the uneven ground

Avoid being electric shocked or burnt

Never touch on hot electrical units.

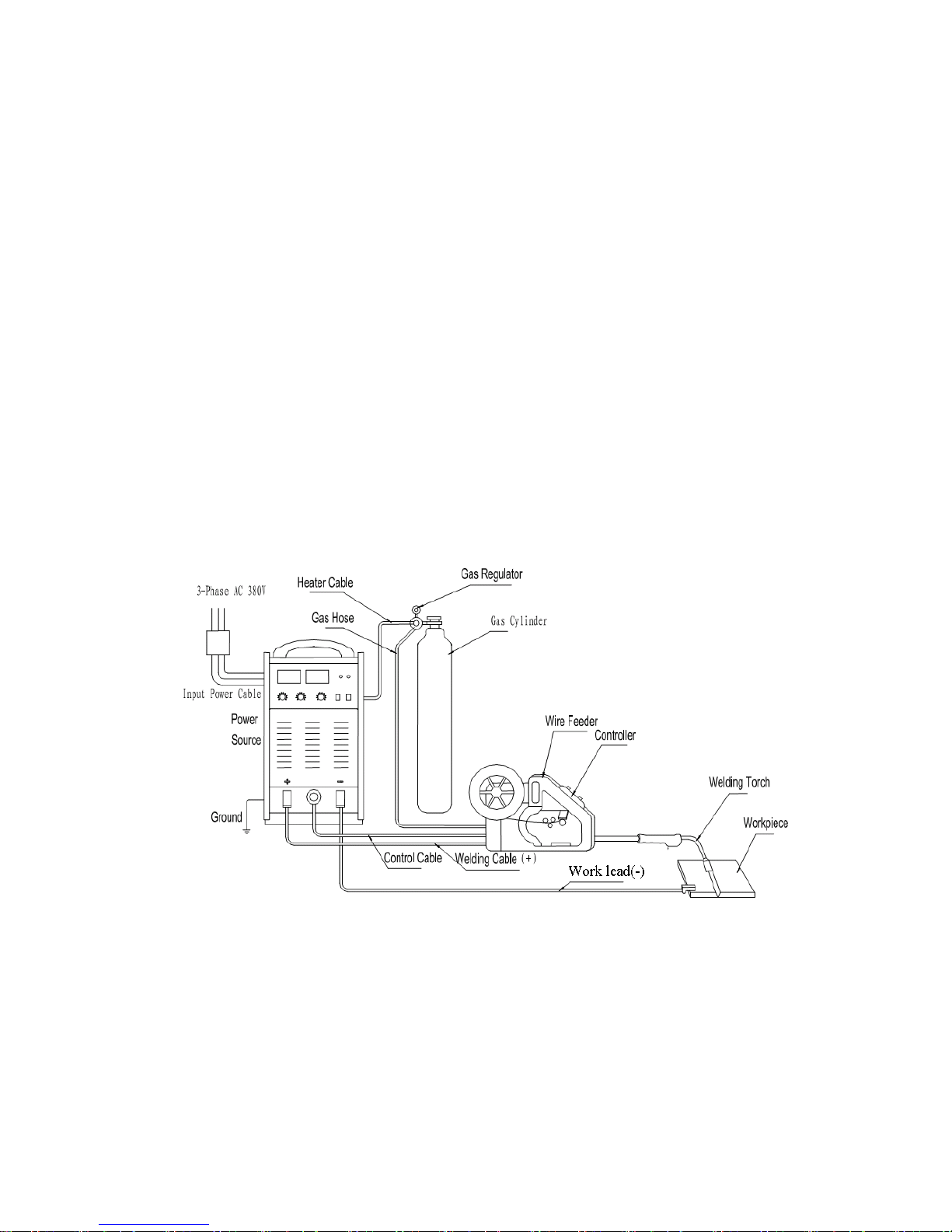

Please instruct the authorized electrician to ground the welder

frame by using proper-sized copper wire.

Please instruct the authorized electrician to connect the welder to

power supply by using proper-sized, well-insulated copper wire.

When operating in the damp, space limited area, must ensure

well-insulated between body and work piece

When operating in the high-rising location, must ensure safety by

using safe net.

Please power off the machine while no longer welding.

Avoid breathing in hazardous welding fume or gas

Please use specified ventilation to prevent being gas poisoned and

asphyxiated.

Especially in the container where oxygen is depleted easily.

Avoid being harmed by arc flash, hot spatter, slag

Arc rays can injure your eyes and make your eyes feel

uncomfortable. Hot spatter and slag can burn your skin.

Please wear proper welding helmet, leather gloves, long- sleeved

suit, hat, apron and boots before welding.

Preventing from fire, explosion, container break accidents

Don’t put flammable material in the working area. Hot spatter and

hot weld can easily start a fire.

Cable must be connected the work piece firmly to ensure good

conductivity in case causing fire by resistance heat.

Don’t weld in the flammable gas or weld container which contains

flammable material, otherwise it can cause explode.

Don’t weld encapsulated container, otherwise it can break.

Ensure a fire extinguisher at hand in case a fire breaks out.