Installation and Operating Manual

Fully automatic charging converter (booster), B2B Battery to Battery charger for optimum

charging of the battery in the living area during driving. Designed for operation at a 13-pole

trailer connector for caravan and living compartments.

VCC 1212-20 C Input 12 V / max. 20 A Output 12 V / max. 24 A No. 3321

Please read these mounting instructions and the operating manual completely and

attentively.

Particularly observe page 11 "Safety Regulations and Appropriate Application",

prior to starting connection and start-up.

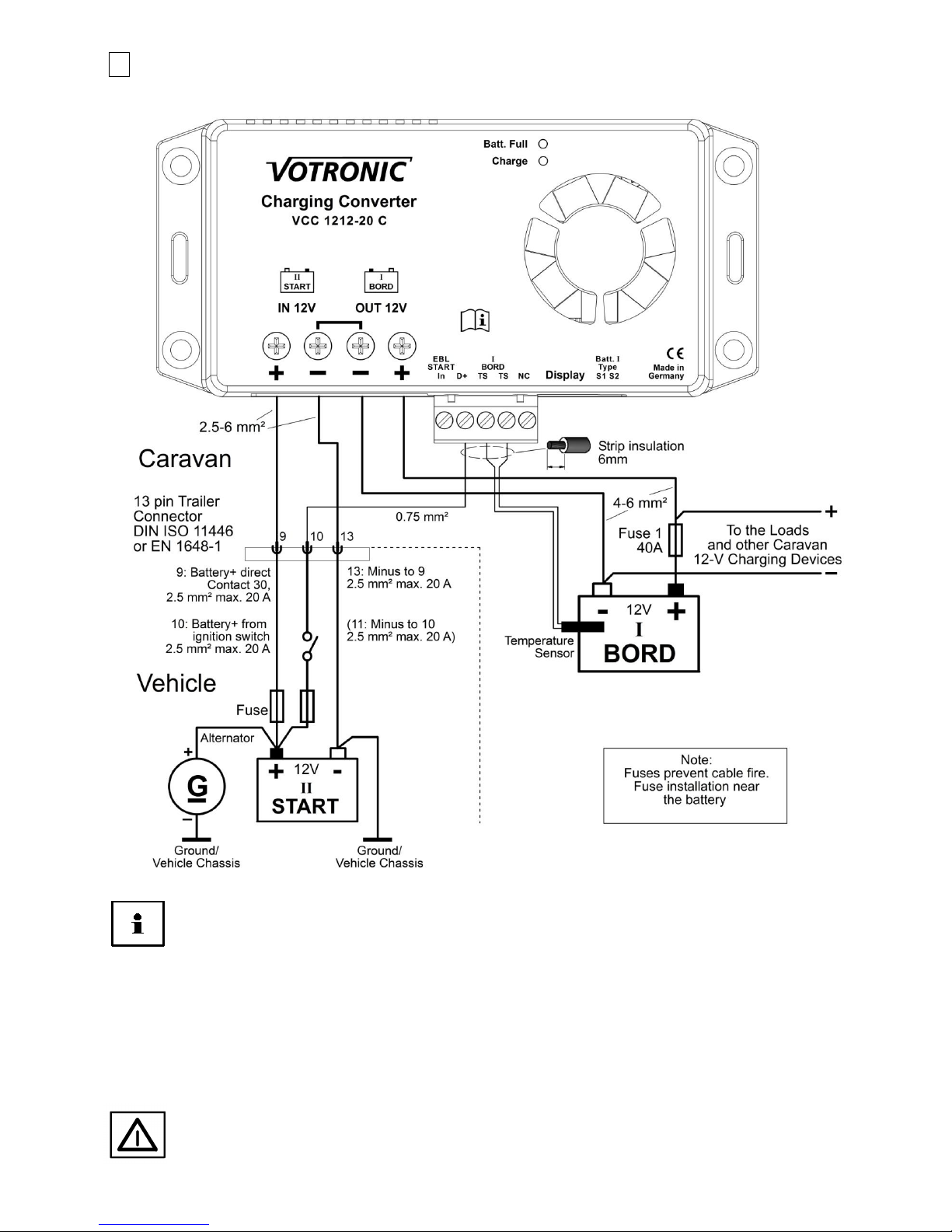

The unit is primarily designed for operation at the 13-pole trailer connector of the towing vehicle for charging of the

caravan battery. Its automatic control ensures, that the rating of the connector and the vehicle's electric system in front of

it (12 V / max. 20 Amperes) will not be exceeded. The efficiency of the unit results from this aspect.

The unit is installed in the caravan, in the living compartment. It supplies the optimum charging voltage for the battery -

independently of the vehicle's board voltage fluctuations or voltage losses of cables/connectors.

This is realized by 4adjustable charging programs IU1oU2 for conventional lead-acid, gel, AGM batteries or advanced

Lithium LiFePO4 supply batteries. They allow unattended, quick and gentle full charging from any charging state with

subsequent trickle charging.

Depending on the driving condition, the voltage of modern EURO standard 6, 6 + plus- vehicles with energy-saving,

intelligent generators fluctuates considerably (12.6 V … 15.5 V). These fluctuations are now completely equalized by the

charging converter to ensure uniform charging of the BOARD battery and protection of the 12 V consumers, which are

connected to that battery.

Due to the higher charging current rates, which are now possible, shorter charging times and fully charged batteries are

achieved, even with conventional generators and long connection cables.

The efficient charging converter ensures high charging capacity, already within short distances.

Full charging when driving longer distances.

It increases or reduces the voltage to the level, which is required for precise charging of the BOARD battery for the

living room with the optimum charging characteristic line.

The charging converter excels by its compact design, low weight (high-frequency switch mode boost and buck

converter technology) and powerfully dimensioned power components for safe operation.

The simultaneously supplied 12 V consumer loads are protected against overvoltage and voltage fluctuations.

The integrated recharging branch 12 V/0 ... 1 A provides charging/trickle charging of the vehicle's 12 V battery in case

of extended standstill periods. It will be activated automatically with external charging of the BOARD battery by means

of a mains supply charger.

Further Characteristics of the Unit:

The charging voltage is free from peaks and is controlled in such a way, that overcharging of the batteries is excluded.

Fully Automatic Operation: The unit is permanently connected to the batteries, and it is automatically activated by the

running generator of the vehicle. Battery discharge in case of an engine stop is avoided.

Charging aid for deeply discharged lead batteries or switched-off LiFePO4 batteries: Gentle preliminary charging of the

(lead-acid, gel, AGM) battery or automatic reactivation of the Li battery, if consumers are possibly still switched-on.

Parallel and Floating Operation: In case of simultaneous consumption, the battery will either continue to be charged or

maintained via trickle charging. Calculation and control of the adaptation of the charging times is effected automatically

by the unit.

Unattended Charging: Multiple protection against overload, overheating, overvoltage, short circuit, incorrect behaviour

and back discharge of the battery by electronically controlled gradual reduction down to separation of unit and battery.

Integrated On-board Mains Suppression Filter: Unproblematic parallel operation of further charging sources (mains

supply chargers, solar systems).

Charging Cable Compensation: Automatic compensation of voltage losses on the charging cables.

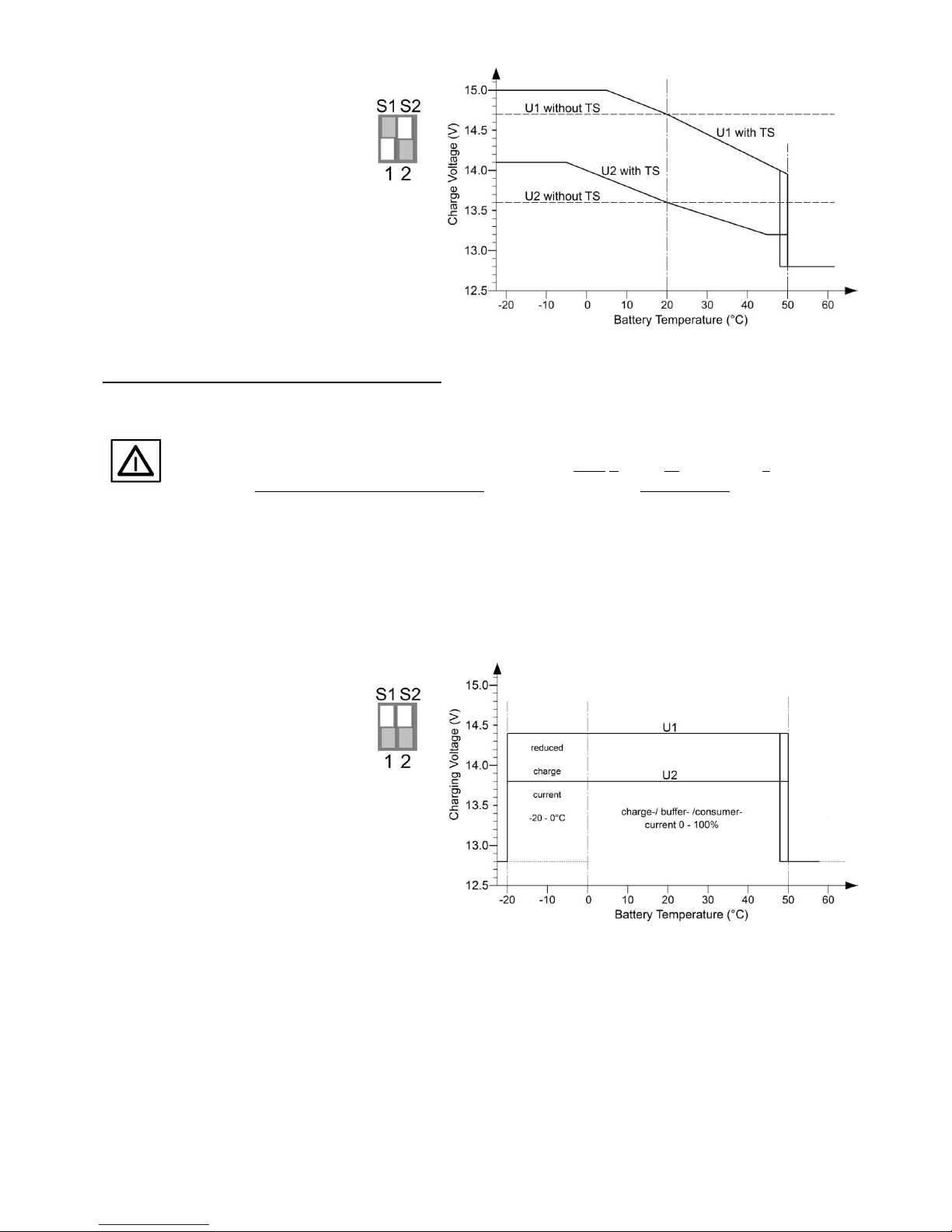

Connection for Battery Temperature Sensor (Sensor 825 included in the standard delivery scope):

Lead batteries (acid, gel, AGM): In case of low outside temperatures, full charging of the weak battery is improved by

automatic adaptation of the charging voltage to the battery temperature, and in case of summery temperatures

unnecessary battery gassing and battery load will be avoided.

LiFePO4 Batteries: Battery protection in case of high temperatures and particularly in case of low temperatures

below 0 °C.