Table of Contents

PREFACE ...................................................................................................................................................................... I

SAFETY INFORMATION ......................................................................................................................................... III

CHAPTER I SAFETY .................................................................................................................................................. 1

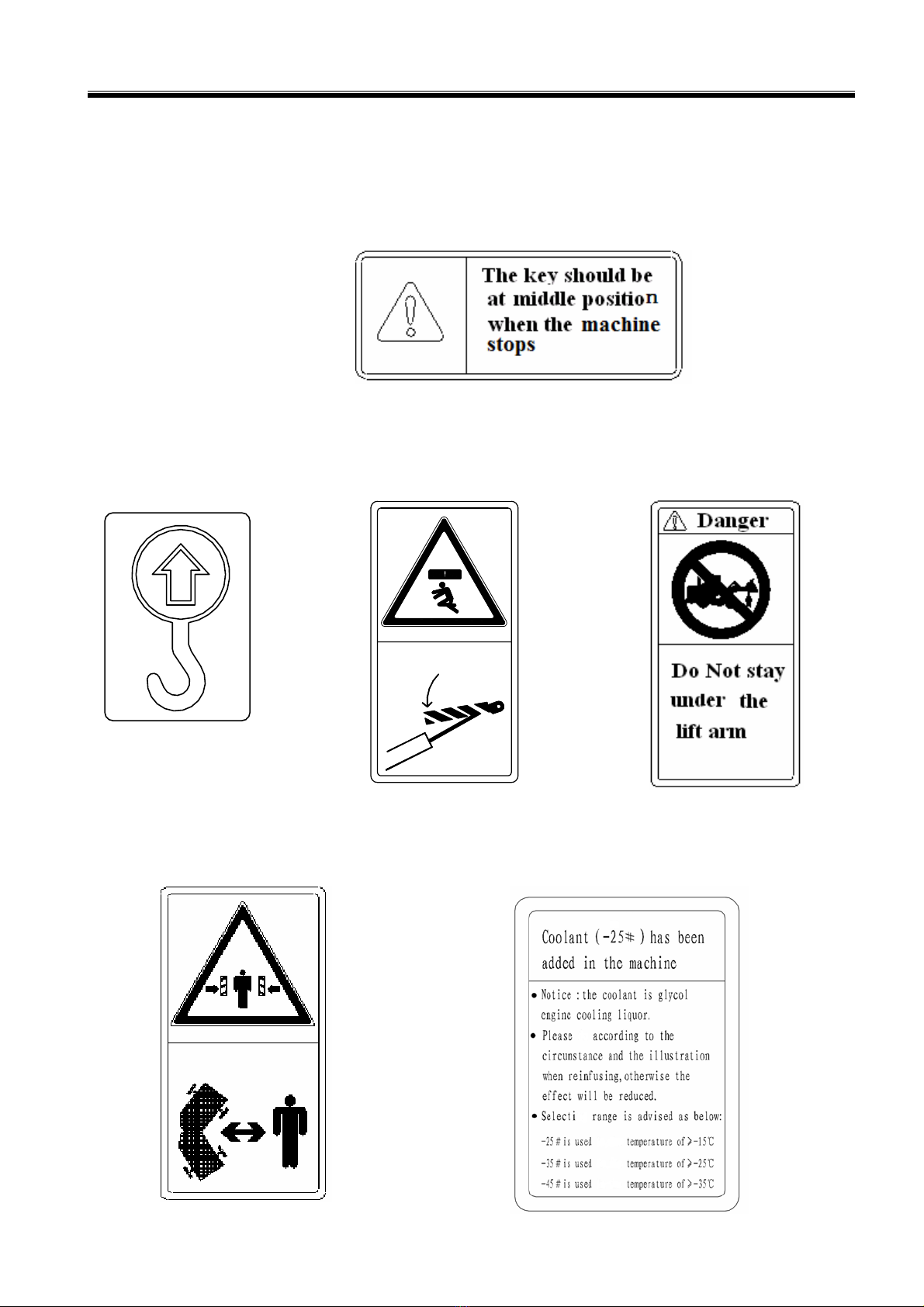

1 SAFETY LABEL POSITIONS AND THE CONTENTS.................................................................................. 1

2 SAFETY RULES ..............................................................................................................................................11

3 SAFETY OPERATION.................................................................................................................................... 13

4. STARTING SAFELY...................................................................................................................................... 17

5 SAFETY DRIVING......................................................................................................................................... 20

6 SAFETY OPERATION.................................................................................................................................... 25

7 SAFETY PARKING ........................................................................................................................................ 30

8 SAFETY EXAMINATION AND REPAIR...................................................................................................... 31

9 SAFETY TRANSPORTATION ....................................................................................................................... 41

CHAPTER II INTRODUCTION................................................................................................................................ 44

1 GENERAL VIEW OF THE MACHINE & COMPONENTS’ NAME............................................................ 44

2 GEOMETRICAL DIMENSIONS.................................................................................................................... 45

3 PRODUCT TYPE AND ITS MEANING ........................................................................................................ 46

4 NAMEPLATE.................................................................................................................................................. 46

5 USE CONDITIONS......................................................................................................................................... 47

6 CIRCUMSTANCES REQUIREMENT ........................................................................................................... 48

7 FEATURES...................................................................................................................................................... 48

8 TECHNICAL PERFORMANCE & PARAMETER ........................................................................................ 49

CHAPTER III OPERATION AND APPLICATION................................................................................................... 51

1 BE FAMILIAR WITH MACHINE.................................................................................................................. 51

2 RUN-IN PERIOD OF NEW MACHINE......................................................................................................... 66

3 OPERATION AND USE OF LOADER .......................................................................................................... 67

CHAPTER ⅣMAINTENANCE ............................................................................................................................. 90

1 MAINTENANCE GUIDE ............................................................................................................................... 90

2. DETAILED RULES OF MAINTENANCE ................................................................................................... 91

3 CONTENT OF MAINTENANCE................................................................................................................... 97

CHAPTER V THE STRUCTURE AND PRICIPLE OF MAIN COMPONENTS AND SYSTEM ........................ 101

1 TRANMISSION SYSTEM............................................................................................................................ 101

2 HYDRAULIC SYSTEM ............................................................................................................................... 101

3 BRAKE SYSTEM ......................................................................................................................................... 103

4 ELECTRIC SYSTEM.................................................................................................................................... 104