Table of dierent automatic guns

Nozzle size ASP 30 MP ASP 30 HVLP

0,8 mm R955.08 R955.08H

1,0 mm R955.10 R955.10H

1,2mm R955.12 R955.12H

1,5 mm R955.15 -

1,8 mm R955.18 -

2,0 mm R955.20 -

2,5 mm R955.25 -

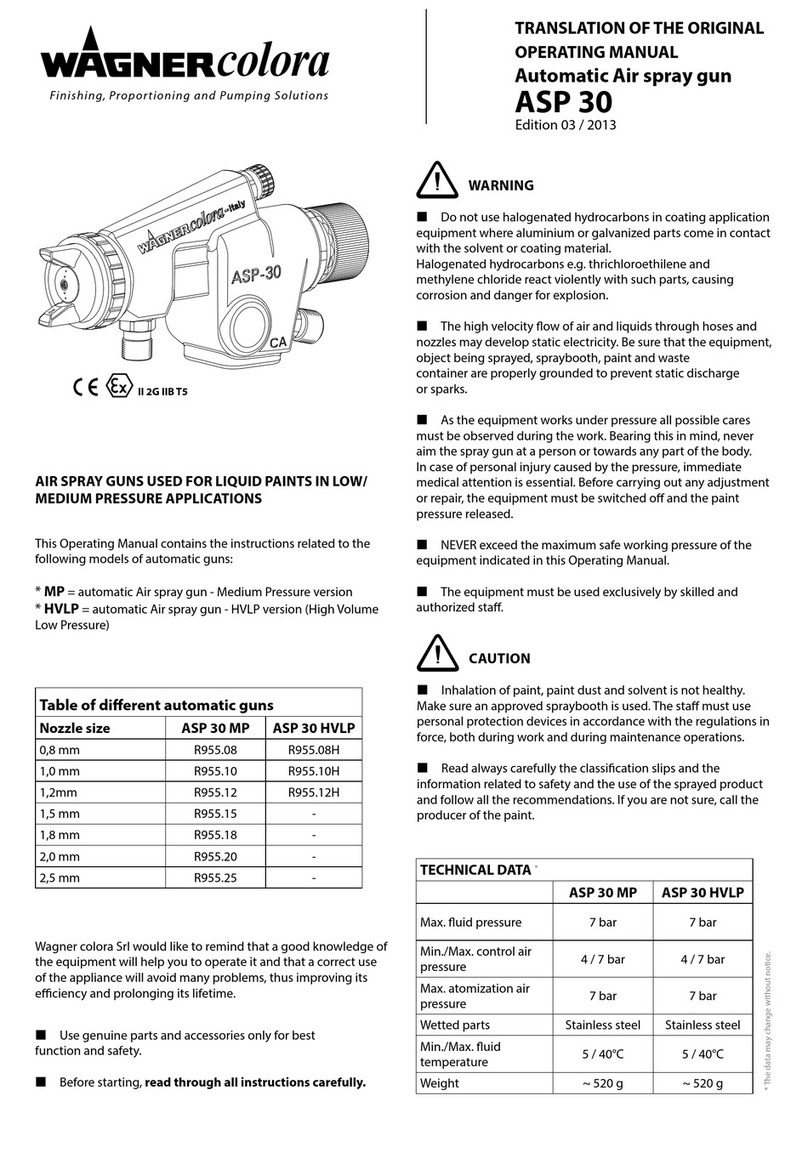

AIR SPRAY GUNS USED FOR LIQUID PAINTS IN LOW/

MEDIUM PRESSURE APPLICATIONS

This Operating Manual contains the instructions related to the

following models of automatic guns:

* MP = automatic Air spray gun - Medium Pressure version

* HVLP = automatic Air spray gun - HVLP version (High Volume

Low Pressure)

Use genuine parts and accessories only for best

function and safety.

Before starting, read through all instructions carefully.

WARNING

Do not use halogenated hydrocarbons in coating application

equipment where aluminium or galvanized parts come in contact

with the solvent or coating material.

Halogenated hydrocarbons e.g. thrichloroethilene and

methylene chloride react violently with such parts, causing

corrosion and danger for explosion.

The high velocity ow of air and liquids through hoses and

nozzles may develop static electricity. Be sure that the equipment,

object being sprayed, spraybooth, paint and waste

container are properly grounded to prevent static discharge

or sparks.

As the equipment works under pressure all possible cares

must be observed during the work. Bearing this in mind, never

aim the spray gun at a person or towards any part of the body.

In case of personal injury caused by the pressure, immediate

medical attention is essential. Before carrying out any adjustment

or repair, the equipment must be switched o and the paint

pressure released.

NEVER exceed the maximum safe working pressure of the

equipment indicated in this Operating Manual.

The equipment must be used exclusively by skilled and

authorized sta.

CAUTION

Inhalation of paint, paint dust and solvent is not healthy.

Make sure an approved spraybooth is used. The sta must use

personal protection devices in accordance with the regulations in

force, both during work and during maintenance operations.

Read always carefully the classication slips and the

information related to safety and the use of the sprayed product

and follow all the recommendations. If you are not sure, call the

producer of the paint.

Wagner colora Srl would like to remind that a good knowledge of

the equipment will help you to operate it and that a correct use

of the appliance will avoid many problems, thus improving its

eciency and prolonging its lifetime.

* The data may change without notice.

TECHNICAL DATA *

ASP 30 MP ASP 30 HVLP

Max. uid pressure 7 bar 7 bar

Min./Max. control air

pressure 4 / 7 bar 4 / 7 bar

Max. atomization air

pressure 7 bar 7 bar

Wetted parts Stainless steel Stainless steel

Min./Max. uid

temperature 5 / 40°C 5 / 40°C

Weight ~ 520 g ~ 520 g