6

1.3 Specifications

1.3.1 DOC (dissolved oxygen concentration) measuring range at an analyte

temperature of 20 °С, mg/dm3 ..………………………………….……..….. 0 to 10,00.

The upper limits of DOC measuring range, depending on the analyte tem-

perature, are shown in Table 1.2.

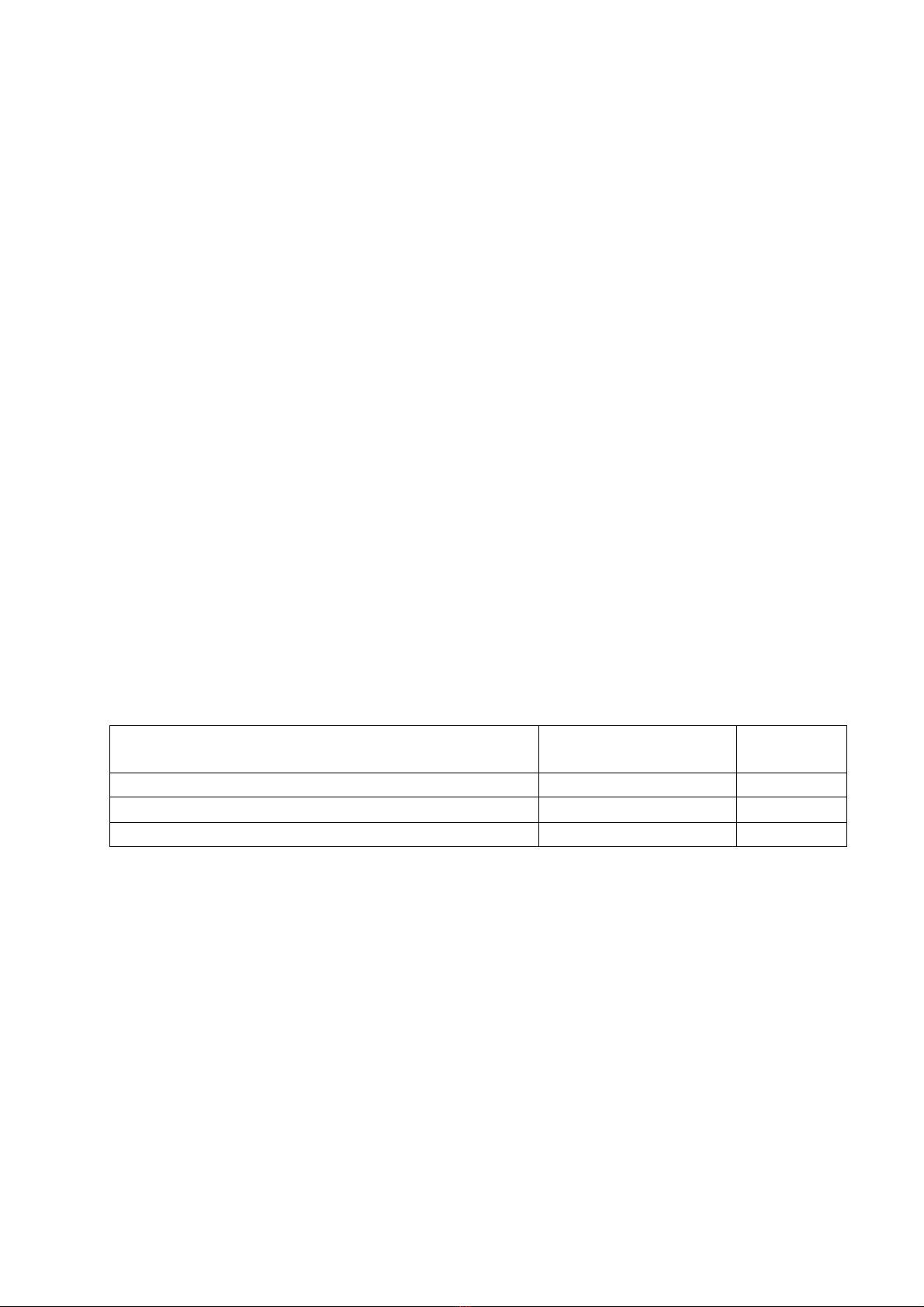

Table 1.2

t, °C 0 5 10 15 20 25 30 35 40 45 50

DOC,

mg/dm3 17,45

15,29

13,48

12,10

10,00

9,85

8,98

8,30

7,69

7,12

6,59

1.3.2 Limits of the analyzer allowable basic absolute error in DOC measure-

ment at an analyte temperature of (20,0±0,2) °С and ambient temperature of

(20±5) °С, mg/dm3 ……………………………….…........................... ±(0,003+0,04С),

where С, here and hereafter, is a measured DOC value in mg/dm3.

1.3.3 Limits of the analyzer allowable additional absolute error in DOC

measurement due to a change in the ambient temperature, by each ±5 °С from the

normal temperature (20,0±0,2) °С, within the operating temperature range from 0

to +50 °С, mg/dm3 ……………………………………….….…………………. ±0,012C.

1.3.4 Limits of the analyzer allowable additional absolute error in DOC

measurement due to a change in the ambient temperature by each ±10 °С from

the normal temperature (20±5) °С, within the operating temperature range from +1

to +50 °С, mg/dm3 ….……….............................................................

±(0,001+0,002C).

1.3.5 Limits of the analyzer allowable absolute error in DOC measurement at

an analyte temperature coinciding with the calibration temperature which varies be-

tween +15 °С and +35 °С, at an ambient temperature of (20±5) °С,

mg/dm3……….…………………………………………...................... ± (0,003+0,04C).

1.3.6 Analyte temperature measuring range, °С ……...……............. 0 to +50.

1.3.7 Limits of the analyzer allowable basic absolute error in analyte temper-

ature measurement at an ambient temperature of (20±5) °С, °C ….……...…... ±0,3.

1.3.8 Limits of the analyzer allowable basic absolute error in analyte temper-

ature measurement due to a change in the ambient temperature by each ±10 °С

from the normal temperature (20±5) °С, within the operating temperature range

from +1 to +50 °С, °С …….....………………………..…………….…………..….. ±0,1.

1.3.9 Limit of the permissible value of the analyzer readout setting time t0.9 in

DOC measurement, min …………..……….…………………………….…………… 2.

1.3.10 1.3.10 Limit of the permissible value of the analyzer readout setting

time tу in DOC measurement, min ……….…………......................…………..…… 30.

1.3.11 Limit of the permissible value of the analyzer readout setting time t0.9

in analyte temperature measurement, min ……………………….………….………. 1.

1.3.12 Limit of the permissible value of the analyzer readout setting time tу in

analyte temperature measurement, min ………………………………………….….. 3.