1.

Description and work device ..................................................................................5

1.1

Intended use............................................................................................................................. 5

1.2

Specifications .....................................................................................................................5

1.3

Composition .......................................................................................................................7

1.4

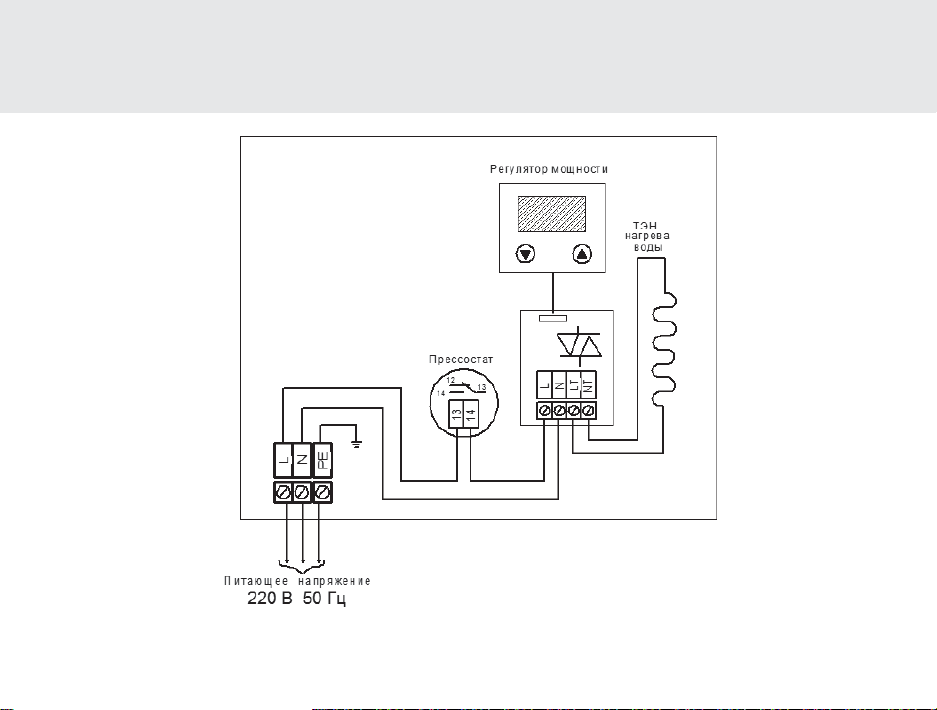

Device and operation of the product........................................................................................ 7

1.5

Instrumentation........................................................................................................................ 9

1.6

Marking and sealing.................................................................................................................. 9

1.7

Packaging….. ............................................................................................................................. 9

2.

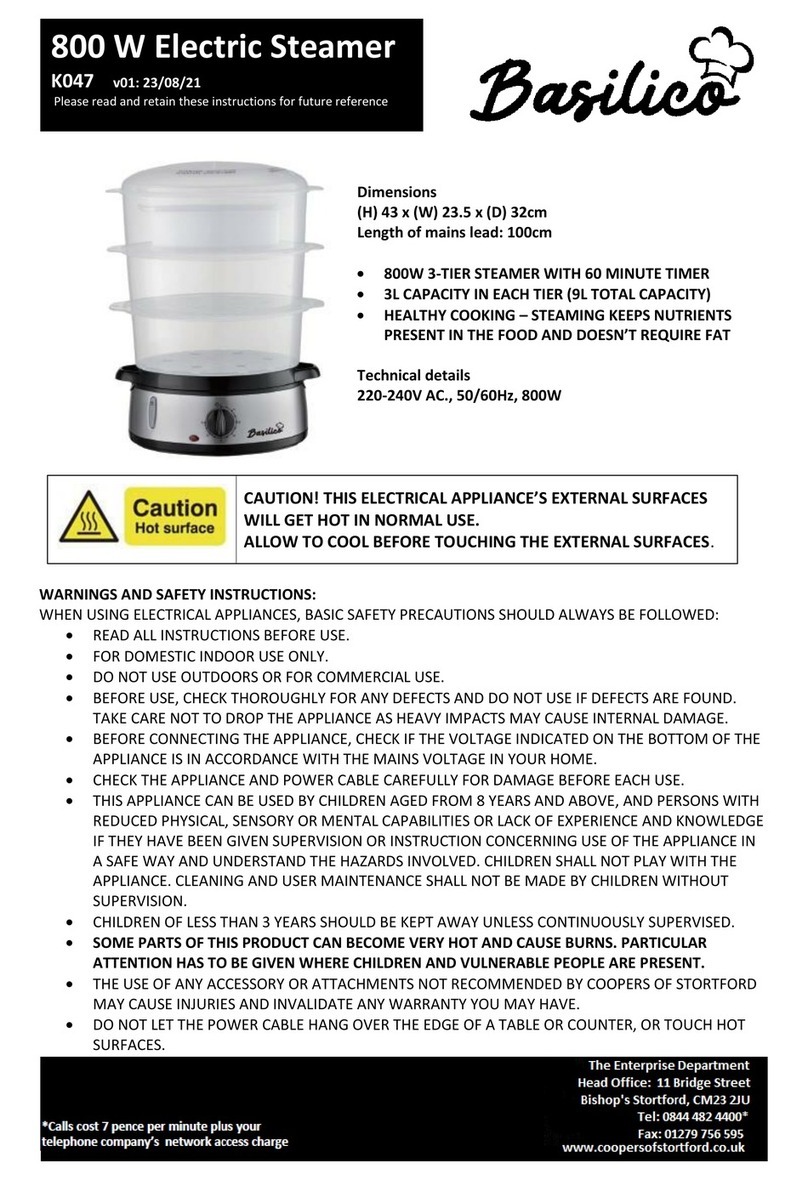

USE OF THE PRODUCT ............................................................................. 11

2.1

Preparation for use………………………………………………………………………………………………………11

2.2

Security measures……………………………………………………………………………………………………………….11

2.3

Electrical connection. Preparation for work………………………………………………………………

……….12

2.4

Operation of the product..............................................……………………………………12

2.5

Security measures...............................................................................................12

2.6

Operating procedure ..........................................................................................13

2.7

Action in extreme conditions

.......................................................................... 14

2.8

Possible malfunctions and their elimination……………………………………………………

14

3.

MAINTENANCE ....................................................................................................15

4.

STOREGE AND TRANSPORTATION .........................................................................15

5.

RECYCLING ..........................................................................................................16

6.

WARRANTY OBLIGATIONS ....................................................................................16

7.

WARRANTY CARD.................................................................................................... 18