Operating instruction_SD2P2X-B4_15324_1en_09/2023

Page 9

www.argo-hytos.com

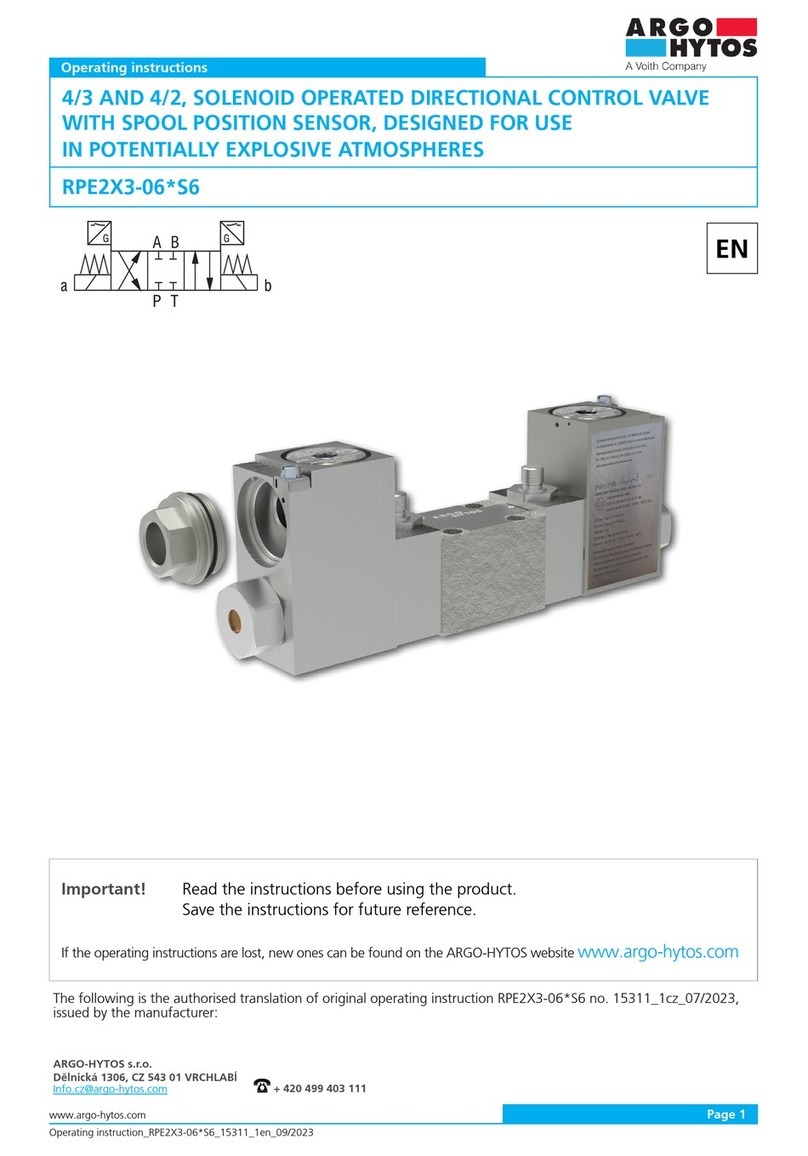

Valves with ATEX certification according to Directive 2014/34/EU and IECEx certification according to IECEx OD 009 and related harmonized

standards may be used in explosive atmospheres consisting of mine gas, gas or dust. The valves are marked with the CE Ex mark of conformity and

are accompanied by a Declaration of Conformity.

Use in explosive atmospheres:

Equipment - group I, mines, where the explosive atmosphere of firedamp consists predominantly methane.

The valve has a high level of safety (EPL = Mb), which makes initiation unlikely during the interval between gas discharge and valve shutdown.

It is designed for category M2 devices that remain off after gas discharge.

Equipment - group II, where the explosive atmosphere consists of gasses other than mine gas.

The valve has a high level of safety (EPL = Gb) which allows the valve to be used in zones 1 and 2. The valve must not be used in zone 0.

There is a risk of explosion. The valve is certified for gas groups IIA (typical gas is propane), IIB (typical gas is ethylene) also for hydrogen from group IIC.

The joint dimensions do not meet the requirements for Group IIC acetylene.

Equipment - group III, where the explosive atmosphere consists of dust and flammable flying particles.

The valve has a high level of safety (EPL = Db) which allows the valve to be used in zones 21 and 22. The valve must not be used in zone 20. There is

a risk of explosion. The valve is certified for all dust groups - IIIA (flammable flying particles), IIIB (non-conductive dust) and IIIC (conductive dust).

2. Valve protection against initiation of explosion of explosive atmosphere

2.1 Protection of electrical parts

The electrical part of the valve is an ATEX and IECEx certified solenoid coil.

The basic is the „d“ protection by flameproof enclosure (EN 60079-1, IEC 60079-1), which prevents the penetration of hot gases into the surroun-

ding explosive atmosphere in the event that an explosion is initiated inside the flameproof enclosure. For explosive atmospheres consisting of dust,

the enclosure „t“ (EN 60079-31, IEC 60079-31) is used. In addition, the coil is sealed with a potting compound.

Certification across standards NEC 500 and NEC 505, 506

NEC 500 (USA), Annex J (Kanada) NEC 505, 506 (USA) CEC Section 18 (Kanada)

Class I Division 1 Group B, C, D T4 Cl 1 Zone 1, AEx db IIB+H2 T4 Ex db IIB+H2 T4 Gb

Class II/III Division 1 Group E, F, G T4 Zone 21, AEx tb IIIC T135°C Db Ex tb IIIC T135°C Db

I M2 Ex db I Mb

II 2G Ex db IIB + H2 T4 Gb

II 2D Ex tb IIIC T135°C Db

Certification ATEX, IECEx and UKCA

Use of the valve in potentially explosive atmospheres

Certification Number Issued Certification body

EU-Type Examination Certificate FM23ATEX0008X 13.6.2023 FM Approvals Europe Ltd. (Notified body No. 6024)

One Georges Quay Plaza, Dublin, Ireland D02 E440

IECEx Certificate of Conformity IECEx FMG 23.0003X 12.6.2023 FM Approvals LLC

1151 Boston-Providence Turnpike, Norwood, MA 02062, USA

UK-Type Examination Certificate FM23UKEX0010X 16.6.2023 FM Approvals Ltd. (Approved body No. 1725)

Voyager Place, Maidenhead, Berkshire, SL6 2PJ, UK

Equipment - group I – MINES Equipment - group II (IIG) - GAS Equipment - group III (IID) - DUST

Category M1– NO Zone 0 - NO Zone 20 - NO

Categorie M2

(the device remains

switched off)

Zone 1

Zone 2

IIA (propane) Zone 21

Zone 22

IIIA (flammable particles)

IIB (ethylene) + H2 (hydrogen) IIIB (non-conductive dust)

IIIC (conductive dust)

Area of application:

The valves are available in three surface temperature classes:

T4 with a maximum surface temperature of 135 °C

The use of the valve in the temperature class is subject to the maximum supply voltage of the coil not being exceeded, the working

fluid temperature and the ambient temperature not being exceeded (see Table 4.4 Basic technical parameters).