USER MANUAL VPC USER MANUAL VPC

04/09/21 04/09/21

For more information visit vpc.com For more information visit vpc.com

RETURN TO INDEXRETURN TO INDEX

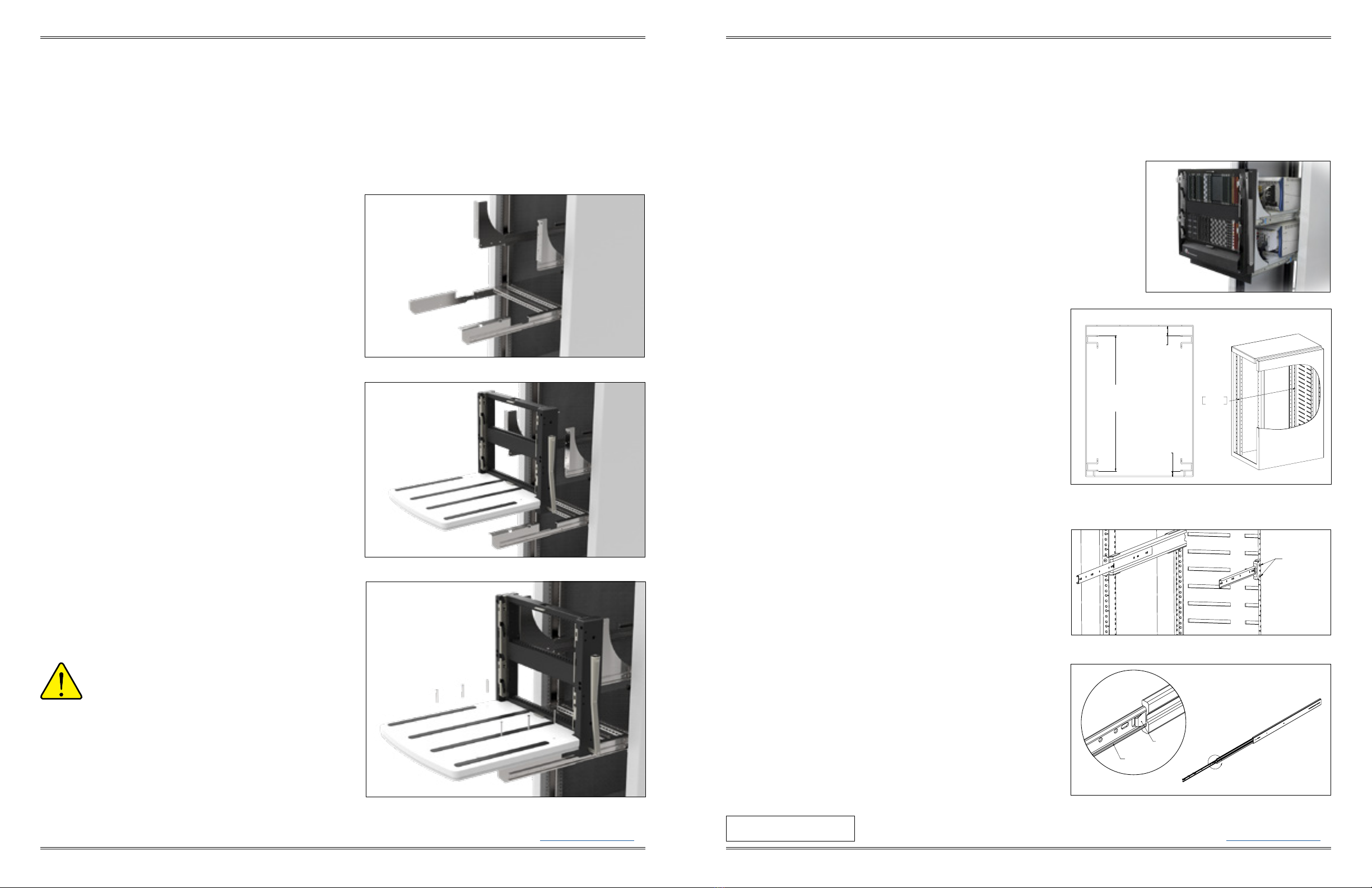

Slides are used with the 9050 and 9050TR receiver. The receiver

includes a mounting bracket kit and hardware. Choose your slide kit

based on the distance from rail to rail and verify that the slides will

not interfere with the rack enclosure. Each kit will support 180 lbs.

TOOLS REQUIRED

Phillips Head Screwdriver

/32 Allen Wrench

DETERMINE YOUR SLIDE KIT

1. Measure dimension A to determine the proper slide kit, ensuring the slide

length does not exceed dimensions A + B (Figure A).

LOCATE AND MOUNT SLIDES

1. Determine an appropriate location in the rack to mount the slides and

receiver. Keep in mind that the cables connecting to instrumentation not

placed on the instrument bracket will need to be long enough for the slides to

fully extend without putting tension on the cables.

NOTE: The “Cable Management” section of the Master catalog

can be used as a guide.

2. Install slides using manufacturer’s instructions. A hard copy is included with

the shipment (www.accuride.com/Resources/pdf/3507-r4-0309.pdf). Make

sure the same position mounting holes are used for each side of the front and

back brackets. Do not fully tighten down the 4 front and 4 rear mounting

screws at this time (Figure B).

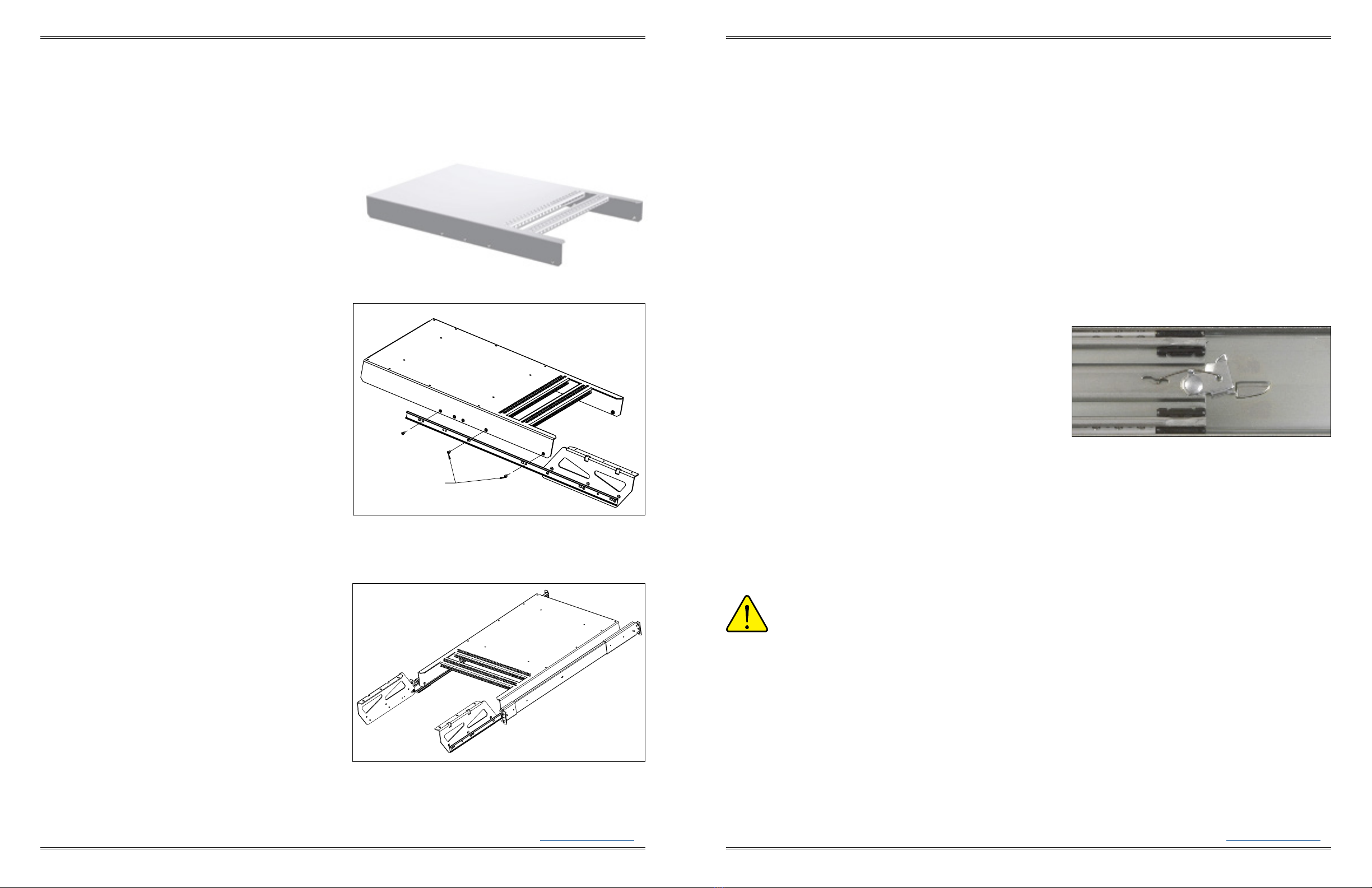

4. Remove the innermost section of each slide by extending the slide fully,

depressing the tab, and continue extending the inner section of the slide until

it is free from the slide assembly (Figure C).

5. Install the instrument bracket and/or cable tray onto the inner sections of

the slide kit following the Instrument Bracket Installation instructions and/or

Cable Tray Installation instructions found in Section 4.

29.50

749.30

TOP VIEW

[50.8]

2.00

DIMENSION B

DIMENSION A

DIMENSION C

[749.3]

29.50

[31.75]

1.25

Figure A. If dimension C exceeds 1" use the Rack Extend-

er Kit, Part # 310 113 406.

SLIDE CONFIGURATION INSTALLATION 9050

RECEIVER, , MODULE, WITH SLIDE MOUNTING • PART #

"SLIDE KIT (FITS "– "DEEP RACKS [. – ]) • PART #

"SLIDE KIT (FITS "– "DEEP RACKS [. – .]) • PART #

"SLIDE KIT (FITS "– "DEEP RACKS [. – .]) • PART #

Dimensions shown: [millimeters]

inches

ALWAYS SUPPORT THE RECEIVER AND

PLATFORM WITH THE MOST ROBUST

MIDDLE SECTION OF THE SLIDES.

To ensure proper support when extending the receiver and table away from

the rack, stop the receiver and platform at approximately 6" from the rack.

Reach around to the rear of the receiver to the slides underneath on both

sides. Manually extend the middle section of the slides forward until fully

underneath the platform. The receiver and platform may then be extended

while holding this middle slide in place. If completed properly, the middle

section of the slides will remain underneath the platform and oer the

strongest support.

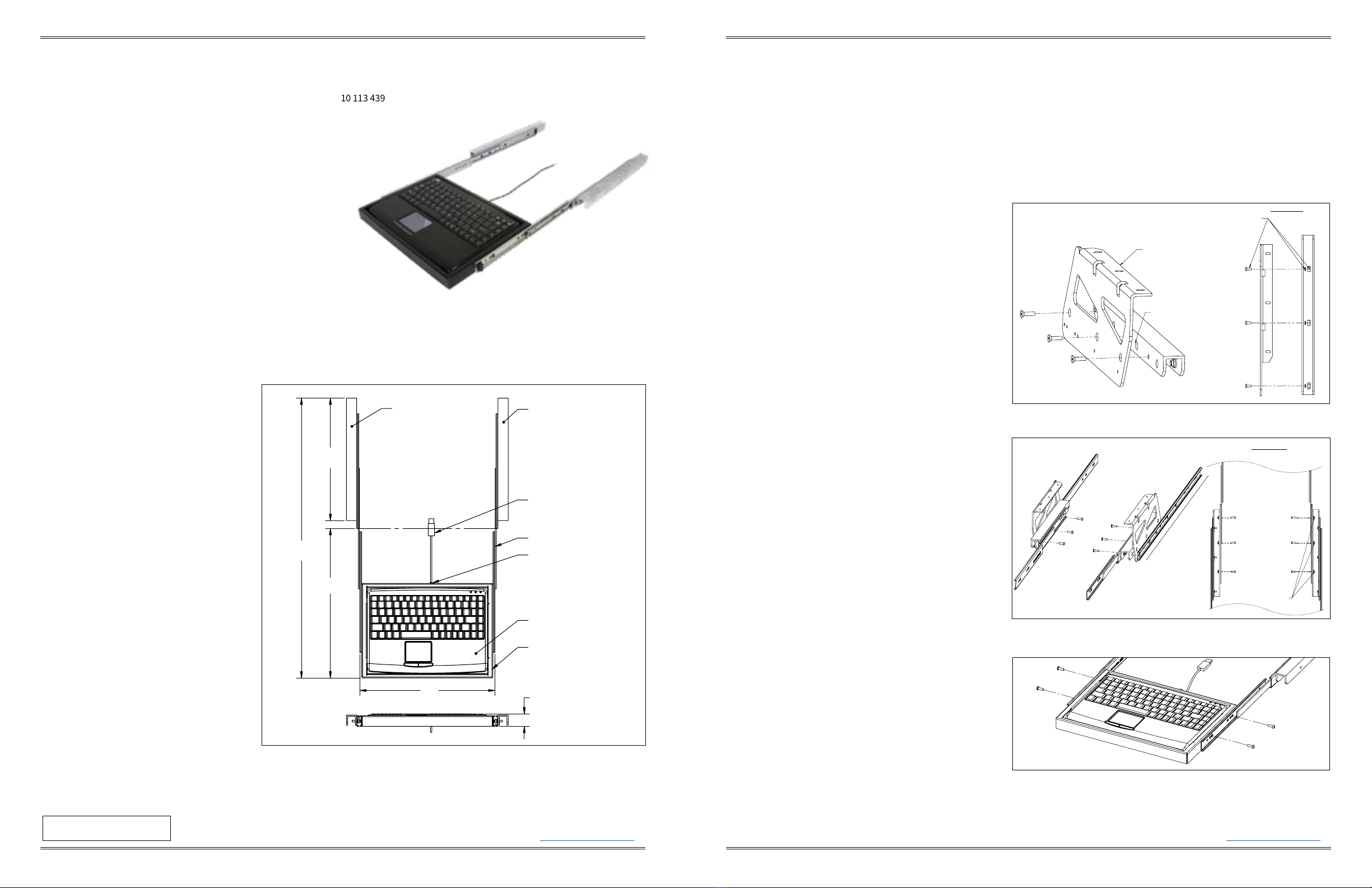

INSTALLATION 9050TR

1. Install inner slides back into slide kit in the rack.

2. Attach the platform mounting flanges to the inner slide rails using the

six 8-32 button head screws provided with the receiver (Figure D).

Do not fully tighten down the screws.

3. Install the 9050TR platform/receiver onto the platform mounting

flanges with the six 8-32 screws (Figure E). Do not fully tighten

down the screws.

4. Pull the receiver out as far as possible. The slides will lock in position.

Push the blue tabs located on the middle section of the slides. Apply

pressure to push the receiver back in toward the rack. The smaller

inner slides move into the middle section, which should not move.

Push receiver until it backs into the rack.

5. Secure the receiver to the rack using the captive 10-32 screws

(Figure F). Be sure to li up on the platform slightly to ensure an

even engagement of the screws.

6. Fully tighten screws in this order:

- 6 8-32 platform mounting screws (as shown in Figure D).

- 6 8-32 button head platform mounting flange screws (as shown in

Figure C).

- 4 front slide mounting screws (Page 2-1, Figure B).

- 4 rear slide mounting screws (Page 2-1, Figure B).

7. Unscrew the 10-32 captive screws and slide the receiver out. Figure E. Install 9050TR into platform mounting flanges.

Figure D. Attach platform mounting flanges to the inner slide

rails.

Figure F. Secure the receiver to the rack with the captive

10-32 screws, taking care to lift up on the platform slightly to

ensure even engagement.

SLIDE CONFIGURATION INSTALLATION 9050TR

RECEIVER, TR, MODULE, WITH "PLATFORM • PART #

"SLIDE KIT (FITS "– "DEEP RACKS [. – ]) • PART #

"SLIDE KIT (FITS "– "DEEP RACKS [. – .]) • PART #

"SLIDE KIT (FITS "– "DEEP RACKS [. – .]) • PART #

A

SLIDE

RELEASE TAB

INNER SLIDE

Figure C. Remove inner section of slide from assembly.

Figure B. Slides installed into rack.

10-32 X 1" MOUNTING

SCREW

2 TYP. EACH SIDE

3 4