98-100 ISSUE 8 3

CONTENTS

WARRANTY........................................................................................................................................5

HEALTH & SAFETY ..............................................................................................................................6

SAFETY PRECAUTIONS........................................................................................................................8

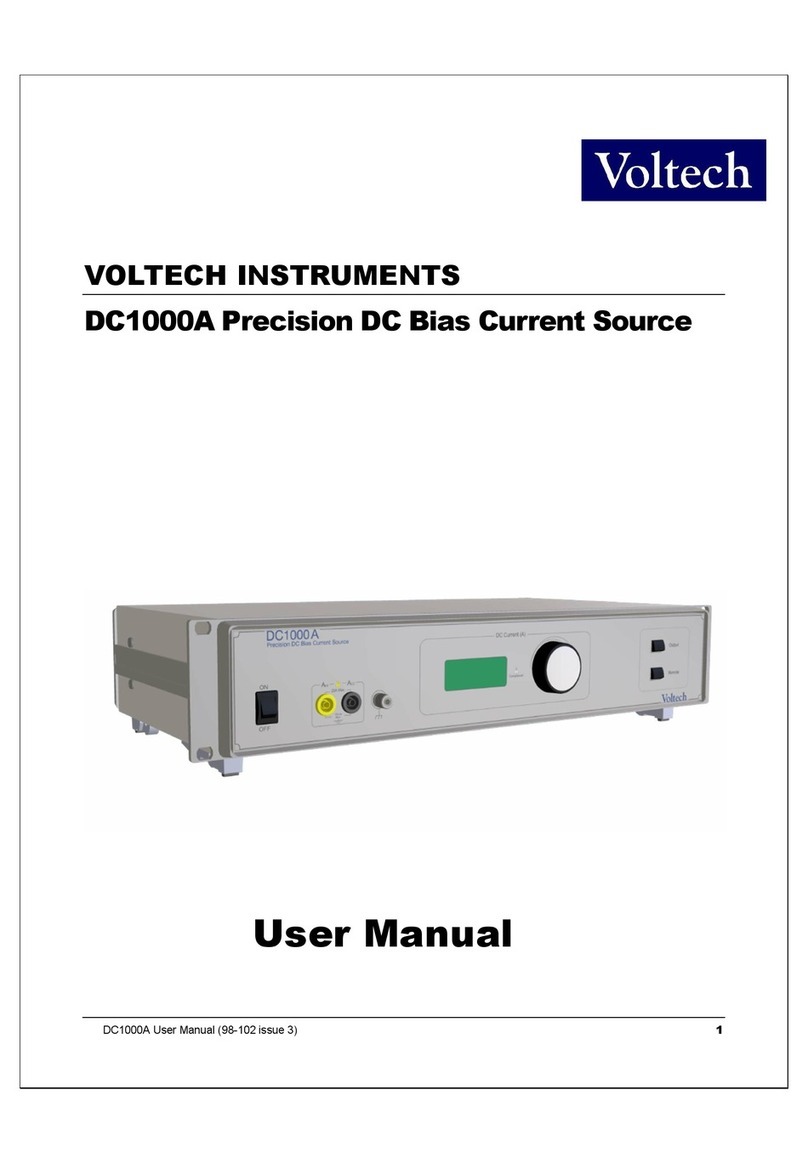

WHAT IS THE DC1000? .......................................................................................................................9

WHAT CAN THE DC1000 DO FOR YOU? ..............................................................................................9

PACKING LIST ...................................................................................................................................10

GETTING STARTED ...........................................................................................................................11

SAFETY INTERLOCK...........................................................................................................................13

USING THE DC1000 WITH A SAFETY SYSTEM ............................................................................................... 13

USING THE DC1000 AND A VOLTECH AT3600/AT5600 WITH A SAFETY SYSTEM ..............................................14

USING THE DC1000 WITH AN LCR METER.........................................................................................16

USING MULTIPLE DC1000S IN PARALLEL ..........................................................................................17

USING A PC TO CONTROL YOUR DC1000 (S).....................................................................................18

USING A PC TO CONTROL YOUR DC1000(S) WITH AN RS232 LCR METER (NOT A VOLTECH AT SERIES

PRODUCT)........................................................................................................................................ 19

USING A PC TO CONTROL YOUR DC1000(S) WITH AN IEEE-488 LCR METER (NOT A VOLTECH AT

SERIES PRODUCT).............................................................................................................................20

USING THE DC1000 WITH A VOLTECH AT3600 OR ATI(AND OPTIONAL PC) ......................................21

AT COMPENSATION WITH MULTIPLE DC1000S........................................................................................... 22

USING IR, ILK, HPDC, HPAC TESTS - (HIGH VOLTAGE TESTS).......................................................................23

USING SURG, MAGI, STRW, WATT, VOC TESTS..................................................................................... 23

LSBX – INDUCTANCE WITH EXTERNAL BIAS (SERIES CIRCUIT)................................................................23

LPBX – INDUCTANCE WITH EXTERNAL BIAS (PARALLEL CIRCUIT)............................................................25

ZBX – IMPEDANCE WITH EXTERNAL BIAS...........................................................................................27

RS232 COMMUNICATION.................................................................................................................30

RS 232 CONNECTION.............................................................................................................................. 30

PINNING ............................................................................................................................................... 30

COMMANDS ..........................................................................................................................................31

TURN THE OUTPUT ON OR OFF ...................................................................................................... 31

SET DC1000 OUTPUT CURRENT......................................................................................................32

GET THE STATUS OF THE UNIT .......................................................................................................... 32

READ THE SERIAL NUMBER ............................................................................................................. 33

GET THE NUMBER OF UNITS ATTACHED .............................................................................................. 33

STATUS NUMBERS ........................................................................................................................... 34

CALIBRATION ................................................................................................................................... 35

ACCESSORIES ................................................................................................................................... 35

PC SOFTWARE ..................................................................................................................................36

INSTALLING THE SOFTWARE ...................................................................................................................... 36