Maintenance 0000−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd 1/ 1

This manual is put at the disposal of the recipient solely for use in connection with

the corresponding type of diesel engine.

It has always to be treated as confidential.

The intellectual property regarding any and all of the contents of this manual, par-

ticularly the copyright, remains with Wärtsilä Switzerland Ltd. This document

and parts thereof must not be reproduced or copied without their written permis-

sion, and the contents thereof must not be imparted to a third party nor be used for

any unauthorized purpose.

Before the operator intends to use the engine or before maintenance work is un-

dertaken, the Operating Instructions or the Maintenance Manual respectively is to

be read carefully.

To ensure the best efficiency, reliability and lifetime of the engine and its compo-

nents, only original spare parts should be used.

It is to be ensured as well that all equipment and tools for maintenance are in good

condition.

The extent of any supplies and services is determined exclusively by the relevant

supply contract.

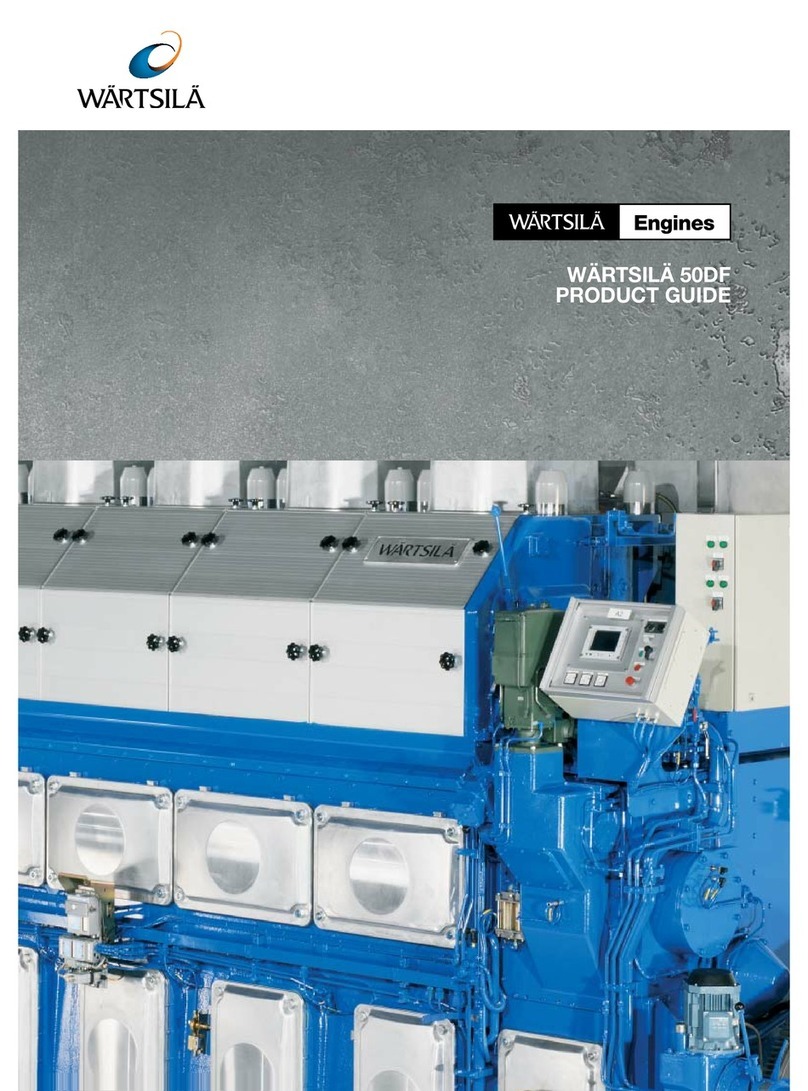

The data, instructions and graphical illustrations etc. in this manual are based on

drawings made by Wärtsilä Switzerland Ltd and correspond to the actual stan-

dard at the time of printing (year of printing is indicated on title page).

Those specifications and recommendations of the classification societies which

are essential for the design have been considered therein. It must be recognized

that such data, instructions and graphical illustrations may be subject to changes

due to further development, widened experience or any other reason.

This manual is primarily intended for use by the engine operating and maintenance

personnel. It must be ensured that it will always be at the disposal of such person-

nel for the operation of the engines and/or for the required maintenance work.

This manual has been prepared on the assumption that operation and mainte-

nance of the engines concerned will always be carried out by qualified personnel

having the special knowledge, training and qualifications needed to handle in a

workman-like manner diesel engines of the corresponding size, the associated

auxiliary equipment, as well as fuel and other operating media.

Therefore, generally applicable rules, which may also concern such items as

protection against danger, are specified in this manual in exceptional cases only.

It must be made sure that the operating and maintenance personnel are familiar

with the rules concerned.

This manual has been prepared to the best knowledge and ability of its au-

thors. However, neither Wärtsilä Switzerland Ltd nor their employees as-

sume any liability − under any legal aspect whatsoever, including possible

negligence − in connection with this manual, its contents, or modifications

to it or in connection with its use.

Claims relating to any damage whatsoever or claims of other nature such as,

but not limited to, demands for additional spares supplies, service or others

are expressly excluded.

Wärtsilä Switzerland Ltd

Winterthur

Switzerland

or Particular Attention

2010