3

SAFETY INSTRUCTIONS

BIO-CIRCLE™ Parts Cleaning Systems are produced in accordance with

applicable standards governing the manufacture, performance and safety of

industrial products.

WARNING: Before using this machine, read all safety and operating instructions

carefully and save this owner's manual for future reference. When using this

parts cleaning system, basic safety precautions should always be observed to

reduce the risk of re, electric shock and personal injury, including the following:

1. Read this owner's manual to familiarize yourself with the unit's operation, its

particular features, applications and limitations.

2. Parts that are damaged or otherwise defective should be repaired or

replaced.

3. Adequate ventilation should be provided when operating the unit. Keep work

areas clean. A cluttered environment invites accidents.

4. Keep children and other persons at a safe distance from the work area. Do

not let unqualied persons handle this machine.

5. Your BIO-CIRCLE™ machine is equipped with a magnet inserted underneath

the grated receptacle in the sink. Always handle it with care, as it will shatter

if dropped and may cause injuries. Keep magnet away from electronic

devices and magnetic media such as oppy discs, credit cards and computer

monitors. Keep magnet away from pacemakers.

6. Do not contaminate the cleaning solution with any ammable or combustible

substances such as gasoline, alcohol, mineral spirits, solvents etc. Drain

parts to be cleaned of any ammable or combustible material before placing

them into cleaning sink. Even small quantities can create a re hazard. Do

not introduce into the unit any cleaning solution other than Bio-Circle L™ as

this will cause malfunctions.

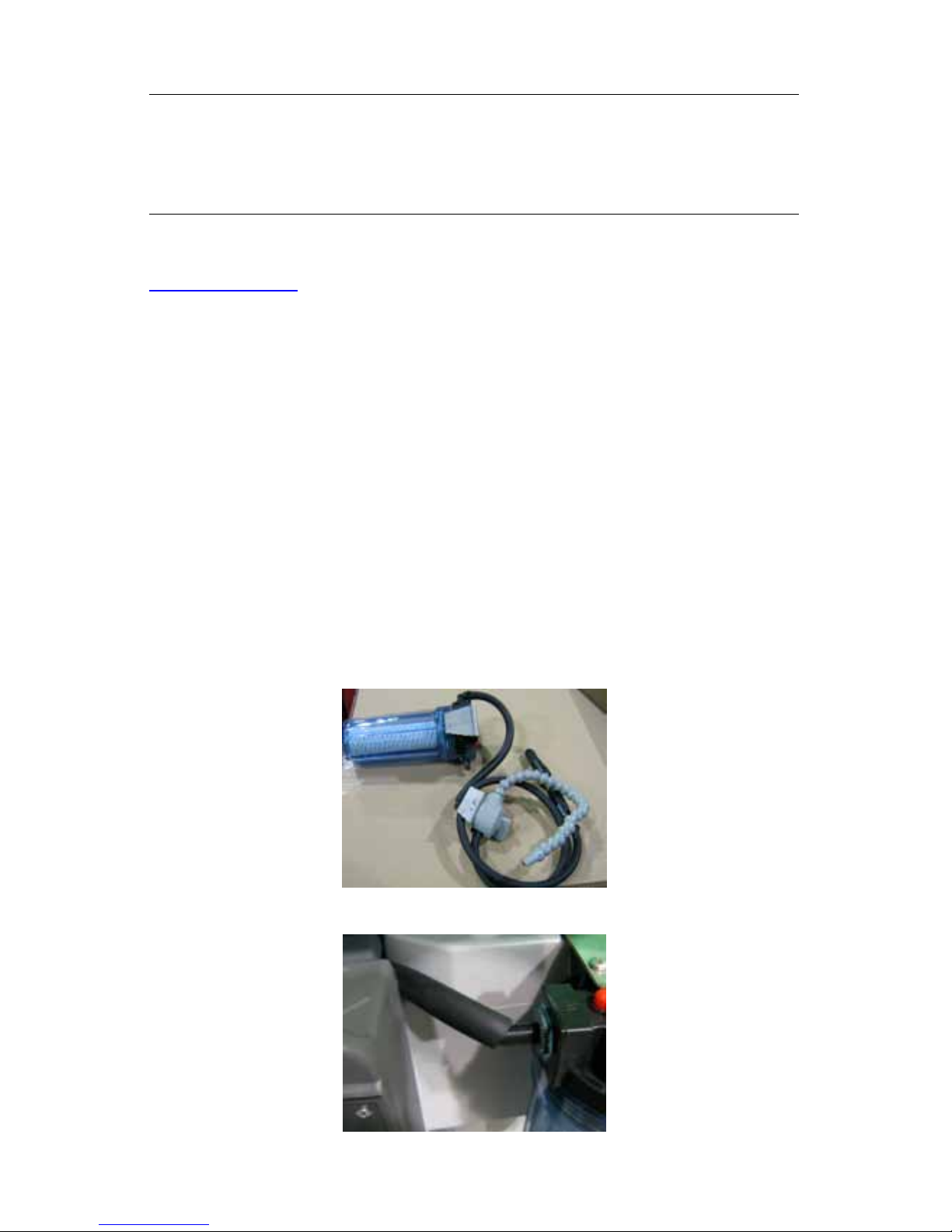

7. The circulation pump & heater coil must always be immersed. Failure to keep

the solution at the proper level can result in a burned-out pump or

overheating heater coil thereby creating a potential re hazard. To help

prevent this, the unit is equipped with a liquid level sensor and a high

temperature limit switch, which will shut off the pump and the heater coil

when the liquid level is low.

8. CAUTION: Used cleaning solution may be irritating to skin and eyes. While

working, always wear appropriate gloves and approved safety goggles.

First Aid: If used cleaning solution is splashed on clothing, change promptly.

Thoroughly wash any body areas that have been in contact with the solution.

Saturated clothing must not remain in contact with skin.

Eye Contact: Flush with water for 15 minutes, lifting eyelid often. See a

physician if required.

Ingestion: Rinse mouth and drink plenty of water. See a physician if

required.

Please refer to WALTER Bio-Circle L™ MSDS No.: L-78E for complete

safety data information.