ICON USER’S MANUAL: SECTION 5 VIRGINIA PANEL CORPORATION

5-1 For the most current information available, visit www.vpc.com. 6/7/18

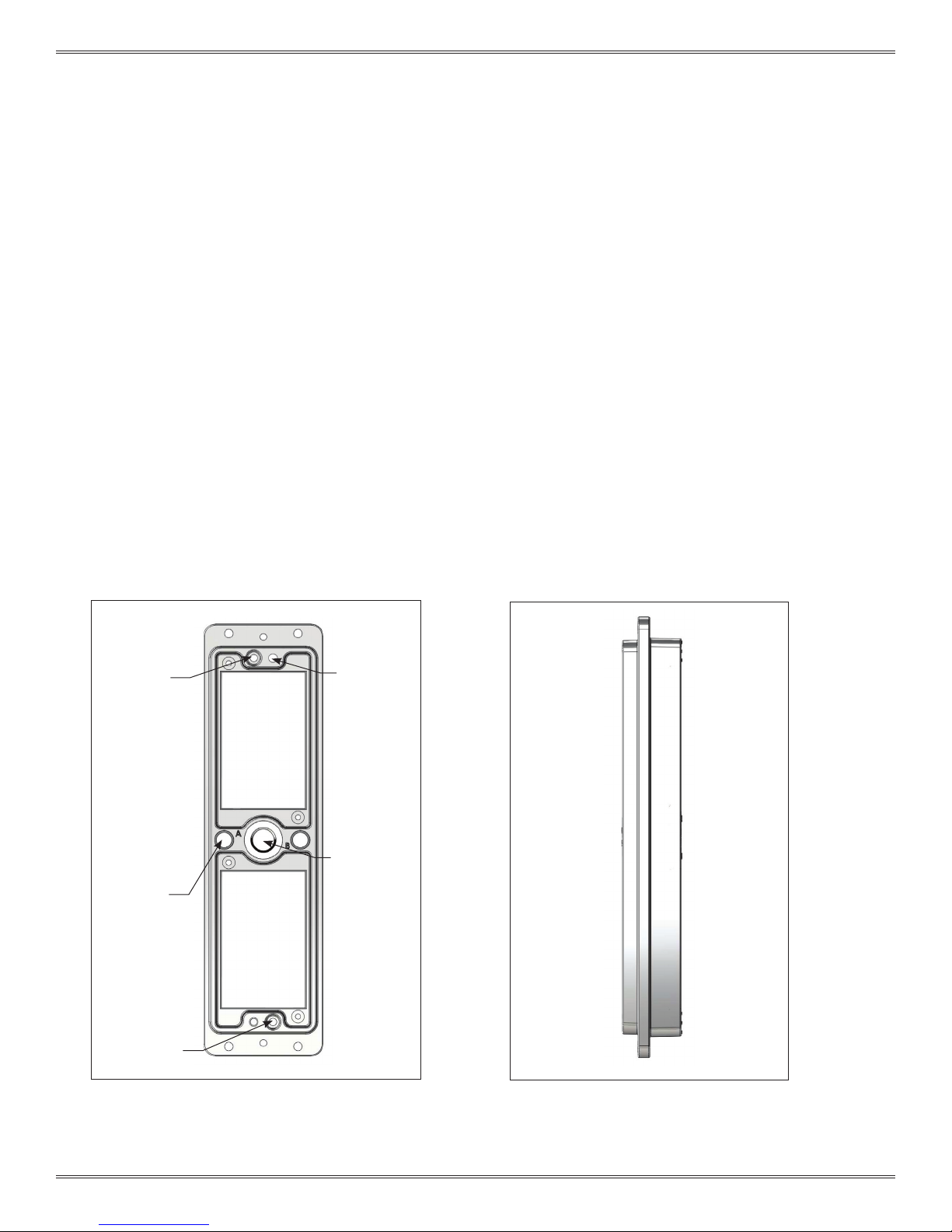

ICON ITA CABLE CLAMP REMOVAL AND INSTALLATION

PART # 410 123 XXX

TOOLS REQUIRED

Phillips Head Screwdriver

CABLE CLAMP REMOVAL INSTRUCTIONS

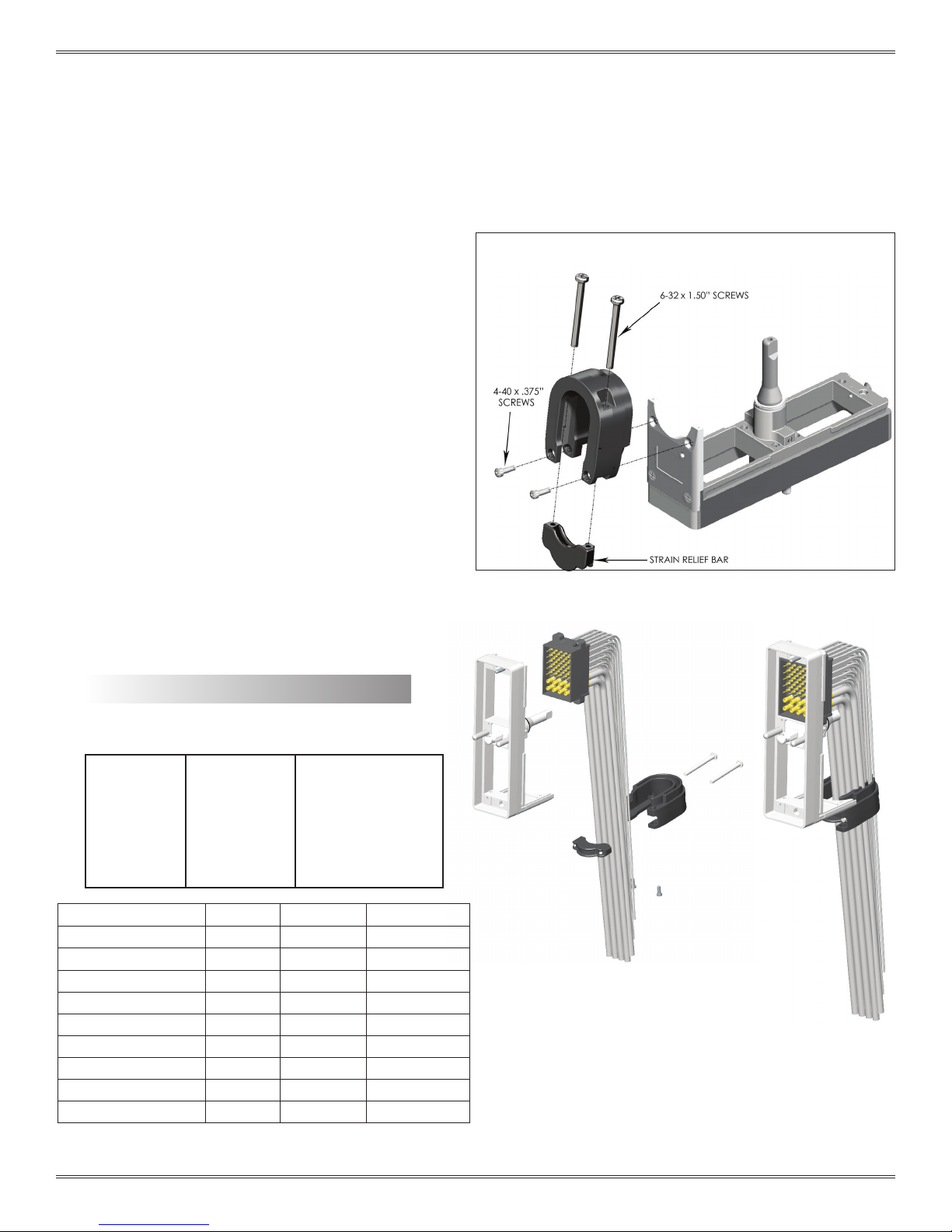

1. After removing the handle and cover, loosen the 6-32 x

1.5” screws to allow the wire(s) or cable to slide freely in

the clamp.

2. Unscrew the 4-40 x .375” screws holding the clamp

to the ITA frame (Figure A). Afterwards, if necessary,

entirely remove the 1.5” screws to allow the wire(s) or

cable to be removed.

CABLE CLAMP INSTALLATION INSTRUCTIONS

1. Place wire(s) or cables into “U” shaped clamp. Install

strain relief bar and start 1.5” screws; alternate screws

when tightening.

2. Install .375” screws to mount clamp to ITA frame. Slowly

alternate tightening the 1.5” screws until the clamp has

cinched the wire(s) or cable tightly.

NOTE: The U-shaped cable clamp is adjustable to

accommodate the amount of wires in your cable bundle.

Figure A. The U-shape allows cables to be preterminated before

clamp installation.

The iCon ITA cable clamp is designed to allow the

test technician to easily recongure or add wired

modules to the system.

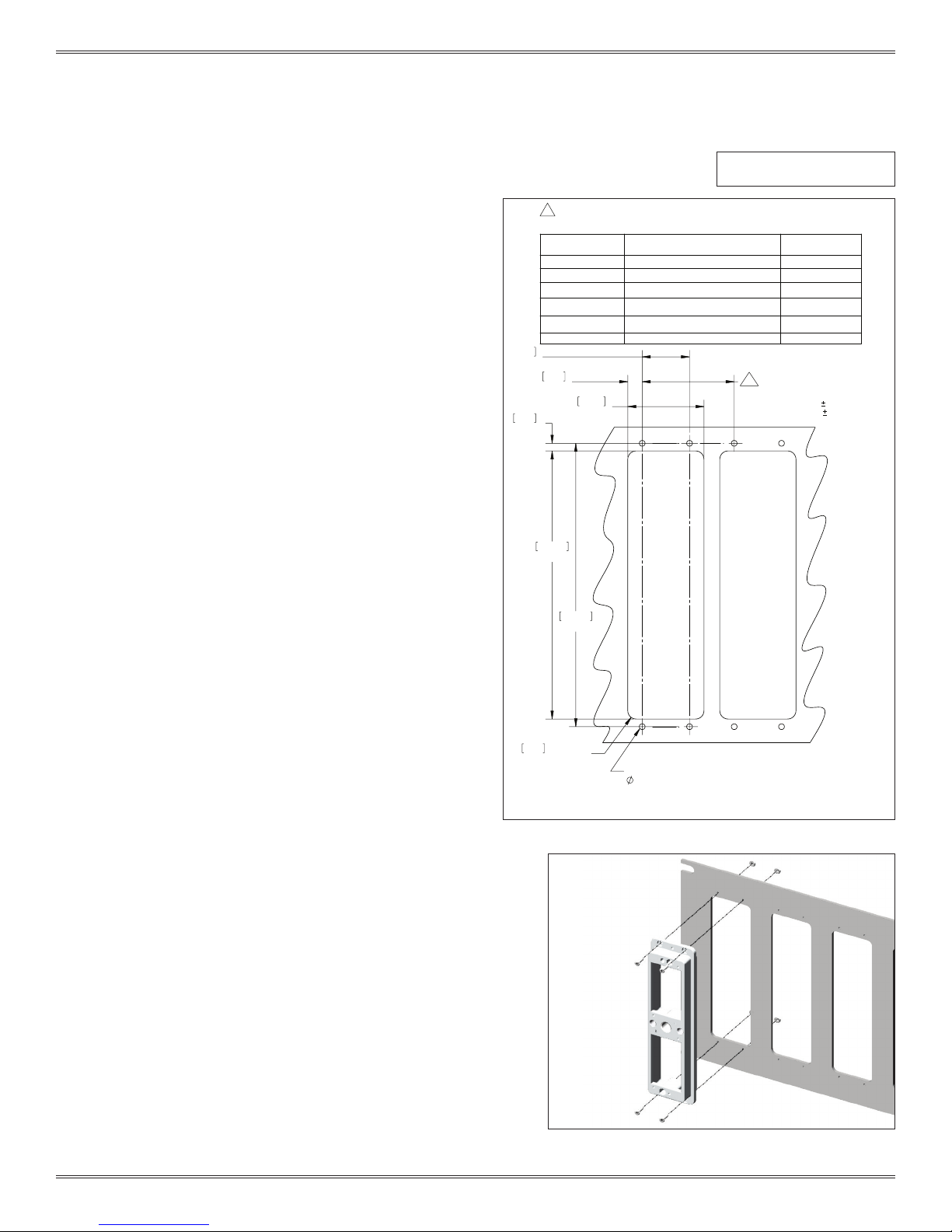

B = 1.2 √(N1d1

2+ N2d2

2 +. . . +Nndn

2)

B = Wire Bundle

Diameter

N1 = Quantity of

rst wire type

N2 = Quantity of

second wire type

Nn = Quantity of

nth wire type

d1= Outside Diameter

of rst wire type

d2

= Outside Diameter

of second wire type

dn= Outside Diameter

of nth wire type

WIRE TYPE Ø [in] # WIRES BUNDLE Ø [in]

26AWG 16878/4 0.043 549 1.21

24AWG 16878/4 0.048 441 1.21

22AWG 16878/4 0.054 348 1.21

M27500-26ml2t08 0.114 78 1.21

M27500-24ml2t08 0.126 64 1.21

M27500-22ml2t08 0.140 52 1.21

M27500-22ml1t08 0.087 134 1.21

22AWG 16878/4 T/P 0.108 87 1.21

24AWG 16878/4 T/P 0.096 110 1.21

NOTE: Acceptable bundle dimension must be reduced

when using sleeving and shrink tubing.

FORMULA TO CALCULATE THE MAXIMUM

NUMBER OF WIRES IN A CABLE BUNDLE