MIO-R290GM2011 Rev E

G&B Specialties Inc. 535 West 3rd Street, Berwick, PA, USA Tel: (570) 752-5901 Fax: (570) 752-6397

US Field Service: 570-441-6988; CAN Field Service 570-854-0482; www.rafna.com

-4-

Service of Front/Rear Mounting Kit.........................................................76

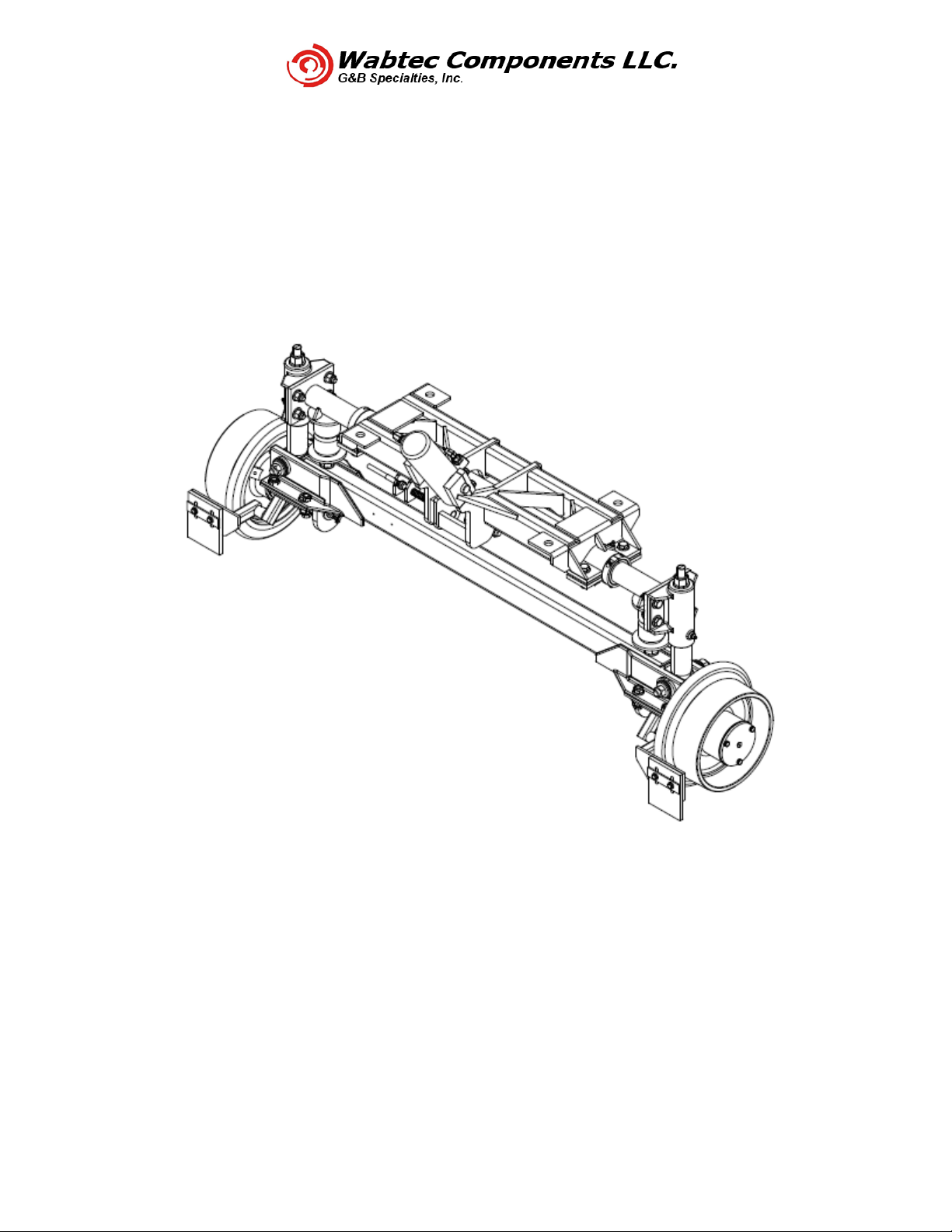

4.0 Front & Rear Railgear kit............................................................................77

Installation Safety Precautions ..............................................................77

Railgear Kits .....................................................................................78

Installation of Railgear Kit ....................................................................79

Installation of Front Railgear Lever Lock Kit..............................................83

Operation of Front Railgear Lever Lock Kit...............................................84

Lever Lock Adjustment ....................................................................84

Removing the Vehicle from Rail – To Raise the Railgear: ...........................85

Parts of Front Railgear Lever Lock Kit .....................................................86

Installation of Rear Railgear Rod Lock Kit .................................................90

Operation of Rear Railgear Rod Lock Kit...................................................91

Placing the Vehicle on Rail – To Lower the Railgear: ................................91

Parts of Rear Railgear Rod Kit................................................................92

Operation Safety Precautions................................................................96

Operation of Railgear Kit (Standard/In-Cab Controls)...................................97

Placing the Vehicle on Rail – To Lower the Railgear: ................................97

Removing the Vehicle from Rail – To Raise the Railgear: ...........................97

Operation of Railgear Kit (Full In-Cab Controls)..........................................98

Service of Railgear Kit .........................................................................99

Railgear Over-Center Adjustment.........................................................101

Rail Wheel Bearing Adjustment............................................................102

Rail Sweep Adjustment......................................................................102

Rail Wheel Load Adjustment ...............................................................103

Check each rail wheel load as follows: ...............................................103

Adjust each rail wheel load as follows:...............................................104

Railgear Alignment ...........................................................................106

Wheel Wear Standards and Recommendations.........................................107

Nominal Rail Wheel Diameter (inches)...................................................107

Min. Allowable Wheel Diameter (inches) ................................................107

R-290 Railgear – Pre-Delivery Check List ................................................108

Parts of Railgear Kit..........................................................................112

5.0 Hydraulic Kit (STD, ICC, & Manual Valve Controls)...........................................129

Installation Safety Precaution..............................................................129

Installation of Hydraulic Manifold Steel Box w/ Insulator ............................131

Pump/Manifold Install/Modification Instructions .......................................139

Installation of Hydraulic Kit ................................................................149

Installation of Hydraulic Kit (STD) .....................................................149

Installation of Hydraulic Kit (ICC Controls)..............................................155

Installation of Hydraulic Kit (FICC Controls) ............................................164

Installation of Hydraulic Kit with Manual Valves .......................................171

Operation Safety Precautions..............................................................181

Operation of Hydraulic Kit..................................................................182

Operation of Standard Railgear Hydraulic System Controls: .....................182

Operation of the Emergency Hand Pump:............................................182

Operation of The Emergency Hand Pump (Locking Manual Valve only): ......183

Service of Hydraulic Kit .....................................................................184

Hydraulic System Relief Valve Setting ................................................184