Installation and Operating Manual

Charging Converter, B2B Battery to Battery, battery charging while driving:

VCC 1212-25 Li Input Voltage 12 V Charging Capacity 12 V / 25 A No. 3300

VCC 1212-45 Li Input Voltage 12 V Charging Capacity 12 V / 45 A No. 3307

VCC 2412-25 Li Input Voltage 24 V Charging Capacity 12 V / 25 A No. 3302

VCC 2412-45 Li Input Voltage 24 V Charging Capacity 12 V / 45 A No. 3309

Note: The unit does not operate, unless the temperature sensor had been

connected (safety disconnection)!

Please read this operating and installation manual thoroughly prior to connection and start-up.

Fully automatic Battery Charging Converter for LiFePO4 batteries in special purpose vehicles, in high-quality

campers, in the marine field.

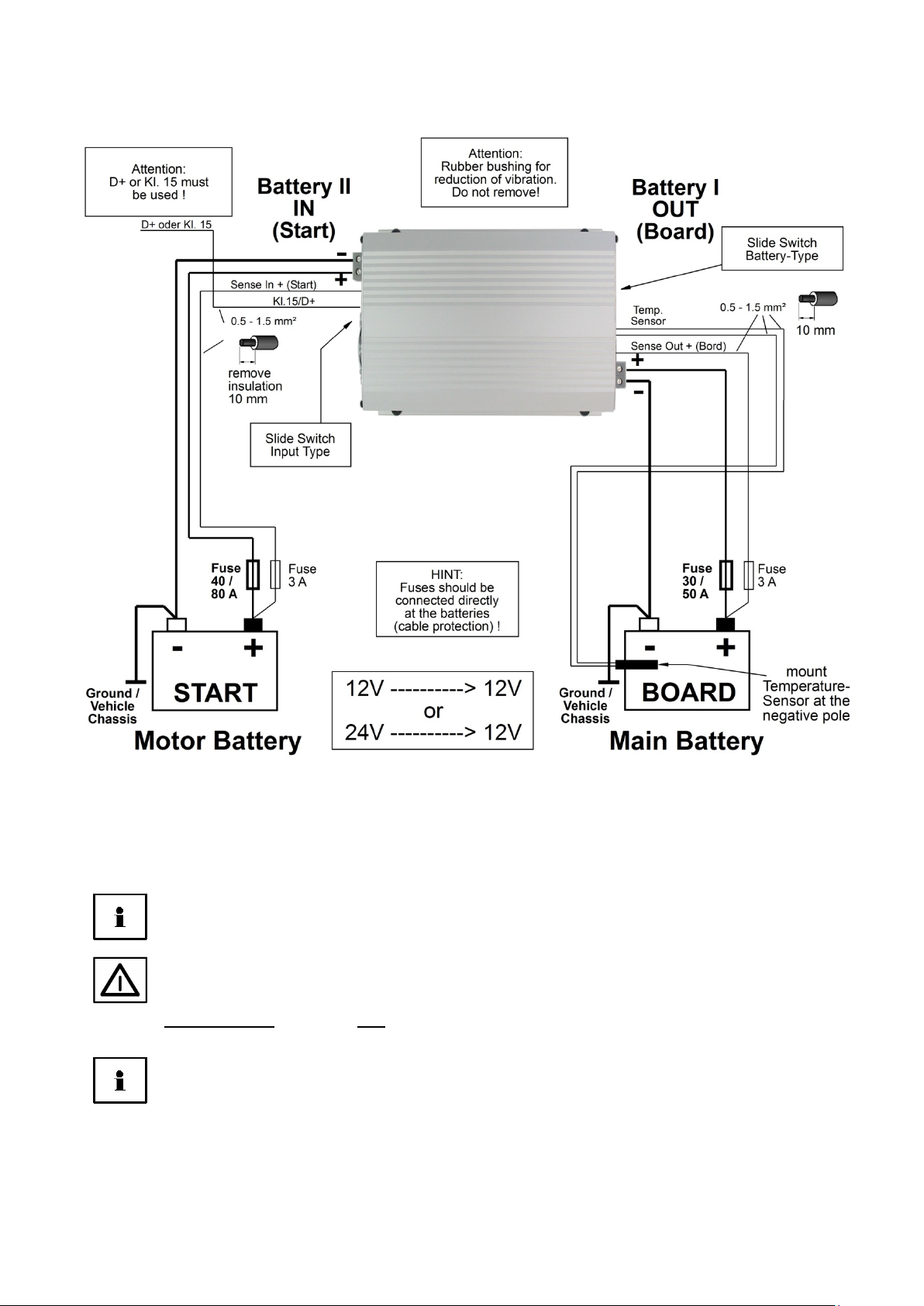

The charging converters (Booster, B2B Battery to Battery) had been developed according to the latest regulations for

supply battery charging (board battery) with LiFePO4 technology during driving.

In contrast to conventional cutoff relays, the charging voltage will be raised or lowered in case of losses on the supply

lines, battery voltage fluctuations etc., thus adapting it automatically to the default charging values. Charging converters

with 24 V input voltage allow charging of the 12 V supply battery without installation of a second generator.

Thus, the charging converter ensures the known high-quality battery charging of the VOTRONIC chargers also during

driving. Due to the intelligent microprocessor charging control with charging characteristic lines "IIU1oU2oU3" and

dynamic calculation of the charging time, automatic, quick and gentle full charging is ensured, as well as subsequent

100 % trickle charge of the connected batteries from any charging state. At the same time, simultaneous supply of 12 V

consumers, which are connected in parallel, is ensured. Overcharging of the batteries is avoided, even in case of

extremely long driving times.

The charging converters excel by their compact design, low weight (high-frequency switch mode technology), powerfully

dimensioned power components and consequently full charging capacity, even with long charging cables or strong

voltage fluctuations at the starter battery (EURO Standard 6, 6 + plus vehicles), information see page 10, table 2, switch

position "D".

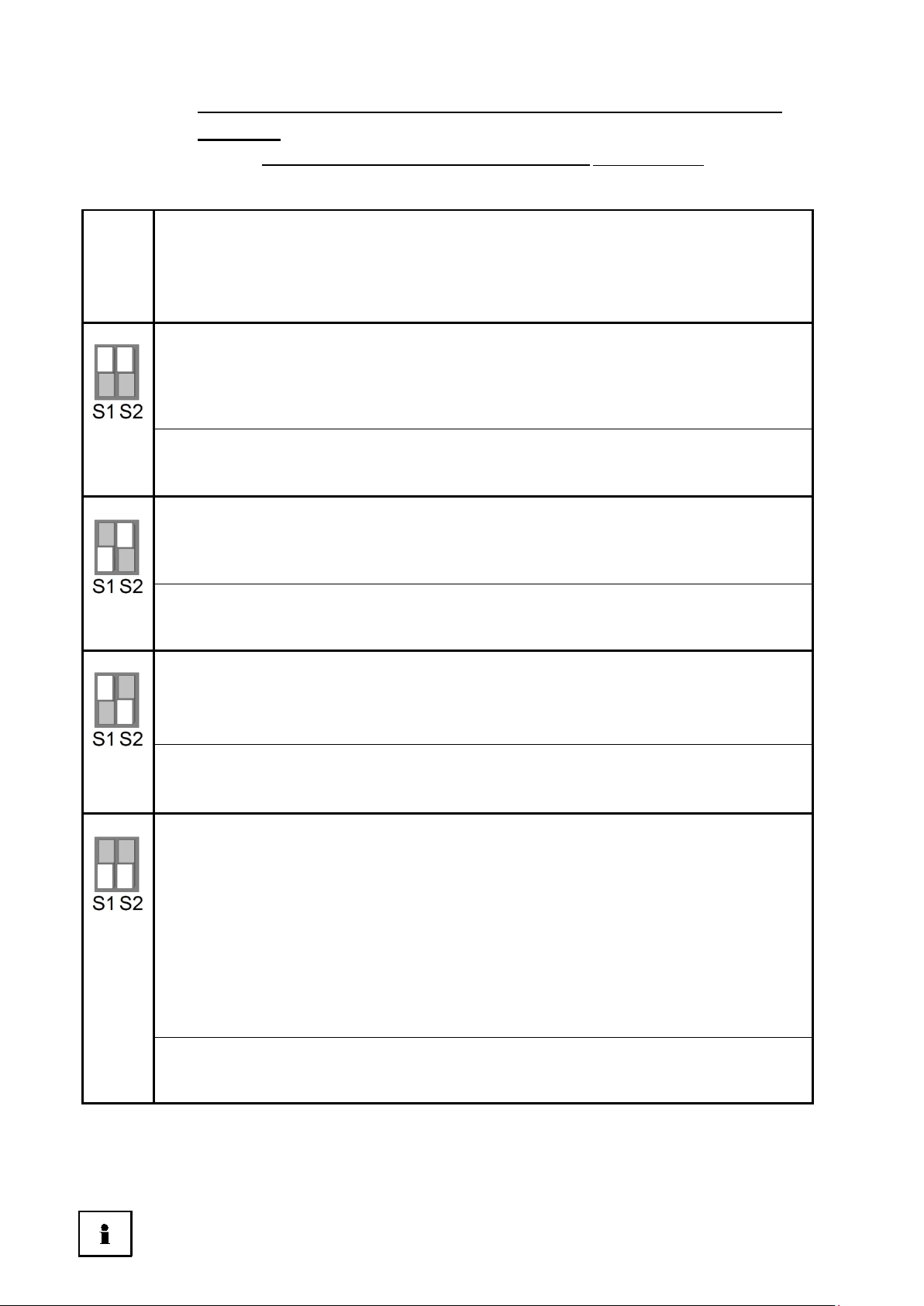

Battery Port and Charging Programs:

Charging Port "OUT": Board battery, supply battery, depending on battery type and battery manufacturer 4 charging

programs selectable,adapted to Lithium LiFePO4 batteries, see table 1, page 8.

Further Characteristics of the Unit:

•The charging voltage is free from peaks and is controlled in such a way, that overcharging of the batteries is

excluded.

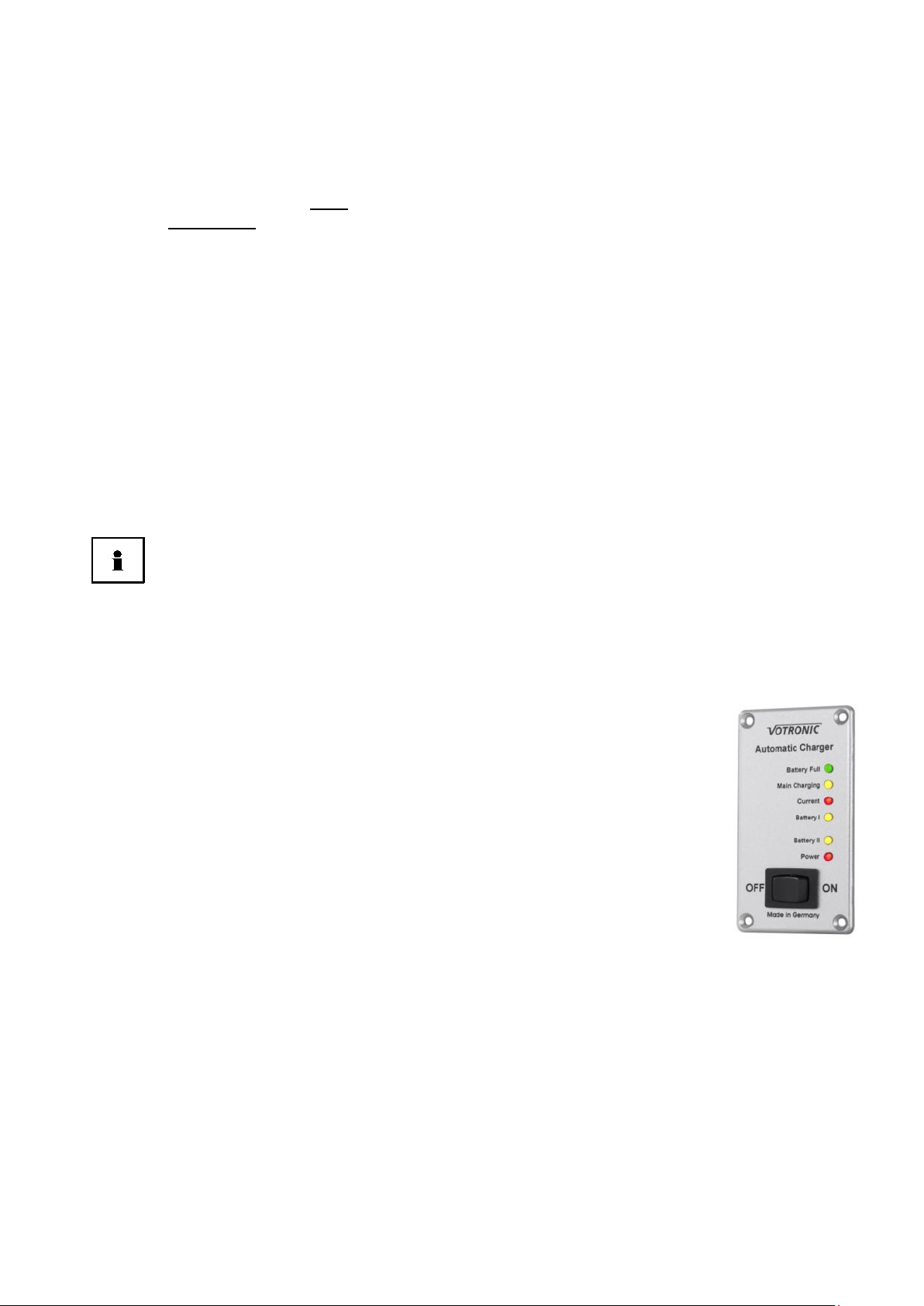

•Fully automatic operation by means of control input (ignition, running motor, D+), as well as voltage control.

•Automatic, adjustable power control giving priority to charging of the starter battery by the generator in case of

overloaded vehicle mains to ensure that the vehicle can be started at any time.

•No discharge (current 0,000 A) of the batteries during stand-by or with switched-off charging converter.

•Parallel and Floating Operation: In case of simultaneous consumption, the battery will either continue to be charged

or maintained via trickle charging. Calculation and control of the adaptation of the charging time is effected

automatically by the charging converter.

•Unattended Charging: Multiple protection against overload, overheating, overvoltage, short circuit, reverse battery

at the output, incorrect behaviour and back discharge of the battery by electronically controlled gradual reduction

down to complete separation of charging converter and battery by integrated safety relays.

•Galvanic isolation between input and output: Complete separation of the battery circuits, even in case of failure,

important for 12 V/24 V mixed systems, avoids undesirable back discharge and suppresses interferences in the board

mains.

•Charging Cable Compensation: Automatic compensation of voltage losses on the charging cables.

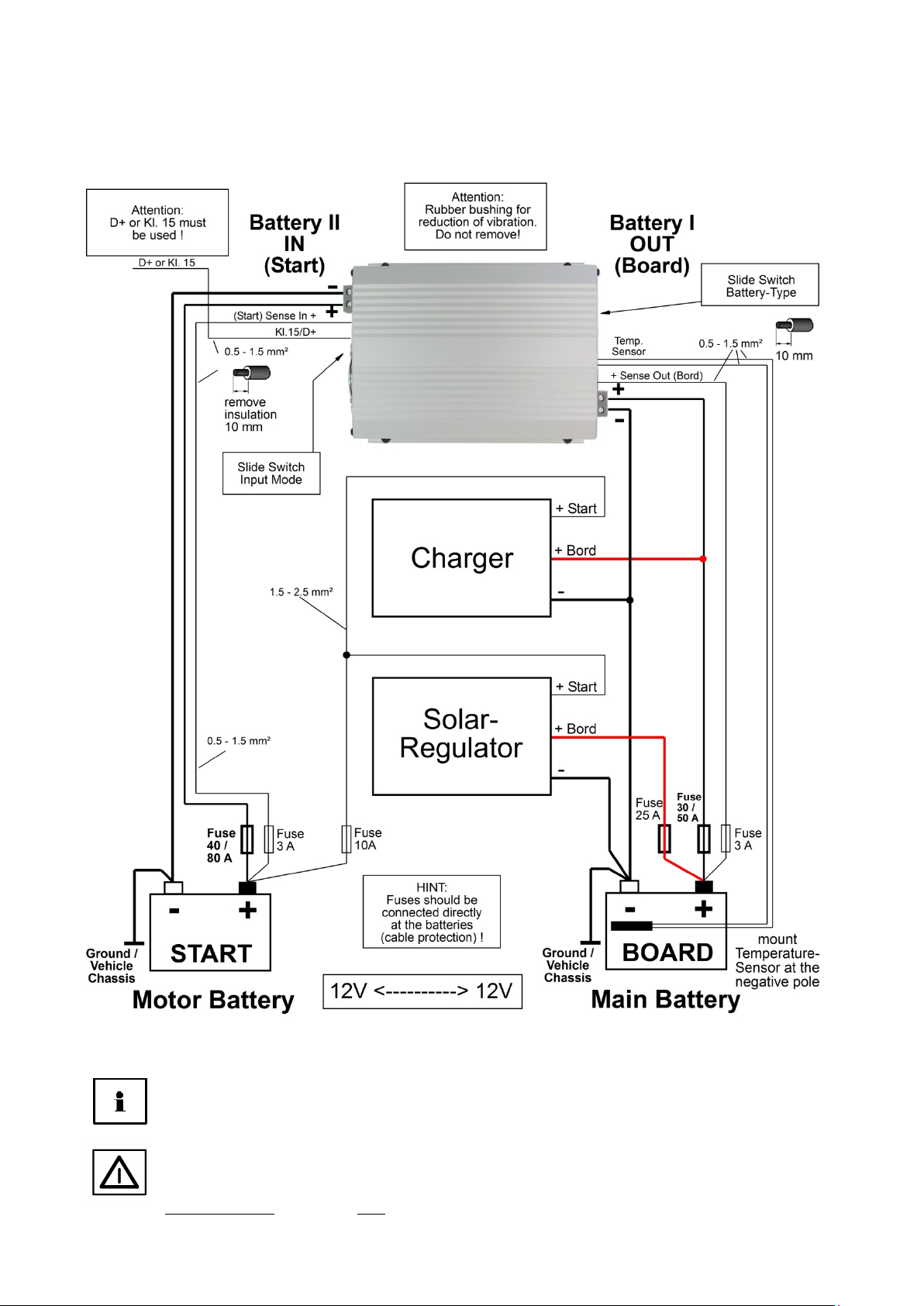

•Integrated On-board Mains Suppression Filter: Unproblematic parallel operation of solar systems, wind and petrol-

driven generators, mains supply chargers etc. at a single battery.

•Temperature control and adaptation of the charging by battery temperature sensor, which allows also charging

beyond the recommended LiFePO4 battery temperatures below 5 °C and above 35 °C.

Battery Lifetime and Efficiency:

•Keep the batteries cool, LiFePO4 preferably above 0 °C. Choose an appropriate location for

installation.

•Store only fully charged batteries and recharge them periodically.