VTAC HSD USER MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

1/9/19

2-2 For the most current information available, visit vpc.com

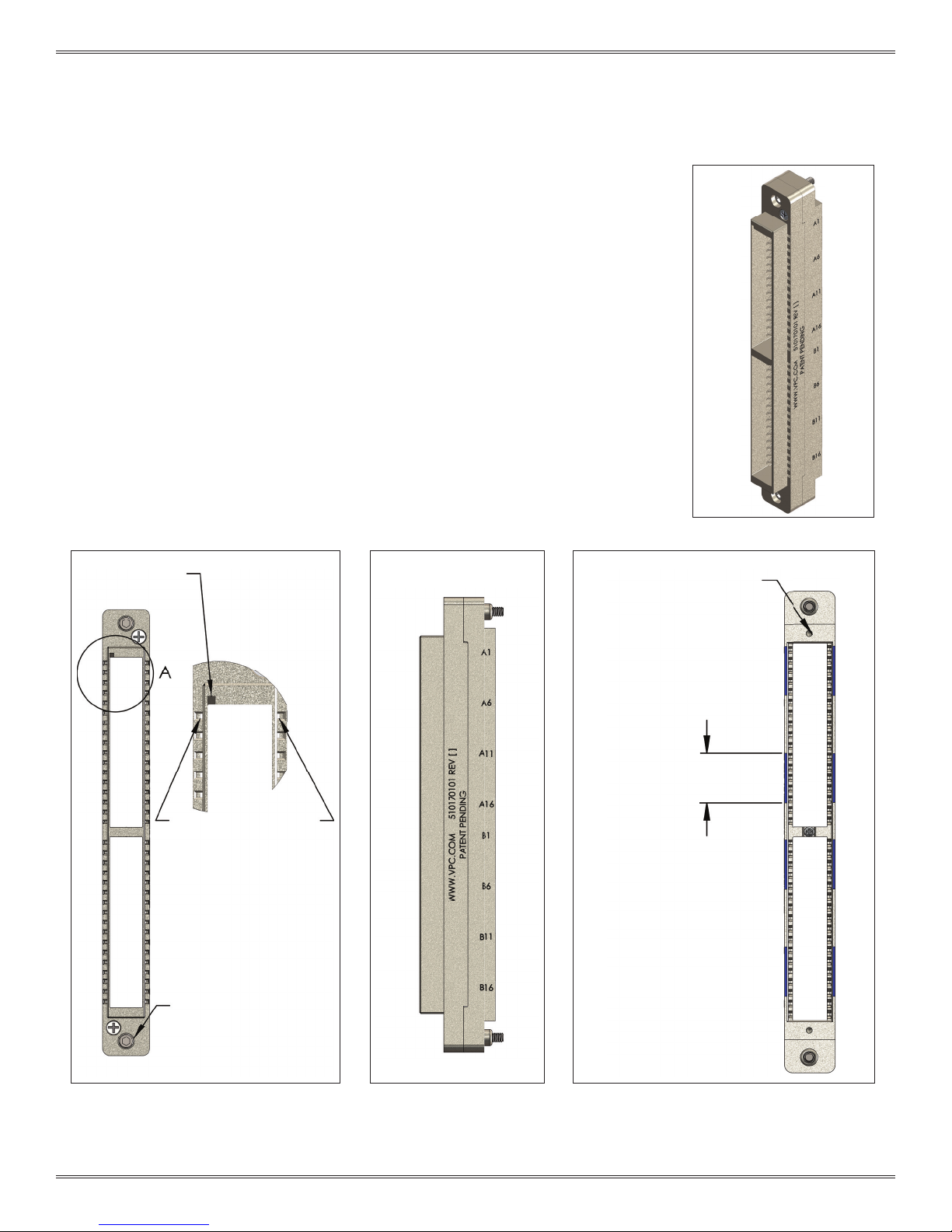

VTAC HSD INSERT INSTALLATION/REMOVAL INSTRUCTIONS FOR RECEIVER MODULE

PART # 510 170 101

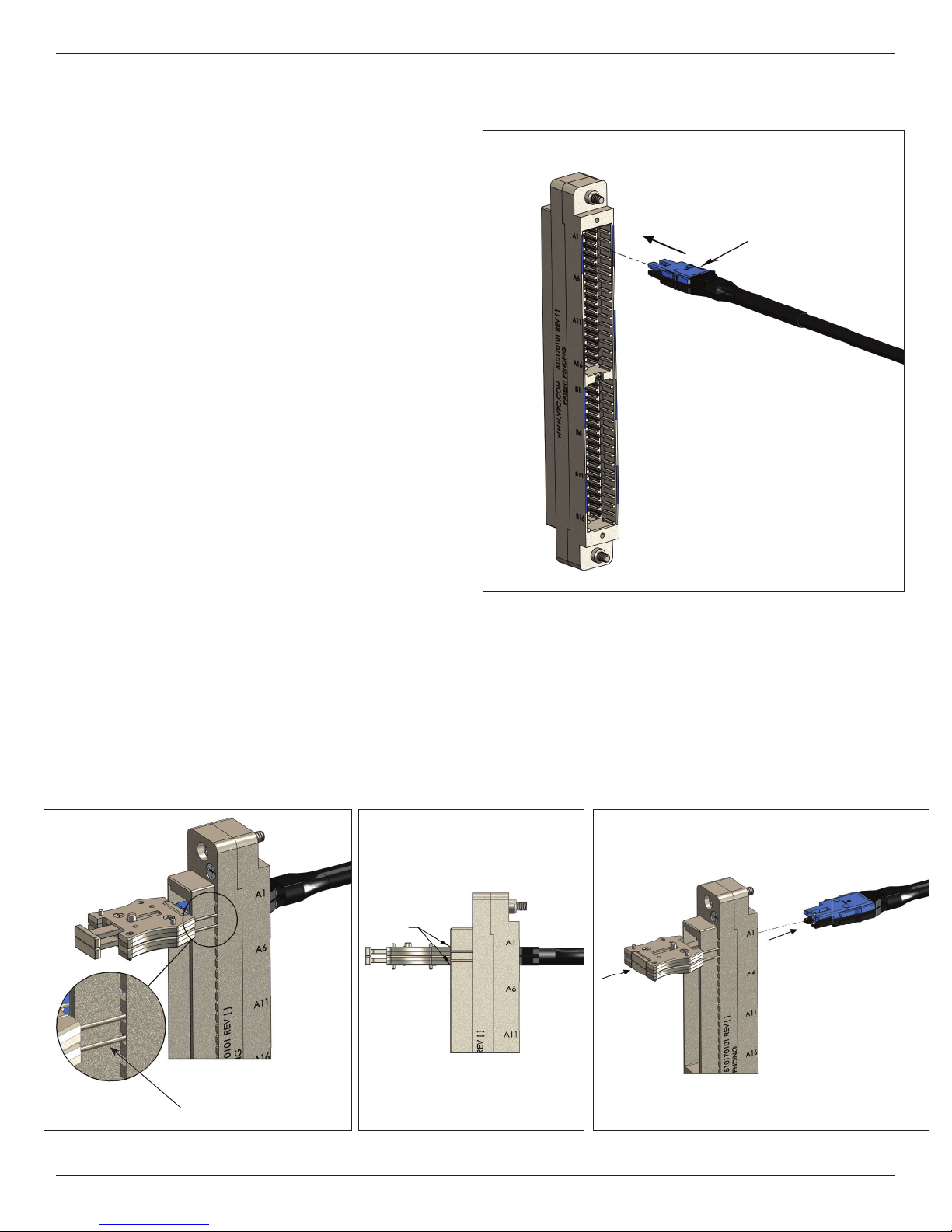

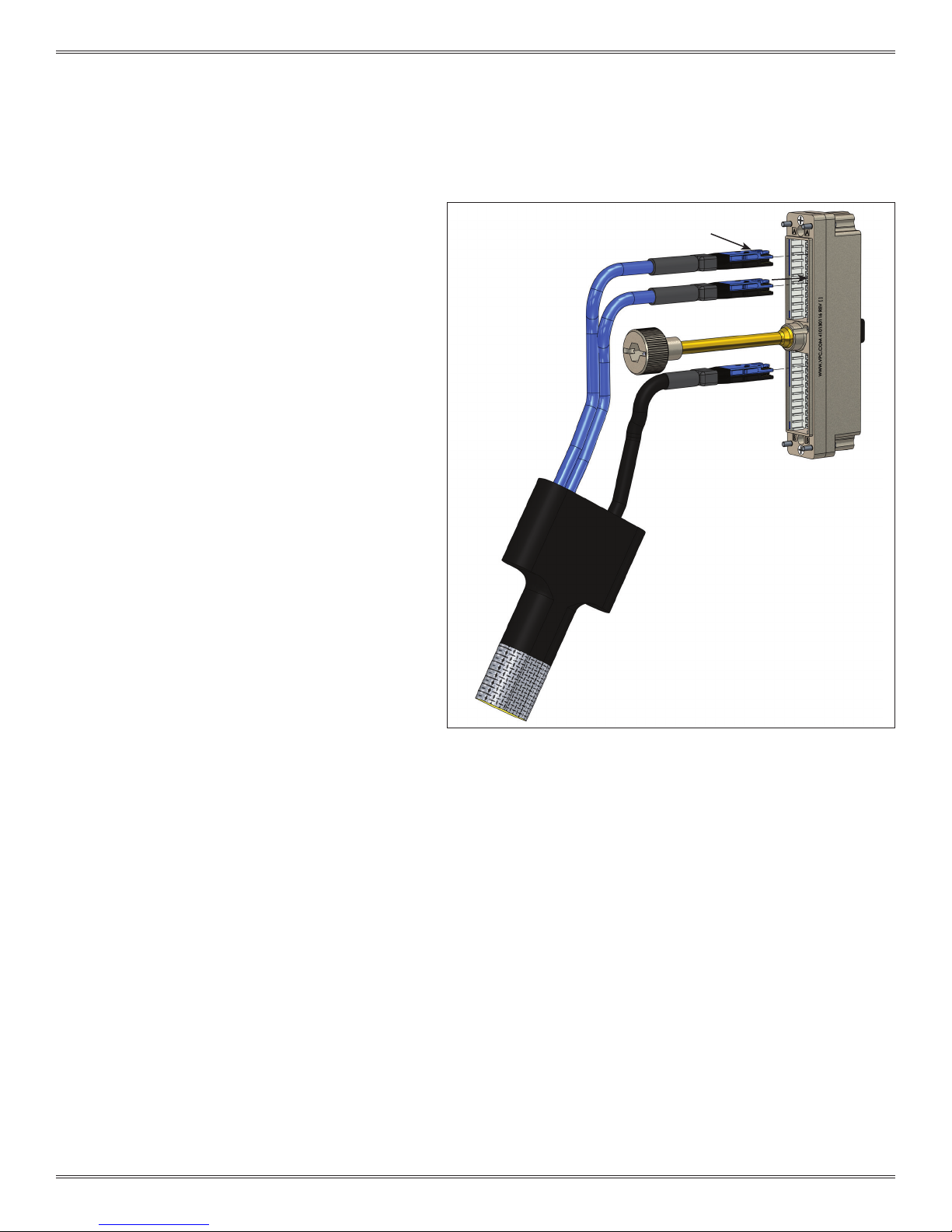

Figure A. VTAC HSD Insert installation.

Figure B. Insert removal tool pins.

TOOLS REQUIRED

VTAC Extraction Tool Kit, Receiver and ITA, Part # 910 112 130

VTAC HSD INSERT INSTALLATION INSTRUCTIONS

1. Ensure that the VTAC HSD Insert(s) is in-line with the

corresponding module location. Apply gentle pressure and

insert the VTAC HSD Insert(s) into the rear (wiring side) of the

module shown in Figure A. The VTAC HSD Insert(s) can only go

into one side. Once in place, gently pull the wire to ensure

the insert(s) is fully seated.

NOTE: To be fully seated, the insert(s) back shoulder should be ush

or below the module rear face as shown in Section 2-1 Figure C.

When plugging a stack of inserts, the blue insert will always be on

top as shown in Section 2-1 Figure A.

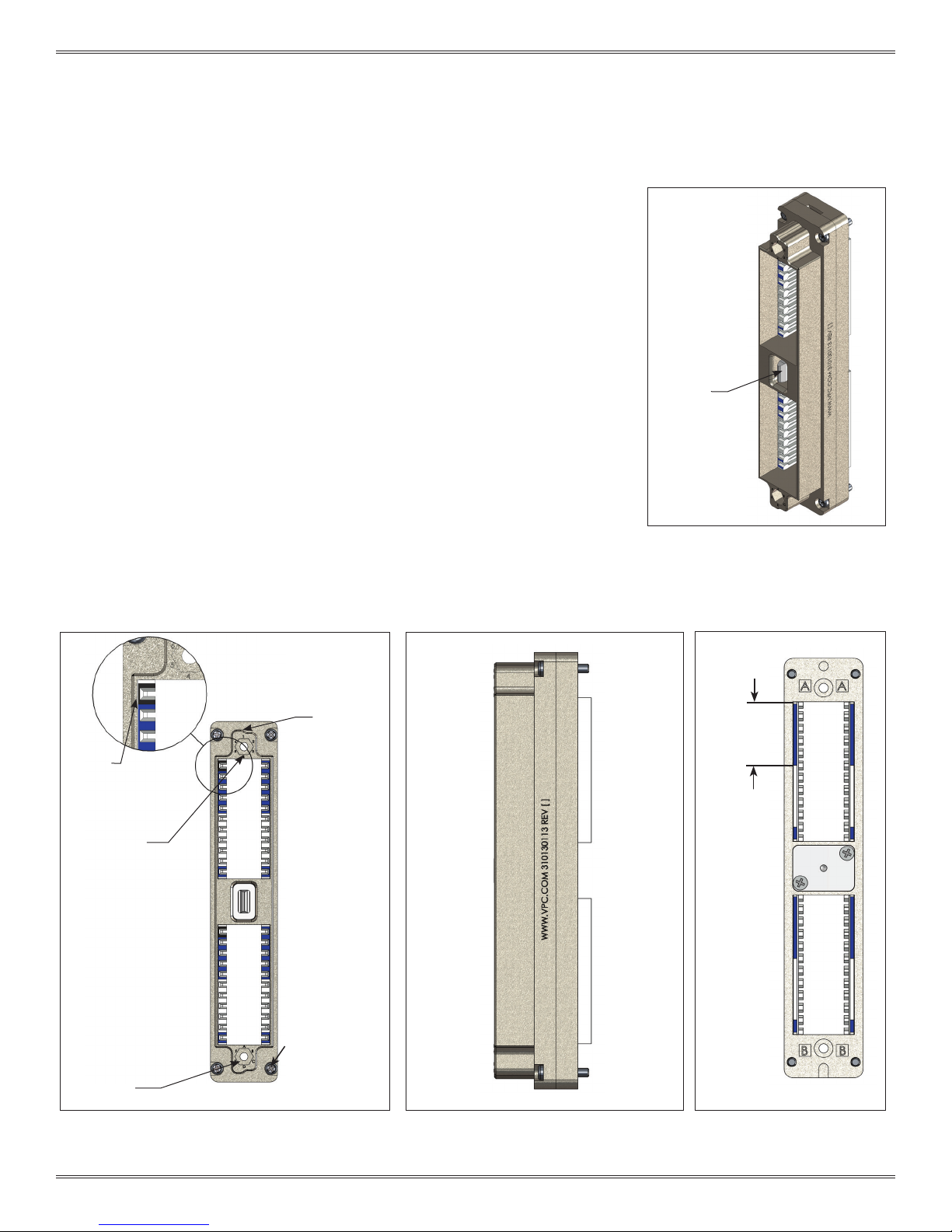

VTAC HSD INSERT REMOVAL INSTRUCTIONS

1. Group the required number of extraction tools together for

the given VTAC HSD patchcord shown in Figure B. The tool

pins should be on the mating side of the module.

WARNING: All inserts within each patchcord must be extracted

simultaneously to prevent damage to VTAC HSD Inserts.

NOTE: The extraction tools are magnetic to aid in stacking them

together.

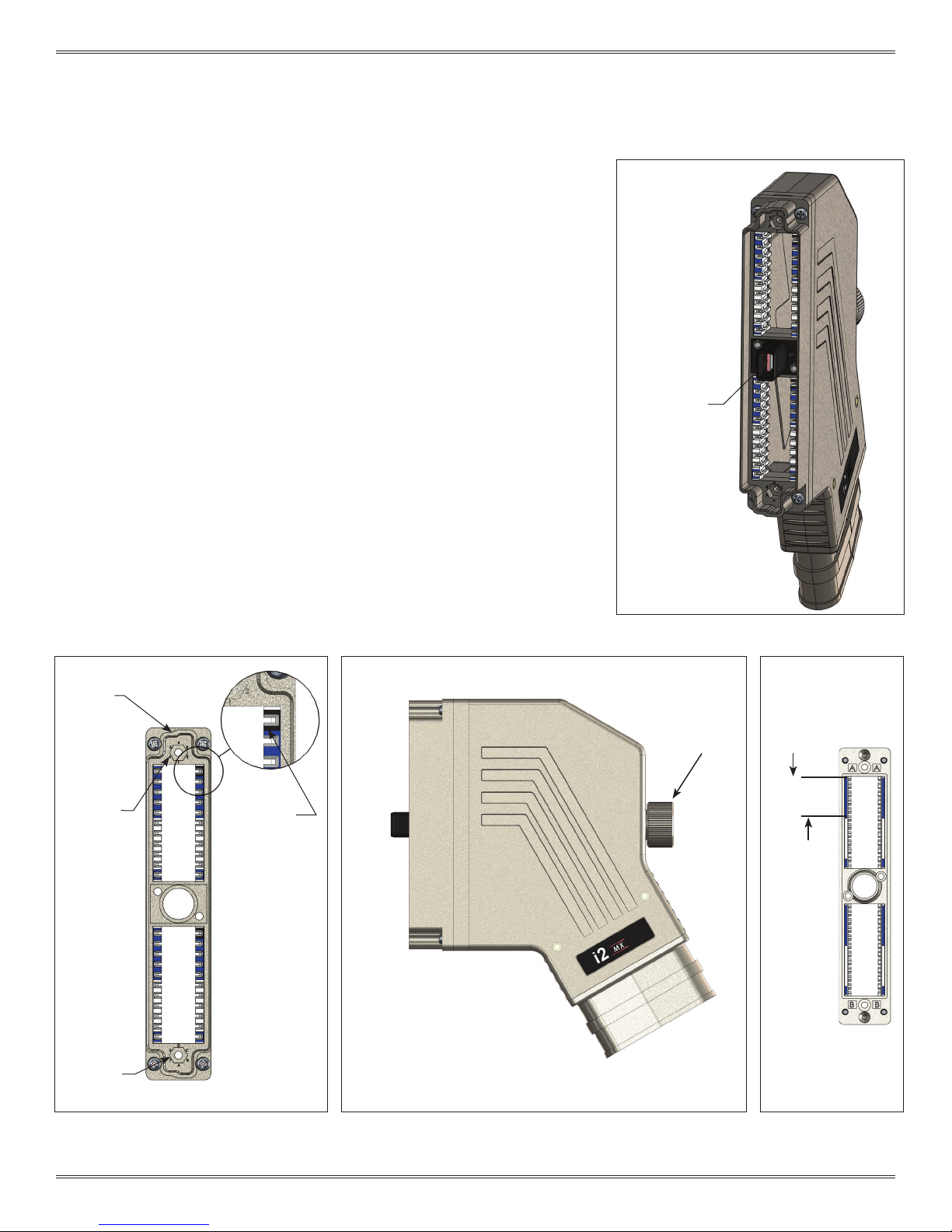

2. While grasping the extraction tool(s) body from the sides

(Figure B),slide tool pins into module’s extraction cavity

square holes until the tool frame is seated against the body

shown in Figure C.

WARNING: The extraction tool(s) need to be seated against

the module front face before the plunger is pushed in. Otherwise

damage to insert(s) may occur.

3. Push plunger of extraction tool(s) in to extract VTAC HSD

Insert(s). The insert(s) will be ejected out the wiring side of the

module shown in Figure D.

Figure C. Seat removal tool

to module frame.

Figure D. Push removal tool plunger.

GRIP

EXTRACTION TOOL

PINS

DETAIL A

SEAT

PLUNGER

PUSH

PLUNGER

BLUE INSERT