WallensteinEquipment.com

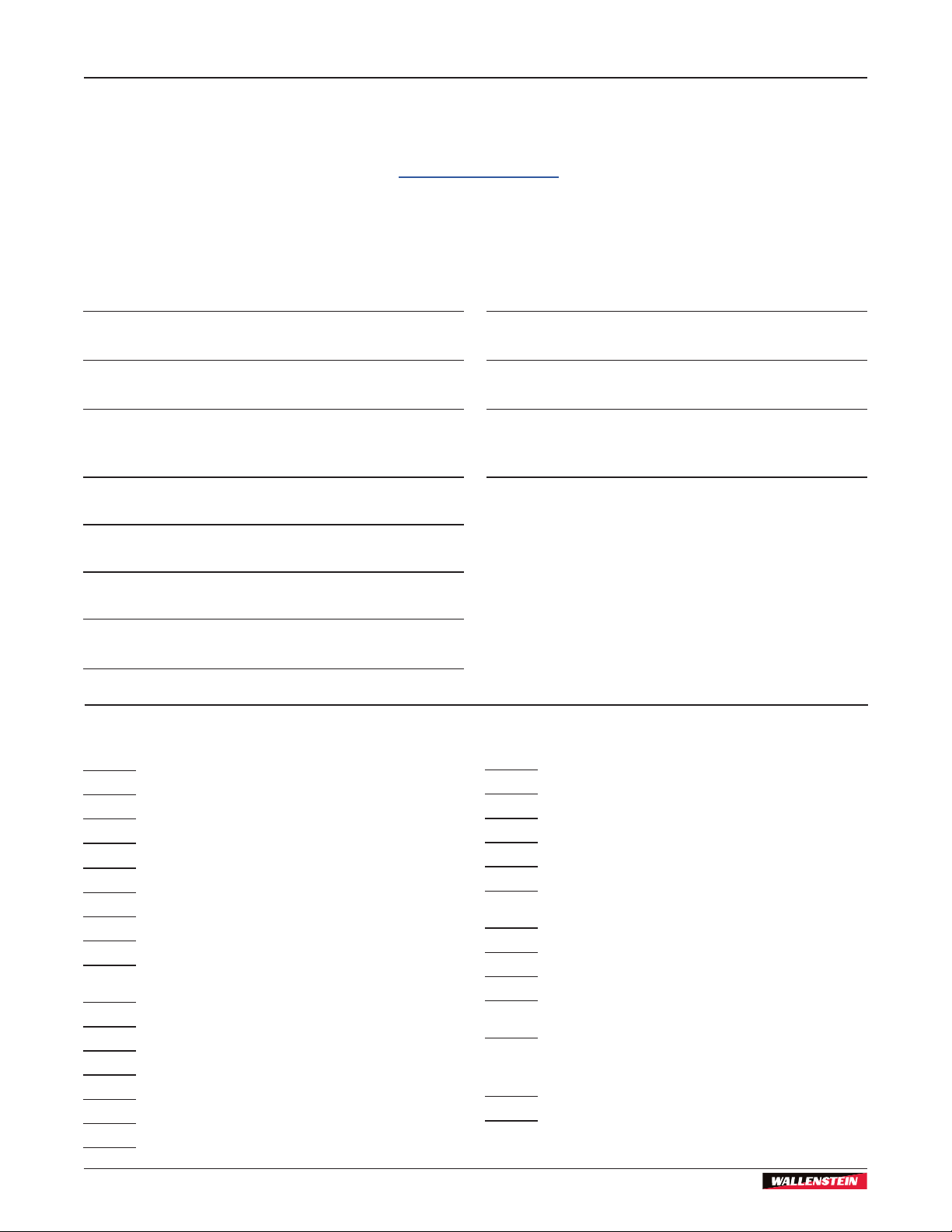

Table of Contents

1. Introduction ..........................................................3

1.1 Delivery Inspection Report ........................................ 4

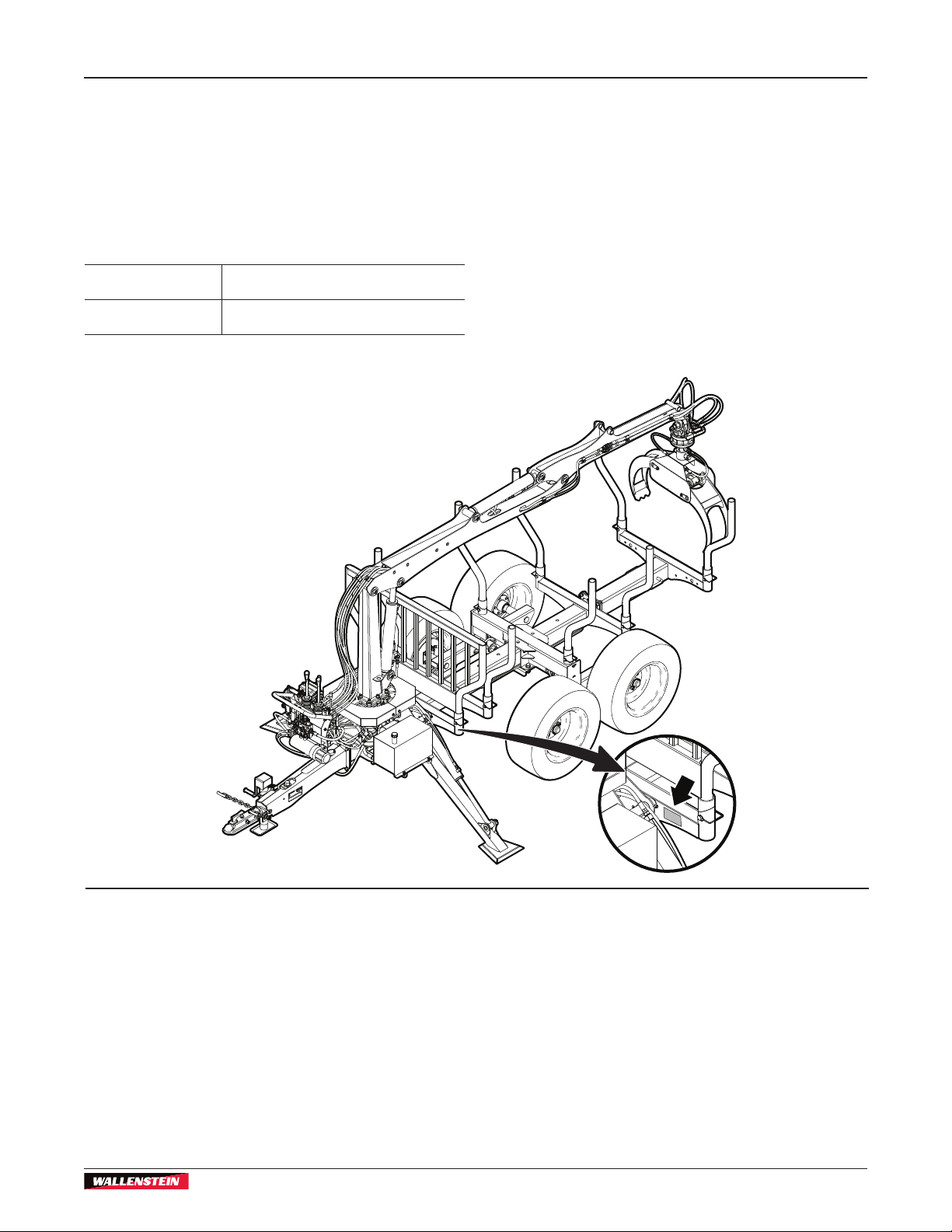

1.2 Serial Number Location............................................. 5

1.3 Types of Decals on the Machine ............................... 6

2. Safety ....................................................................7

2.1 Safety Alert Symbol .................................................. 7

2.2 Signal Words............................................................ 7

2.3 Why Safety is Important............................................ 7

2.4 Safety Rules ............................................................. 8

2.5 Equipment Safety Guidelines..................................... 9

2.6 Safe Condition .......................................................... 9

2.7 Safety Training.......................................................... 9

2.8 Sign-Off Form......................................................... 10

2.9 Work Site................................................................ 11

3. Safety Signs........................................................13

3.1 Safety Sign Locations ............................................. 14

3.2 Safety Sign Explanations......................................... 15

3.3 Information Decals.................................................. 16

3.4 Replace a Safety Sign............................................. 17

4. Familiarization ....................................................18

4.1 New Operator ......................................................... 18

4.2 Training.................................................................. 18

4.3 Operator Orientation................................................ 18

4.4 Machine Components............................................. 19

5. Controls ..............................................................23

5.1 LX95 6.5 hp Engine Controls................................... 23

5.2 LX115 10 hp Engine Controls.................................. 24

5.3 Operator Control Panel Lock ................................... 26

5.4 Boom Lock Pin....................................................... 27

5.5 Stabilizer Latch ....................................................... 27

5.6 Main Hydraulic Controls.......................................... 28

5.7 LXT95 Sliding-Axle Control...................................... 29

5.8 LXT95 Surge Brake Control..................................... 30

5.9 Bunk Posts............................................................. 30

5.10 Hydraulic Winch Controls........................................ 31

6. Operating Instructions .......................................32

6.1 Operating Safety ..................................................... 32

6.2 Pre-Start Checklist ................................................. 33

6.3 Machine Break-In.................................................... 33

6.4 Engine Operation .................................................... 34

6.5 Hydraulic System Operation.................................... 38

6.6 LXT95 Surge Brake Operation ................................. 39

6.7 LXT115 Electric Brake Operation ............................. 40

6.8 LXT95 Sliding Axle Operation .................................. 40

6.9 Start the Machine.................................................... 41

6.10 Stop the Machine.................................................... 41

6.11 Emergency Stop ..................................................... 41

6.12 Set Up the Machine................................................. 42

6.13 Load the Log Trailer................................................ 44

6.14 Unload the Log Trailer............................................. 45

6.15 Hydraulic Winch Operation...................................... 47

7. Transport.............................................................50

7.1 Transport Safety ..................................................... 50

7.2 Prepare the Machine for Transport .......................... 50

7.3 Attach to a Tow Vehicle .......................................... 52

7.4 Trailer Jack............................................................. 53

8. Storage................................................................56

8.1 Storage Safety........................................................ 56

8.2 Place the Machine in Storage.................................. 56

8.3 Replace the Engine Fuel.......................................... 57

8.4 Remove the Machine from Storage ......................... 57

9. Service and Maintenance...................................58

9.1 Service and Maintenance Safety.............................. 58

9.2 Fluids and Lubricants.............................................. 59

9.3 Maintenance Schedule............................................ 60

9.4 Grease Points ......................................................... 61

9.5 Clean the Engine Air Filter........................................ 66

9.6 Replace the Hydraulic Fluid and Filter ...................... 67

9.7 Brake Maintenance ................................................. 68

9.8 Synthetic Winch Rope Maintenance ........................ 71

9.9 Tire Maintenance and Safety ................................... 72

9.10 Clean the Machine .................................................. 72

11. Specifications ...................................................75

11.1 Machine Specifications........................................... 75

11.2 Hydraulic Hose Specifications................................. 75

11.3 Bolt Torque............................................................. 76

11.4 Hydraulic Fitting Torque .......................................... 77

11.5 Lug Nut Torque....................................................... 77

12. Product Warranty..............................................78

13. Index..................................................................79

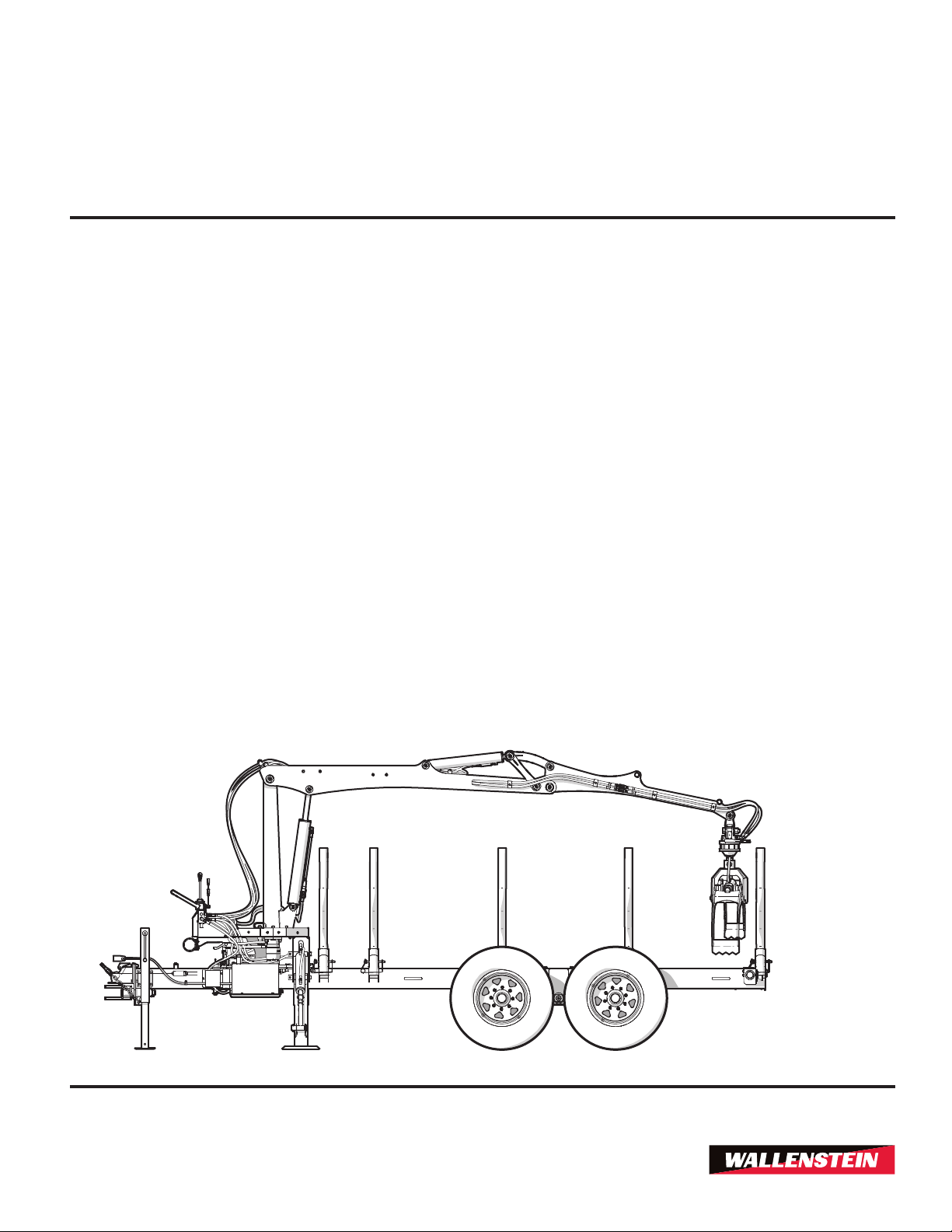

LXT95 / LXT115

Log Loader Trailer

2