A5P | 01

and the chainsaw out of control.

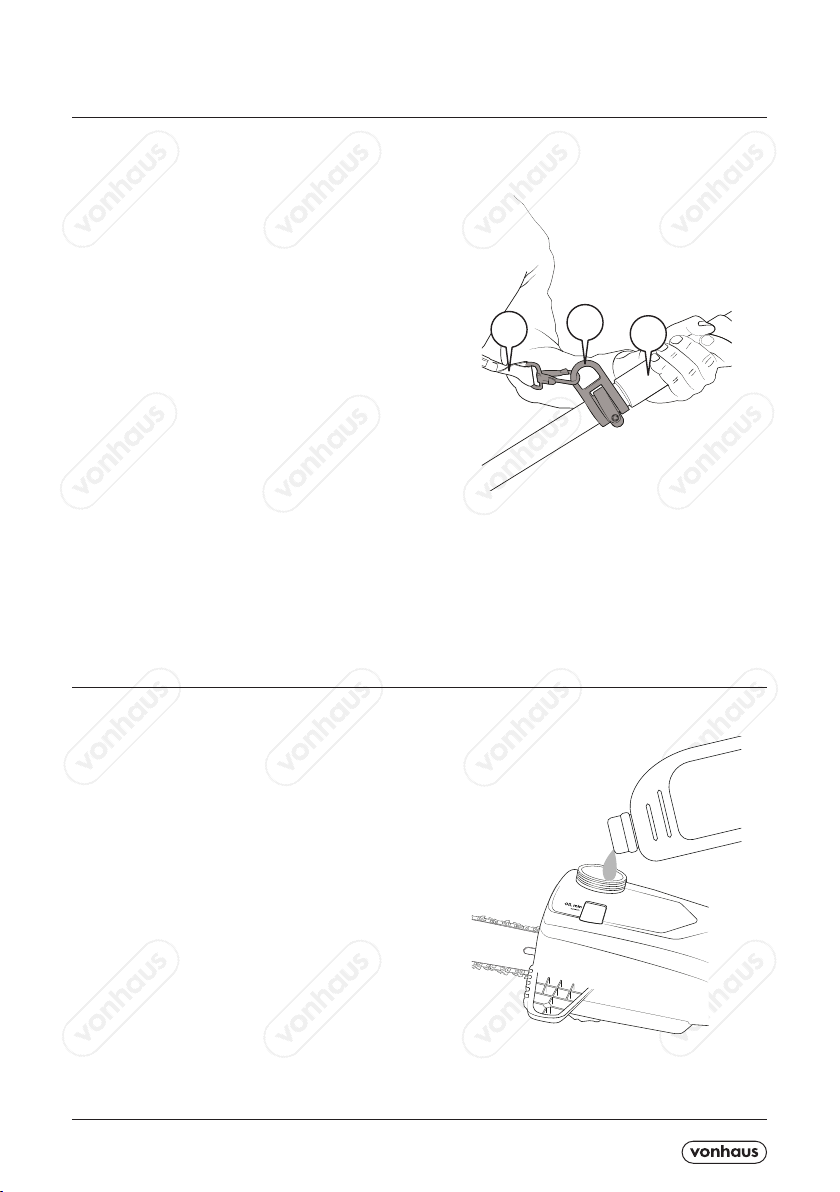

Use extreme caution when cutting brush and saplings.

Fine branches can catch in the chain, whipping them

towards you and/or pulling you o balance.

Always carry the chainsaw by its front handle, switched

o and away from your body.

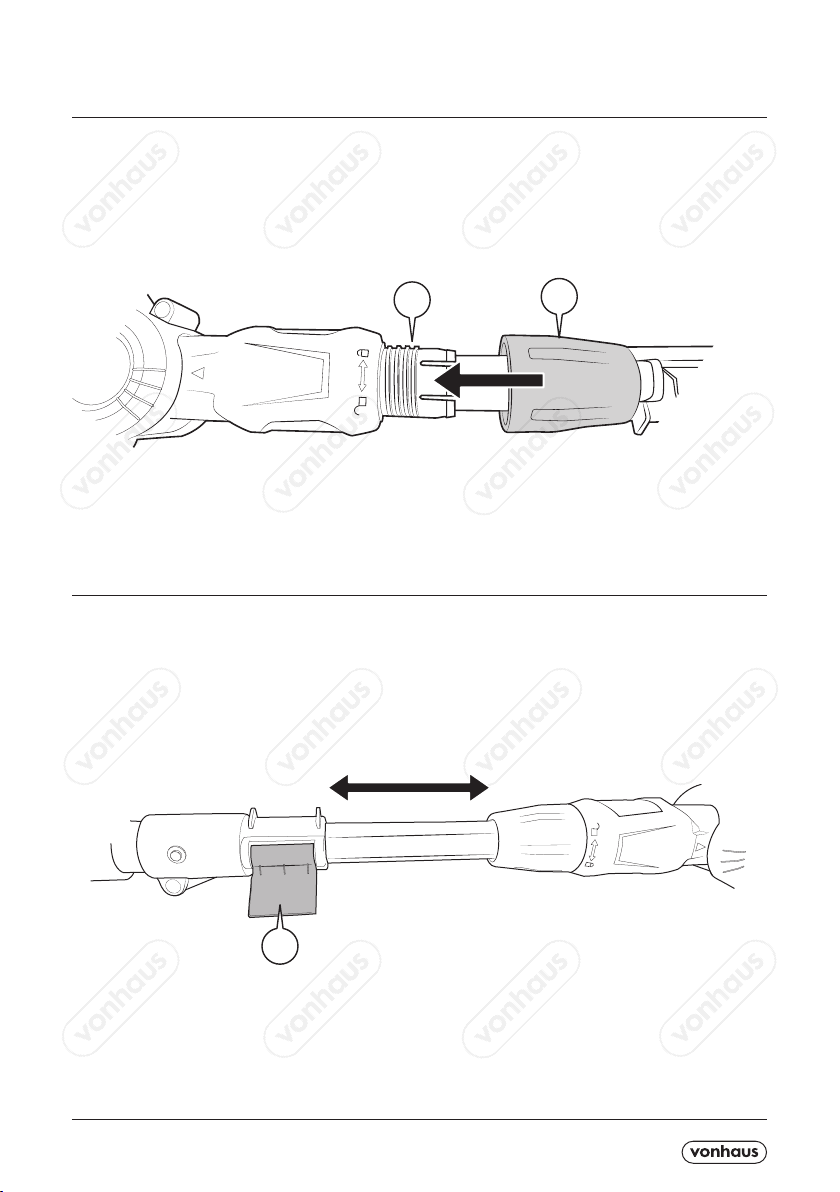

When transporting or storing always t the guide bar

cover. Always follow instructions for oiling, adjusting

chain tension and changing accessories. Incorrect

tension or a poorly lubricated chain can break the chain

or increase the chance for kickback.

Always keep handles dry, clean, and free from oil and

grease.

Only use your chainsaw for cutting wood. Do not use it

for cutting plastic, masonry or non-wood materials as

this could result in a hazardous situation.

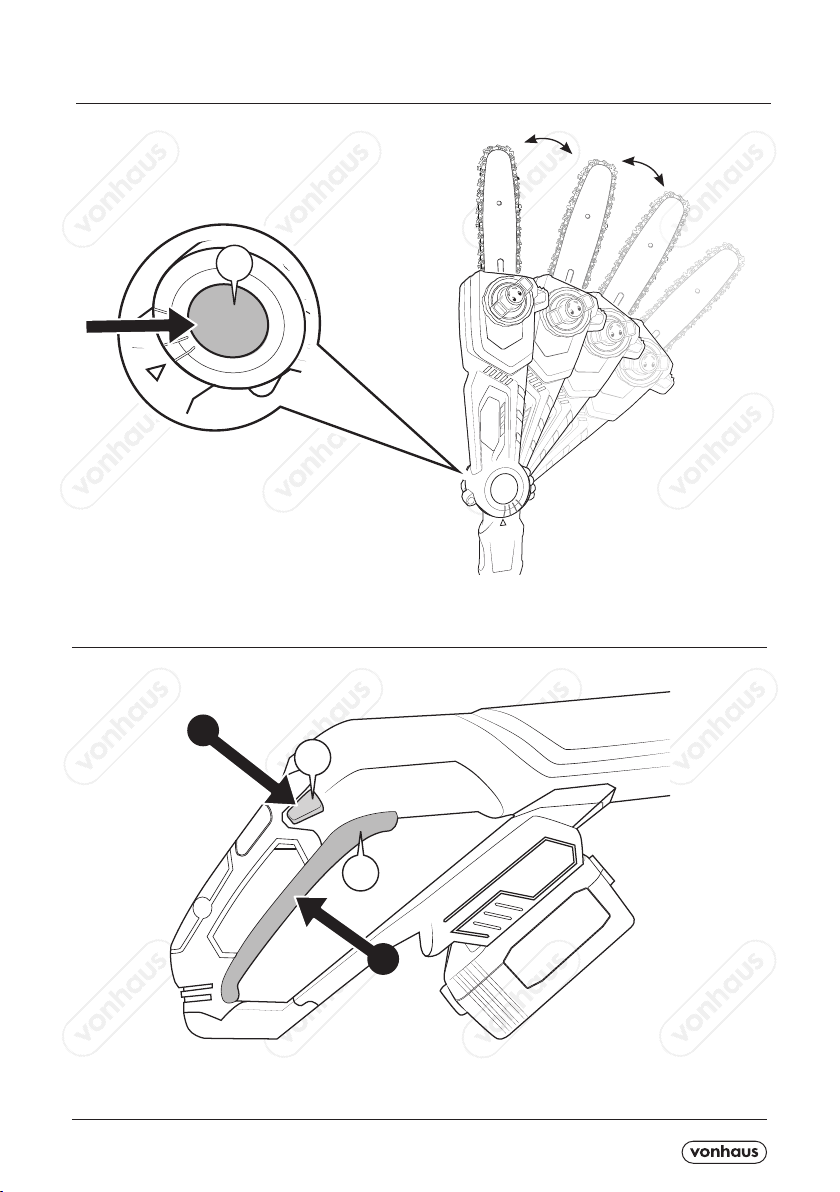

KICKBACK CAUSES & RELATED WARNINGS

Kickback is a sudden reverse reaction, which can make

your chainsaws guide bar rapidly kick back towards

you. Kickback is caused by tool misuse and/or incorrect

operating procedures/conditions.

Kickback can occur when; The ‘nose’ or the ‘tip’ of

your chainsaws guide bar touches an object or wood

contracts and ‘pinches’ the saw’s chain in a cut.

Keep a rm grip on the saw with both hands, with body

and arms braced to resist kickback.

Do not over-extend your reach or cut above shoulder

height.

Always start cuts with the chain saw already running.

Never start cutting with the tip of the guide bar.

Never cut with the tip of the guide bar.

Be careful when continuing cuts you are already working

on. Never cut through more than one branch at a time.

When lopping o branches, be careful not to touch any

other branches.

When cross-cutting, pay attention to trunks standing very

close to each other.

When possible use a saw-horse.

Only use replacement bars and chains specied by the

manufacturer.

Make sure that the chain is always properly sharpened.

Always follow the manufacturer’s sharpening and

maintenance instructions.

BATTERY WARNINGS (INCLUDING BUTTON CELLS,

AA BATTERY’S, LITHIUM PACKS)

WARNING The use, and particularly abuse of portable

sealed secondary lithium cells and batteries may result in

the creation of hazards and may cause harm.

Do not dismantle, open or shred secondary cells or

Keep batteries out of the reach of children.

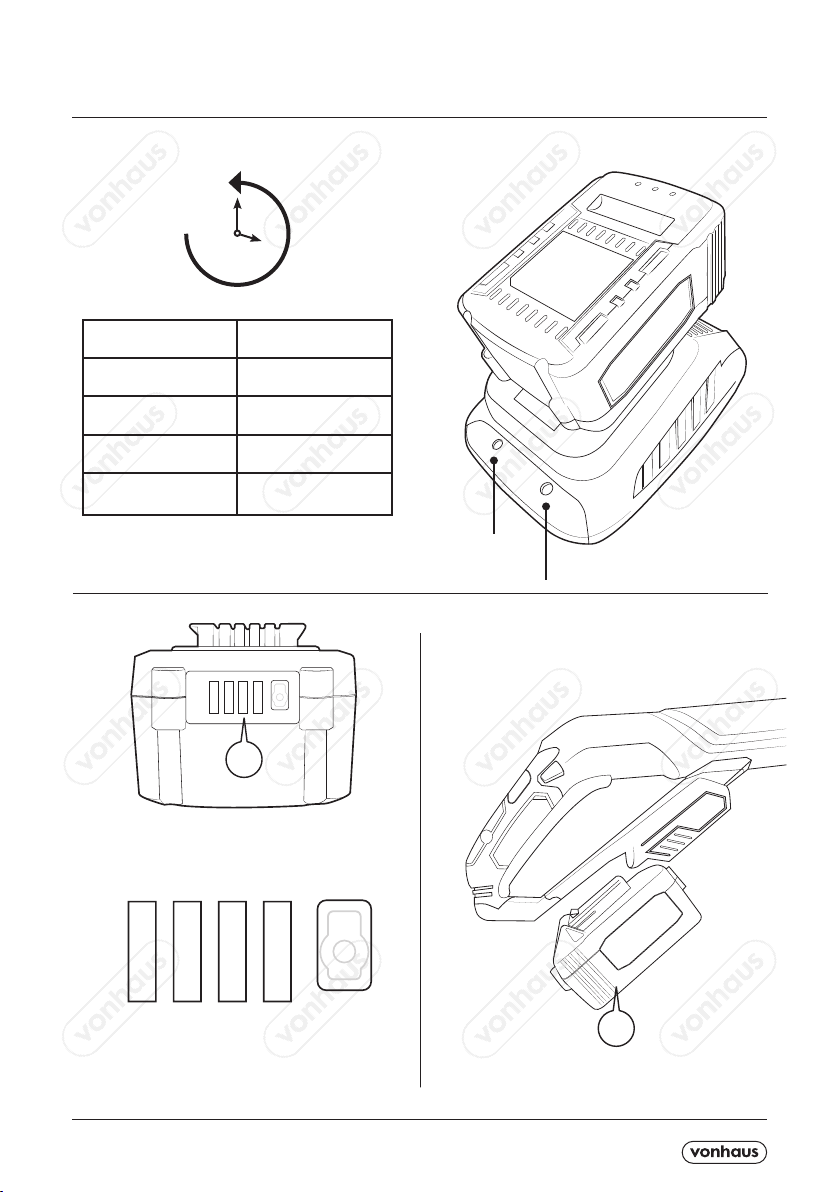

NOTE the battery pack is not fully charged out of the box.

Secondary cells and batteries need to be charged before

use, always refer to the cell or battery manufacturer’s

instructions and use the correct charging procedure.

Recharge only with the charger specied by the

manufacturer. A charger that is suitable for one type of

battery pack may create a risk of re when used with

another battery pack.

Use the appliance/power tool/machines only with

specically designated battery packs. Use of any other

battery packs may create a risk of injury and re.

First read the safety instructions and then follow the

charging notes and procedures.

Incorrect reassembly may result in a risk of electric shock

or re.

Protect the battery and charger against water and

moisture. Always keep cells and batteries clean and dry.

Wipe the cell or battery terminals with a clean dry cloth if

they become dirty.

Protect the battery from heat and re. Place the charger

in a position away from any heat source and avoid

storage in direct sunlight.

Do not maintain secondary cells and batteries on charge

when not in use.

After extended periods of storage, it may be necessary to

charge and discharge the cells or batteries several times

to obtain maximum performance.

Do not short-circuit a cell or battery.

Do not store cells or batteries haphazardly in a box

or drawer where they may short-circuit each other or

be short-circuited by conductive materials. When the

battery pack is not in use, keep it away from other metal

objects such as paper clips, coins, keys, nails, screws

or other small metal objects that can make a connection

from one terminal to another. Short-circuiting the battery

terminals together may result in burns or a re.

Do not expose cells or batteries to mechanical shock.

Never attempt to open the battery pack for any reason or

if the plastic housing of the battery pack breaks or cracks,

immediately discontinue use and do not recharge.

When possible, remove the battery from the appliance/

power tool/machine when not in use.

Do not leave a battery on prolonged charge when not in

use or stored for extended periods of time as this may

cause damage to the battery.

To facilitate cooling of the battery pack after use, avoid

placing the charger or battery pack in a warm environment

such as a metal shed or an uninsulated trailer.

To reduce the risk of electric shock, unplug the charger

from the outlet before attempting any cleaning. Removing

the battery pack will not reduce this risk.

In the event of a cell leaking, do not allow the liquid

to come into contact with the skin or eyes. If contact

has been made, wash the aected area with copious

amounts of water and seek medical advice.

Seek medical advice immediately if a cell or battery has

been swallowed.

Always observe the polarity marks (+) and (-) on the cell,

battery and equipment and ensure correct use.

Retain the original cell and battery literature for future

reference

When disposing of secondary cells or batteries, keep

cells or batteries of dierent electrochemical systems

separate from each other.

Do not use any cell or battery which is not designed for

use with the equipment.

Do not mix any cells of dierent manufacturers, capacity,

size or type within a device.

Always purchase the battery recommended by the

device manufacturer for the equipment.

ADDITIONAL SAFETY INFORMATION FOR BATTERY

CHARGERS.

This appliance should not be used by children and/

or persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge.

Children shall not play with the appliance.

Do not place any object on top of the charger or place

the charger on a soft surface that may result in excessive

internal heat.

Do not attempt to disassemble the charger. Take it to

an electrician or tool repairer when service or repair is

required.

Appliances/power tools/machines with Lithium-ion

batteries shall only be charged with the specically

designed Lithium-ion battery charger purchased with

this tool. Do not attempt to charge the battery with any

charger other than the one supplied as this is potentially

dangerous.

Before using the charger, read all instructions, labels and

cautionary markings on the charger.

The charger is not intended to be used for any purpose

other than charging the battery pack for this tool. Any

other use may result in risk of re or electric shock. Do

not attempt to use the charger on any other voltage or

rating than those stated on the rating plate.

Do not use the charger for any purpose other than that for

which it is intended.

Do not use the charger to charge any device other than

the appliance/power tool/machine it was sold with.

Do not use an extension cord unless absolutely

necessary. The use of an improper extension cord could