Valves

As you are looking at your machine you will notice there are five valves. The valve

located on the bottom of the tank/suction line is used to shut off the flow to the pump

during transport or any time you need to isolate the tank from the pump. This valve

needs to be opened during operation to provide flow to the pump. Failure to have this

valve open can result in damage to the pump. The next two valves (3”) are located on the

pressure side (top) of the pump. You will notice that one is oriented horizontally and the

other vertically. The horizontal valve is used to control the jets inside the tank. The

vertical valve is plumbed to a three inch line and acts as a high volume recirculation

valve for breaking up mulch and mixing any floating seed into the mulch. The third and

smallest valve is also located on the pressure side of the pump. This is the valve that

controls the flow to the hose and gun. Make sure this valve is CLOSED unless the hose

and gun are attached. If this valve were to be opened upon start up, water/hydroseed

would begin to spray out of the valve. The final valve is located on the suction line. This

is the valve to isolate the pond when utilizing the pond suction feature.

Plumbing

All of our machines run a flange style poly plumbing system. These systems provide less

resistance and better flow than conventional threading plumbing and are easy to

disassemble/reassemble. All of the flange clamps use a regular 5/16” socket or wrench.

You will find a gasket located in between the two connects parts. If you ever disassemble

your unit take time to make sure the gasket is properly seated and clean before

reassembly

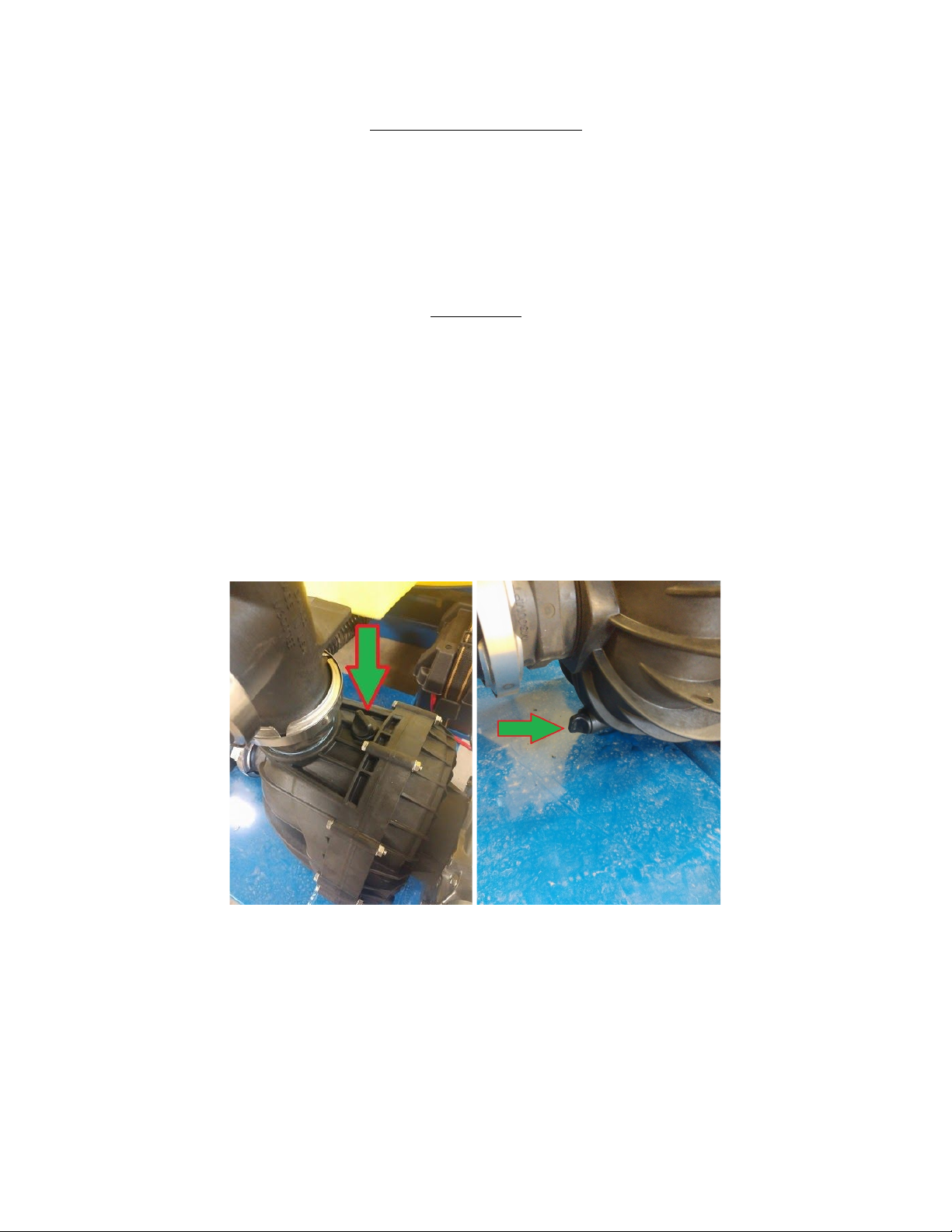

Camlocks

Most pieces of the hydroseeder use camlock fittings. These fittings make removal of the

sections quick and easy. You will notice that the gun, tips, and hose sections are all

connected using these fittings. To connect these fittings, simply insert the male end into

the female end and push each cam lever down until they are fully closed. There are two

camlock fittings located on the unit. The first is located on the valve the hose attaches to.

Simply take the female end of your spray hose and attach it in the way previously

described. Take time to make sure the levers are fully locked! The second camlock is

located on the top of the unit. This is for your garden hose water fill line. We will be

covering this next.

Lifting and Moving Hydroseeder

The 400 JAH units are equipped with fully enclosed fork pockets for safe and confident

loading and unloading of the machine. NEVER attempt to lift or move the machine from

the front while loaded - damage WILL occur to the frame. You may pick up while machine

has product in it from the side fork pockets.