8

2.10

OPERATING SAFETY

1. Please remember it is important that you read

and heed the safety signs on the Log Grap-

ple Trailer. Clean or replace all safety signs if

they cannot be clearly read and understood.

They are there for your safety, as well as the

safety of others. The safe use of this machine

is strictly up to you, the operator.

2. All things with moving parts are potentially

hazardous. There is no substitute for a cau-

tious, safe-minded operator who recognizes

potential hazards and follows reasonable

safety practices. The manufacturer has

designed this Log Grapple Trailer to be used

with all its safety equipment properly attached,

to minimize the chance of accidents. Study

this manual to make sure you have all safety

equipment attached.

3. Close and secure all guards and shields

before starting and operating.

4. Read and understand operator's manual

before starting. Review safety instructions

annually.

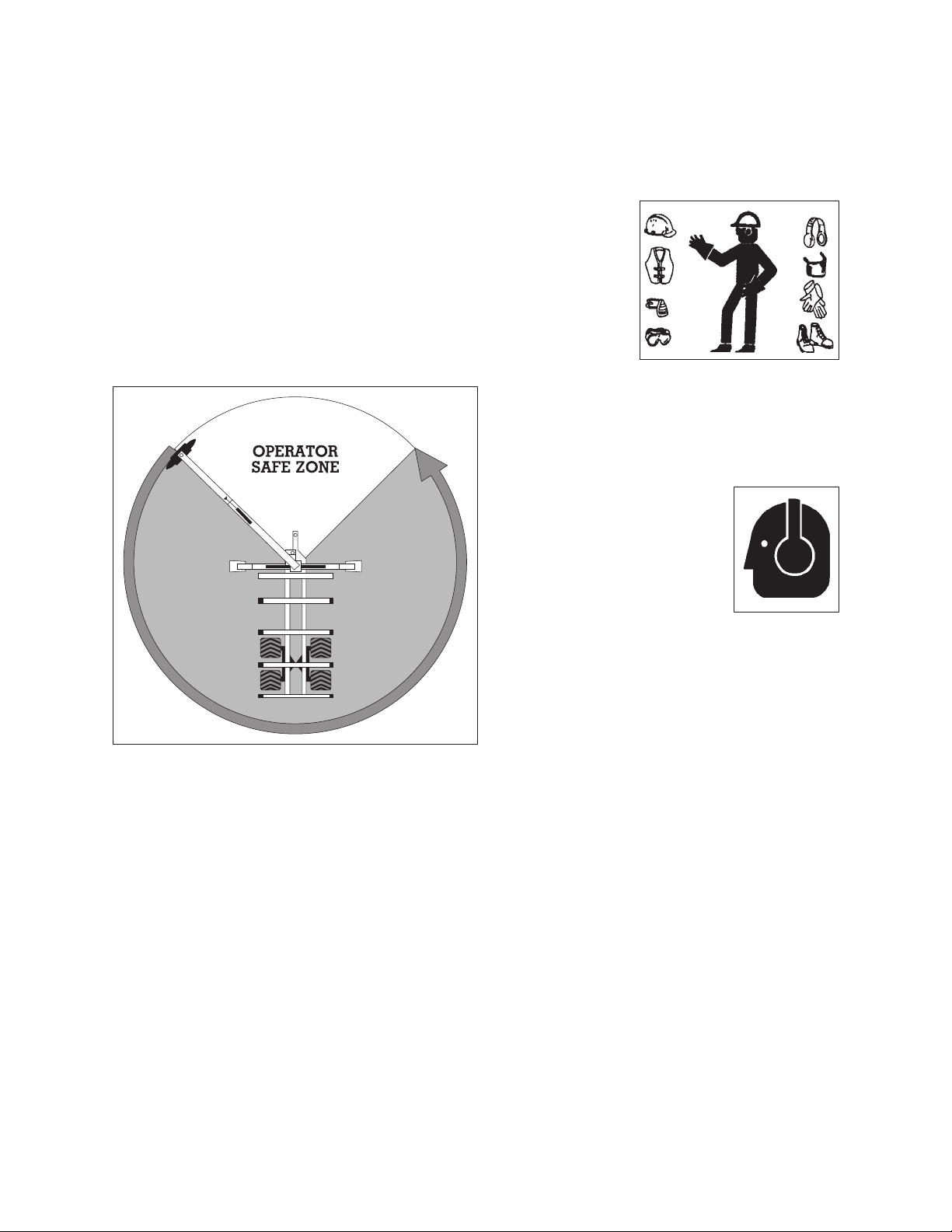

5. Personal protection equipment including hear-

ing protection, hard hat, safety glasses, safety

shoes, and gloves are recommended during

assembly, installation, operation, adjustment,

maintaining, repairing, removal, or moving.

Do not allow long hair, loose-tting clothing, or

jewellery to be around moving parts.

6. Keep hydraulic lines and ttings tight, in good

condition and free of leaks.

7. Never place any part of your body where it

would be in danger if movement should occur

during assembly, installation, operation, main-

tenance, repairing or moving.

8. Lower grapple and boom, place all controls in

neutral, stop engine, remove ignition key and

wait for all moving parts to stop before servic-

ing. adjusting, repairing or maintaining.

9. Install boom lock pin before moving, storing or

transporting.

10. Do not run machine inside a closed building to

prevent asphyxiation from engine exhaust.

11. Extend stabilizers to support frame during

loading and unloading.

12. Position the trailer to provide a rm base for

the stabilizer pads before loading or unload-

ing.

13. Fully extend the stabilizers before operating.

14. Never use alcoholic beverages or drugs which

can hinder alertness or coordination while

operating this equipment. Consult your doc-

tor about operating this machine while taking

prescription medications.

15. Do not allow riders on this machine at any

time. There is no safe place for any riders.

16. Never allow children or unauthorized people

to operate or be around this machine.

17. Stay away from overhead utilities and obstruc-

tions. Review position of power lines.

18. Stay 50 ft (15 m) away from power lines.

Electrocution can occur without direct contact.

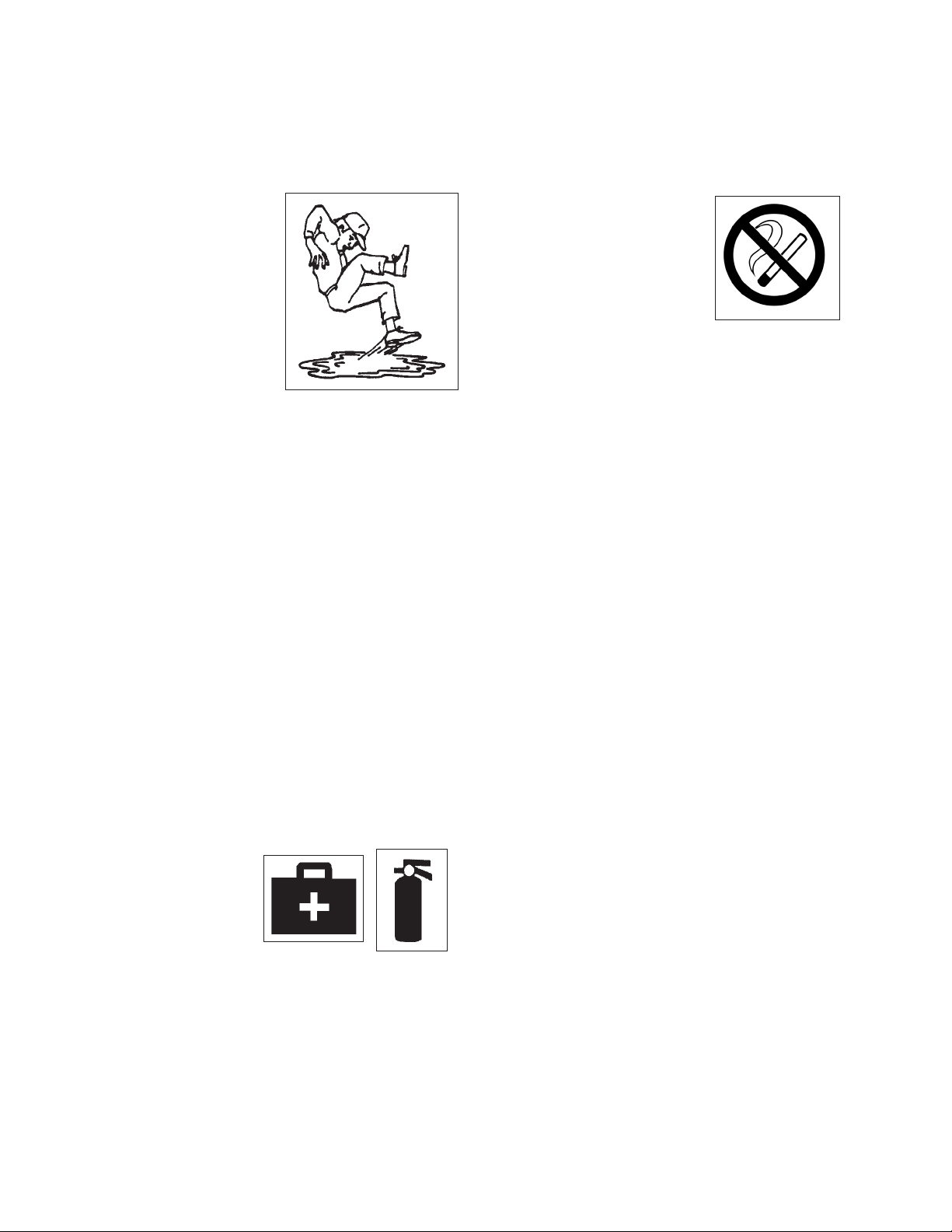

19. Keep the working area clean and free of de-

bris to prevent tripping. Operate only on level

ground.

20. Keep all bystanders at least 20 ft (6 m) away

from trailer, grapple and logs when loading or

unloading or when the engine is running.

21. Do not operate

machine unless

located in safe

zone behind

controls.

22. Do not move or

carry people on

boom or grap-

ple.

22. Do not overload lift or trailer capacity.

23. Do not exceed a safe travel speed when

transporting. Use safety chain on trailer

model when attaching to truck.