10

18

GB IRL AUS USA NZ CDN IND

&RQWDFWDGGUHVVIRUDGGLWLRQDOLQIRUPDWLRQĺVHHWLWOHSDJH.

Warranty

:HJXDUDQWHHWKDWIURPWKHWLPHLWLV¿UVWSXUFKDVHGIRUDSHULRGRIWKHOHJDOO\YDOLGUHTXLUHGZDUUDQW\

SHULRGPD[LPXP\HDUVWKLVGHYLFHZLOOQRWH[KLELWDQ\PDWHULDORUSURFHVVLQJHUURUV,IGHIHFWVDUH

discovered during the warranty period, MESTO or the distributor in your country will repair the device

ZLWKRXWFKDUJLQJIRUWKHODERURUPDWHULDORUDWWKHGLVFUHWLRQRI0(672UHSODFHWKHGHYLFHLWVHOIRULWV

defective parts.

If such defects are discovered, please contact us immediately. We require the invoice or cash register

receipt for purchase of the device.

7KHZDUUDQW\GRHVQRWLQFOXGHZHDULQJSDUWVVHDOV2ULQJVGLDSKUDJPHWFRUGHIHFWVZKLFKKDYH

occurred due to improper use or unforeseeable circumstances.

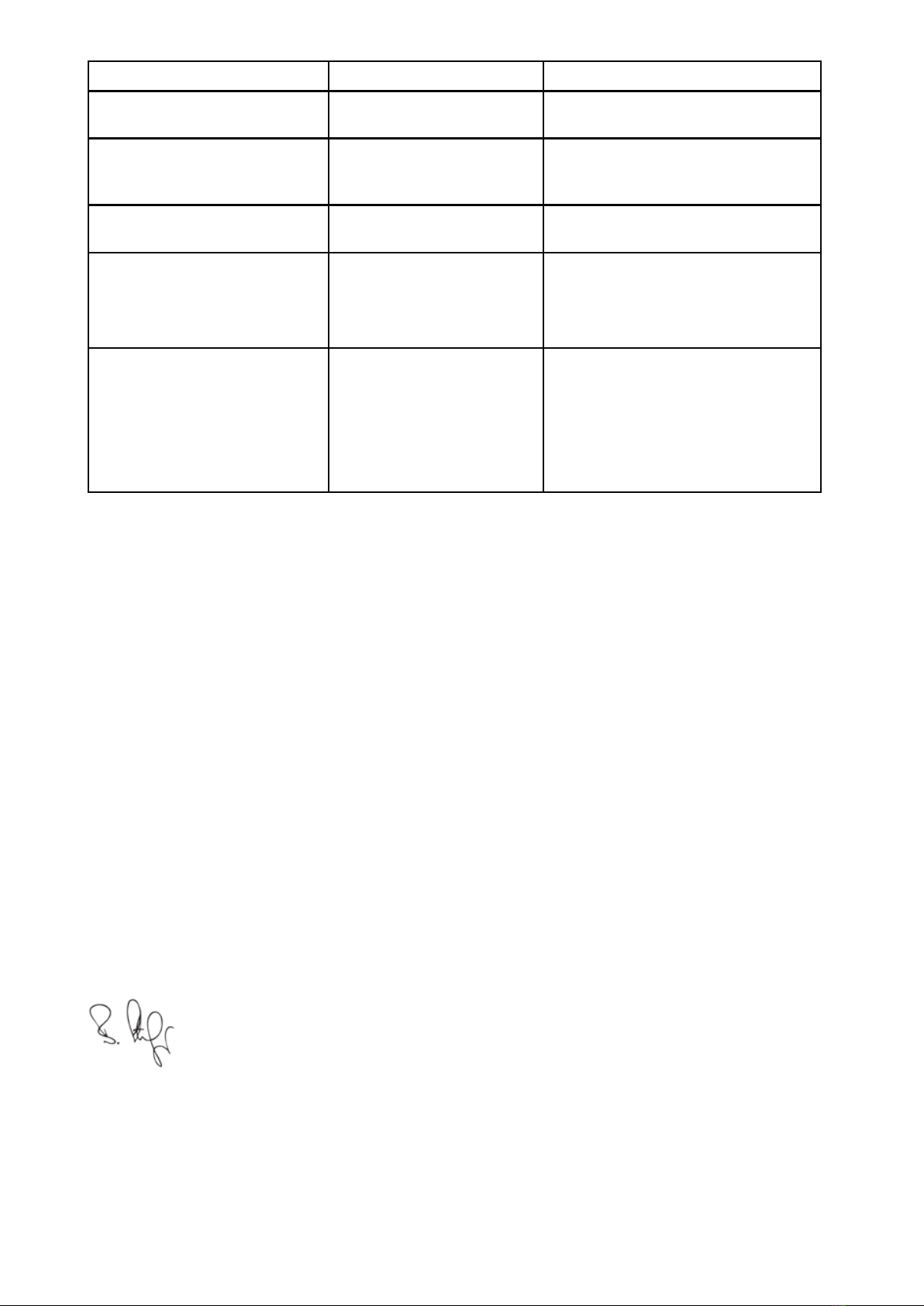

Fault Cause Remedy

/LTXLGÀRZVRXWRIWKHSXPS Valve disk [23] dirty of

defective.

Clean or replace the valve disk.

)LJ.

The nozzle does not spray

even though pressure is

present.

Filter [22] and / or nozzle

[21] blocked.

&OHDQWKH¿OWHURUDQGQR]]OH)LJ

.

Safety valves blows off too

early.

Safety valve [12] is defec-

tive.

5HSODFHVDIHW\YDOYH)LJ

The shut-off valve does not

close.

Liquid emerges without the

lever being activated.

O-ring [24] on the pressure

bolt not greased.

Defective pressure bolt [25]

or O-ring [24].

Grease the O-ring of the pressure

EROW)LJ5HSODFHWKHSUHVVXUH

bolt or O-ring. )LJ.

Pressure gage is not indicating

any tank pressure.

Pressure gage [16] defec-

tive.

Sever attachments (at top, at bottom,

RQULJKW>@)LJ Open panel

[27], unscrew pressure gage [16] with

wrench and replace. )LJ

,QVHUW¿[LQJNQRE>@IURPWKHVSDUH

SDUWVSRXFK>@SXVKWRWKHULJKWDQG

insert panel [27]. )LJ.

CE Declaration of Conformity

according to EC Machinery Directive 2006/42/EC, Appendix II, No. 1A.

We,

MESTO Spritzenfabrik Ernst Stockburger GmbH

Ludwigsburger Straße 71

D-71691 Freiberg

declare under our sole responsibility that the products high-pressure spraying devices of the series

3565, 3585, 3595, 3615 from factory number 1289536 in the version supplied comply with all relevant

provisions of the Directive 2006/42/EC. Furthermore, the device complies with the Directive 97/23/EC

for pressure equipment.

Rolf Rehkugler, Ludwigsburger Str. 71, D- 71691 Freiberg, is authorized to compile the technical

documentation.

Freiberg, 15.12.2011

Bernd Stockburger - Managing Director –