2

Contents

1 DiUse Owner’s Manual .............................................................................................................. 4

1.1 General safety precautions ................................................................................................ 4

2 Liability and Warranty ................................................................................................................. 5

2.1 Liability .................................................................................................................................. 5

2.2 Warranty ............................................................................................................................... 6

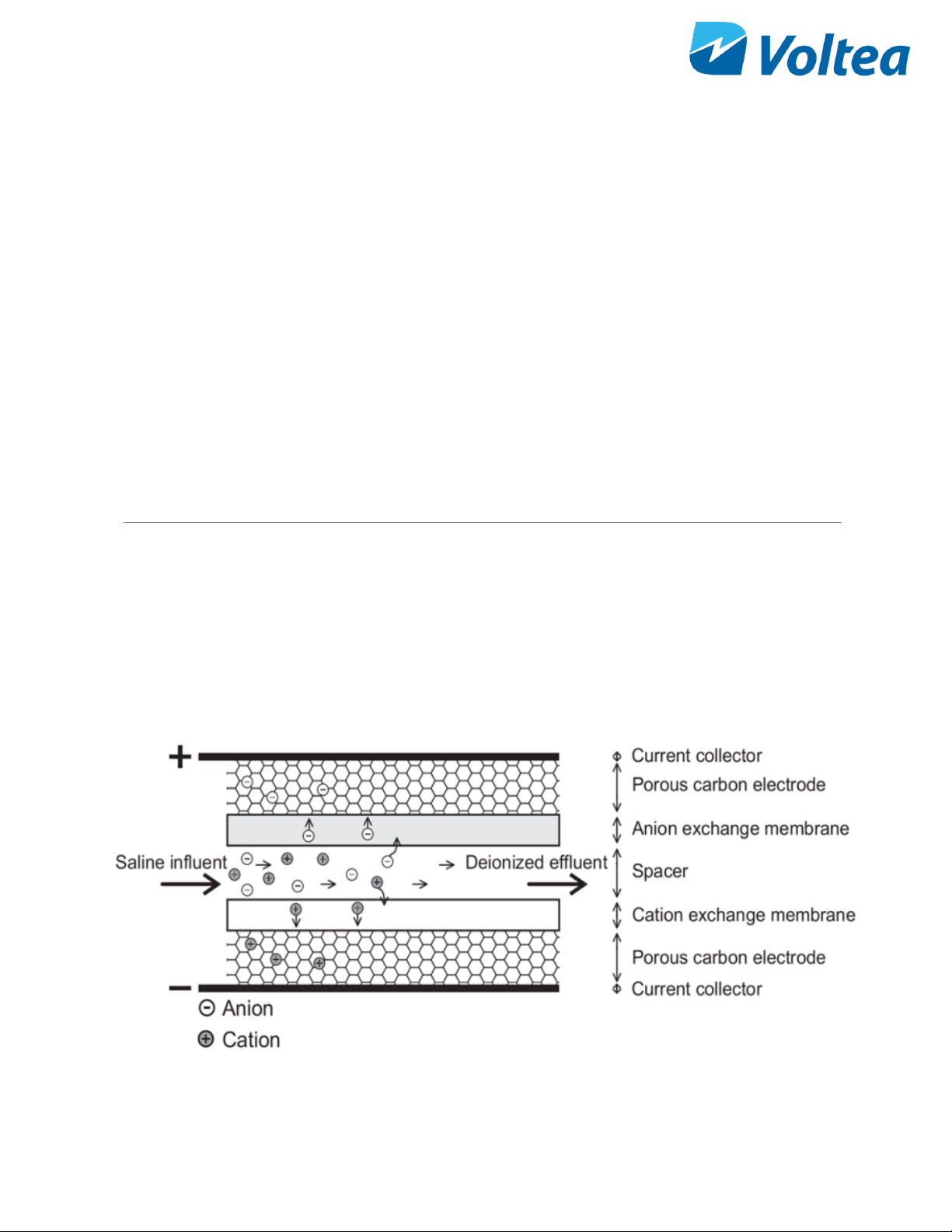

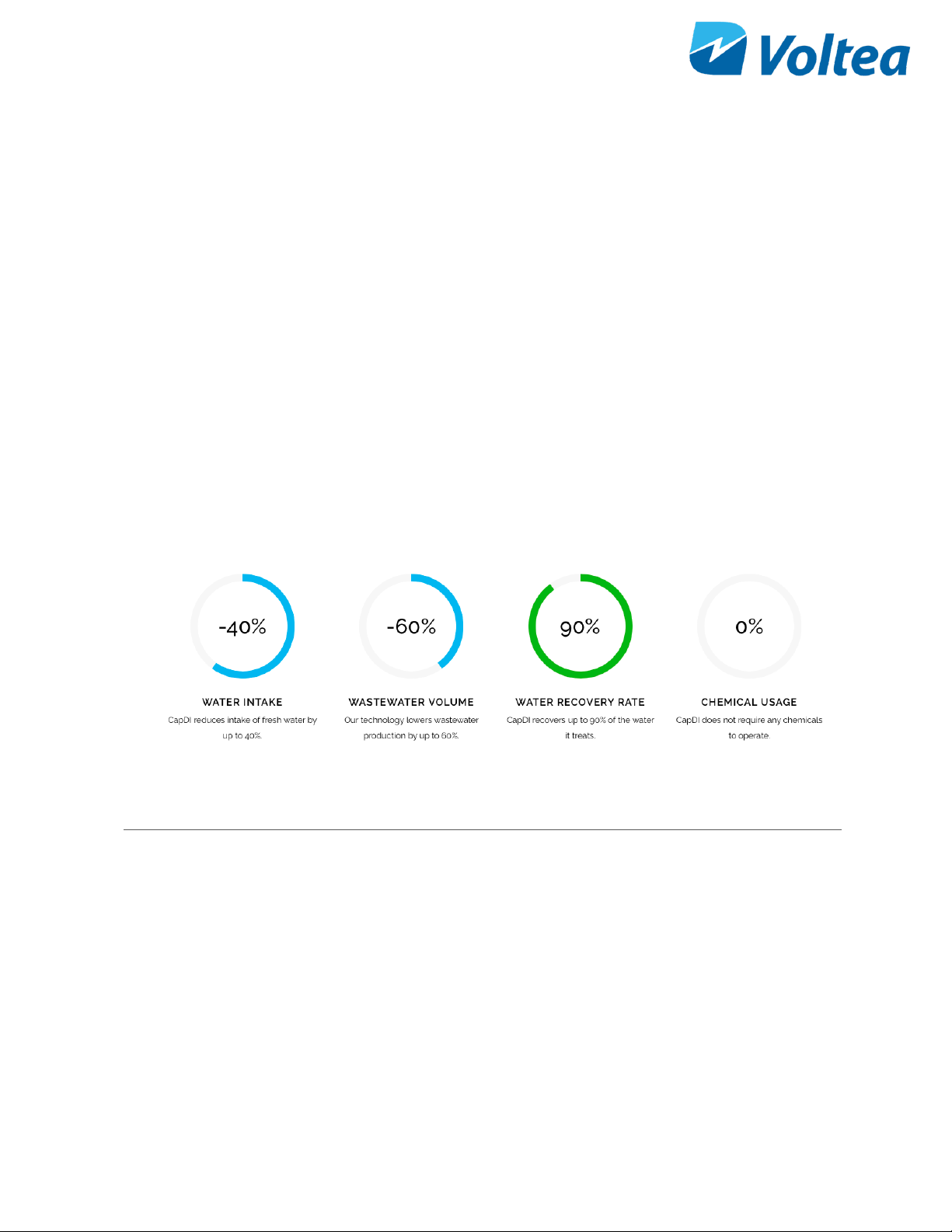

3 Voltea CapDI - Membrane Capacitive Deionization .............................................................. 6

4 DiUse ............................................................................................................................................ 7

4.1 Features ............................................................................................................................... 7

4.2 Specifications ....................................................................................................................... 8

4.3 Feed water quality ............................................................................................................... 9

5 System Overview ...................................................................................................................... 10

6 System Installation .................................................................................................................... 11

6.1 Packing ............................................................................................................................... 11

6.2 Tools and materials .......................................................................................................... 11

6.3 Module installation ............................................................................................................ 11

6.4 Placing leak sensor ........................................................................................................... 14

6.5 Placing the covers. ............................................................................................................ 14

6.6 Water connections ............................................................................................................ 14

6.7 Powering the system up/down ........................................................................................ 14

6.8 Filling the Cleaning In Place (CIP) container ................................................................ 15

6.9 Flushing the module ......................................................................................................... 17

7 System Start Up - Operation ................................................................................................... 18

8 System Control Through LCD ................................................................................................. 18

8.1 DiUse Screen Navigation Chart ...................................................................................... 19

8.2 Voltea DiUse ...................................................................................................................... 19

8.2.1 Process steps ............................................................................................................ 20

8.2.2 Alarms ......................................................................................................................... 21

8.3 Device info ......................................................................................................................... 22

8.4 System ................................................................................................................................ 23

8.5 User functions .................................................................................................................... 24

9 Changing Flow Restrictors ....................................................................................................... 24