2

1 Safety instructions

To obtain warranty, all work has to be done by skilled and trained workers only!

Use only original parts of WALTHER-PRÄZISION to ensure proper operation and function!

The use of this guide does not release the operator from compliance with the relevant industrial safety regulations.

E.g.: Ordinance on Industrial Safety, etc. The operator of a WALTHER tool parking station has the duty to take care

of planning measures to ensure an orderly operation and to monitor their implementation.

The use of the tool parking station in applications where the safety of persons depends on its function

is not admissible. The tool parking station must only be operated when the complete machine / facility corresponds

to the EC-machinery directive!

General safety instructions

- The parking stations must not be put on the floor without protection against dropping or tipping.

- The tool parking stations must only be released from the crane when they are firmly anchored to the ground.

- The anchoring in the hall floors must be checked for tightness before commissioning.

- During automatic and manual operation keep away hands and any other parts of the body away from the

hinged lid mechanism - danger of injury!

Hazard notes

Hazards exist in case of incorrect product selection, inappropriate use and lack of maintenance

and injuries to persons and damage to property can occur through:

- Functional limitations of connected system or tools

The operator must in particular make sure that

- the permissible loads are kept.

- the tool parking station is only used according to the intended purpose.

- the tool parking station is only operated in a perfect, functioning condition.

- the operating personnel are sufficiently acquainted with the working method and the safety

instructions of the tool parking station.

- during the operation of the tool parking station, no safety devices are removed and/or deactivated.

On completion of the assembly and installation work, and before the operational start-up of the

tool changing system, the following points should be observed:

- Check all screwed connections once again for secure seating.

- Before operational start-up of the tool parking station, a function test must be carried out

(see maintenance and functional test in the associated operating instructions).

The following points should be observed during operation or in case of malfunction:

- Work within the protective guard must only be carried out by trained and

authorised personnel.

- During the robot’s coupling movement do not touch anything between the robots, tool parking station,

and tool side as they move towards each other.

- Every fault should be rectified immediately. Accumulation of faults can lead to a loss of safety.

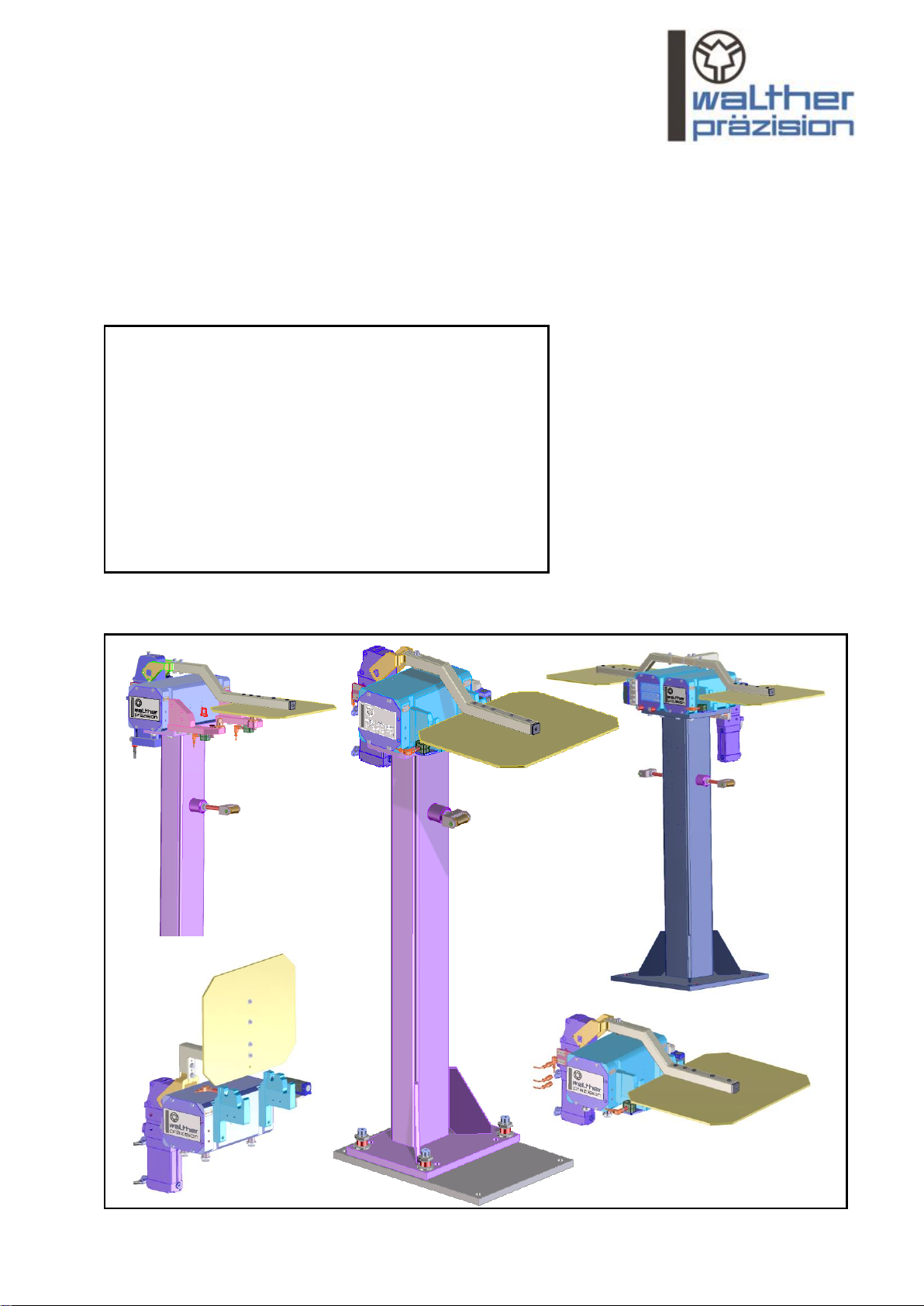

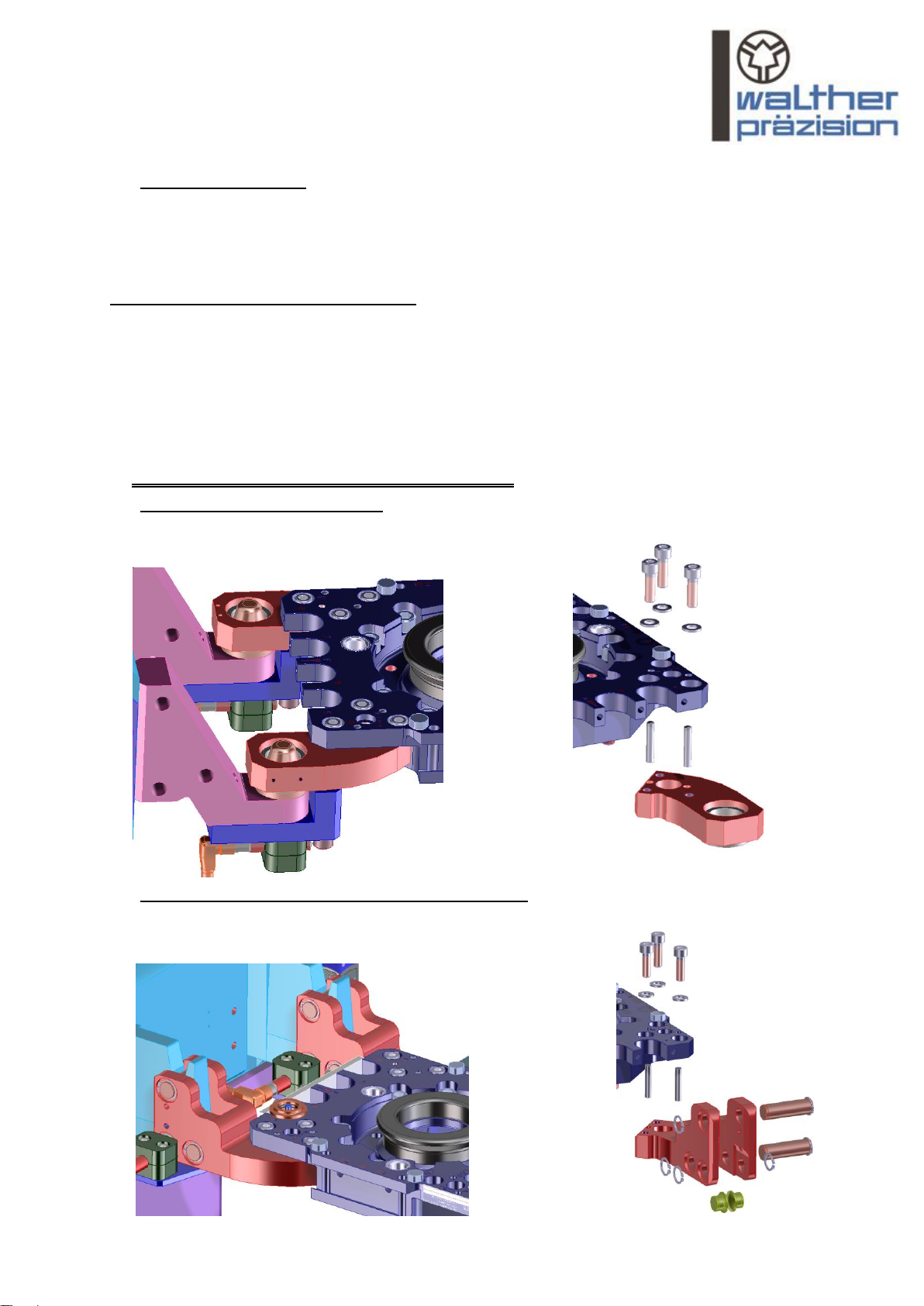

2 Installation manual

2.1 General

The tool parking station station has to be assembled, while taking into account the general accident prevention

guidelines, so that:

- a perfect operation is guaranteed.

- it is ensured that all single components and all mobile parts are without damage.

To avoid damage when dropping and picking up the tool side, as well as to prevent life-threatening injuries during

installation of the parking station, the following points must be observed:

- The installation works –mounting and installation of the tool parking station –may only be carried out

by qualified persons under consideration of the safety instructions.

- Before beginning of the installation works all components of the tool changing system must be checked for

transport damage.

- Check whether all screw connections are correctly and properly tightened.

- Any occurring radial stresses caused by long and heavy connection hoses must be absorbed by suitable

supporting devices.