strings

24pcs

7920W

EG4 Electronics

www.eg4electronics.com

9

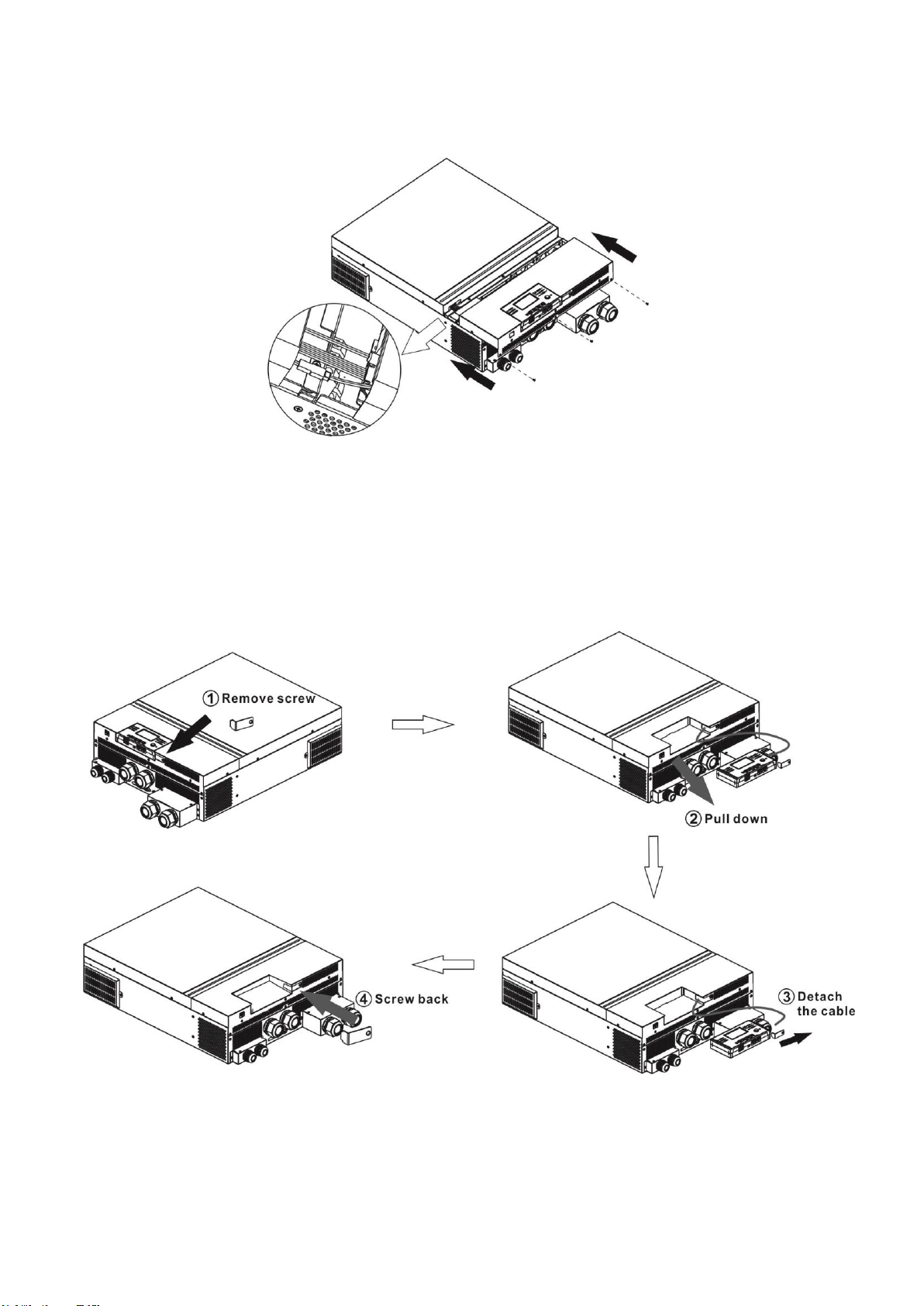

Final Assembly

After correctly connecting all wiring, re-connect three cables and then put bottom cover back by screwing

five screws as shown below.

Remote Display Panel Installation

The LCD module can be removed and installed in a remote location with an optional communication cable.

Please take the follow steps to implement this remote panel installation.

Step 1. Remove the screw on the bottom of LCD module and pull down the module from the case.Detach the

cable from the original communication port. Be sure to replace the retention plate back to the inverter.

EG4 Electronics

www.eg4electronics.com

10

Step 2. Prepare your mounting holes in the marked locations as shown in the illustration below. The LCD

module then can be securely mounted to your desired location.

Note: Wall installation should be implemented with the proper screws to the right.

Step 3. After LCD module is installed, connect LCD module to the inverter with an optional RJ45

communication cable as shown below.

M3

Ø5-Ø9

RS-232 communication

to PC

USB communication to

PC

BMS communication

Remote communication

EG4 Electronics

www.eg4electronics.com

11

Communication Connection

Serial Connection

Please use the supplied serial cable for connection between the inverter and your PC. Install the

monitoring software from the bundled CD and follow the on-screen instructions to complete your installation.

For detailed software operation, refer to the software user manual on the bundled CD.

Wi-Fi Connection

This unit is equipped with a Wi-Fi transmitter. The Wi-Fi transmitter can enable wireless communication

between off-grid inverters and monitoring platform. Users can access and control the monitored

inverter with downloaded APP. You can find the “WatchPower” app on the Apple® Store or “WatchPower

Wi-Fi” in the Google® Play Store. All data loggers and parameters are saved in iCloud. For quick installation

and operation, please check Appendix III.

Dry Contact Signal

There is one dry contact (3A/250VAC) available on the rear panel. It could be used to deliver signal to external

device when battery voltage reaches warning level.

Unit Status

Condition

Dry contact port:

NC & C

NO & C

Power Off

Unit is off and no output is powered.

Close

Open

Power On

Output is

powered

from Battery

power or

Solar energy.

Program 01

set as USB

(utility first)

or SUB (solar

first)

Battery voltage < Low DC

warning voltage

Open

Close

Battery voltage > Setting

value in Program 13 or

battery charging reaches

floating stage

Close

Open

Program 01 is

set as SBU

(SBU priority)

Battery voltage < Setting

value in Program 12

Open

Close

Battery voltage > Setting

value in Program 13 or

battery charging reaches

floating stage

Close

Open

BMS Communication

A special communication cable is required if you are connecting to Lithium-Ion battery banks. Please refer

to

Appendix II- BMS Communication Installation

for details.

EG4 Electronics

www.eg4electronics.com

12

OPERATION

Power ON/OFF

Once the unit has been properly installed and the batteries are connected correctly, simply press the On/

Off switch (located on the display panel) to turn on the unit.

Inverter Start-Up

After this inverter is turned on, the WELCOME light show will be started with RGB LED BAR. It will slowly

cycle through entire spectrum of nine colors (Green, Sky blue, Royal blue, Violet, Pink, Red, Honey, Yellow,

Lime yellow) for about 10-15 seconds. After initialization, it will light up with default color.

The RGB LED bar can light up in different color and light effects based on the setting of energy priority to

display the operation mode, energy source, battery capacity and load level. Parameters such as color, effects,

brightness, speed and so on can be configured through the LCD panel. Please refer to LCD settings for the

details.

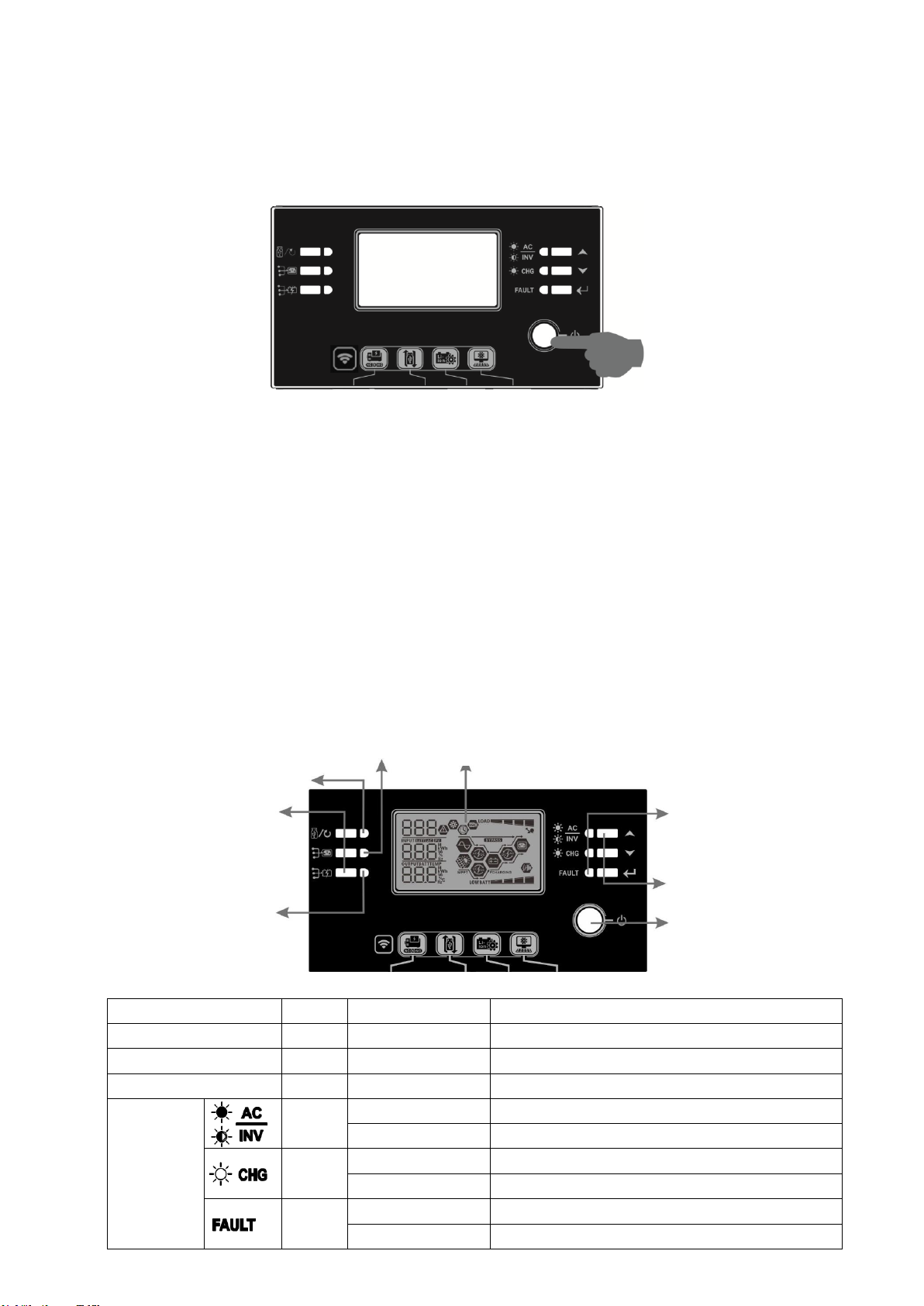

Operation and Display Panel

The operation and the LCD module, shown in the chart below, includes six indicators, six function keys, on/off

switch and a LCD display to indicate the operating status and input/output power information.

Indicators

LED Indicator

Color

Solid/Flashing

Messages

Setting LED 1

Green

Solid On

Output powered by utility

Setting LED 2

Green

Solid On

Output powered by PV

Setting LED 3

Green

Solid On

Output powered by battery

Status

indicators

Green

Solid On

Output is available in line mode

Flashing

Output is powered by battery in battery mode

Green

Solid On

Battery is fully charged

Flashing

Battery is charging.

Red

Solid On

Fault mode

Flashing

Warning mode

Status indicators

Function keys

On/off switch

Function keys

Setting LED 3

Setting LED 1

Setting LED 2

LCD display

EG4 Electronics

www.eg4electronics.com

13

Function Keys

Function Key

Description

ESC

Exit the setting

USB function setting

Select USB OTG functions

Timer setting for the Output source

priority

Setup the timer for prioritizing the output source

Timer setting for the Charger source

priority

Setup the timer for prioritizing the charger source

+

Press these two keys at the same time to switch RGB

LED bar between output source priority and battery

discharge/charge status.

Up To last selection

Down To next selection

Enter To confirm/enter the selection in setting mode

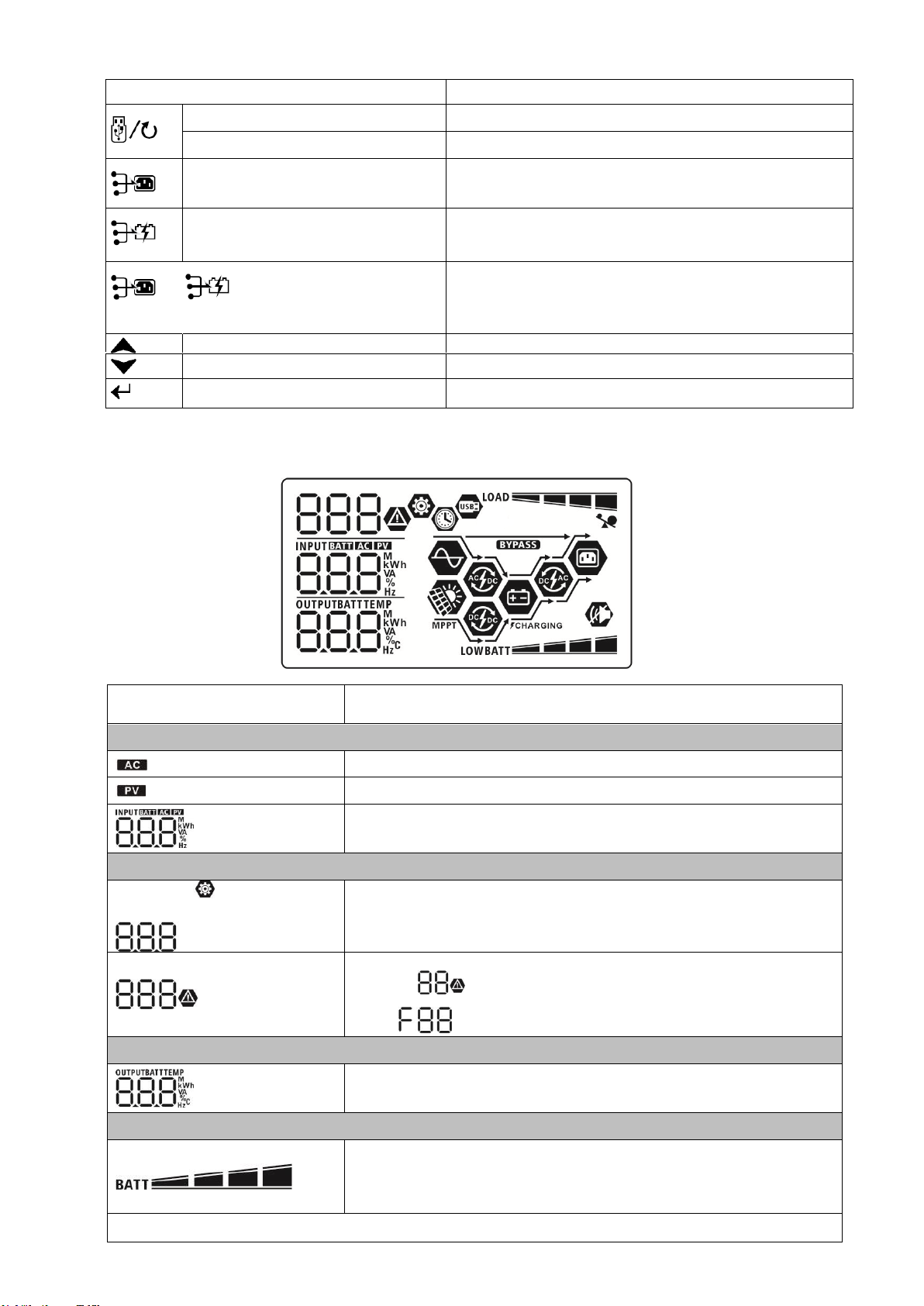

LCD Display Icons

Icon

Function description

Input Source Information

Indicates the AC input.

Indicates the PV input

Indicates input voltage, input frequency, PV voltage, charger

current, charger power, battery voltage.

Configuration Program and Fault Information

Indicates the setting programs.

Indicates the warning and fault codes.

flashing with warning code.

Fault: lighting with fault code

Output Information

Indicates output voltage, output frequency, load percent, load in

VA, load in Watt and discharging current.

Battery Information

Indicates battery level by 0-24%, 25-49%, 50-74% and 75-100% in

battery mode and charging status in line mode.

NOTE: When battery is

charging, it will

present battery charging

status.

Warning:

EG4 Electronics

www.eg4electronics.com

14

Status Battery voltage LCD Display

Constant

Current mode /

Constant

Voltage mode

<2V/cell 4 bars will flash in turns.

2 ~ 2.083V/cell Bottom bar will be on and the other three bars

will flash in turns.

2.083 ~ 2.167V/cell Bottom two bars will be on and the other two

bars will flash in turns.

> 2.167 V/cell Bottom three bars will be on and the top bar will

flash.

Floating mode. Batteries are fully charged. 4 bars will be on.

In battery mode, it will present battery capacity.

Load Percentage Battery Voltage LCD Display

Load >50%

< 1.85V/cell

1.85V/cell ~ 1.933V/cell

1.933V/cell ~ 2.017V/cell

> 2.017V/cell

Load < 50%

< 1.892V/cell

1.892V/cell ~ 1.975V/cell

1.975V/cell ~ 2.058V/cell

> 2.058V/cell

Load Information

Indicates overload.

Indicates the load level by 0-24%, 25-49%, 50-74% and 75-100%.

0%~24% 25%~49%

50%~74% 75%~100%

Mode Operation Information

Indicates unit connects to the mains.

Indicates unit connects to the PV panel.

Indicates load is supplied by utility power.

Indicates the utility charger circuit is working.

Indicates the solar charger circuit is working.

Indicates the DC/AC inverter circuit is working.

Indicates unit alarm is disabled.

Indicates USB disk is connected.

Indicates timer setting or time display

EG4 Electronics

www.eg4electronics.com

15

Other manuals for 6500 EX-48

1

Table of contents

Other EG4 Inverter manuals

Popular Inverter manuals by other brands

RNG

RNG KIT-STCS60D owner's manual

Mitsubishi Electric

Mitsubishi Electric FR-D720-0.4K instruction manual

FoxESS

FoxESS T Series user manual

UNIRAC

UNIRAC SolarMount installation manual

meibes

meibes Solarstation XXL Technical information for installation and operation

EnerSys

EnerSys OutBack Power Radian International Series Operator's manual

EASTMAN

EASTMAN ESM3K/48 manual

Wagan

Wagan Slim Line user manual

Vector

Vector MAXX SST VEC056D User's manual & warranty information

Toshiba

Toshiba TOSVERT VF-S9 instruction manual

ULTIMATE SPEED

ULTIMATE SPEED 300W USSW 300 B2 Operation and safety notes translation of the original instructions

Sealey

Sealey GG0720 instructions