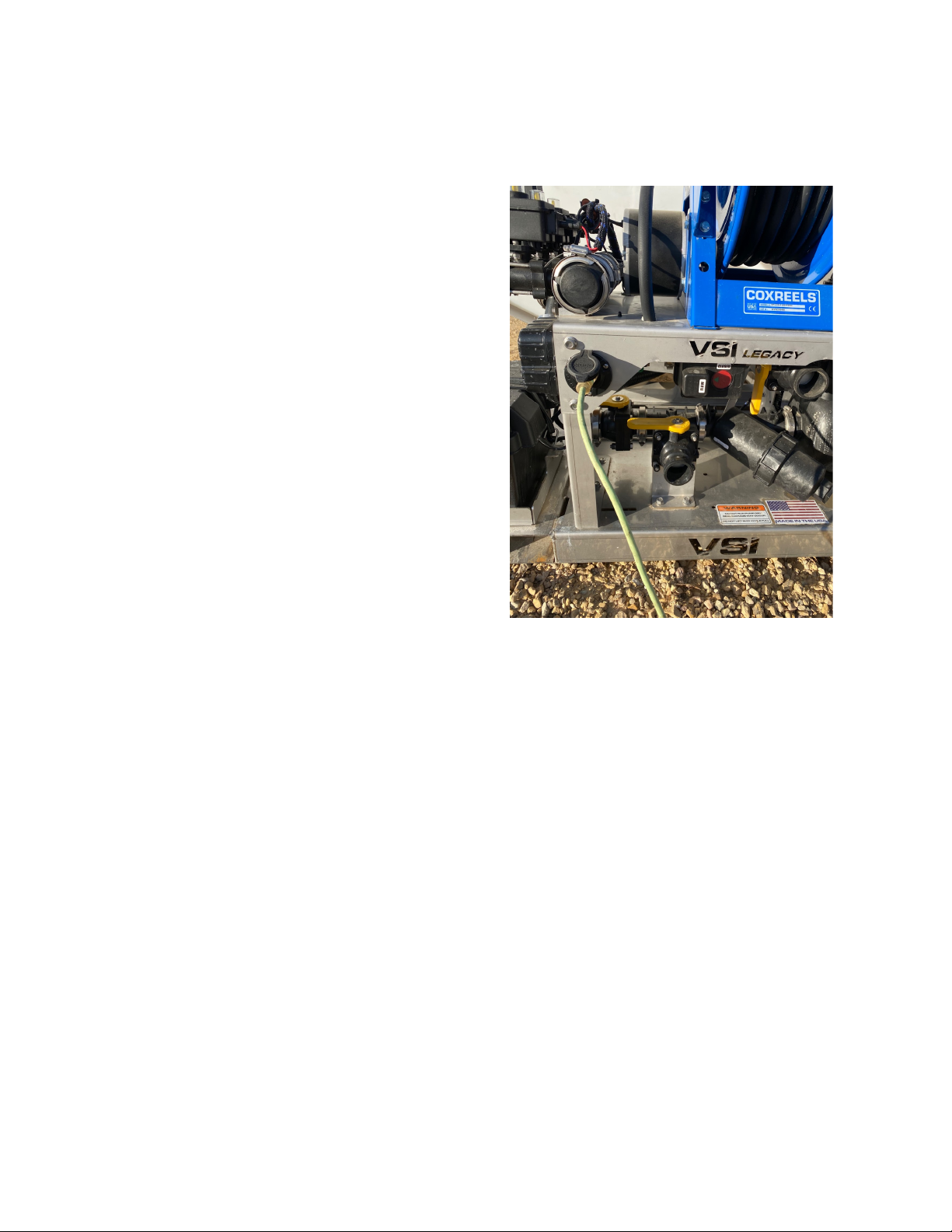

Large Nozzles

The post treatment tips are the top ones

on each end and the central boom with

a vertical camlock in the middle that

sprays out of the jet nozzle holes in the

stainless pipe. These nozzles are to be

used when spraying 90 -120+ gallons

per acre or when pre-treating at higher

speeds than a typical parking lot such

as roadways or large logistics centers

where speeds commonly exceed 25

mph.

Center Boom

Connection Points

Pre Treatment Fan

Nozzle

There are two available connection

points on the center boom, the center

fan nozzle and the center boom pipe.

The center fan nozzle is designed to be

a pre-treatment tip only. The design of

the tip allows it to cover slightly more

than the width of the truck and provide

an even coverage of the application

surface.

Tip - It is very common for people to

want to pre-treat with the jet nozzle

holes because they see local roadway

and highway departments leaving “lines”

of brine on the road. The reason they do

this is because of the high rate of speed

at which they travel on roadways

requiring a heavier jet pattern to not get

diluted in the wind, plus they have very

high traffic levels from cars to track the

product evenly. Parking lots are

different. Lower speeds and less traffic

means that a fan tip is preferable, which

is why our center pre-treat nozzle is a

fan.

If you run the small, outside pretreat

nozzles with the center jets, your

application rate WILL NOT be balanced

and your outer nozzle performance will

suffer due to the center jets robbing a

majority of the liquid pressure/volume

from the outside nozzles.

Center Boom Pipe

Connection

The center boom pipe connection

utilizes the 1” stainless steel pipe inside

of the boom shroud. This connection

point will be used for all post treatment

applications and high speed

pretreatment applications. As stated

before, the center boom will not be

balanced when using the small side

nozzles, but this configuration can be

used in areas where very slow post

treatment application is required.

Normal post treatment application will

consist of the center boom pipe and

medium side nozzles.