9570-540 – 01/21Page 2

INSTALLATION AND FUNCTION TESTS

1. Initial inspection:

a. Carefully unpack safety breakaway from shipping carton.

b. Inspect safety breakaway for any damage to threads, O-rings,

exterior, etc.

2. Lightly lubricate ALL O-rings on mating connections with

petroleum jelly or other suitable lubricant. DO NOT USE pipe

dope or thread sealant.

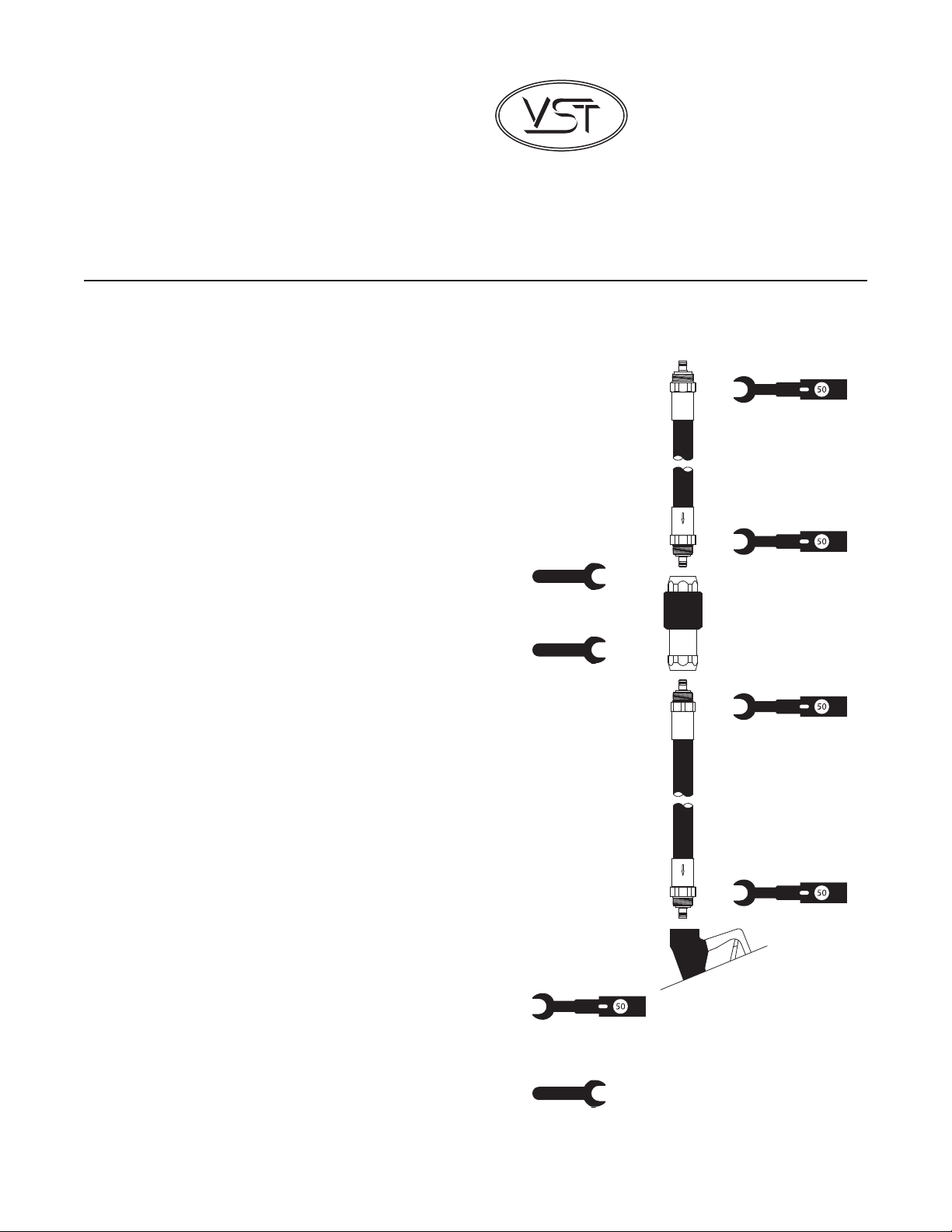

3. Attach breakaway on mating connection and tighten by hand.

NOTE FLOW DIRECTION ARROW (where applicable). Use

the hex on the breakaway body to tighten. DO NOT USE the

breakaway body to tighten the unit.

4. Tighten breakaway connection to 50 ft.-lbs. of torque. DO NOT

OVER TIGHTEN. Use the hex on the breakaway body to tighten.

Use a torque wrench with an open-end attachment to fit the

hose couplings and an open-end wrench to properly tighten

breakaway connections. DO NOT USE channel-locks or pliers

to tighten connections. Proper ft.-lb. torque may not be achieved

with these tools.

5. Purge air from the system by pumping one-tenth (1/10) to two

tenths (2/10) of a gallon of fuel into an approved container.

Inspect each breakaway joint connection for liquid leaks and

meter creep. Make proper adjustments at the breakaway

connection if necessary.

6. Check the nozzle shut-off action by dispensing fuel into an

approved container at least three times to assure proper

automatic operation. To test, operate the nozzle and submerge the

spout tip in fuel until the fuel level covers the vent hole. The main

valve of the nozzle automatically shuts off when liquid covers the

vent hole at the end of the spout. The dispenser should deliver a

minimum of 3 gpm. Hold open latch will disengage automatically

when liquid covers the vent hole in the spout.

7. Measure the resistance between the dispenser outlet casting

and the tip of the nozzle spout. Use an electronic multimeter set

on the high range of the ohmmeter function. Resistance should

not indicate more than 70,000 ohms per foot of hose. Example:

The measured resistance for a 12-foot hose must not exceed

840,000 ohms (840 kilohms).

BREAKAWAY REATTACHMENT PROCEDURES

These VST reattachable breakaways can be reconnected in either

one of two methods:

METHOD 1: Use of the VST Breakaway Assembly Tool (VST-

BAT-200) with the appropriate reassembly plates for this breakaway.

1. Follow INSTALLATION PREPARATION steps 1 - 3.

2. Inspect both safety breakaway halves for damage that may

have occurred during separation. Include looking for external

damage to the product, damaged threads, damaged O-rings,

missing O-rings, proper placement of O-rings, etc. If damage is

detected, replace with new product.

3. Prior to reassembling, be sure the mating parts are undamaged

and clean.

4. Lightly lubricate ALL O-rings on mating connections with

petroleum jelly or other suitable lubricant.

FIGURE 2.

VST Breakaway Assembly Tool

VST Installation Procedure for

Phase II EVR Vacuum Assist

Safety Breakaway Devices

Part Number Series:

VST-HEVR-SBK;

VST-ISVR-SBK