3

OPERATION

Lifting

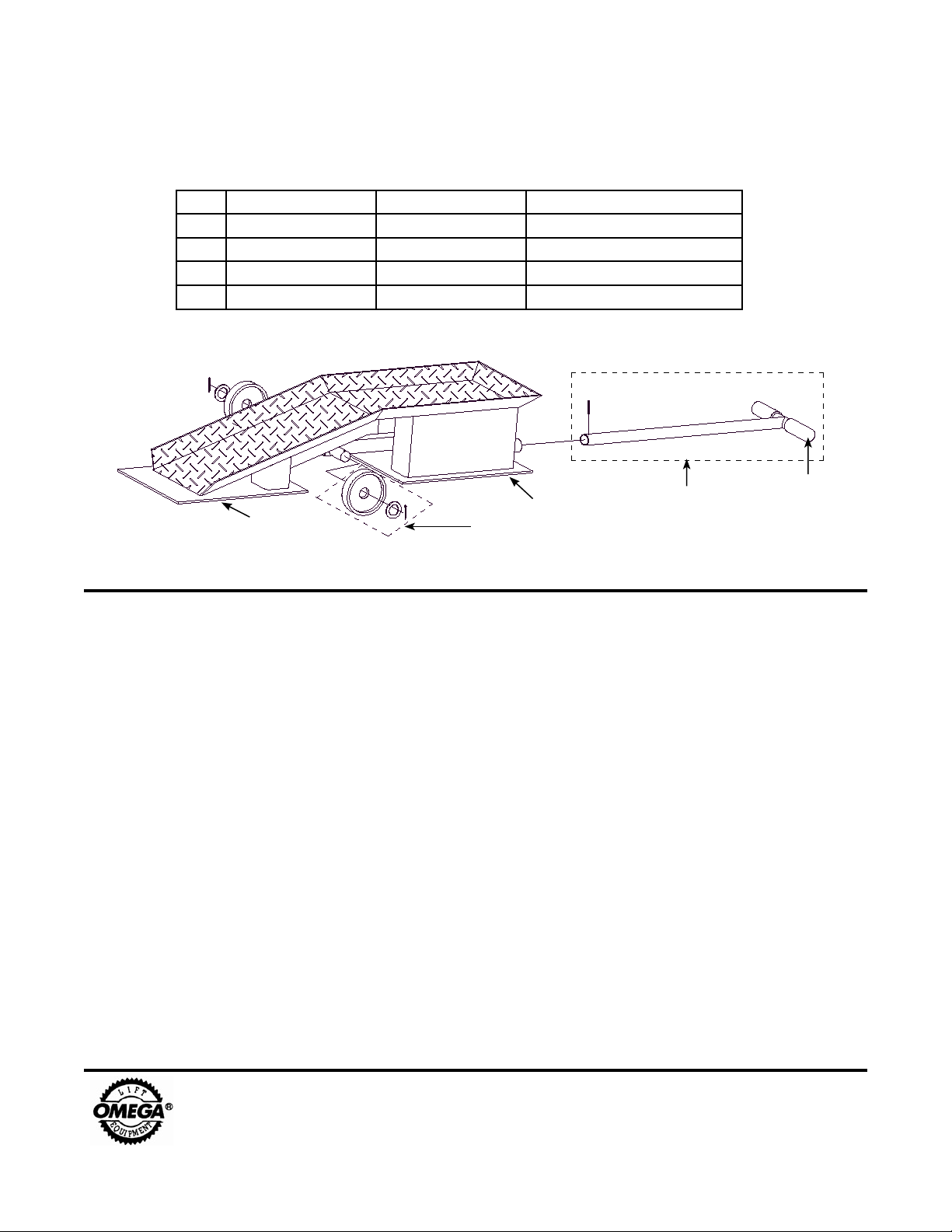

1. Center the two ramps against the tires of vehicle.

Be sure the wheels to be driven on the ramps

are positioned straight forward in alignment

with the ramps, and center the two ramps against

the tires.

2. After positioning the truck ramps, keep the handle

in lowest position in order to lower the base to

surface. The rubber padded base will prevent ramps

movement while vehicle is being driven onto or off

the ramps.

Note: Must keep the handle in lowest position

in

order to lower the base to contact the floor/

surface.

3. Drive the vehicle onto the ramps.

Another person, standing clear from vehicle

path and the ramps, should observe and

guide the vehicle operator when ascending and

descending the ramps.

4. Once the vehicle reaches the top of the ramps,

apply brakes only to prevent over-travel.

Never accelerate or apply brakes suddenly.

Proceed slowly and cautiously.

5. Place the vehicle in neutral. Release brakes; vehicle

should not move.

6. Turn the engine off, set parking brake. Place vehicle in

park (or in reverse gear for manual transmission).

7. Get out of the vehicle and securely chock the

remaining wheels on the ground.

8. Be sure that both tires are properly positioned on

the ramp’s support platform.

Using caution in positioning your body clear

of danger, shake vehicle sideways and

endways to be sure that vehicle and ramps

are stable. Check that ramps have not become

damaged or bent during loading.

Do not disconnect brakes, engine, transmission

components, drive train, drive shaft, universal

joints, or wheels while the vehicle is on the ramps.

Lowering

Be sure that all tools and personnel are clear

before lowering vehicle.

1. Lower the vehicle slowly and cautiously, never apply

brakes suddenly.

2. After lowering the vehicle, pull the handle up to dolly

the ramp away.

MAINTENANCE

Periodically inspect the ramp. To help prevent rust, wipe

clean after each use. If rust appears, sand affected area

and cover with suitable utility paint. Store the ramp in

a clean, dry area.

•

Study, understand, and follow all instructions

provided with and on this device before use.

• Rated capacity is PER PAIR! DO NOT exceed

rated capacity.

• Use as a matched pair to support one end

of a

vehicle only. Use only ONE (1) PAIR per vehicle.

• Use only on hard, level surface.

• Center load between the sides of the ramp.

•

Ramps are not to be used to simultaneously

support both ends or one side of a vehicle.

• Maximum allowable tire width is 10.75"/ 27.3cm

for model 93200; and 15.5"/39.4cm for model

93201.

• Use only on those vehicles whose GVWR is

less than 66,000 lb.

•

Do not use other lifting equipment in conjunction

with the ramps.

• No alterations shall be made to this device.

• Failure to heed these markings may result in

personal injury and/or property damage.

! WARNING

!

!

!

!

!

BEFORE USE

1. Verify that the product and the application are

compatible, if in doubt call Omega Tech. Service

(888) 332-6419.

2. Before using this product, read the operator's manual

completely and familiarize yourself thoroughly with

the product and the hazards associated with its

improper use.

3. Inspect before each use. Do not use if bent, broken

or cracked components are noted.

4. Ensure that all parts move freely.

!