EC DECLARATION OF INCORPORATION ....................................................................................................................... 4

1INTRODUCTION ................................................................................................................................................. 5

1.1 TARGET GROUP OF THE ASSEMBLY INSTRUCTIONS ............................................................................................................ 5

1.2 LIST OF SIGNS AND SYMBOLS ....................................................................................................................................... 5

2SAFETY............................................................................................................................................................... 5

2.1 GENERAL INFORMATION ............................................................................................................................................. 5

2.2 DANGERS FROM RESIDUAL ENERGY............................................................................................................................... 5

2.3 WARRANTY AND LIABILITY........................................................................................................................................... 5

2.4 CORRECT USE ........................................................................................................................................................... 6

2.5 INCORRECT USE ........................................................................................................................................................ 6

2.6 QUALIFICATION OF PERSONNEL .................................................................................................................................... 6

3TRANSPORT....................................................................................................................................................... 7

3.1 PACKAGING .............................................................................................................................................................. 7

3.2 TASKS BEFORE TRANSPORT .......................................................................................................................................... 7

4DESCRIPTION OF FUNCTION .............................................................................................................................. 7

4.1 PURPOSE OF THE DEVICE............................................................................................................................................. 7

4.2 TECHNICAL DATA ....................................................................................................................................................... 8

4.3 TYPE LABEL .............................................................................................................................................................. 8

5INSTALLATION AND START-UP............................................................................................................................ 8

5.1 HOSE MOUNTING...................................................................................................................................................... 8

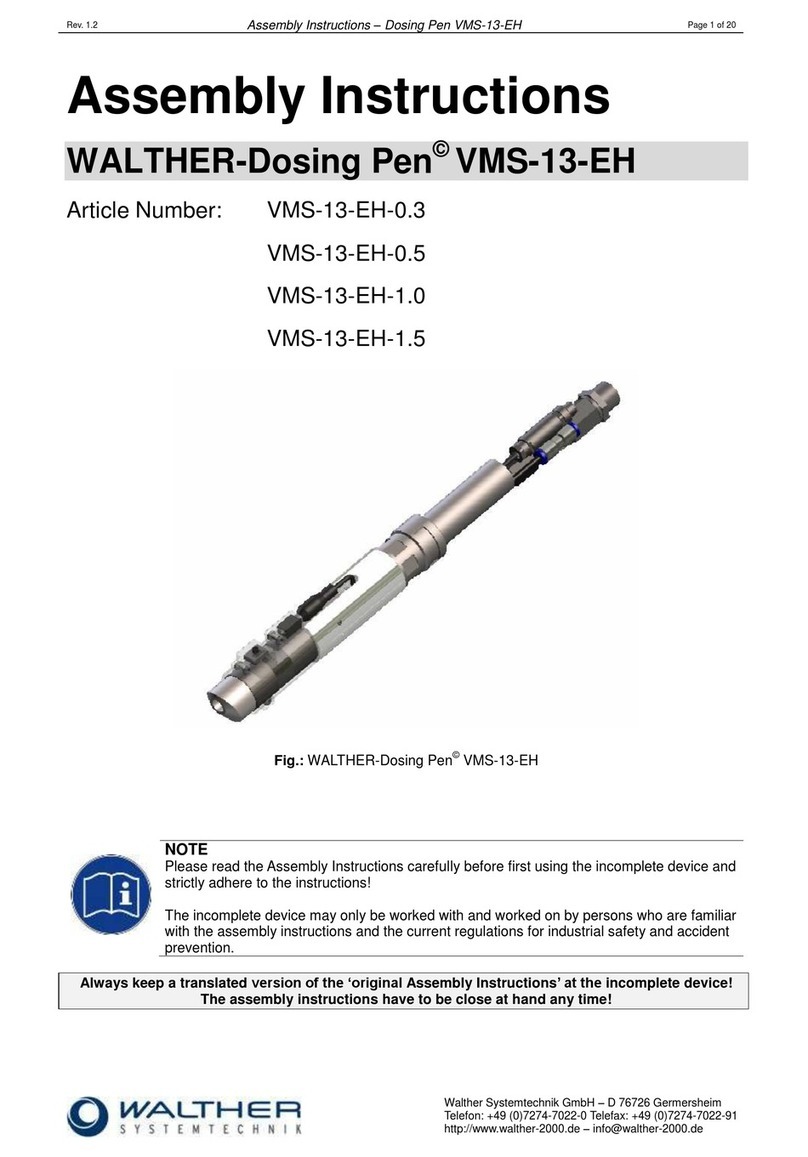

5.2 TOTAL VIEW /DESCRIPTION......................................................................................................................................... 9

5.3 ADJUSTING THE DEVICE .............................................................................................................................................. 9

5.4 SMS-02 WITH RASTER-NEEDLE DETECTION ................................................................................................................. 10

5.4.1 Terminal Assignment for Needle Query..................................................................................................... 10

5.4.2 Terminal Assignment for Magnetic Valve.................................................................................................. 10

5.5 INSTALLATION DIAGRAM FOR COLOR-MARKING SYSTEMS................................................................................................ 11

6OPERATION ..................................................................................................................................................... 11

6.1 GENERAL INFORMATION ........................................................................................................................................... 11

6.2 OPERATION INFORMATION /OPERATING CONDITIONS .................................................................................................... 11

6.3 OPERATING ELEMENTS ............................................................................................................................................. 12

7MAINTENANCE AND REPAIR ............................................................................................................................ 13

7.1 GENERAL INFORMATION ........................................................................................................................................... 13

7.2 CLEANING .............................................................................................................................................................. 13

7.3 EXCHANGING THE AIR VALVE (11.0.0) ........................................................................................................................ 13

7.4 EXCHANGING THE RETURN CHECK VALVE,COMPLETE (10.0.0)......................................................................................... 13

7.5 REPLACING THE NEEDLE (7.0.0) AND THE NOZZLE (2.1.0).............................................................................................. 13

7.6 EXCHANGING THE SEALING BUSH (6.0.0) .................................................................................................................... 14

7.7 INSERTING GASKETS AND O-RINGS: ............................................................................................................................ 14

7.8 MAINTENANCE FOR OPERATION IN COLOR-MARKING SYSTEMS (NORMAL OPERATION) ........................................................ 14

7.9 SPARE PARTS .......................................................................................................................................................... 15

7.10 CUSTOMER SERVICE /SUPPORT............................................................................................................................. 15

8TROUBLESHOOTING ........................................................................................................................................ 16

8.1 GENERAL INFORMATION ........................................................................................................................................... 16

8.2 FAILURES: .............................................................................................................................................................. 16

8.3 SPRAY IMAGE/TYPE OF DEFECT .................................................................................................................................. 17

9TAKING OUT OF SERVICE ................................................................................................................................. 18

9.1 SHORT INTERRUPTION .............................................................................................................................................. 18

9.2 LONG-TERM INTERRUPTION....................................................................................................................................... 18