7

5. Description

5.1. Grease separator WNG-S1/S2

A grease separator is used wherever greasy wastewater is to be expected. The grease separator separates fats, oils and

sludge from the wastewater. Thanks to the flushing and disposal device, the grease separator can be disposed of with

almost no odor nuisance, since the odor-tight closed system does not have to be opened for this. The hose of the disposal

vehicle can be connected to the permanently installed disposal line, which is led to an easily accessible point. The separa-

ted fats are pumped directly into the disposal vehicle. This eliminates the time-consuming and unhygienic laying out of the

disposal hoses through utility and storage rooms (e.g. food areas). In addition, there is no odor nuisance there

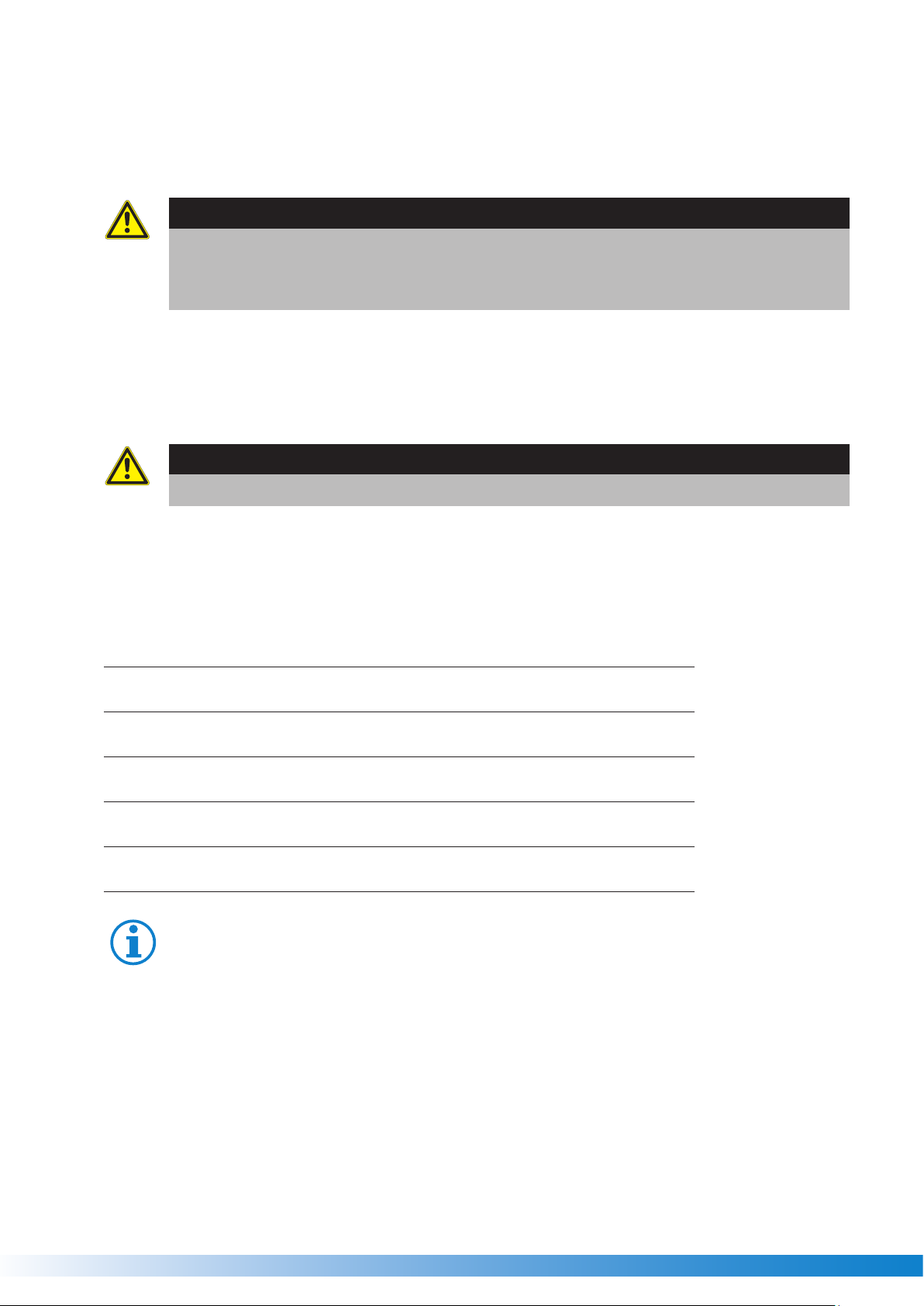

5.2. Specifications of the grease separator

Typ WNG-S1

Sludge trap 100 liter

Grease separation capacity 120 liter

Weight 103kg

600

1150

850

1015

easy transport with

pallet truck

Intake

DN 100

Drainage

Connection possibility

for venting

Outlet DN 100

Drainage

Typ WNG-S2

Sludge trap 200 liter

Grease separation capacity 482 liter

Weight 143kg

1790

1688

1020

1490690

easy transport with

pallet truck

Intake

DN 100

Drainage

Connection possibility

for venting

Outlet DN 100

Drainage

5.3. Intended Use

The separator system is intended exclusively for the separation of saponifiable oils and fats of vegetable and animal origin.

Any use going beyond this is considered improper. The manufacturer is not liable for any resulting damage; the user alone

bears the risk!

Animal and vegetable oils and fats must not be discharged into public waste disposal facilities or waters, as they cause

cross-sectional constrictions and blockages in the disposal lines when cold. Furthermore, after a short decomposition

time, fatty acids are formed, which lead to unpleasant odors and attack pipes and structures in the drainage system. The

solidified layer of fat on the surface of the water also inhibits the necessary oxygen supply in waters and sewage treatment

plants. In addition, DIN1986 Part 1 requires the retention of harmful substances. For these reasons, grease separator sys-

tems must be provided that must be disposed of accordingly. The temperature in the separator should be as low as possib-

le. With an increase of 10 ° C the separation efficiency is halved.

Compliance with the operating, maintenance and repair conditions prescribed by the manufacturer is also part of the inten-

ded use.

6. Installation

6.1. Installation site / requirements

Free-standing installation in frost-free rooms

Before installing the grease separator, check the following:

Separation systems should be installed near where the waste water occurs. Furthermore, the suction connection for clea-

ning vehicles should be easily accessible.

• The system should not be set up in the vicinity of common rooms, especially not in the vicinity of windows or ventilation

openings, so that unpleasant smells are avoided

• It is easy to reach for cleaning vehicles

• Room with good air circulation and / or ventilation as well as an even and sufficiently stable installation surface

(observe stability / ceiling load)

• Room temperature at least 15°C.

• Sealed floor covering with integrated drainage point.

• Hot and cold water connection

• Room height at least 60 cm higher than the grease separator system, so that the revision lid can be opened during

cleaning work.

• Free working space, at least 1 m, in front of the grease separator system.

• The wastewater is to be fed to the separator system for grease in a free gradient

• Inlet with calming section of min. 1 m (slope 1:50). Transition from on-site downpipe to the calming section equipped

with 2x 45° bends DN 250 at least

• If the supply line is longer than 10 m, it must be vented separately.

• Foreign objects (cutlery, crown corks, mustard bags, bones, etc.) interfere with the separation process

• In areas at risk of flooding, the system can be secured against floating

6.2. Mounting

• Install inlet and outlet

• Establish pipe connections to the house installation at the inlet and outlet.

• Make sure that the seals are sufficiently greased.

• The pipe materials used should be resistant to animal and vegetable fats, oils and their degradation products (seal

made of NBR, high temperatures).

Immediately at the outlet of the separator and before mixing with other wastewater, a device for sampling and inspection

must be installed (depending on the version already included in the scope of delivery)

The sampling point or facility of the separator system must be freely accessible and arranged in such a way that only

wastewater that has passed through the separator system is sampled

6.3. Backflow-free installation

Separator systems for fats whose still water level is below the backflow level must be drained via downstream lifting

systems

• Where aplicable mount the direct disposal pipe - The disposal pipe provided for emptying should have a diameter of at

least 50 mm inside width

• The choice of the pipe material for the disposal line should be based on the waste water content (extremely high solid

content) and the particular operating situation (overpressure / underpressure).

• The disposal line from the grease separator to the transfer point to the disposal vehicle should be laid with a steadily

rising gradient. Changes in the direction of the line through 90 ° bends should be carried out with a large radius if

possible