Vytran LLC: PTR-200-PRL Polyimide Recoater Operator’s Manual Version 1.2 iii

Table of Contents

1Introduction............................................................................................................................................ 1

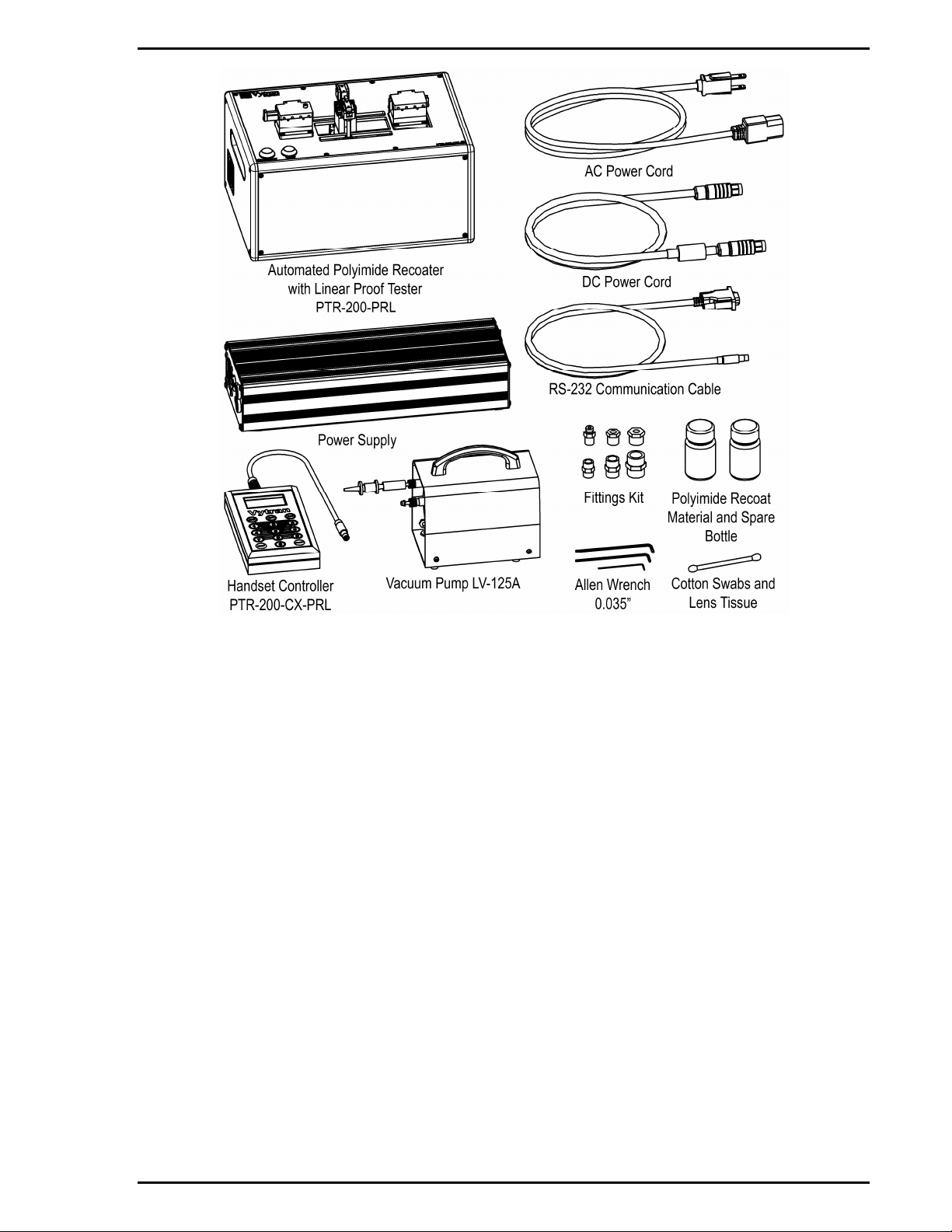

1.1 Parts Checklist............................................................................................................................... 1

1.2 Powering Up................................................................................................................................... 2

1.3 Shutting Down................................................................................................................................ 2

2Controlling the PTR-200-PRL................................................................................................................ 3

2.1 Main Menu ..................................................................................................................................... 3

2.2 Configuration Menus...................................................................................................................... 3

2.2.1 Inject........................................................................................................................................ 3

2.2.2 Undercoat ............................................................................................................................... 3

2.2.3 Overcoat ................................................................................................................................. 4

2.2.4 Recoat Length......................................................................................................................... 5

2.2.5 Proof Test ............................................................................................................................... 5

2.3 Options Menu................................................................................................................................. 6

2.4 Parameter Limits............................................................................................................................ 7

2.5 Configuration Menu Flow Chart..................................................................................................... 8

2.6 Options Menu Flowchart.............................................................................................................. 12

2.7 Abort Flowchart............................................................................................................................ 14

3Recoat Injection System...................................................................................................................... 15

3.1 Priming the Injection System ....................................................................................................... 15

3.2 Cleaning the Die........................................................................................................................... 17

4Recoat and Proof Test Process .......................................................................................................... 19

4.1 The Polyimide Recoat Process.................................................................................................... 19

4.2 The Fiber Holding Blocks, V-Grooves, and Inserts...................................................................... 19

4.3 Stripped Fiber Requirements....................................................................................................... 19

4.4 Loading......................................................................................................................................... 20

4.5 Recoating..................................................................................................................................... 21

4.6 Proof Testing................................................................................................................................ 21

4.7 Unloading..................................................................................................................................... 22

5Maintenance........................................................................................................................................ 23

5.1 Planned Maintenance .................................................................................................................. 23

5.2 Inspecting the Fiber Holding Blocks............................................................................................. 23

5.3 Inspecting and Cleaning the Die.................................................................................................. 23

5.4 Load Cell Calibration.................................................................................................................... 24

5.5 Flush Recoat System................................................................................................................... 24

5.6 Purge Recoat System.................................................................................................................. 24

5.7 Replacing Recoat Material........................................................................................................... 25

5.8 Replacing a Heater ...................................................................................................................... 25

5.9 Changing the Fiber Holding Block V-Grooves............................................................................. 25

5.10 Replacing the Die..................................................................................................................... 26

Appendix A: MSDS PI2525 ........................................................................................................................ 27

Appendix B: MSDS NMP............................................................................................................................ 35

Appendix C: Pyralin Product Information ................................................................................................... 43