T

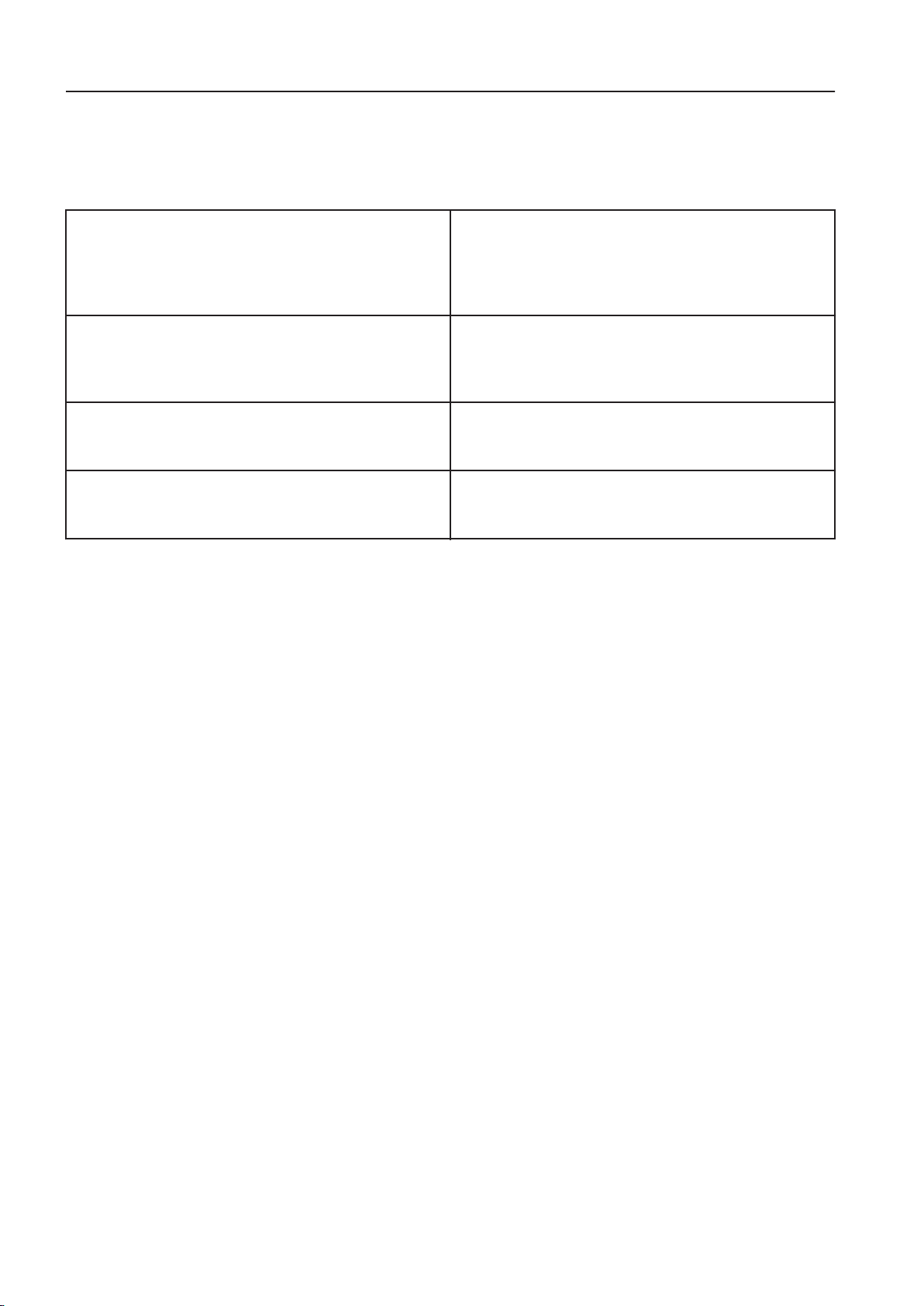

Table of contents

Foreword ................................................................. 1

Identification numbers ......................................................... 6

r

e

s

n

t

a

t

i

o

n

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Machine view ..................................................................... 12

CE-marking, EMC-directive ............................................... 13

Communication equipment, installation ............................. 16

Safety components ............................................................ 17

Product plates ................................................................... 18

Information and warning decals ........................................ 19

USA federal clean air act ................................................... 29

n

s

r

u

m

e

n

t

a

n

e

l

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3

Instrument panel, left ......................................................... 34

Instrument panel, front ...................................................... 40

Display unit ........................................................................ 47

Instrument panel, right ....................................................... 80

Instrument panel, rear ....................................................... 90

t

h

e

r

n

t

r

o

l

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

Controls ............................................................................. 91

Cab .................................................................................. 104

Control lockout system .................................................... 110

Operator comfort ............................................................. 111

p

e

r

a

t

i

n

g

n

s

r

u

c

i

o

n

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4

0

Safety rules when operating ............................................ 146

Measures before operating ............................................. 152

Starting engine ................................................................ 153

Hydraulic system, warming up ........................................ 157

Operating ......................................................................... 158

Steering ........................................................................... 160

Braking ............................................................................ 163

Exhaust aftertreatment system ........................................ 165

Stopping .......................................................................... 176

Parking ............................................................................ 177

Retrieving and towing ...................................................... 179

Attachments, alternative lowering ................................... 183

Transporting machine ...................................................... 186

p

e

r

a

t

i

n

g

e

c

n

i

q

u

e

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

9

1

Eco driving ....................................................................... 192

Whole-body vibrations ..................................................... 193

Rules for digging ............................................................. 195

Boom Suspension System (BSS) .................................... 197

Working within dangerous areas ..................................... 199

Attachments .................................................................... 207

Attachments, connecting and disconnecting ................... 210

Pressure release ............................................................. 221

Buckets ............................................................................ 222

Offset boom ..................................................................... 227

Hammer ........................................................................... 228

Lifting objects .................................................................. 230

Equipment towing ............................................................ 234

Signalling diagram ........................................................... 243

T

a

b

l

e

f

n

t

e

n

t

s